Drywall is a modern material for interior decoration, which is today at the peak of its popularity. The combination of great opportunities and affordable prices make gypsum boards (gypsum boards) an indispensable material for leveling walls, erecting interior partitions, decorating door and window slopes, creating suspended ceilings, curved surfaces and structures of various shapes. Consider the technical characteristics that a quality drywall sheet should have in accordance with the requirements of GOST, and find out which types of material should be preferred for use in certain conditions.

Gypsum plasterboard is a rectangular product consisting of pressed gypsum grade G4 (GOST 125-79), enclosed on both sides in a thin layer of durable cardboard. In addition to gypsum and cellulose, in the production of gypsum boards, it is possible to use various adhesives and foaming agents for the gypsum component. The perfectly flat surface and strength of drywall allow it to simultaneously act as a reinforcing frame and the basis for finishing.

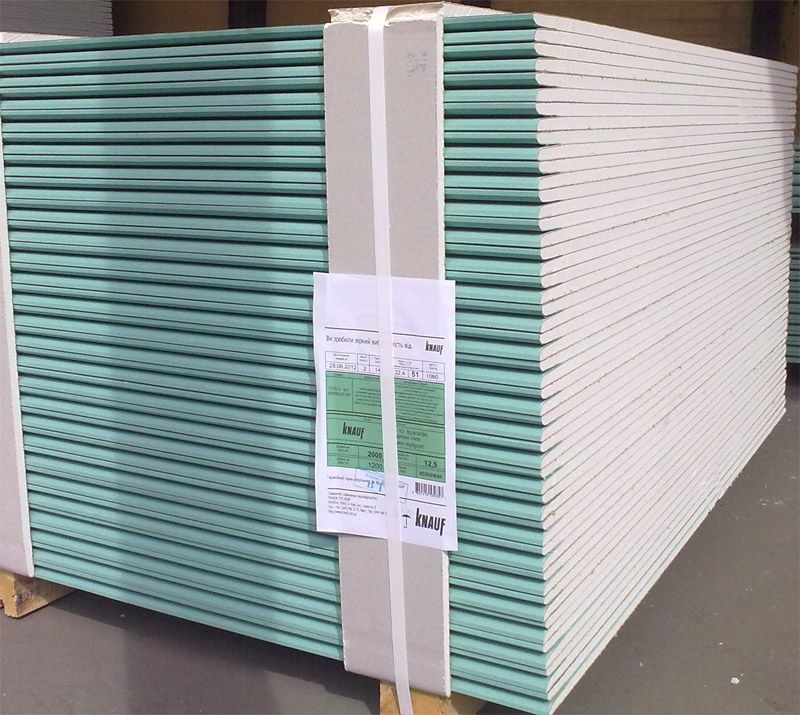

70% of drywall presented on the Russian market is produced under the Knauf brand (Knauf). Knauf plasterboard products comply with Russian standards GOST 6266-97 and GOST 32614-2012, as well as the German standard DIN 18 180.

GKL classification

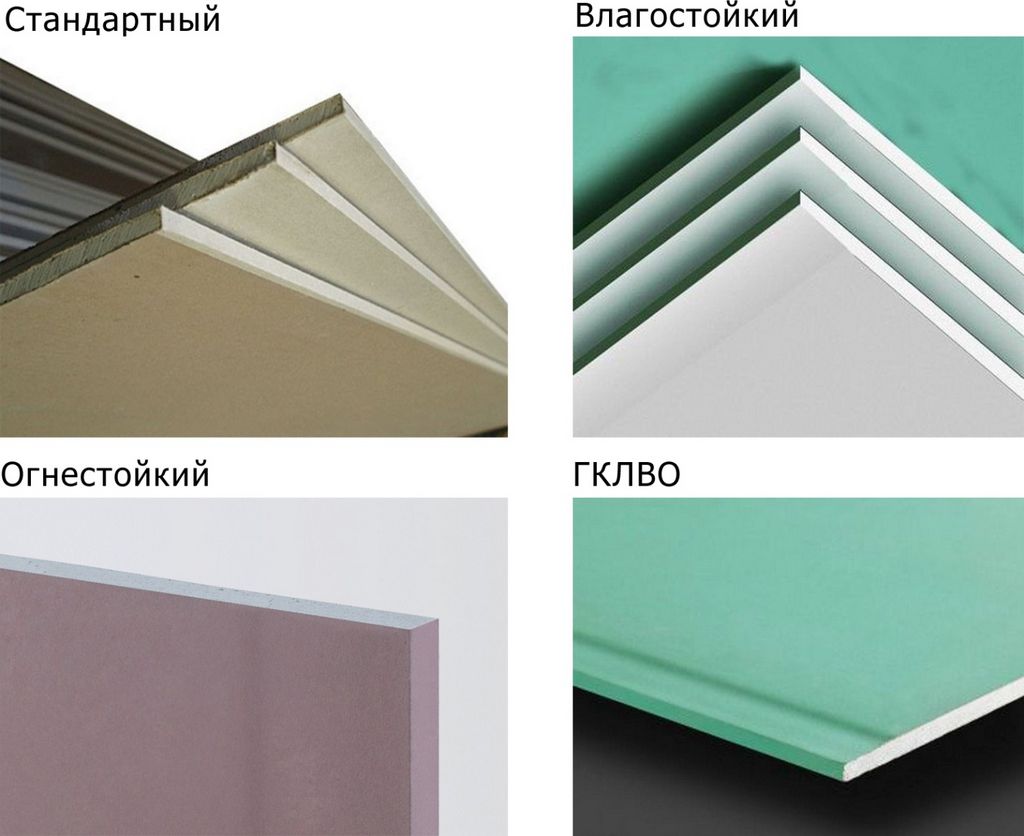

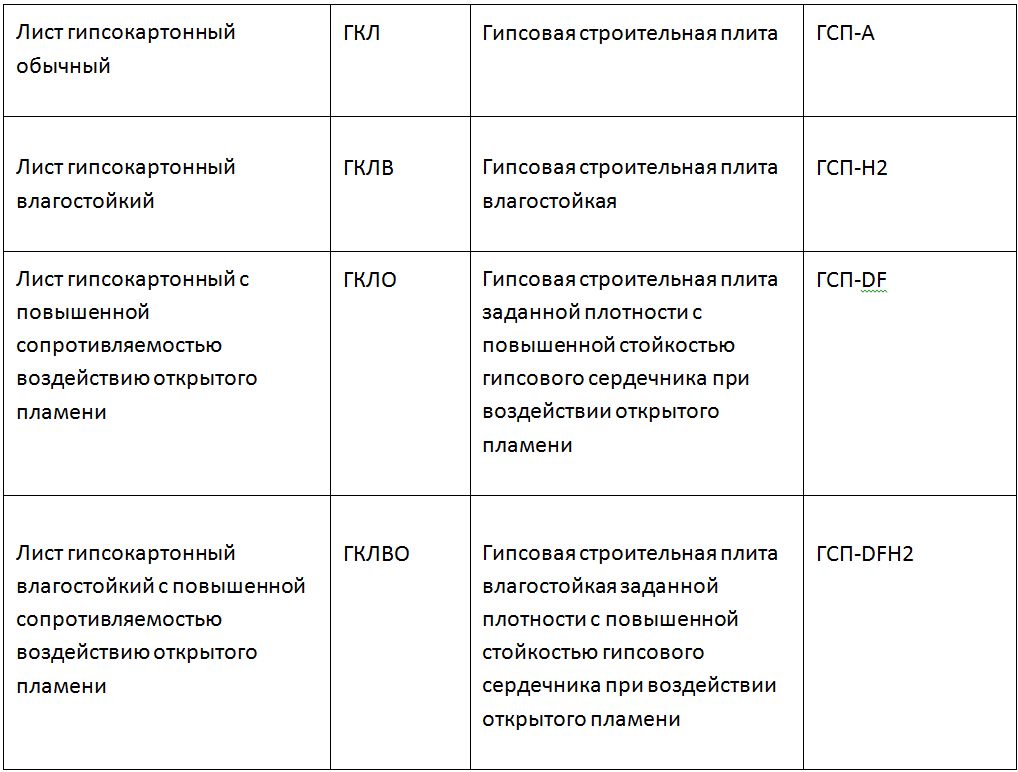

The technical characteristics of drywall sheets depend on which variety they belong to. According to GOST 6266-97, the following types of drywall are distinguished:

- ordinary - abbreviated GKL;

- moisture resistant - GKLV;

- drywall with increased fire resistance - GKLO;

- a material that combines the properties of a moisture-resistant material and increased resistance to open fire - GKLVO.

In 2012, a new interstate standard was adopted, developed in cooperation with Knauf. In GOST 32614-2012, put into effect on the territory of Russia since 2015, drywall is called gypsum building boards. According to the new GOST, the material is divided into 8 types:

- A - drywall, corresponding to the standard GKL;

- H - moisture resistant gypsum boards;

- F - fire-resistant boards;

- D - plates having a given density, which depends on the operating conditions;

- I - material with increased hardness;

- E - facade slabs with low water absorption and minimal vapor permeability;

- P - products intended for subsequent application of gypsum plaster or tiling;

- R is a material with increased bending strength in any direction.

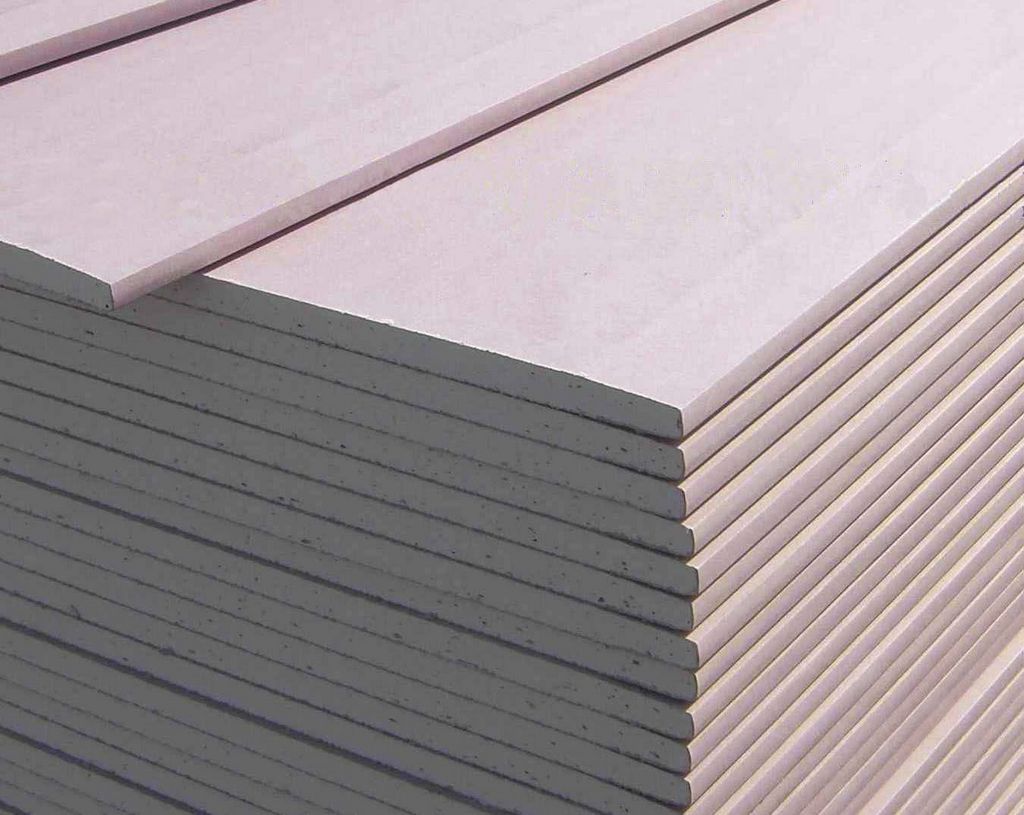

Standard drywall

Standard or ordinary GKL (GSP-A according to the new GOST), which is also called construction or basic, is used more often than other types for finishing apartments. With his help the walls are aligned, sheathed ceiling and wall frames made of metal and wood. It has a light gray surface, the use is possible only in rooms with normal humidity. Standard drywall.

Moisture resistant GKL

Moisture-resistant drywall GKLV (according to the new standard - GSP-H2) is used in rooms with medium and high humidity. The resistance of the material to moisture is achieved by adding modifiers to gypsum that reduce its absorbency, as well as antifungal compounds. The moisture-resistant appearance of drywall is easily recognizable due to the green color of the surface. The scope of the moisture-resistant material is wider than that of the base GKL and includes such premises as a kitchen, a bathroom, a heated loggia, and an insulated balcony. GKLV can be used for the manufacture of slopes, subject to the use of high-quality waterproofing, even wall decoration in the shower room is possible.

Moisture-resistant material absorbs no more than 10% moisture compared to conventional GCR.

Fireproof drywall

GKLO differs from other types of drywall in the presence of special additives in the gypsum core that provide resistance to high temperatures and prevent the spread of smoke and fire during a fire. At Knauf, high-density fire-resistant material is designated GSP-DF.

According to GOST, the resistance of GKLO and GKLVO products to open fire must be at least 20 minutes.

The technical characteristics of this type of GKL create a separate area of application: sheathing of cable and ventilation ducts, steel and wooden structures that need fire protection. The cardboard layer of a fire-resistant sheet usually has a light pink tint; the marking, as required by GOST, must be red. For finishing wet rooms, drywall is used, denoted by the letters GKLVO (GSP-DFH2 according to the new standard), which combines the properties of a fire and moisture resistant material.

The most fire-resistant drywall is Knauf Fireboard, which has additional fiberglass reinforcement.

Designer drywall

GKLD - design, flexible or arched drywall, which is not mentioned in GOST 6266-97. Designed to create structures of complex curved shapes: arches, decorative elements of a suspended ceiling. A small thickness (6–6.5 mm) and reinforcement with fiberglass reinforcing mesh allow this material to be bent without wetting.

High strength drywall

The use of reinforced drywall is advisable for heavy loads on the wall, if it is necessary to fasten a heavy object. An example of such a material is Diamant drywall from Knauf. This manufacturer also manufactures products of large thickness (18, 20, 25 mm) called high-strength or massive plates. Such material can also be fire and moisture resistant.

Product parameters

The main technical characteristics of drywall are regulated by the GOST 6266-97 standard.

The size

The size of the drywall sheet can be different:

- The standard lengths of the product are 2, 2.5 and 3 m. There are manufacturers producing sheets having a length of 1.5 to 3.6 m.

- The sheet width is usually 1.2 m, although recently small-format products with a width of 0.6 m have appeared on sale, providing more convenient transportation.

- The thickness of the sheet can be from 6 to 12.5 mm. If we are talking about reinforced plates, then we can talk about a greater thickness, reaching 25 mm. Sheets having a minimum thickness are intended for the manufacture of bent structures. Drywall 9 mm thick is used for the ceiling, 12.5 mm for walls.

The most popular Knauf plasterboard format is 250 x 120 cm.

Tip: Although 9mm drywall is suitable for the ceiling, experienced craftsmen recommend using standard 12.5mm thick wall material for the ceiling surface, which provides better fastening of self-tapping screws and recessed fixtures.

The weight of GKL and GKLV sheets from Knauf does not exceed 1 kg per square meter. m., fire-resistant boards have everything from 0.8 to 1.06 kg per sq. m. If the mass of the sheet is higher than indicated, most likely, there was a violation of the conditions of transportation and storage of the material, due to which it was saturated with moisture.

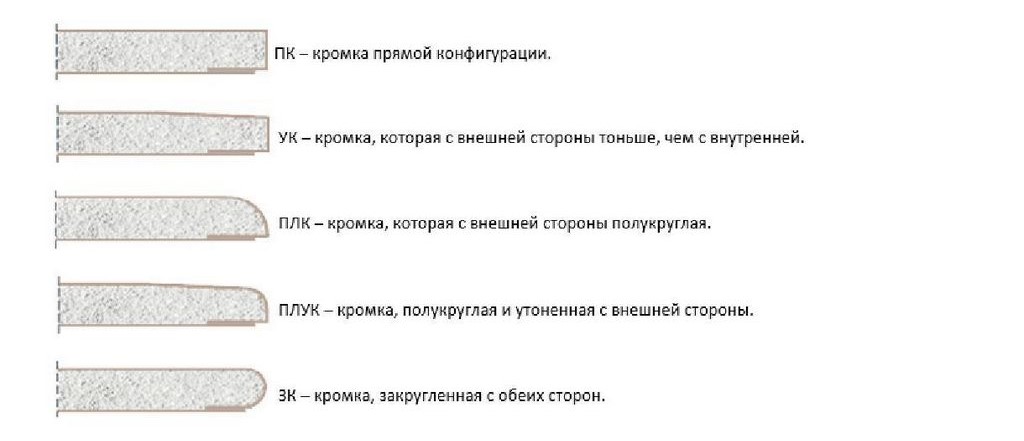

Edge shape

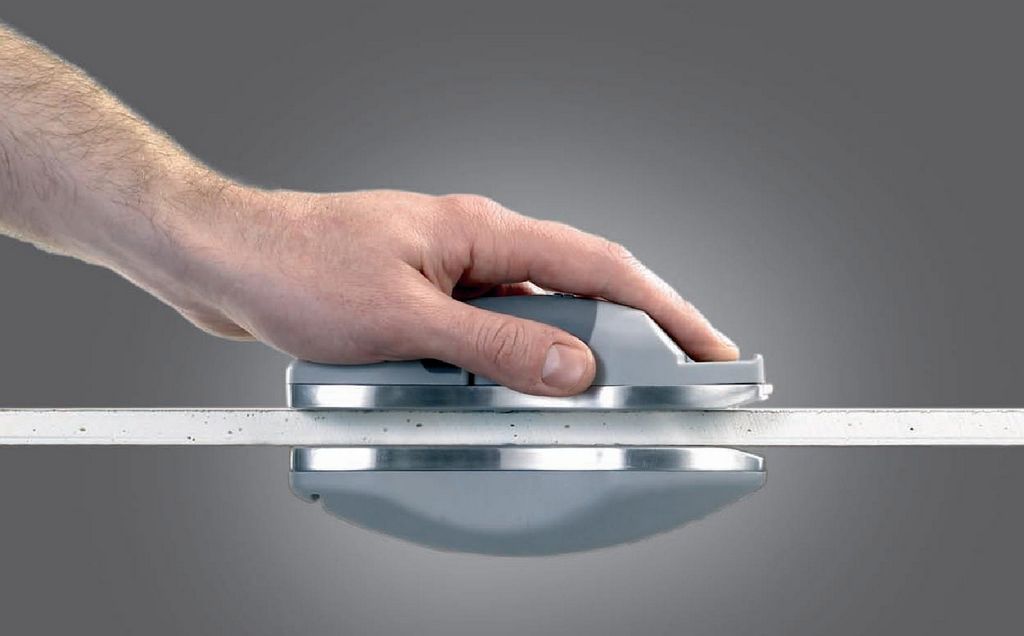

Plasterboard sheets can have a different shape of the longitudinal edge. Often it has a smaller thickness, which allows you to carefully putty the joints. The type of edge is necessarily indicated in the product labeling.

Drywall from Knauf most often has a PLUK edge.

Sheets with tapered edges are well suited for finishing the room; when installing in several layers, it is better to use sheets with a straight edge.

Fire-technical characteristics

Due to the natural properties of gypsum, any drywall is a non-combustible material that can withstand an open flame for some time. There are several documents that define the class of drywall according to various indicators:

- combustibility group according to GOST 30244 - G1;

- degree of flammability according to GOST 30402 - B2;

- the ability to form smoke (GOST1.044) - group D1;

- toxicity level (GOST1.044) - group T1.

Conventions

You can find out all the information about the technical characteristics of the sheet from its marking, which includes:

- designation of the type of sheet or plate;

- information about the group to which the product belongs;

- indication of the type of longitudinal edge;

- sheet parameters (length, width, thickness);

- standard according to which the product is manufactured.