Gypsum fiber sheet (GVL) is a finishing material with very attractive technical characteristics. It consists of 80% gypsum, 20% cellulose and, unlike the usual drywall has a homogeneous structure without a shell. Let's find out how gypsum-fiber sheets differ from gypsum boards, what characteristics they should have according to GOST and what application they can find.

The main parameters of GVL

GVL is a sheet finishing material having a rectangular configuration. Its technical characteristics and manufacturing technology are regulated by the requirements of GOST R 51829-2001. Both sides of the gypsum fiber sheet have a smooth sanded surface, treated with a water repellent and a special impregnation that prevents dusting of the material.

According to GOST, a gypsum-fiber sheet can have the following dimensions:

- length - 150, 200, 250, 270 or 300 cm;

- width - 50, 100 or 120 cm;

- thickness - 1, 1.25, 1.5, 1.8 or 2 cm.

Knauf, which won first place in the Russian market among gypsum fiber manufacturers, produces products with the following parameters (size and weight):

regular sheets:

- 250x120x1 cm, weight of one element - 36 kg;

- 250x120x1.25 cm, weight - 45 kg.

Elements for prefabricated dry floor screed (Knauf-superpol):

- 120x120x1 cm, weight - 17.5 kg;

- 120x120x2 cm, weight - 17.5 kg.

According to the properties of gypsum fiber products are divided into two types:

- conventional (GVL);

- moisture resistant (GVLV).

Depending on the type of longitudinal edge, there are:

- sheets with a straight edge (PC);

- GVL with a folded edge (FC).

Positive characteristics of GVL

The technical characteristics of gypsum fiber products are impressive:

- high density and strength (1250 kg / m³) - nails can be hammered into gypsum fiber, it does not crumble;

- low coefficient of thermal conductivity provides effective thermal insulation of the walls - the material is warm to the touch;

- good sound insulation - from 35 to 40 dB, depending on the thickness;

- excellent fire resistance - GVL can be used to protect wooden structures and communications from fire in case of fire;

- frost resistance - the material can be used for finishing walls, floors and ceilings in unheated rooms, for example, on a balcony;

- moisture resistance - refers to GVLV, ordinary gypsum-fiber material is hygroscopic - it can accumulate and release moisture, but does not sag like drywall.

The positive characteristics of GVL can also include the absolute environmental friendliness of the material and ease of processing and installation.

Disadvantages of gypsum fiber sheets

With all its advantages, GVL has some disadvantages:

- fragility and brittleness of the material - the sheet can break even due to its own weight;

- large weight compared to drywall;

- the cost of GVL is higher than that of GKL.

Appearance and marking of gypsum fiber sheets

Unlike drywall, which differs in color depending on its properties, GVL sheets have the same white-gray color. Each sheet has a marking applied in accordance with GOST in blue on the reverse side. There are no special designations; on a gypsum-fiber moisture-resistant sheet with a straight edge, it will be written like this:

GVLV-PK-2500x1200x10 GOST R 51829-2001 (size is indicated in mm).

In accordance with GOST, high-quality material should not have oil stains, damage to the front surface, ends and corners.

Scope of gypsum fiber

Knauf gypsum fiber sheets are successfully used for wall decoration in residential premises, as well as for the construction and decoration of public and industrial buildings. Gypsum fiber is used for the construction of interior partitions and walls in apartments, it is allowed to use waterproof type GVL in rooms with high humidity, such as a bathroom, with subsequent tiling.

Sheathing of frame structures, such as partitions, wall cladding, suspended ceilings, involves the use of GVL with a seam edge.

As a separate area of application, we can mention the use of GVL for the installation of a rough floor covering - dry floor screed by Knauf technology. To create such a floor, the so-called Knauf supersheets are used, which have a straight longitudinal edge.

Due to the high fire resistance, it is possible to use GVL for fire protection of load-bearing structures, wooden elements, cable channels. The environmental friendliness of the material allows it to be used for finishing the ceiling, floor and walls in any living room, including a bedroom and a nursery.

Differences between GVL and GKL

Despite the similar composition, gypsum-fiber and gypsum boards have a different structure, which determines the difference in the technical and operational characteristics of these finishing materials:

- The homogeneous structure of gypsum fiber provides a smooth cut without chips, while drywall can crumble at the cut points. In this regard, GKL is usually used in solid pieces, but gypsum fiber can be cut into elements of any size.

- The use of GVL instead of GKL is advisable in those places where increased resistance to shock and damage is required.

- Drywall has high plasticity, which allows you to create a variety of structures of any shape, while gypsum fiber breaks with a strong bend.

- GKL and GVL differ in the level of frost resistance. Drywall withstands only 4 cycles of freezing and thawing, after which cracks appear on it, gypsum fiber can withstand 15 cycles.

- The fire resistance of gypsum fiber is much higher than that of drywall.

- Materials have a difference in price - ordinary drywall is 2 times cheaper than a gypsum fiber sheet of the same thickness.

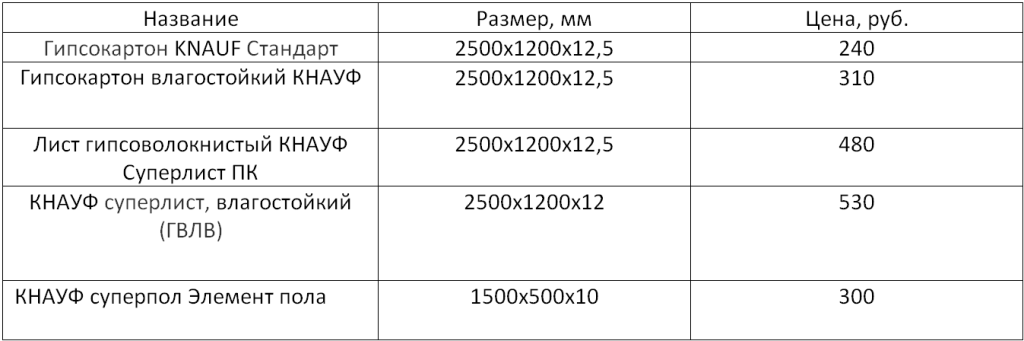

For comparison, here is a table of approximate prices for different types of GVL and GKL from KNAUF: