To transmit electricity over distances, along with overhead lines, power cables are widely used. As for the power supply of consumers located in the buildings of industrial enterprises, as well as the implementation of electrical wiring in residential buildings, insulated wires and cable lines are widely used for these purposes. One of the most successful types of such wires, which is widely used in electrical networks, is the VVG cable.

In general, a power cable is an electrical conductor of large cross section with one or more cores. Each such core is covered with a layer of insulation, in addition, they are all enclosed in a protective sheath. Also, in some models, protective screens or armor can be used to improve their performance.

During operation, power cables pass very high currents through themselves, therefore, the isolation of their individual current-carrying cores from each other and from the external environment is made in compliance with the highest reliability requirements.

The transmission and distribution of electricity in low-power household electrical networks is carried out using copper and aluminum electrical wires, which are significantly inferior to power cables in terms of reliability and power, but are more compact, easy to use and cheap.

Characteristics of VVG cables

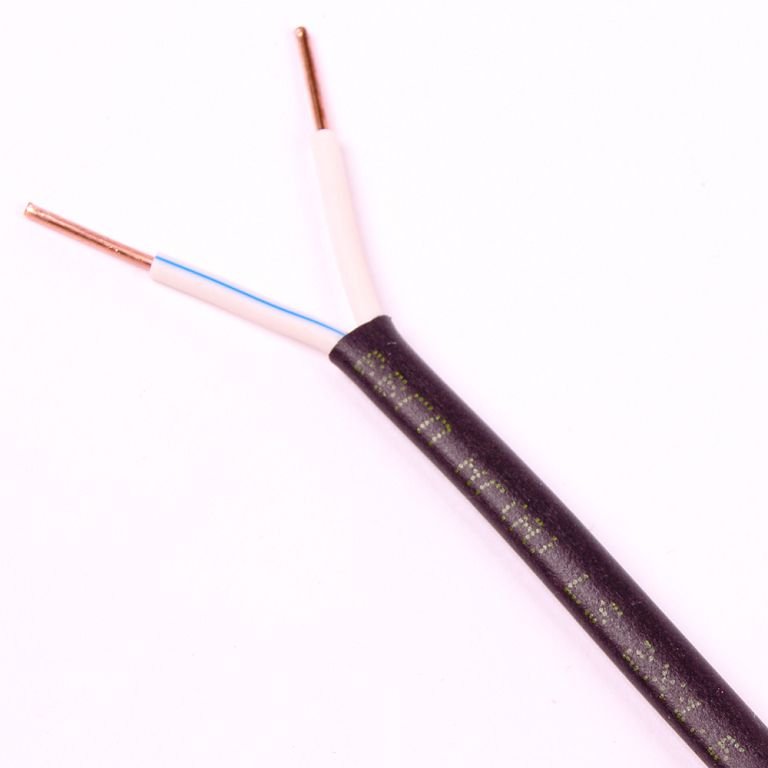

It is advisable to start the description of such products by deciphering their abbreviations. Consider it using the example of a VVG 2x4 cable. Decoding cable VVG:

- the first letter "B" corresponds to PVC insulation of cable cores,

- the second "B" - PVC insulation shell,

- the letter "G" means the absence of protective covers,

- and the numbers 2x4 - respectively, the number of cores and their cross section.

The maximum temperature at which the long-term use of wires of the VVG brand is permissible is +50 C0, the minimum is -50 C0. In this case, the maximum possible temperature of their heating during overload can reach +80 C0, and in the case of a short circuit current flowing for no more than 4 s, it can be increased to +160 C0.

Let's continue to get acquainted with the technical characteristics of the VVG cable, it has several (from one to 5) individual copper cores that are covered with insulation. If the number of such conductors is more than 2, then all of them may have the same diameter, or one of the conductors intended for neutral or ground wires may have a slightly smaller cross section.

As an insulation material in the manufacture of VVG cables, polyvinyl chloride plastic compound or, for short, PVC is used. This material is a type of plastic, which is characterized by high dielectric properties, resistance to aggressive chemicals and low flammability. There are models of cables, the insulation of which is made of PVC compound, which has improved properties:

- Reduced flammability (VVGng).

- Reduced smoke and gas emission.

The cores can be produced in solid (single-wire) and multi-wire versions. In addition, VVG cables are distinguished with round and sector (segment) sections of copper conductors.

The cross section of each individual core depends on their purpose and the power of the supplied consumers. The VVG cable line includes models with a core cross section ranging from 1.5 to 240 mm2. Depending on the diameter and number of cores, the weight of the VVG cable also varies.

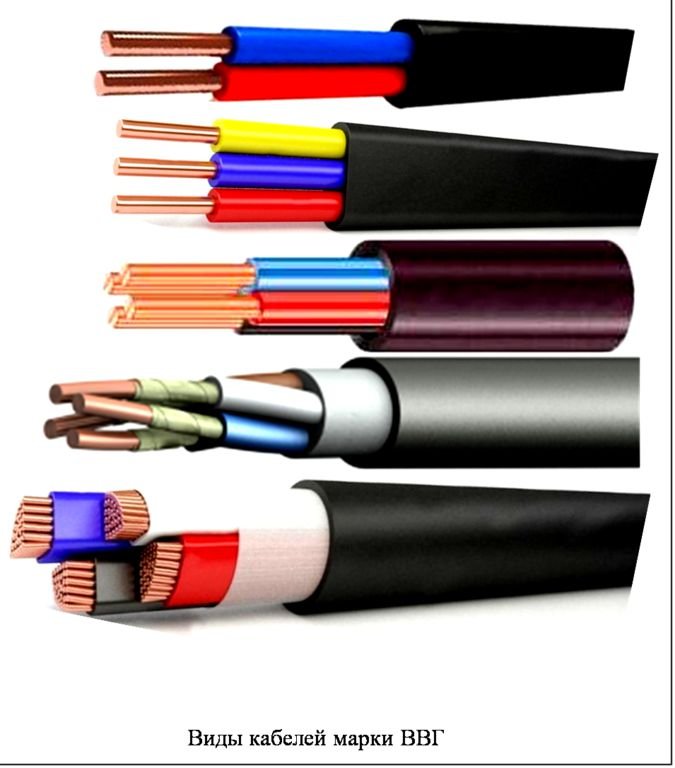

Depending on the functional purpose, the required section and the location of the laying, VVG cables of various diameters can be used, made in different versions: flat, non-combustible, etc.

There are such marking options:

- VVG. Universal option.

- AVVG.With aluminum conductors.

- VVGng. Incombustible.

- VVG-P and VVGng-P. Flat and, accordingly, non-combustible flat.

- VVGz. Filled. This means that between the insulated cores there is an additional dielectric filler.

When laying any cable line, there is a need for bends and turns of current-carrying wires. In order to ensure maximum reliability and durability of such an electrical network, it is necessary to adhere to well-defined requirements for the maximum bending radius of its conductors. For the VVG brand, this parameter ranges from 7.5 to 15 of its diameters.

Scope of application

Power cable VVG of any section is designed for use in electrical networks with a voltage of 660 and 1000 V with a frequency of 50 Hz. The main purpose of such cable lines is to supply powerful consumers of electricity at enterprises and industrial facilities, however, they can also be successfully used in the installation of home electrical wiring (for example, VVG 2X4 and VVG 3X2.5).

The insulation of these products does not allow their laying in places with aggressive environmental influences. These gasket options include:

- In the ground without the use of special boxes.

- In reservoirs. Although the insulation characteristics of such wires allow them to be laid in places with high humidity, they are not intended for use in water.

- under a layer of plaster. Since the external insulation of VVG power cables is made of PVC compound and does not have an additional protective layer, it is better to use the VVG-ng brand if it is necessary to lay them under plaster.

Despite all the positive qualities of PVC insulation, its significant drawback is poor frost resistance. Therefore, work on laying such lines cannot be carried out at temperatures below -15 C0.

Advantages of VVG cables

Due to its excellent technical characteristics, VVG brand power cables have the following advantages:

- Ensuring the high quality of the transmitted electricity. The main task of any power transmission system is to preserve the quality of electrical energy as much as possible. To do this, the conductors of such a system must have such technical characteristics as low active and reactive resistance, as well as high quality insulation. Today, copper is one of the best materials to use in this kind of system.

- Fire resistance. Allows the use of wires of this type in rooms with increased fire hazard.

- High insulation tensile strength. It makes it possible not only to protect the electrical network from the occurrence of short circuits in the event of unintentional mechanical stress on the wires, but also provides ease of wiring installation, as well as the operation of electrical appliances. In addition, products of the VVG brand are distinguished by increased resistance to mechanical vibrations.

- High dielectric properties of PVC insulation. This makes it possible to produce reliable and powerful cables of relatively small diameter. According to regulatory documents, each VVG copper power cable is tested with increased voltage, the value of which, depending on the rated voltage of the cable, is 3 or 3.5 kV.

- Moisture resistant. Although such products are not designed for laying in water, their insulation is sufficiently resistant to the effects of a humid environment. This allows the use of cables of this type in places with high humidity (up to 98%), which include bathrooms, toilets, kitchens, showers, etc.

- High reliability. The VVG power cable, laid in protective systems, such as special cable boxes, corrugated tubes or cable runners, is distinguished by exceptionally high reliability.

- Long service life.According to the specification description, the minimum service life of this cable is 30 years.

- Wide model range. A large selection of sections of copper and aluminum conductors allows you to select with high accuracy the required cable diameter for powering electrical installations of a certain power. This makes it possible to significantly save money in the design and installation of electrical wiring. In addition, the ability to use VVG-P cables (flat) allows you to achieve maximum convenience when performing installation work.

- Convenient color and digital marking of current-carrying cores. The phase wire has white, red or brown insulation, the neutral wire is blue, and the ground wire is yellow with a green stripe.

Choosing a VVG cable for wiring an apartment

To supply electricity to the panel at the entrance to the apartment, as a rule, a VVG 3X6 power cable is used (it can also be 3X10 and 3X16).

Unlike PVA and ShVVP wires, which are often used for wiring, the VVG 2X4 copper cable meets higher requirements, since it is also intended for use in industry. In other words, VVG 2X4, with an equal cross section, has a larger maximum allowable current, higher insulation quality, and it supports combustion much worse. In addition, each such product undergoes production tests, which cannot be said about most of their household counterparts. As for the choice of the type and cross section of the cable for powering electrical appliances located in the apartment itself, it all depends, first of all, on their technical characteristics. One of the most common is the VVG 2X4 brand.

Power calculation table

When choosing a cable, you need to know what the permissible load of each wire section is. Add up the power of all consumers on the selected power line, take a margin of at least 30% and select the required cable section in accordance with the table.

| Conductor cross section, sq. mm | Copper conductors | |||

| 220 V | 380 V | |||

| current, A | power, kWt | current, A | power, kWt | |

| 1,5 | 19 | 4,1 | 16 | 10,5 |

| 2,5 | 27 | 5,9 | 25 | 16,5 |

| 4 | 38 | 8,3 | 30 | 19,8 |

| 6 | 46 | 10,1 | 40 | 26,4 |

| 10 | 70 | 15,4 | 50 | 33 |

| 16 | 85 | 18,7 | 75 | 49,5 |

| 25 | 115 | 25,3 | 90 | 59,4 |

| 35 | 135 | 29,7 | 115 | 75,9 |

| 50 | 175 | 38,5 | 145 | 95,7 |

| 70 | 215 | 47,3 | 180 | 118,8 |

| 95 | 260 | 57,2 | 220 | 145,2 |

| 120 | 300 | 66 | 260 | 171,6 |

The disadvantage of VVG cables is their relatively high price, so it is advisable to use them to connect powerful consumers of electricity, for example, electric stoves, cooking surfaces or instantaneous water heaters.