Soundproofing materials

There are several types, divided by performing certain functions.

Soundproofing - reflection of incoming noise. The sound insulation of a wall is determined by its thickness. The thicker the structure, the better the sound insulation. Noise isolation index 52-60 dB. Additional soundproofing materials include drywall.

Noise absorption - the absorption of noise by the material used, which has a structure of fibers, with the addition of crumbs, looks like cells. Noise reduction coefficient 0-1. The average value is 0.4.

Soundproof materials include films, membranes. They are thin and at the same time have a good ratio. The mineral membrane has a thickness of 0.25-0.37 cm. It is aragonite - "Teksound", barite - vinyl.

Polyethylene has a thickness of 0.5 cm. It is mounted under the wallpaper. As well as lead foil having a thickness of 0.7 cm.

The most applicable materials are divided into types.

ZIPS soundproofing panel used indoors under wallpaper to achieve silence in the apartment. This is a sandwich panel consisting of mineral wool and drywall. Depending on the type, the thickness of the panel varies from 40-130 mm. Drywall is used with a thickness of 12.5 mm. Installation is carried out using a vibration-proof gasket. The connection between them is made using a thorn-groove. The noise insulation index increases by 9-18 dB (depending on the thickness of the ZIPS).

fiberglass

Vibroacoustic sealant

High vibration isolation of joints in the mounted structure (made of plasterboard), as well as reduction of structural noise. The seams of the created structure under the wallpaper are filled with sealant. When using it is necessary to protect the eyes and skin from contact. After drying, it is not dangerous, non-toxic.

Isoplast

Material is made from coniferous trees. It does not allow noise to penetrate from the outside, while it has thermal insulation properties. It is used both under wallpaper and putty. Environmentally friendly material. Easy to install. Its disadvantage is the high cost.

Noise reduction up to 27 dB.

Soundproof wallpaper

The lining under the wallpaper is made of foamed polyethylene covered with paper. This is a roll material of a sound-absorbing type. It has the property of a heater, as well as such features:

- safety for health - the material is created from elements harmless to human health;

- prevents the spread of mold, does not rot;

- installation of roll material does not reduce useful square meters;

- service life of 50 years.

There is another advantage - leveling the walls before wallpapering.

Disadvantages - high cost. And also if the room is damp, the accumulated condensate will be collected by water droplets on the wallpaper.

The substrate for the wallpaper is made of cork, non-woven.

Soundproof membrane

Roll material of mineral composition. Installation is carried out on glue to various surfaces. Noise reduction is up to 22 dB. The membrane has a number of features:

- does not tear;

- harmless to health;

- service life up to 20 years;

- at a temperature of -20 0C does not burst.

Soundproof putty

The soundproofing mixture contains granules that reflect sounds. It is applied in a thin layer to reduce noise coming from the room, as well as improve acoustics.

For the best effect, the mixture is applied in a layer of 20 mm.

Minus the mixture - does not suppress strong sounds. Sometimes putty is applied in 2 layers.

Shumozol

This is a roll material created on a bitumen basis. It is thin with good noise-absorbing properties. Mounted on glue for drywall and putty. It has the following properties:

- impact noise removal up to 27 dB;

- has waterproofing properties;

- flexible;

- harmless to health.

Minus - high cost.

Cork

Cork materials are divided into groups with their own functions.

- Pressed sheet created from crumbs. Does not rot.Has a service life of 40 years. Does not spread mold. Sheet thickness 2-4 mm. Can be produced in rolls. Impact noise reduction index 12 dB.

- Substrate. Created by mixing granules of cork and synthetic rubber. Reduces impact noise. Used as a substrate for various finishing materials. Waterproofing is required for the installation of the substrate.

- Basis - kraft paper, bituminous impregnation, cork crumb. Waterproofing during installation is not required. But, with strong moisture, the crumbs peel off from the base and begin to rot.

Cork sound insulators have positive properties and some disadvantages - they cannot stand high moisture, and they are also expensive.

Zvkukoizol

This is a seven-layer material created from cardboard sheets and a mixture of quartz sand. The panel has a thickness of 1.3 cm. The noise absorption index is 38 dB. Mount the panels with glue.

There is also soundproofing in rolls. This is foamed polyethylene foam and bitumen. It is a waterproofing agent. Elastic, durable.

Features of the choice of thin sound insulation for walls

As mentioned above, it is undesirable to use plasterboard sandwiches and decorative soundproofing panels to protect walls in small apartments. They will steal useful centimeters from the usable area and make small rooms look like a box. What to do in this case? Is it worth giving up the desire to protect the apartment from airborne noise?

On sale you can find ultra-thin soundproofing materials that can provide the expected effect without losing living space. These are soundproof membranes. They came to us from the military industry. Until recently, such materials were used for soundproofing submarines, now almost all professional recording studios are protected from external noise with the help of them. And just recently, soundproofing membranes appeared in retail.

There are many advantages to this choice:

- The membrane thickness is only 3.7 mm. Ultra-thin roll material is able to provide such sound insulation of walls, which is formed by the thickest sound-proof sandwich, while the area of the room will not be reduced in any way.

- Today, it is almost impossible to find an alternative that can protect a residential apartment even from low-frequency noise.

- The soundproofing membrane helps to mount relatively inexpensive soundproofing systems with the highest possible efficiency.

- The physical and chemical properties of noise-insulating membranes are unique: they are made from natural materials and are based on polymers. Contains no bitumen or rubber. The material itself is very flexible, it is elastic, strong and durable. It boasts viscoelastic properties and high bulk density. These qualities are key indicators that help to say that we have the best soundproofing material that can be used to protect walls.

- Every inhabitant who does not have professional building skills is able to install the sound insulation of the wall of a residential apartment using a membrane. A structure is being constructed, the thickness of which is not more than five centimeters. At the same time, the level of mid-frequency noise will be reduced by 70%.

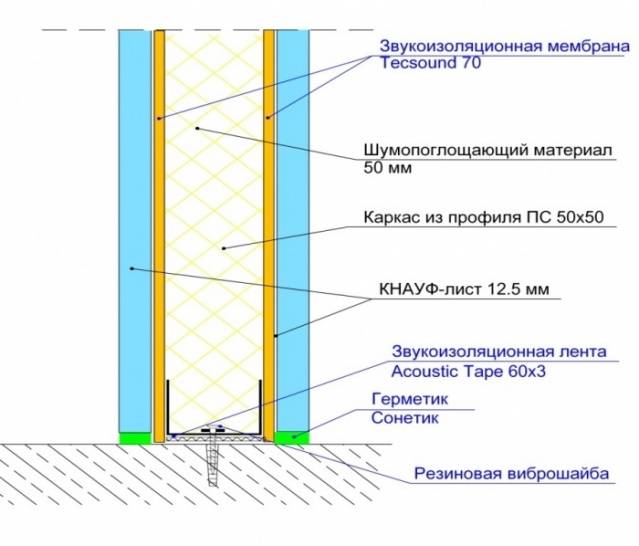

To install soundproof membranes, it is necessary to construct a metal frame; a direct suspension is used as its attachment to the wall. It also provides the necessary space savings. The order of work is this:

- The frame is being built.

- Mineral wool slabs are laid in it.

- Then the membrane is stretched.

- The entire structure is covered with plasterboard sheets.

A more detailed story about installing the membrane on the walls will show the video:

The length of one roll of the membrane is five meters, the width is one meter twenty-two centimeters. The area of one soundproofing roll is six meters one centimeter. One square meter weighs only seven kilograms.

Advantages and disadvantages

All of the above wallpaper options have high

soundproofing characteristics, however, in addition to this, there are also other

qualities:

- Ecological purity. Everything

The products are made of high quality materials, which do not bear

harm to the human body and health. As for the cork cloth,

it is made from natural ingredients. - Ability to use in

rooms with high humidity. If we talk about cork and velor

models, they are not considered universal coatings, especially with wet

air, but taffeta and vinyl products can be used absolutely

in every room from the bathroom to the bedroom. - variety of patterns and

patterns. If cork products do not have a colorful design, then the rest

options can be selected according to various preferences and parameters. How

as a rule, cork canvases are a rational solution for decorating

office, study or library. - High strength.

Vinyl canvases can boast of the increased strength of the material.

Other types of products are less durable, which means that they will often have to be

glue and glue. The lifespan of a vinyl sheet

is at least ten years, which is an order of magnitude higher than the rest

rolls. - Ease of sticking.

Almost all types of wallpaper can be handled without unnecessary difficulties.

The only material that can bring inconvenience is cork.

For pasting such canvases, it is better to invite a specialist. After all, technology

and the materials themselves differ from the traditional ones used in conventional

wallpapering. - Price. If

consider the price line, then vinyl is considered the cheapest

products on non-woven and paper basis. The rest is enough

expensive, so if the budget has it, then you can take it, and if

no, you can glue vinyl as an alternative.

Assortment of wallpapers in the modern construction market

allows you to choose exactly what is best for you and your

wallet. Soundproof wallpaper will help create optimal indoor

conditions, even without major sound insulation.

Soundproofing the walls in the apartment with drywall

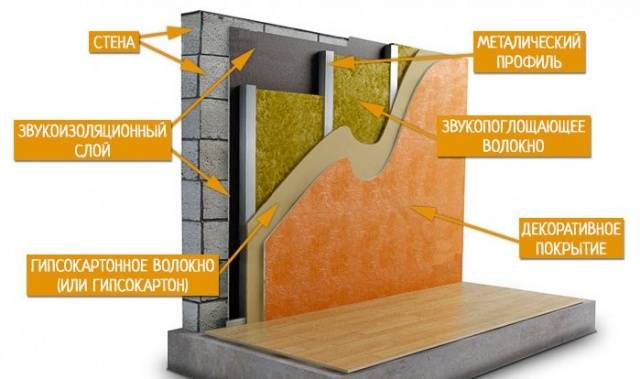

Until recently, the soundproofing of walls in a residential apartment was carried out using a multi-layer structure, which was constructed from gypsum board sheets and a soundproofing sheet. The principle of its construction is quite simple:

- First you need to walk along the surface of all the walls, find all the cracks and potholes, embroider them with a spatula, and then fill them with cement mortar.

- Then a frame is erected from wooden or metal profiles.

- If metal profiles are selected, it is necessary to place rubber or cork material under them at the points of contact with the walls for sound insulation. Otherwise, the metal element will become a good conductor for the penetration of airborne noise from neighboring apartments or from the street.

- Profiles are laid on the wall in increments of sixty centimeters.

- After the frame is ready, you can lay rigid slabs made of mineral wool or fiberglass directly on the walls.

- The entire structure is covered with drywall. The sheets are screwed to the profiles with self-tapping screws.

- The joints of the sheets are laid with a sickle.

- The surface of the wall is puttied and processed with fine-grained sandpaper.

- The end result is a surface that can be decorated with any modern finishing material.

Such a design on the walls has two goals: it simultaneously protects the room from the penetration of noise and reduces heat loss in the room in winter.After laying the GKL sheets, a perfectly flat surface is obtained, which can be decorated with anything.

This design of soundproofing walls has its drawbacks. They must be taken into account before starting work.

- Firstly, the protection of drywall walls will reduce the room by about fifteen centimeters. For small rooms, this method of sound insulation is not suitable.

- Secondly, the construction of a frame structure is a dusty and time-consuming task, requiring the possession of certain building skills.

Before choosing this option for soundproofing walls in a residential apartment, you should carefully weigh the pros and cons of the described design.

DIY wall soundproofing

Before you make soundproofing, you should always inspect the walls for cracks and holes in them, which are best puttied. This is the main component of complex sound insulation. After sealing the cracks, the noise will pass into the room less.

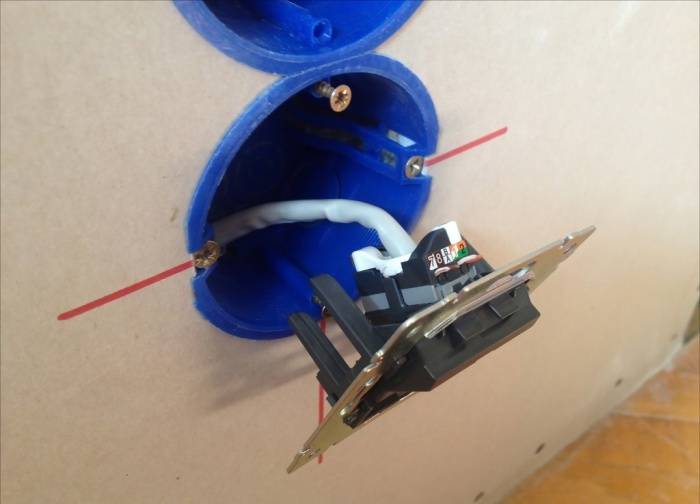

The second step in the fight against annoying noise is to inspect the landing sockets of sockets and switches. To do this, you need to de-energize the room where soundproofing work is being carried out. it barks in a common shield in the entrance. After a power outage, you still need to check the socket or switch for operability. If there are no signs of the presence of current, then you can safely get to work. To begin with, the contents of the outlet are pulled out, the empty space behind it is filled with foam rubber, glass wool or foam plastic, and other materials will be suitable. Then this structure is sealed with a quick-setting mortar and after it dries a little, a socket or switch is installed. Such processing of landing nests will significantly reduce the amount of incoming noise.

You can also go the other way and simply move the outlet to a new location, and fill the old hole with mounting foam.

The third stage of preparation for soundproofing is the sealing of holes and cracks that occur at the junction of heating and plumbing pipes to the wall. Be sure to fill all significant holes with soundproofing material and cover with a layer of cement mortar or putty. Only these actions in combination can reduce the noise in the room to a good level, as a result of which the correct and effective sound insulation of the walls is created.

To perform noise and sound insulation of the walls, it is necessary to make a frame.

If the room has loose windows and doors, then no soundproofing of the walls will help. First you need to replace them.

To obtain high-quality protection, it is not necessary to mount the profile on the wall. It is better to retreat 2 cm from it and make a rubber or cork gasket. Vibration isolation will reduce the possibility of sound penetration.

After the construction of the frame, the most important stage begins - work with noise-absorbing materials. And if at this stage no mistakes are made, then the sound insulation of the apartment will be provided to you at the highest level.

The laying of mineral wool and the installation of panels do not cause difficulties. In the case of soft materials, careful padding must be carried out. The denser the cotton wool, the better the sound insulation.

It is very important to fill all the gaps, especially those near the profiles. Their cavities are also recommended to be tightly packed with cotton wool.

This will reduce the loudness. If gaps remain after installation, they can be filled with mounting foam.

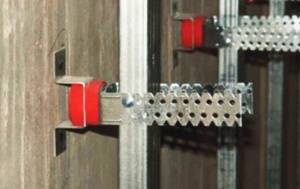

Ceiling soundproofing

In addition to the noises that come through the walls, neighbors from above often disturb - steps, creaking floorboards, etc. interfere with sleep. The way out in this case is to make a suspended plasterboard ceiling, but not simple, but on special vibration-damping suspensions. Why? Because sounds are transmitted through vibrations, and stomp - especially.If you use a conventional rigid mount for plasterboard to the ceiling, there will be no effect, the sound insulation of the ceiling will not improve, even if the space between the main and suspended ceilings is filled with sound-absorbing material. Vibrations will be transmitted through suspensions and spread by drywall. Therefore, it is necessary to use special suspensions with a vibration damping gasket. For example, Vibrofix SP and Vibrofix P.

The use of these hangers reduces the level of noise penetrating through the ceiling by 18 dB with Vibrofix P and 25 dB with Vibrofix SP. The soundproofing of the ceiling made with their use will cut off not only shock noises, but also airborne ones - speech, etc. (if you fill the space with a layer of mineral wool).

To save money, you can use conventional suspensions, but mount them to the ceiling through foamed thin soundproof materials (Dichtunsband KNAUF), but better - staple fiberglass (Vibrostek, folding it in two layers). The fact is that foamed materials are crushed, lose their properties, and fiberglass stably keeps its characteristics. If you are afraid of fiberglass dust flying in the air, do not. The design must be airtight in order for it to be effective.

Since one of the requirements for a good soundproofing structure is the presence of a massive outer layer, it is advisable to hem with two layers of gypsum plasterboard with a seam spacing and sealing the seams with sealant on each of them. But again, the combination is better - GVL + GKL. If the sounds are very loud, a soundproof membrane can be placed between them.

For soundproofing the ceiling in the apartment, you can use basalt or fiberglass mats. If possible - special soundproof ones; if not, choose one of the normal brands (more on this below).

There is one more point: it is necessary to seal the joints not with putty, but with soundproof acoustic sealant. It does not harden and does not transmit vibrations. If you make a false ceiling according to these rules, the sound insulation in the apartment will improve significantly.

What to do if you want to make a stretch ceiling? The same, but without finishing. If there are noises from above, but not very strong, you can try to get by with Isoplat, but again: the noise reduction will not be so significant.

Functional purposes of the wallpaper substrate

Depending on the manufacturers, wallpaper layers may have different additional properties, but they are all designed to perform functions such as:

- Ensuring thermal insulation of walls. Interlayer sheets are not the main saving material. They serve as additional protection against frost and wind, as they have insulating properties. A soft plate under the wallpaper provides comfortable conditions and helps save money spent on heating.

- Noise reduction in the room. The bottom layer, glued under the finishing coating, is in high demand among residents of panel houses, because it is not for nothing that the walls in them are called paper. In such buildings, sound insulation is low. There are quite a few sources of noise - these are both neighbors and a roar coming from the street. The use of this material increases the level of protection against hum and retains heat.

- Wall waterproofing. The bottom layer, glued to the base, is able to protect brand new coatings from high humidity and sudden temperature fluctuations. Condensation does not form on the base, as the substrate does not absorb moisture.

- Wall alignment. When applying an insulating layer, you will not need to spend money on finishing putty. It will help eliminate problems with uneven walls, as it has the same structure throughout the canvas. The substrate will provide a perfectly flat surface for wallpapering.

Types of sound-absorbing wallpaper

Tufted wallpaper

- They are a two-layer material, and the basis is a dense fabric, and an artificial pile is applied on top.This gives it a good density, and when used on the walls, it will seem that they are covered with a synthetic carpet.

- When using such wallpaper around the entire perimeter of the room, you can significantly reduce the level of noise entering there. In addition, this finishing material can be a good insulation for a cold wall.

- Do-it-yourself cleaning of such a coating is quite easy, and ordinary wallpaper glue is used for gluing it. And lastly, this material also has excellent vapor permeability, as a result of which the atmosphere in the room will be as comfortable as possible due to natural ventilation.

Faux velor

- Outwardly, it resembles velvet paper, but the material has a higher density. A paper web is used as a base, and vinyl fibers are glued on top, which also perform a decorative function.

- Such wallpapers can be different both in texture and in colors. The length of the fibers can also be selected individually, in addition, natural elements can be used to complement them - sisal, jute, etc., on which various images are also applied.

- The material adheres well to any surface. Their soundproofing qualities are not so good, but they can protect against the noise of neighbors.

- It should be said that quite often this type of finishing coating is used in office premises. At the same time, other qualities of artificial velor wallpaper are not of the highest level - they have poor thermal insulation properties, do not tolerate moisture, and are not strong enough.

Cork wallpaper

Making a decision to purchase such a finishing material will save the room from unnecessary sounds from the outside. After gluing it, almost ¾ of the incoming noise from the street will not enter the house.

At its core, this is one of the options for duplex coverage. As in most options, compacted paper acts as a base, on top of which a cork veneer is glued.

The material is 100% natural, because. for its manufacture, the top layer of cork oak bark is used. And its very structure guarantees good sound absorption, as it is cellular. The latter are filled with air, which prevents sounds from entering the apartment.

In addition, such wallpapers also guarantee heat retention, as well as excellent natural ventilation of the room. Thanks to all this, the atmosphere in the apartment will be cozy and pleasant.

Also, to achieve even greater soundproofing properties, you can use a denser coating, which can be cork in rolls or cork slabs. In such materials, compressed cork chips are used instead of thick paper.

Soundproofing installation

Depending on the choice of soundproofing used

material is selected and the method of fastening. If using Phonestar GW panels,

then they are attached to the wall surface with a special adhesive solution and dowels.

The procedure is not complicated, but it can take a long time to install. There is

a list of tasks to be completed:

- Surface preparation.

Visually assess the surface for cracks and cracks. If

there are they must be repaired. You also need to look at

evenness of the wall. If there is a gap of more than one centimeter, then

must first be plastered. As a rule, such work is carried out

master, since it will be difficult for an inexperienced builder to achieve an ideal

evenness. - At the second stage it is necessary

prepare vibration isolation strips. Stripes are glued to the wall

places where there will be joints of plates. It should be understood that even the slightest gap can

transmit noise from the street or from neighbors. - You need to glue the strips when

liquid nails or similar materials capable of

absorb vibration and noise. - Over the prepared

surfaces are attached to the wall with Phonestar GW plates. Wherein

it is necessary to use materials that do not transmit sounds and

noise.

You can even make high-quality and effective noise protection

independently if you know the basic rules and requirements for installation work.

If there are no skills, then it is better to trust professionals. Depending on whether

what exactly will be the soundproofing, the appropriate

activities and procedures.

Today's market provides an opportunity to choose

sound insulation according to any parameters and characteristics. If for work

a small apartment is provided, then initially you need to choose the best

material, because the thickness of the sound insulation layer also depends on how much

room involved. There are very thin or thick types of noise insulation, and

Everyone should choose according to their parameters and preferences.

Everyone understands that the expected result can be achieved only

in the event that you choose the right materials and their number of layers.

A multi-layer cake will protect the house as effectively as possible. Today, even with

wallpaper can make soundproofing, despite the thin base of the material. Select

soundproofing canvas for wallpaper is not an easy task, but it is precisely from this that

depends on how efficient the processing will be.

Decorative panels are a new word in wall soundproofing

Ready-made decorative panels greatly facilitate the task of soundproofing walls in an apartment. But their use becomes possible if the rooms have perfectly even walls. And all because many of these products are fastened to each other according to the "thorn-groove" system. If there is a noticeable difference in heights, the panels will simply lead. There are quite a few advantages of decorative soundproofing panels.

- Each weighs about four kilograms, so one person is able to work with individual elements.

- The decorative panel after installation in the room will not need to be additionally decorated. And this is a significant savings.

- Soundproof panels are attached directly to the wall using special fasteners or glue, the frameless system does not take centimeters from the room.

- Ease of installation, excellent end result, high sound insulation properties - the described sound insulation of the walls in the apartment is chosen when it is necessary to protect everything: both internal and external partitions.

If the walls in the apartment are soundproofed using wall panels, it is important to comply with certain conditions: the installation itself takes place only in dry rooms, when all the “wet” work has already been completed

There are two ways to install: on the crate and on the glue. The batten option is chosen when it is not possible to level the walls or you want to save as much as possible on such work. For example, if you plan to soundproof uneven brick walls in a new house, it is better to choose mounting on a crate for installing decorative panels.

For its manufacture, bars with a section of 19x44 mm are used. They are attached to the walls with self-tapping screws in increments of 29 cm. After the installation of the frame is completed, decorative soundproof panels are applied to the planks and attached to them using special brackets (their length is 10-14 mm).

Decorative sound insulation for walls, the surface of which has a perfectly even structure, can be simply glued to the existing base. Special glue is not applied to the entire slab, it must be smeared with strips around the perimeter at a distance of 2 cm from the edges of the decorative element, then the center is marked with drops every 20 cm. After that, the soundproofing panel is simply applied to the wall and pressed against it. The next element is pressed against the wall a little away from the first panel, and then shifted laterally to the already glued element.