Marking of polyethylene pipes

The procedure for marking pipes is approved by GOST. Information is applied in one line, with the same font size by color printing or thermal embossing with a certain depth. The marking system for polyethylene pipes should display the following indicators:

- information about the manufacturer (name or trademark);

- symbol of the pipe material - PE (polyethylene);

- numbers indicating the brand of raw material granules from which the pipe is made - 32, 63, 80.100 (the higher the indicator, the greater the wall density);

- quality standard according to which the product is manufactured - GOST or DU;

- the outer diameter of the pipe (from 16 to 1200 mm) and the thickness of its wall;

- pipe SDR coefficient indicating the load limit;

- purpose of the pipe (technical or drinking).

Additionally, the number of the production line or batch, as well as the date of manufacture of polyethylene pipes, can be indicated. Color marking is also used: a yellow longitudinal strip along the entire length indicates that the pipe is intended for a gas pipeline, blue for a water pipeline.

What does SDR mean?

One of the main indicators of the strength characteristics of a polyethylene pipe, which is provided for by GOST and must be indicated when marking, is SDR. This parameter allows you to define the capabilities of products. The decoding of this designation in English (Standart Dimension Ratio) is a standard dimensional ratio.

The SDR coefficient of a pipe shows the ratio of its outer diameter to the wall thickness, the following formula is used to calculate the indicator:

SDR = D : S where D is the outside diameter (in mm) and S is the pipe wall thickness (in mm).

The higher the SDR coefficient, the thinner the pipe wall, and vice versa - for a pipe with thick walls, this indicator is less. Thus, a pipe with a low SDR will have more capacity and ability to withstand severe loads than a product with a high ratio.

Important! If you choose a product with better performance characteristics from pipes of the same diameter and with different SDRs (for example, 17 and 21), you should give preference to a smaller coefficient - 17. However, you need to take into account: the greater the wall thickness, the lower the throughput of the pipe due to its reduction internal section

The outer diameter of the pipe is PE 100 SDR 17.

Specifications:

- Material: PE 100

- SDR: 17

- Nominal pressure: 8 atm.

- Diameter: 32 to 225 mm

- Wall thickness: 2 to 13.4 mm

- GOST: 18599-2001

In addition, the quality indicators of the material made it possible to significantly reduce the wall thickness of the product, which lightened its weight.

PE 100 pipes are recommended for wide application in such cases:

- for the installation of water pipes;

- for pipelines intended for the transport of liquid food products, for example, in the production of milk, juice, brewing and winemaking.

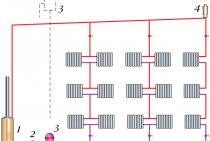

Table of diameters of polyethylene pipes:

Application areas.

Products marked PE 100 SDR 17 are pipes of a new generation due to the use of advanced technologies used in the production of polyethylene PE - 100. A feature of these products is uniquely high strength indicators, which has a significant impact on enhancing the performance of polyethylene pipes.

Pipes of this type are recommended for use in pressure water supply systems and gas pipelines. At the same time, they are considered ideal for the installation of pipelines with a large cross section. In the manufacture of this type, it turns out to be very significant material savings due to the possibility of reducing the wall thickness while maintaining the high strength of the product.

Technical characteristics allow their widespread use in the construction of long pipelines.

Production.

A polyethylene pipe marked "100" is made of low-pressure polyethylene PE-100, which has a high density and strong intermolecular bonds, by extrusion of a molten polyethylene mass.

This material, which has a high degree of "crystallinity", gives products created from it:

- high tensile and tear strength;

- resistance to various destroyers of weather, chemical and biological origin;

- Possibility of operation in high and low temperature conditions.

Contrary to popular belief, this pipe can be easily soldered when the temperature rises to an appropriate level.

Advantages.

- Durability over 50 years;

- The material is resistant to corrosion processes;

- The eraser does not salt or mineralize, unlike metallic compounds;

- The dense crystal lattice of this plastic allows for a more rigid and hermetic fastening;

- Pipes are known for their small linear expansion, i.e., even with a strong temperature difference, they do not deform.

Conclusions.

Now you should know the outer diameter of PE 100 SDR 17. And also these pipes have an optimal ratio of cost and quality. The thickness of the walls allows the use of materials in a variety of industries, from home production to industrial water supply.