Today, owners of residential buildings and apartments are increasingly using polyurethane foam insulation technology. And such a choice is the right position if the thermal insulation is well-planned and well-executed. This technology performs several important functions - it reduces the heat loss of the room and unloads the air conditioning system on hot days. Thermal insulation with polyurethane of all building elements is a guarantee of long-term operation without the risk of deformation of walls, foundations and ceilings. And another advantage of PPU is affordable cost. In this article, we will answer current questions on the topic, voice the methods of seamless insulation with polyurethane foam, and also consider the advantages and disadvantages of the method.

Overview of liquid polyurethane foam insulation (PPU)

Illiterately executed thermal insulation can lead to the opposite effect and harm the living space. An important role in the process of insulation is played by the choice of materials. The thing is that not all positions are acceptable for use in certain cases. The opinions of experts about polyurethane foam insulation differ. For this reason, we will conduct an independent investigation, analyze the pros and cons of the technology and summarize the available information.

What is polyurethane foam

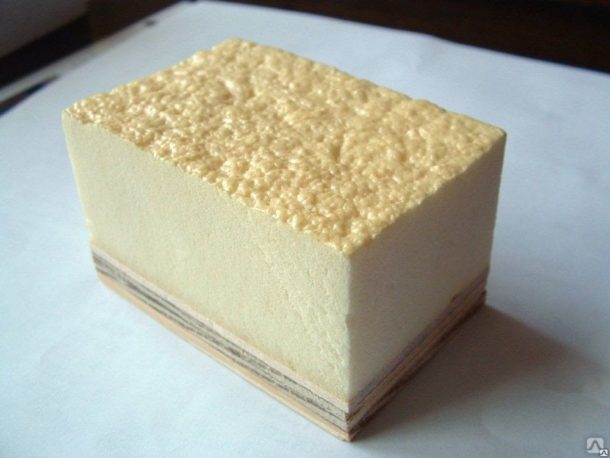

To begin with, we will understand the question of what is polyurethane foam. One of its varieties is familiar to each of us from early childhood - this is the well-known foam rubber. It is widely used for the production of soft toys, sponges for bathing and other popular devices. We note right away that other types of polyurethane are used for thermal insulation of rooms, but their composition is similar to the usual foam rubber.

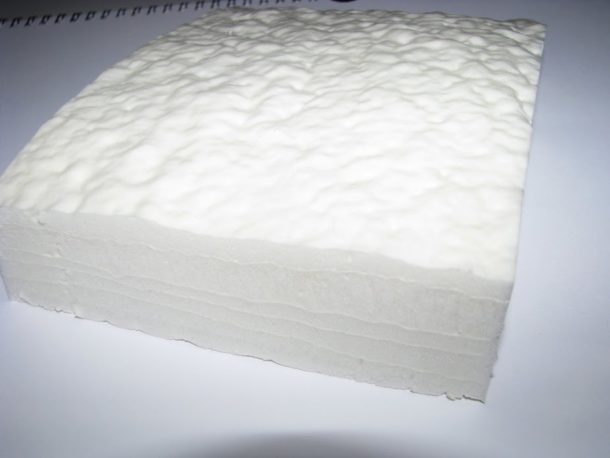

Polyurethane foam is a porous filler that belongs to the group of gas-filled polymers. For its production, natural ingredients are used.

A characteristic feature of all polyurethanes is their gas filling, which reaches 90% of the total mass. Depending on the component used for the production of foam, it can be elastic or rigid.

Thermal insulation of building structures involves the use of finished parts, but liquid self-foaming compounds are more popular due to their ability to polymerize and quickly solidify.

PPU insulation is a two-component structure. It contains polyol and polyisocyanate. In the process of mixing, they enter into a chemical reaction, the result of which is the formation of a polymer polymer with the simultaneous release of carbon dioxide. This material is sold in the form of filled cylinders or barrels. The result of its application is a foamed rigid structure with isolated cells.

What is seamless insulation

The seamless method of laying PPU involves the creation of a sealed, windproof cocoon. The two preheated components are mixed under high pressure in a special gun. After that, the finished mixture in the form of fine dust is sprayed onto the surface, where it foams and hardens. Seamless spraying with polyurethane foam increases the effectiveness of thermal insulation and minimizes the risk of bridges for cold penetration.

Important! Polyol and diisocyanate must be mixed in equal proportions to achieve the stated qualities of thermal conductivity. Therefore, PPU insulation must be trusted by qualified workers using high-class equipment.

Specifications

Many sellers sell PPU with low thermal conductivity. The most common option is 0.020-0.022 W / (m × ° K), less often they sell material with characteristics of 0.017 W / (m × ° K).The porous structure of polyurethane foam provides good sound insulation and waterproofing properties. The rise of the foam compared to the initial volume occurs in a ratio of 1:40. The vapor permeability of the material varies from 0.02 to 0.05.

Note! Even if the insulation technology has been broken, the actual thermal conductivity of polyurethane foam does not lose its properties and deserves a high rating.

Application area

To date, polyurethane foam insulation is the most effective way to increase the thermal insulation of a room. For this reason, this material is widely used in various industries. Let's list a few examples:

-

insulation of buildings with sandwich panels, as well as insulation of roofs during the construction of industrial facilities;

-

construction and repair of residential premises in order to insulate external walls, foundations, doors, windows, attics and balconies;

-

thermal insulation of pipeline communications (oil pipelines, fuel oil pipelines);

-

cold insulation of automobile or railway installations for transportation;

-

thermal insulation of pipelines for hot and cold water supply during initial laying or repair;

-

use in the furniture industry for the purpose of manufacturing foam rubber;

-

application in light industry for the manufacture of artificial leather.

What preparatory work is needed to start with liquid foam insulation?

The process of preparing the insulated surface takes place in several main stages:

-

Cleaning of dirt and debris - plaster, old paint, stains and mold must be removed from the surface.

-

Drainage - such a measure will achieve the most dense connection of the insulation with the surface.

-

Protection - places that do not require thermal insulation should be covered with foil, paper towels or protected with a special lubricant.

-

Processing - for high-quality adhesion of the insulation to the surface, it is necessary to treat it with a special primer, and pre-seal any holes and cracks with sealant or construction tape.

-

Test spraying of polyurethane foam - it is desirable to carry out a trial version on a similar surface. After spraying, the resulting material is recommended to be studied in detail and checked for shortcomings for timely correction.

How is liquid polyurethane foam applied to insulated structures using seamless technology?

The most common method of mounting polyurethane foam is spraying. But for the production of thermal insulation structures, experts prefer the pouring method. In this case, liquid PPU is poured into special molds, and the finished parts are used for installation after they have solidified.

On the floor

Spraying liquid foam is possible on almost any surface. Brick, concrete, wood, metal, bituminous coatings are insulated in this way. The concrete floor is insulated under the screed and along the logs. The preparatory process is reduced to degreasing oil stains and cleaning dirt. After that, the open joints are filled with foam and connected to each other.

The process of warming along the lags is more complicated - it requires the dismantling of the old screed, the removal of dust and debris, and the obligatory marking of the passage of structures.

On the walls

After the surface of the walls is prepared and cleaned, the future frame is mounted. For these purposes, a wooden beam or a metal profile is used - the racks are placed vertically in one plane. Next, you should connect the equipment according to the instructions and apply a test layer of PPU. It is recommended to start work from hard-to-reach places.

To the ceiling

Thermal insulation of the ceiling with polyurethane foam is considered one of the most effective ways of insulation. The liquid material penetrates hard-to-reach crevices and voids and can be applied in multiple layers. Such a coating completely repeats the surface relief and does not require finishing preparation. After one layer has dried, the next one should be applied.

Attention! The thickness of each layer should not exceed 20 mm.

on the roof

Thermal insulation of the PPU roof takes place in several stages. To begin with, the old material is removed from the surface, after which it is thoroughly cleaned. The components are mixed in the installation and applied to the roof in several layers.

The nuances of applying to different surfaces

There are several nuances that should be taken into account when insulating polyurethane foam on different surfaces:

-

Do not leave unprotected layers in the open sun.

-

Machining a wet, damp or unprepared surface will result in poor bonding of the material.

-

PPU cannot be combined with other cleaning agents - the surface must be protected.

-

It is not recommended to pour PPU in cases where the technology involves spraying.

-

Do not use poor quality low pressure equipment.

What are the advantages of seamless PU foam insulation?

The advantages of PPU are as follows:

-

excellent thermal insulation properties;

-

durability;

-

lack of seams;

-

good adhesion with different materials;

-

self-extinguishing ability;

-

environmental friendliness of the material;

-

low level of moisture absorption;

-

the possibility of applying to any geometric surface;

-

universality;

-

light weight and no load on the room.

What will determine the cost of such insulation?

The cost of PPU insulation will depend on the amount of foam spent. The average price per cubic meter of such a composition is approximately 10,000-12,000 rubles. This volume is usually enough to process 20 m2, but in rooms with uneven surfaces, the consumption may increase.

Conclusion

PPU thermal insulation is an effective and affordable method of warming any premises. The material is completely environmentally friendly and safe. But its main advantage is high thermal insulation properties and excellent adhesion. To obtain a good result, we recommend using high-quality materials and contacting experienced craftsmen.