Our lives are changing day by day, new technologies are being introduced to the market. Materials are being improved, and what until recently seemed like science fiction is turning into the most ordinary things. Such a novelty is arched drywall with a thickness of 6.5 mm. Thanks to this invention, the implementation of interesting ideas, involving the use of complex curvilinear forms, was simplified, and the design fantasy got the opportunity to spread its wings even more.

What is flexible drywall?

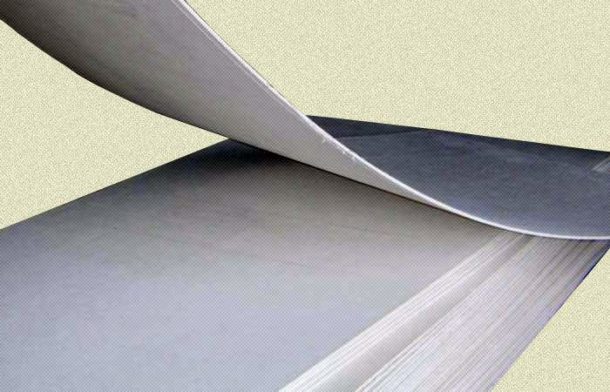

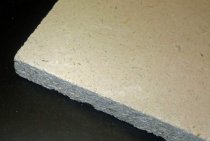

In essence, this is a traditional drywall sheet, consisting of a gypsum core, which was reinforced on both sides with fiberglass deepened into it. This finishing material is used in construction and decoration. It differs from the usual GCR by almost half the thickness. The remaining overall parameters largely correspond to the standard ones, for example, the size of a sheet of arched drywall from Knauf is 1200 × 2400 mm.

Due to its reduced thickness and special additives, arched gypsum board has acquired high elasticity. It is his ability to bend well in both directions that is widely appreciated by interior designers, as it helps to create the most bizarre figures. With the help of arched drywall are made:

- rounded niches;

- columns;

- domed, strongly curved structures;

- vaults;

- rounded corners;

- wavy lines on ceilings and walls;

- bizarre arches.

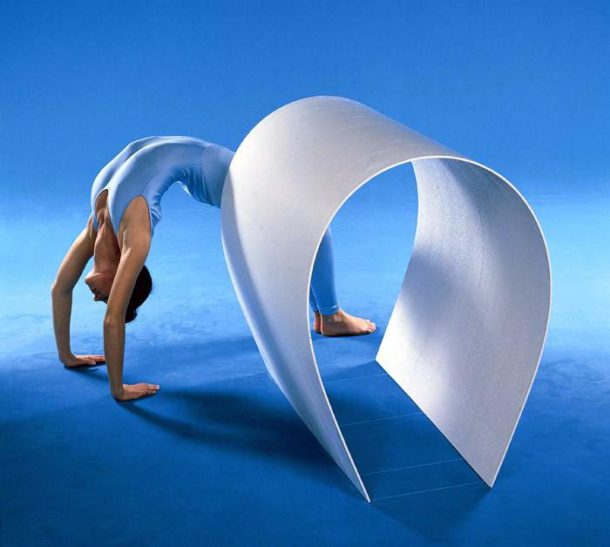

Flexible drywall has found application in the creation of structures in the style of hi-tech and modern. The photo below shows an arch-portal made of arched plasterboard.

Unfortunately, reducing the thickness by six millimeters did not have the best effect on the strength of the finished structure. Therefore, in some cases, sheets are mounted in two layers, for example, if we are not talking about an arch, but about curly shelfcapable of deforming under the weight of things installed on it.

Advantages of flexible gypsum board

Flexible arched drywall sheet has the following advantages:

- Ease of bending. Ordinary GCR to give them the desired shape must be moistened, passed over their surface with a needle roller or notched before use. Arched GKL with a bending radius not exceeding 100 cm, it is enough to knead in the longitudinal direction. Directly bending, both along the inner and outer radius, should be done along the long edge. This requirement is due to the longitudinal arrangement of fiberglass filaments.

- Mounting speed. Performing dry bending of the material allows you to build structures, eliminating a number of processes: the sheet does not need to be wetted, mounted on special stencils, and wait for it to dry completely. This has a positive effect on the overall duration of the installation work.

- Moisture resistant. Ordinary drywall is not used in rooms whose microclimate is characterized by high humidity (kitchens, bathrooms, showers, basements, balconies). Otherwise, it may lose strength, and, having been saturated with water, become covered with mold. The resistance of flexible drywall sheets in this indicator exceeds even GKLV, and the additives in the core will prevent the development of the fungus.

- Ease of construction. When installing, there are no significant differences between the arched type of drywall and the usual one. Its installation takes place on a frame made of a metal profile. True, its flexible variety is used, with cuts and perforations. As fasteners, ordinary self-tapping screws are used.

- Design possibilities. Using this novelty, it will be easy to make not only arched interior niches, but also many more complex structures: fireplace portals, sheathing of spiral staircases and much more.A smooth front surface requires a minimum of preparatory work before applying the finish.

Note! To protect the fragile edges of the sheets from destruction after installation, special arched corners made of plastic and metal are installed on them.

Nothing is perfect: material flaws

This statement also applies to flexible drywall sheets.

- Adding fiberglass reinforcement and other special additives to the core increases the density of drywall along the way. Therefore, such sheets are harder to cut, fix them with self-tapping screws, and process with a planer.

- In structures that require additional rigidity, as mentioned above, the arched GKL is laid in two layers, which is associated with additional labor costs.

- The price of the described material is 330–370 rubles. per sheet - exceeds the cost of standard wall and ceiling tiles, and if a two-layer installation is planned, the difference will grow even more.

Technology of work with arched sheets

Knauf offers the following bending methods for its Knauf sheets:

- Dry, the minimum bending radius when using which is 100 cm.

- Wet, with a permissible bending radius of 30 cm or more.

Procedure for dry bending:

- The framework is being prepared.

- The sheet is bent along the frame, fastened with screws from the middle to the edges. The step between the screws is 15–17 cm.

Wet bend:

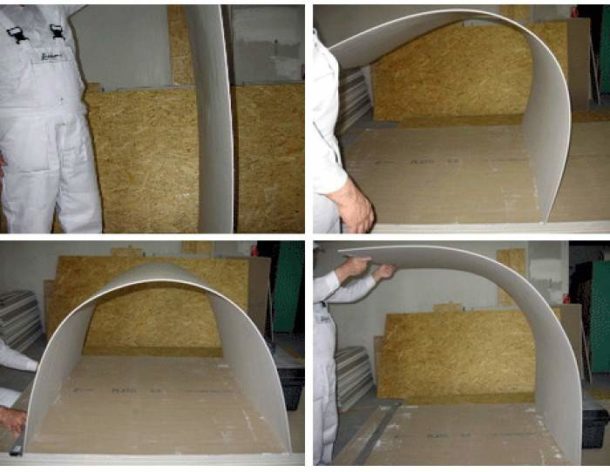

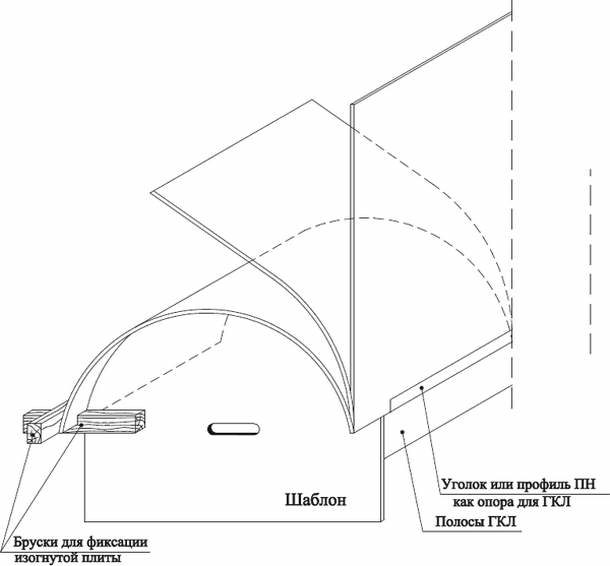

- A template is being made.

- The compressed side of the sheet is rolled with a needle roller, placed on gaskets to prevent moisture from entering the reverse side. If the other side gets wet, the cardboard may tear during the bending process.

- The workpiece is wetted with water with a brush or sponge until the liquid is no longer absorbed.

- The sheet is installed on the template, its center must coincide with the axis of the template. The edges are pressed with bars, the workpiece is left in this position until completely dry.

Summing up, it is worth noting that the advantages of the arched version of drywall exceed all its possible disadvantages. Flexible plasterboards are widely used in modern construction for the construction of complex structures. Features of working with arched sheets - in the video below.