Heating in the house

At the first stage, you should decide on the types of radiators and options for their connection, since buildings should be prepared in advance for the selected type of heating. A modern space heating system includes several components.

These include:

Do-it-yourself polypropylene heating wiring without a soldering iron

You can find their different options in large numbers in our markets.

The general instructions for installing batteries look like this:

- first choose a place to place them;

- bring pipes to them;

- connect them together;

- make a test run, and if everything is in order, turn on the heating at full power.

How to install heating radiators with polypropylene pipes with a jumper for quick shutdown

4 About the features of the installation of polypropylene products for home craftsmen on a note

It is quite possible to create a high-quality heating system from PP pipes with your own hands

But be sure to take into account the following recommendations:

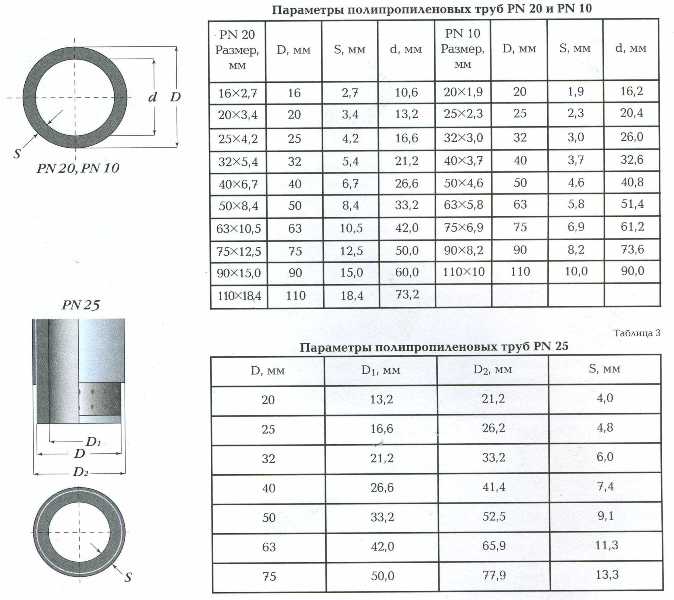

- Polypropylene products Dn 20x3.4 are connected to metal-plastic pipes with dimensions 16x2, Dn 25x4.2 - to pipes 20x2, Dn32x5.4 - to 26x3.

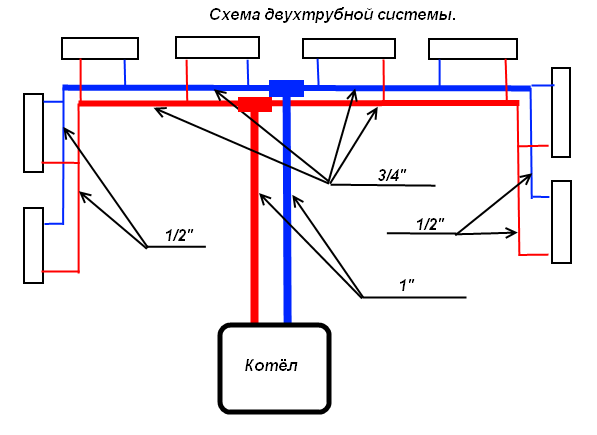

- It is undesirable to use PP pipes with parameters greater than 20x3.4 when implementing a two-pipe heating scheme powered by a pipeline (main).

- The maximum length of the branch supplying the coolant from the last battery to the heating boiler is 25 m. If the length of the line is longer, uniform heating of the radiators is not possible.

High-quality heating system from PP pipes

Note! All work on connecting PP pipes with your own hands must be done using soldering special devices. Such tools are designed specifically for soldering polymer products.

Others cannot be used.

One more moment. The first soldering of polypropylene pipes usually causes some difficulties for home craftsmen. Therefore, experts advise to train in front of her. Get inexpensive pipes, try to connect them with a soldering tool, fill your hand, and only after that proceed with the installation of the heating system.

The place of radiators in the heating system

The use of radiators in residential heating plays a key role today. Not all residential properties, especially apartments in multi-storey buildings, can be converted to underfloor heating. Therefore, the main work on heating the internal living spaces is performed by radiators or the good old and well-known to us, batteries.

Radiators transfer thermal energy from the coolant to the surrounding space. Heat transfer is carried out due to the large heating surface of the heating device. In modern models, there are a number of technical improvements, thanks to which it has become possible to connect in a variety of ways and with any wiring scheme.

in old cast-iron and steel batteries there was only one upper and one lower branch pipe, through which hot water is supplied and the return flow is carried out.

In modern models, in addition to the main supply and output pipes, there are built-in air vents. This battery design has radically changed the quality of the functionality of the heating system. If there are air pockets in the heating devices, it is enough to open the bleed valve and bleed the air.

In many respects, thanks to modern models of heating batteries, it has become possible to choose the most convenient connection scheme, to install heating devices in those places in the living room in which they are most effective. The quality of the heating water circuit depends on the correct piping.The process is necessary if you are using a pipeline made of polypropylene pipes.

Important! In the presence of metal risers, the strapping is made from other consumables. It can be metal copper pipes or metal-plastic

The use of polypropylene pipes in this case is strictly prohibited.

The reason for the incompatibility of metal pipes with polypropylene products is the presence of a threaded connection. Given the fact that propylene pipes have a high coefficient of thermal expansion, when a hot coolant is supplied, the threaded connection will lose its tightness and stability. Therefore, if you want to connect a heating radiator made of polypropylene pipes, try to use fittings, adapters and couplings made of similar materials.

take into account the difference in diameters of pipes made of different materials

1 Which layout of polypropylene pipes for the house to choose

This is the very first question to be solved by everyone who is interested in a polypropylene heating system. There are two types of wiring - top and bottom. In the first case, the pipeline (supply) is laid in the attic or under the ceiling surface. And the risers go down from him. Heating devices are connected to them. The return pipeline at the top wiring from polypropylene pipes is laid in the cellar of a private house or on the floor.

A similar scheme is recommended for situations where water in the heating system circulates according to a natural principle. Also, the upper wiring is performed when it is impossible to conceal the installation of polypropylene pipes.

Upper wiring of polypropylene pipes in the house

When arranging such systems, pay attention to the following important tips:

- In the attic, you should definitely install an air vent with your own hands, which will automatically bleed air from the heating system, and a special expansion tank. The latter is necessary to protect the pipeline and equipment from pressure drops.

- It is allowed not to use the circulation pump.

With the lower wiring diagram, both pipelines (return and supply) are laid under the ceiling of the cellar or along the floor of the basement (first) floor of a private house. Moreover, the pipes are laid parallel to each other. Such a scheme is used for a separate supply of hot water to each heating riser.

Choosing pipes

Having taken care of the choice of pipes for the heating system in a private house, the vast majority of owners opt for polypropylene products. This can be explained by a solid list of their undeniable advantages over pipelines made of other materials:

- polypropylene is not subject to corrosion, which significantly increases the life of the heating network;

- installation is easy and simple. It is enough just to master the very simple skills of owning a special welding machine;

- deposits do not accumulate on the inner surface of the pipeline;

- propylene pipes are strong and at the same time have a sufficient margin of flexibility;

- even when the heating system freezes, polypropylene pipes will not be affected;

- the construction of a heating system based on polypropylene pipes is much cheaper than using other materials.

For hot water and heating systems, pipes marked PN 20 and PN 25 are best suited. Such pipelines are designed to work with a coolant having a temperature of up to 100 degrees Celsius and an operating pressure of 20 and 25 atmospheres, respectively.

Some mistakenly believe that the use of pipes and valves of a larger diameter will improve the efficiency of the heating system. This is by no means the case, and such an approach will only make the design of the heating system more cumbersome and expensive.

3 Types of systems by the number of pipelines, choose one of two schemes

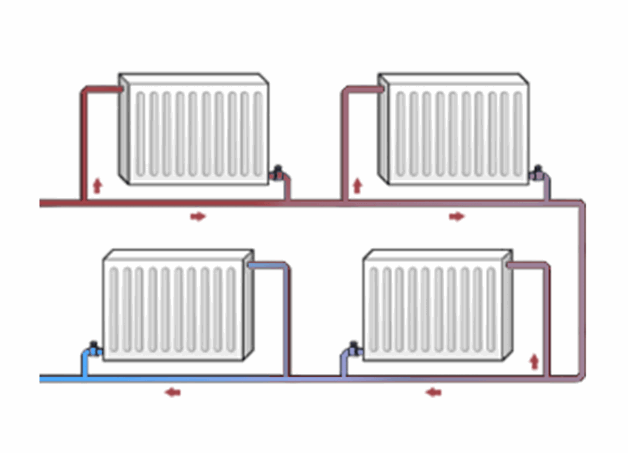

Heating lines made of polypropylene pipes in the house can be single-pipe and two-pipe. In the first case, all heating devices in a private house are connected in turn to the main pipe. The minus of the scheme is the poor heating of the batteries at the very end of such a heating chain. This is explained by the fact that hot water is cooled while moving along the highway.

Single-pipe systems are mounted in small dwellings. Moreover, living rooms are always connected to the riser first. And then all the premises for technical purposes.

For a large private house, a two-pipe system is more suitable. In it, the return and supply lines are laid in parallel. Due to this, all heating batteries receive a coolant with the same temperature. Naturally, during repairs, only one riser can be disconnected from the system. The rest of it will work as before.

Two-pipe piping system

When installing two-pipe lines with your own hands, it is advisable to design a lower one-sided connection of the system elements. This is easy to do with the help of special fittings with a special temperature controller. It will give you the opportunity to set a comfortable microclimate in all rooms.

Stages of connecting heating radiators

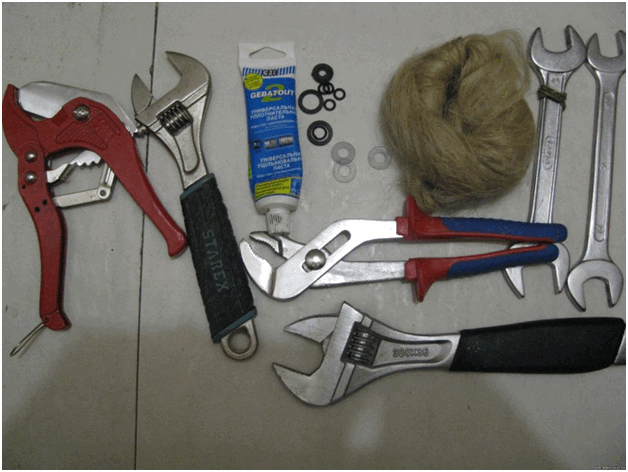

Installing batteries in the house and subsequent connection will require additional equipment and accessories from you. All valves, as well as the main consumables, must also be made of polypropylene. Ball valves today are available in any modification, both straight and angled.

For reference: You can use brass fittings, but it is more expensive and, most interestingly, the joints of brass fittings with a propylene pipe or coupling will lose their strength over time.

To make the connection correctly, you will need: seals, a set of keys, thread paste, mounting tape, threads for making threads.

The binding is performed as follows.

A multiflex is used - a tooling into which a coupling equipped with a union nut is inserted. Such a connection is able to interact with any outputs and inputs.

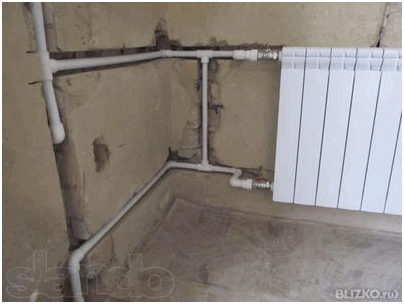

Polypropylene pipes are laid at a suitable height. The allowable gap between the line and the wall is 20-30 cm. Special brackets are the places where the pipe is attached to the wall.

If you want to hide the pipes in the wall, then the pipe is brought to the surface only at the points of connection to the radiators.

Batteries are usually attached to the wall with pins. In some cases, corner brackets are used to hang the batteries. For sectional radiators, the number of brackets is determined by the number of sections.

Installation of the crane in the battery. The plastic faucet is disassembled. Then the fitting is screwed into the seat and fixed with a union nut, after which the nut is tightly tightened. The plastic body of the faucet is put on over the fitting.

The supplied pipe, with the help of bends, is brought directly to the tap, after which the soldering iron comes into action. To work with polypropylene pipes, use an 800W burner, which is set to a heating temperature of 270 0 C. It is not recommended to set the temperature more or less. The heated sleeve is put on the tap outlet. The whole process, with appropriate preparation, takes no more than 5-10 minutes. Do not forget to install thermostatic regulators at the connection points.

For reference: pipes connected to the radiator must be geometrically correctly located, without tension and inclinations. Otherwise, the junction will be under constant voltage, and the slope of the line created will disrupt the normal circulation of water in the system.

To get an idea of how the finishing work is done: connecting pipes to a radiator, we suggest you watch this video.

What pipes to use

During the installation of the heating system from the pipes in question, you may need to connect plastic elements with metal-plastic pipes. When doing this work, make sure that the diameters of both types of pipes fit together.

Connections of polypropylene and metal pipes to each other

Stick to the following pattern:

- for connection to metal-plastic products 20x2 mm, use polypropylene pipes measuring 25x4.2 mm;

- to pipes made of metal-plastic with dimensions of 16x2 mm, polypropylene pipes with dimensions of 20x3.4 mm must be connected;

- polypropylene pipes with dimensions of 32x5.4 mm are connected to metal pipes with dimensions of 26x3 mm.

If the pipes are laid to the batteries in the house from the main pipeline, and the wiring is carried out in accordance with the two-pipe scheme, it is necessary to lay a polypropylene pipe measuring 20x3.4 mm.

The use of pipes with a larger diameter does not make much sense. It also makes no sense to use radiator valves larger than 1.2 inches. Therefore, the statement that with an increase in the diameter of polypropylene pipes and thermostatic valves in the premises becomes warmer is not true.

To ensure the required performance of the heating system, it is important that the supply pipeline between the boiler and the latest battery has a length of no more than 25 m. In this case, the boiler power should not exceed 12 kW

Thus, in order for, for example, a heating system with pipes measuring 20x3.4 to work as efficiently and correctly as possible, it should include a maximum of 6 batteries of 10 sections each.

If it is necessary to connect more batteries, it will be necessary to increase the length of the pipes for their installation, which will negatively affect the uniformity of heating of the batteries installed at a greater distance from the heating boiler.

Installation of heating from polypropylene pipes and aluminum radiators

However, if it is impossible to refuse to connect more batteries or increase the length of the pipes, equip the heating system using larger pipes. For example, 32x5.4 mm. Connect metal-plastic pipes 26x3 mm to them.

There is also another solution to this problem - instead of one heating circuit, you can equip two.

Reinforced polypropylene pipes

To reinforce (strengthen) pipes made of polypropylene, fiberglass or aluminum foil is used. The sole purpose of reinforcing polypropylene is to reduce the degree of its "sagging" when heated. To do this, the reinforcing layer can be laid inside the PP layer or located outside the pipe surface, which to some extent determines the operational properties of the pipes.

More about this…

PP pipes reinforced with fiberglass

Polypropylene pipes reinforced with glass fiber are three-layered: the inner and outer layers in them consist of ordinary (pure) polypropylene, and the middle layer consists of a mixture of PP and fiberglass.

The elongation of pipes of this type is no more than 1.5 cm per 10 meters of the pipe, which is practically not noticeable when using them.

Another advantage of this type of pipe is that it can be easily welded using conventional welding equipment, the same “iron” used for welding ordinary, non-reinforced polypropylene. At the same time, the pipes do not require preliminary preparation and removal of the fiberglass layer.

It remains to be added that PP pipes with fiberglass can withstand pressure up to 25 atmospheres, are unpretentious, not subject to corrosion and, thanks to all these properties, are the most popular among builders and heat engineers.

Aluminum reinforced pipes

When reinforcing, aluminum can be in the center of the polypropylene layer or located almost outside it.The last option, in which a layer of aluminum foil is on the surface of the pipe, is called the classic one. When using it, a minimum thermal expansion of the pipes is observed. However, the connection of such pipes requires the preliminary removal of the aluminum reinforcing layer (its stripping), which in itself is a complex and time-consuming process.

Pipes with an internal arrangement of aluminum are easier to prepare for welding. For this, a special cleaning tool is used, with the help of which an angular cut of the edge of the pipe is made, protecting aluminum from subsequent contact with the coolant.

Violation of pipe welding technology, poor cleaning of aluminum can lead to pipeline damage and emergency situations.

As you can see, heating can be made of polypropylene, the main thing is to mount it correctly!

We connect the heating radiator to polypropylene pipes

In the private sector, in the houses of the old housing stock and in new buildings, work is currently underway to re-equip heating systems. Old heating equipment, steel and cast iron radiators are replaced with new appliances. Modern industry produces bimetallic, steel heating devices with improved parameters and characteristics. Accordingly, in parallel, the old steel pipelines through which the coolant circulates are replaced with new consumables. Today, polypropylene pipes take the first positions in the creation of a heating circuit.

Accordingly, in view of such a large-scale modernization of heating systems, reasonable questions arise. How is the distribution of the water circuit made of polypropylene at home carried out? How does the connection of a heating system radiator to polypropylene reinforced pipes look like? We will understand in detail and consider what constitutes the connection of polypropylene consumables to heating sources in detail.

Heating system options

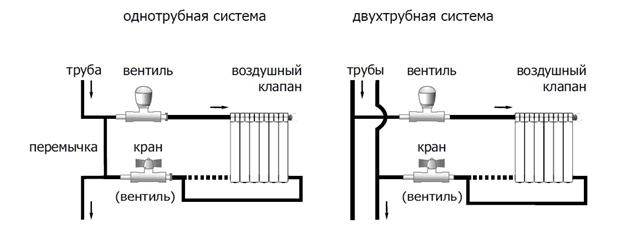

Today, two heating systems are used that can be used to install heating radiators in a house: one-pipe and two-pipe

One pipe scheme for connecting a heating radiator.

A one-pipe system is a heating system in which hot water enters the entire building, flows down from top to bottom through pipes and heaters that are installed in individual apartments. This system is quite common today, it is used for apartment buildings. But it is this installation method that has significant drawbacks:

- there is no way to regulate the temperature of the heating equipment (in rare cases there is a chance to install an additional expensive system);

- on the upper floors the temperature is higher than on the lower ones;

- if it is necessary to carry out repair work, the entire riser is turned off;

- complete disconnection from the central heating system is quite complicated.

A two-pipe system for connecting heating radiators is a supply of hot water through one pipe, and already cooled down - through another (this is the so-called return). All radiators with such a system are connected only in parallel. A two-pipe heating system is used for private houses, cottages.

It is not only very convenient and efficient, but also has such advantages as the ability to adjust the temperature of the radiators, which will be the same for all batteries, regardless of the number of floors.

The heating system itself consists of such elements as:

Two-pipe scheme for connecting a heating radiator.

- heating radiators with a plug at the bottom and a valve at the top;

- radiator cap;

- thermostat and valve (for a two-pipe system);

- stopcock;

- shank;

- bypass (for a two-pipe system);

- couplings and locknuts for fixing heating radiators;

- risers in the form of heating pipes (can be made of polypropylene, polyethylene, metal).

Tying with polypropylene pipes

Piping of radiators can be carried out using a variety of pipes, but experts recommend using polypropylene. Ball valves for strapping are also bought in polypropylene, they can be straight and angled, this option is the simplest and most inexpensive. Brass fittings are more expensive, and installation is more difficult.

Polypropylene strapping is performed as follows:

- the coupling with the union nut is inserted into the multiflex, which is easily connected to any outlet;

- the pipes themselves are attached to the walls at a convenient height, they should not fit snugly to the surface, it is better to leave a gap of 2-3 cm. The pipes are fixed with special brackets, which are fixed to the wall with nails or self-tapping screws.

Polypropylene strapping to radiators can also be carried out when pipes are laid into the wall, in which case they come to the surface only at the connection points.

Piping of radiators can be carried out using a variety of pipes, but experts recommend using polypropylene.

Fasteners for batteries can be very different, most often it is a pin connection, which is fixed on the wall surface. Corner brackets can also be used, which also allow you to hang radiators at the required height. For panel batteries, fasteners are supplied in the kit, for sectional batteries, you need to buy separately. Usually, two brackets or pins are enough for one section.

The connection of cranes is carried out in this way:

- the crane is disassembled, a fitting and a union nut are screwed into the radiator;

- the nut is tightly tightened with a special wrench.

As you can see, this process is extremely simple. To perform such work, you only need to purchase a special plumbing key for American women, without which it is unlikely that you can simply install a tap.

The following materials and tools are required for battery installation and piping:

- a set of special keys;

- seals for threaded connections;

- tow and thread paste;

- thread for carving.

Features of connecting radiators

Installation of heating differs in some features:

- It is necessary to observe the distance from the radiator to the window sill of 100 mm. If the gap between the batteries and the bottom of the window sill is different, then the heat flow is disturbed, the effect of the heating system will be low.

- From the floor surface to the battery, the distance should be 120-150 mm, otherwise a sharp temperature drop occurs.

- In order for the heat transfer of the equipment to be correct, the distance from the wall must be at least 20 mm.

At the same time, we take into account that the installation method and the efficiency of heating radiators are greatly influenced by the installation method: under the window sill in the open form, the efficiency of the heating system is maximum - 96-97%, in a niche in the open form - up to 93%, in a partially closed form - 88-93 %, fully closed - 75-80%.

The heating radiator can be installed using a variety of methods, its piping is carried out with metal, polyethylene, polypropylene pipes

It is important during installation to correctly position not only the pipes, but also the batteries themselves, to connect in accordance with all recommendations and standards. In this case, the heating system will work very efficiently and will not require repairs.

Share this helpful article:

Types of radiators for piping

To install a heating system, you must select the type of radiator. Different types of heating equipment differ in fasteners to the wall, materials of manufacture, pipe connection. Today, manufacturers offer the following options:

Sectional radiators.

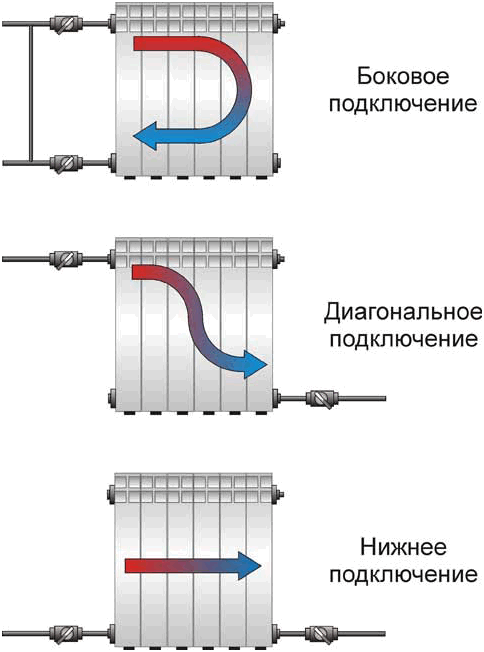

- Panel steel batteries, made in the form of relatively thin solid panels. Connection of such radiators can be side or bottom.

- Sectional lightweight, made of aluminum.Bimetallic ones are also often used. Such batteries can be connected in one or several sections, the connection to the common system is lateral, polypropylene pipes are ideal.

For apartments with central heating, bimetallic radiators are used (cast iron ones are used less and less, this is due to their large weight, bulkiness, fragility). This is due to the fact that the water that is supplied to the heating system often contains alkali, sand, which can damage other types of radiators.

For a private house, aluminum, steel panel radiators are excellent, while all conditions for connection must be observed (steel and aluminum radiators are used for a copper pipeline, only aluminum radiators are used for a regular one).

Accessories for connecting radiators

Heating is a rather complex system, the connection of which requires the participation of a specialist. In addition to radiators and pipes, it is also necessary to prepare components, without which the connection will simply be impossible.

The connection kit consists of:

Accessories for connecting radiators.

- a set including a plug, adapters, a manual air vent, a wrench to bleed air from batteries plus pipes;

- futorki, or adapters that have the right and left threads;

- special tools for screwing adapters.

Shutoff valves for batteries are also required, do not forget about pipes. This also includes ball valves, valves for stopping the supply of the working flow or regulating it.

What can be the binding of polypropylene pipes

The piping for a home heating system can be very different. The thing is that the consumer is always trying to reduce the amount of consumables, while trying to equip radiators in all heated rooms.

It should be said right away that these are relics of the past. Unlike expensive metal pipes, polypropylene consumables are much cheaper and easier to install. therefore, saving on the length of the pipeline is not worth it. Choose the type of strapping that will bring the most benefit in your case. The only factors that may affect the choice of type of strapping are the following factors:

- what heating scheme is used (one-pipe system or two-pipe);

- what type of radiator connection you have chosen (diagonal, side or bottom).

As a rule, when using any heating scheme: one-pipe or two-pipe, any type of connection for heating radiators can be used.

according to experts, laying the pipeline must minimize the number of bends. A smooth highway remains resistant to hydrodynamic loads. The pipeline will reduce the number of zones in which air can accumulate.

For tying a single-circuit and double-circuit heating system using polypropylene pipes, there are some peculiarities.

- usually in such a system a serial connection of radiators is used;

- a bypass is always mounted in front of the battery, connecting the supply pipe and the return pipe. During normal operation of the heating system, the bypass is not activated. During preventive maintenance or in case of an emergency, the water supply to the radiator is stopped. The coolant circulates freely through the bypass.

- both parallel and series connection of batteries is used;

- both radiator pipes are connected to different pipes. The upper one is connected to the supply pipe, the lower branch pipe is connected to the return. Usually in two pipe systems, radiators are connected in parallel, so the installation of bypasses is not required.

Tying polypropylene pipes with radiators is carried out in two ways: by soldering and using fittings.Installation of radiators and their connection is carried out using a soldering iron and plumbing keys for an American.

Methods for installing radiators and piping

Connection of heating radiators is carried out after windows and doors are inserted, floors and walls are prepared for fine finishing. Connection options and types of radiators, pipes are selected in advance so that the room is already ready for their installation.

A modern heating system consists of a number of components. Among them, one can distinguish directly the heating boiler, pipeline and heating devices - radiators, which are presented in a wide range.

The process of installing the battery itself is quite simple: you need to mark the place for installation, bring the pipes, put the radiator itself and make the connection. Consider the process of installing radiators using polypropylene heating pipes in more detail. Let's find out what types of systems and connections can be used for this, what is necessary for the connection of the heating system itself.

Thermal expansion of polypropylene

Polypropylene, like any other plastics, has a thermal expansion that averages 15 cm per 10 linear meters of the pipe when it is heated by 40 degrees or more. This means that polypropylene can be safely used for cold water supply, but pipes made of simple PP are not suitable for heating and hot water supply: they will sag, creating coolant stagnation zones and contributing to a local increase in pressure in the pipeline, which in turn can lead to to an emergency.

It is unlikely that there will be users who agree with such risks of using polypropylene pipes. It is for this reason that for the installation of heating systems, not simple polypropylene is used, but reinforced.