Drives and actuators

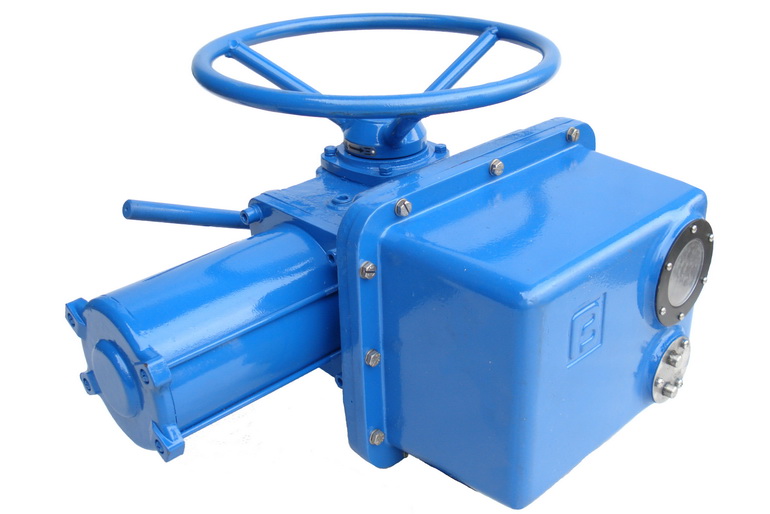

An electric valve actuator is a device that is a type of electric actuator used for the mechanization and automation of pipeline valves, and is widely used in all industries, playing a crucial role in almost all technological processes. Most often, electric actuators are used for remote control of valves, their opening and closing, as well as for determining the position of the valve. In addition to electric actuators, there are pneumatic, hydraulic and electromagnetic valve actuators.

Mechanisms of executive electric single-turn or linear-stroke are intended for movement of regulating bodies in systems of automatic control by technological processes according to command signals of automatic adjusting and operating devices.

The principle of operation of the mechanisms is to convert an electrical signal coming from a regulating or control device into a rotational movement of the output shaft, or a linear movement of the output rod.

Multi-turn electric actuators for gate valves and valves

Electric actuators for gate valves, valves, etc.

Multi-turn electric actuators and actuators (electric actuators) are designed to transmit torque to fittings (usually gate valves and valves) when it is rotated by one revolution or more. Mechanisms and drives are designed to actuate shut-off and control valves in automatic control systems for technological processes, in accordance with command signals from regulating and control devices.

Single/quarter-turn electric actuators for valves, valves, dampers

Electric actuators for butterfly valves, ball valves, butterfly valves, etc.

Single-turn (or part-turn) electric actuators and actuators are designed to transmit torque to valves (usually valves, valves, butterfly valves, etc.) when it is rotated by one revolution or less (from 0 to 360 °).

Linear actuators for valves, dampers

Electric actuators for valves, various dampers, etc.

Linear actuators are designed to actuate shut-off and control valves (usually valves, dampers). They transmit force to the valve stem during its translational movement and are used in automatic control systems for technological processes in accordance with the command signals of regulating and control devices.

All types of electrical actuators:

- single-turn lever actuators MEO

- single-turn flange actuators MEOF

- Also, NEW! Single-turn actuators PrimAR-M PrimAR-MF

- linear or linear actuators (MEP electric drives)

- new line of actuators MEP-S

- FDA drives, MEO in atomic design, mechanisms of foreign manufacturers and many others.

Electric actuators for air dampers, air valves, etc.

Pneumatic actuators for pipeline fittings: - multi-turn pneumatic actuators (gate valves, valves) - part-turn or single-turn pneumatic actuators (disk valves, ball valves) - linear pneumatic actuators (valves, dampers)

Manual gearboxes for pipeline fittings

Instruments for control and regulation of technological processes

Types of control circuit protection

Like any complex electromechanical device, an automatic valve has several types of control circuit protection against various kinds of overloads.

The control panel has a button ZKU, which serves for instant emergency shutdown of the electric motor. At the same time, there are also automatic protection elements:

- Undervoltage protection, also called zero protection. Its operation occurs at the moment of complete disappearance of voltage within the network or its critical decrease. The goal is to exclude the possibility of self-starting the electric motor in the event of a sudden restoration of voltage. This protection is carried out using magnetic starters and electromagnetic voltage relays.

- Electric self-locking. This type of protection is achieved by switching on the opening contact on the starter software in the power supply circuit of the starter PZ and vice versa. That is, while the software starter is in the on position, the power supply circuit of the PZ starter will definitely be open, and it is impossible under any circumstances to force the PZ starter together with the software magnetic starter.

- Protection of the electric motor against overload in case of emergency jamming of the valve is carried out by opening the contacts of the clutch limit switch ВМ, which is introduced into the common power supply circuit of both induction coils of the starters.

- Maximum protection guarantees complete motor safety in the event of short-term overload and short circuit. It is carried out as a result of the use of fuses or electromagnetic circuit breakers.

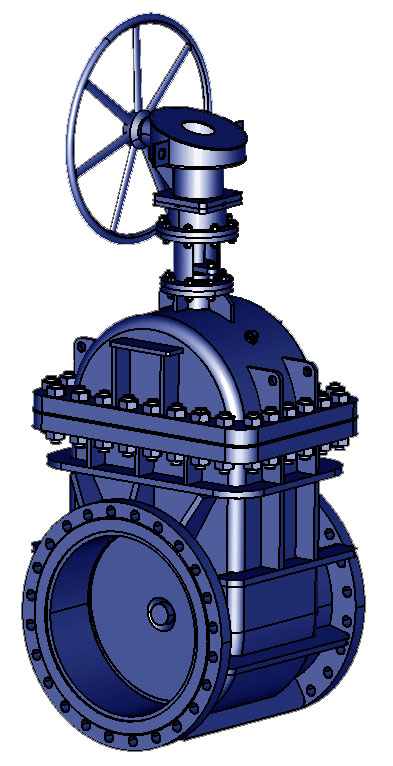

What is a valve with a gearbox

A geared valve is a type of industrial valve that can be used to control or shut off flow within a pipeline. It must be installed during the installation of any pipeline, as it solves many problems and facilitates the operation of the equipment.

The locking element, located inside the housing, moves due to the rotary-translational movements of the gearbox. Relative to the axis of the pipe and the flow, it is perpendicular.

Such a node has found a large scope due to a convenient design solution. Plant "Admiral" offers steel (stainless, alloy and carbon) gate valves for all types of pipelines. Each of them must be selected based on the operating conditions. You can get acquainted with the products in the convenient catalog of the company.

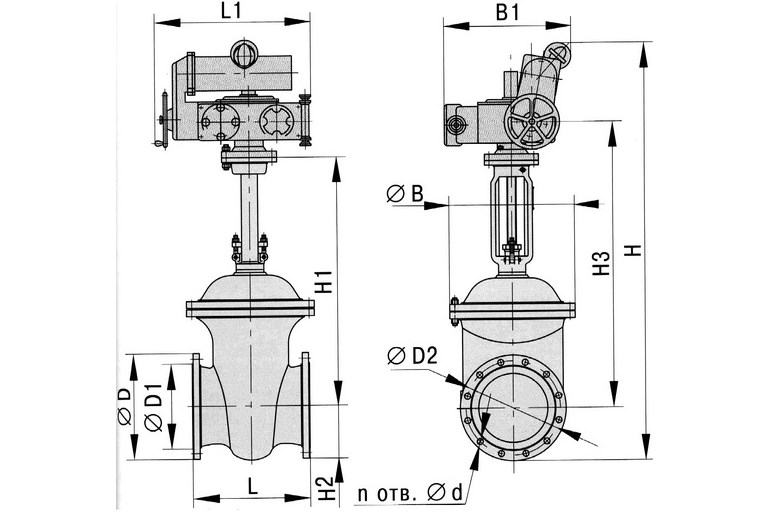

The gate valve with a reducer is mounted on pipelines of large diameter (from 350 to 2200 mm), at an allowable temperature of the medium from -70 to +450 ◦С. They are able to withstand pressure up to 2.5 MPa.

Due to the ability to withstand high speed inside the system and the aggressive effects of the environment, as well as temperature changes, the valve with a gearbox is mounted on pipelines:

● chemical industry;

● metallurgical industry;

● oil;

● for domestic pipelines;

● gas pipelines.

To choose the right valve, it is necessary to take into account the diameter of the pipeline, what will be the working medium, temperature and pressure

It is important to consider what liquids and gases will flow through it.

Advantages and disadvantages of a valve with a gearbox

The main advantage of such a part is the ability to open and close the flow without much effort. Therefore, it is used on pipelines of large diameter, where the mass of the adjustment device is so large that additional mechanisms for control are needed. In addition, the gearbox has a number of advantages, which include:

● with a fully open shutter - minimum hydraulic resistance;

● movement of the flow of the working medium is possible in any direction;

● small building length.

The disadvantages include:

● high construction height and weight, which increases the load on the pipeline. It also makes it impossible to install in hard-to-reach places;

● cannot be used in a pipeline with crystallization of substances;

● A large differential pressure in the casing is not allowed.

The plant of industrial valves "Admiral" manufactures reliable gate valves with a gearbox. The best raw materials and parts are used for production, and thanks to our own production workshops, we can control the quality at every stage.

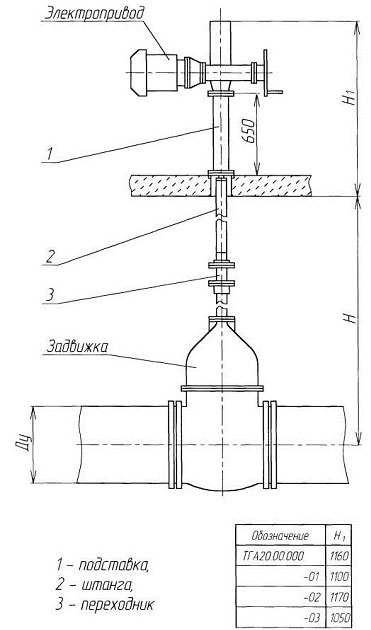

Functions and principle of operation

Gate valves with an electric drive perform the usual functions of shut-off valves - shut-off and control:

- block the pipe completely or partially;

- open the lumen of the pipe to release the flow.

We recommend that you familiarize yourself with: Purpose and main types of HDPE ball valves for pipes

The functioning of the locking device, driven by an electric drive, is carried out in three modes:

- commissioning;

- automatic;

- remote.

The adjustment mode of operation is used after installation or replacement (repair). Here, commands are sequentially given (contacts are closed) to the electric drive, which it “remembers” and uses in further operation. Adjustment of the operation of the electric drive is carried out after installation, with manual adjustment of the extreme positions (open-closed).

Automatic mode is the operating mode of the locking device, when the electric drive is set to change the parameters of the flow, its pressure, temperature. Changes in parameters are fixed by special sensors. They also “give a signal” to the control circuit, the contacts are closed, the magnetic drive is applied. The electric drive sets the blocking mechanism to the required position.

Remote mode is when the operation of the electric drive of the valve is controlled from the operator's control panel in manual mode.

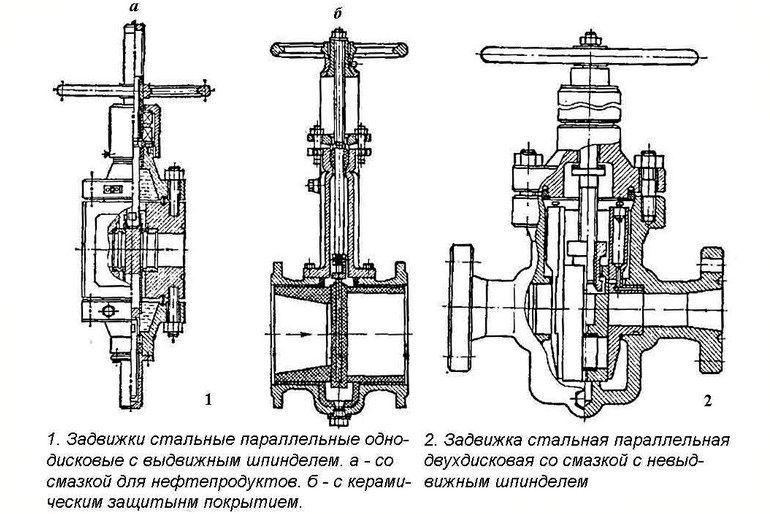

Types and classification of water valves

According to the design of the shut-off body, valves for plumbing systems are divided into:

wedge;

parallel;

gate;

hose.

Wedge gate valves are equipped with a cone-shaped gate, which in the “closed” position fits tightly into the space between the saddles. The wedge can be of different types:

- rigid, having the form of a solid plate narrowed to the bottom. It smoothly descends into the lower part of the device and blocks the through holes of the saddles in the perpendicular direction, thus interrupting the movement of the working medium. A stiff wedge securely seals the bore, but is more prone to rusting and more difficult to fit to saddles. Therefore, in such devices there is a danger of jamming and difficulties arise in raising the wedge during sudden temperature changes;

- double-disk - consisting of two disks, which are movably fastened together at an angle to each other. When the valve is actuated to close, both elements rotate relative to each other and close the passage holes in the saddles, firmly pressing against their sealing surfaces. When opened, they move away from the saddles, freeing the passage for the working substance. This design of the locking element provides a good level of tightness, reduces the risk of jamming and increases the working life of the entire device;

- elastic, two disks of which are interconnected by an elastic rubber part. It is able to bend under the influence of water pressure, thus providing a tighter pressing against the sealing materials of the saddles. Gate valves with a rubberized wedge require less effort to operate, have smooth passage surfaces that reduce friction and wear of the shut-off body elements.

Parallel valves include devices in which the sealing surfaces of the shut-off or regulating body are located in parallel planes to each other.

For furnace chimneys, gate valves are used, the design of which includes a frame and a metal plate with a handle. When the valve is opened, the plate moves out of the frame, when it is closed, it returns to its original position.

Wedge design

A product with a wedge is used for heating systems and related communications, pumping liquid hydrocarbons, gaseous substances and chemicals, hot and cold water. The use of the design in the oil, gas transport, energy industries, as well as in the field of housing and communal services speaks for itself. The valve has technical features, and also helps to close or open the movement through the pipe (hence the 2 phases of operation - open / closed). This is manifested in the fact that the seat of the locking movable element is placed at an angle, and the lock itself is made in the form of a wedge.

During operation, the wedge enters the gap between the seats and reliably blocks the path of the substance moving through the pipe. Depending on the valve, the following wedge-shaped valves are distinguished: rigid; double-disk; elastic. The rigid wedge has good tightness and stability due to secondary elastic seals. Double-disk products wear out less compared to rigid ones (in which seals quickly fail), have a high amplifying ability and a low probability of jamming. But their dimensions are much larger than those of rigid ones, which leads to additional metal consumption. The elastic valve is represented by disks interconnected by elastic parts.

Such a product is resistant to temperatures and operating pressure, but does not cope well with media that have impurities. Rigid products are less metal-intensive, but are labor-intensive to manufacture. Double-disk - always large, but easy to make

Elastic - are average in terms of performance between hard and two-disk. IMPORTANT! The design of the gate valve control element with a wedge can be of different models, but they are all made according to the quality standards of the current GOST 24856-2014

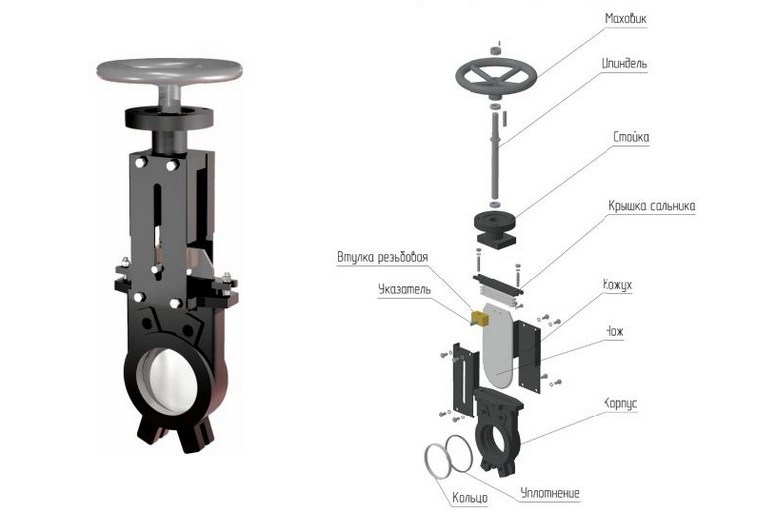

The wedge valve quickly shuts off the flow of the moving substance. For this, manual flywheels and automated systems are used, which is very convenient for remote objects. The device of the product is very simple and is represented by: a metal case with locking elements; a spindle-nut inside or outside the body (pulls the spindle to its full extent); gate); flange connectors (ensure tightness); seals (rubber, polyurethane, fluoroplastic, metal surfacing, elastomers). Depending on the spindle, wedge structures are retractable and non-retractable (compact). The second type is often used for underground pipelines. Retractable spindles - cast iron or steel, have the property of full bore (with a not narrowed recess for the diameter of the nozzles).

The presented products are sliding, they are equipped with an electric wire. Fixed spindles are always immersed in the transported medium, therefore, they require frequent replacement

Of course, such a device wins over retractable devices due to its compactness and construction weight, but they are durable and wear-resistant. IMPORTANT! The product is driven by a flywheel or electric, pneumatic, hydraulic actuators. Manual or automatic control of the wedge valve is selected depending on the pumped medium

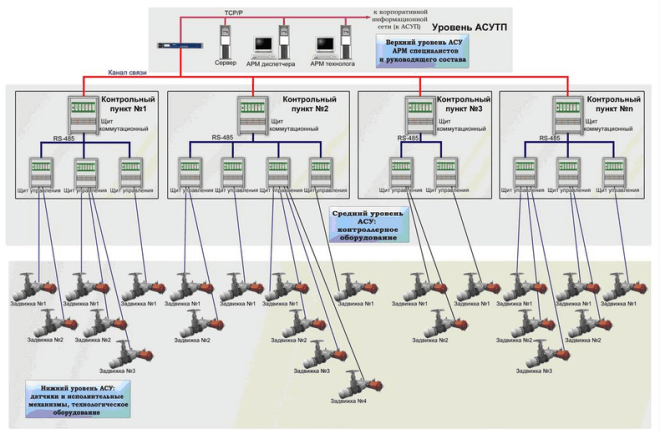

Gate valve drive automation

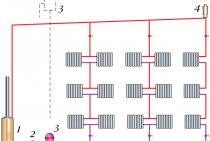

Scheme of an electric drive with an electromechanical clutch.

Gate valves, as a rule, perform 2 commands: to close or open the pipeline, depending on the state of the controlled elements (pumps or fans) and on changes in the controlled parameters (level, pressure, temperature, flow, etc.).

The valve can be remotely controlled by hydraulic, electric and pneumatic actuators. Basically, when automating valves, they use an electric drive due to the ease of control.

The asynchronous motor is a gate valve electric drive, the output shaft of which is connected to the worm gear, and the output gear of the worm gear engages with the gate valve output screw.

During the operation of the electric motor, the shutter, together with the screw, lowers or rises, closing or opening the valve. The output gear of the gearbox through the intermediate gearbox transmits rotation to a number of discs with cams. During the opening of the valve, the cams turn to the right and switch the contacts of the KVO microswitch. During the closing of the valve, the cams turn to the left and switch the contacts of the KVZ microswitch. The discs with cams are located in such a way that during the full opening of the valve, the KVO switch is activated, and during the full closing - the KVZ switch.

The electrical circuit diagram of the gate valve electric drive control provides for 3 control modes: remote, automatic and adjustment.

The remote mode is used when controlling the electric drive from a distance, for example, from a dispatcher console. To prepare this mode, the control switch 1PU is set to the “Remote” position, the 2VB toggle switch to the “on” position, and the 1VB toggle switch to the “off” position. The control panel is powered by switch B.

What is it and why is it needed

The valve, which has an electric drive in its design, is used on water supply and sewerage pipelines. Also, this equipment is installed in air conditioning and even heating systems. This is possible provided that chemical, aggressive liquids do not circulate in the pipelines. The motorized valve armature arrangement allows the system to function efficiently.

The presence of electric drives greatly simplifies the management of the heating system, water supply, etc. If earlier it was necessary to unscrew the valve manually, now this work is performed by the mechanism. Such shut-off valves are used today in many industrial enterprises. It is especially advisable to install this equipment in places unsafe for human access.

Where are electric gate valves used?

It is possible to install shutoff valves, which are actuated by electric current, both on household pipelines and on industrial communications, highways. The variability of the pipe diameter is from 1.5 cm to 200 cm. Gate valves have the same diameter as the pipe section on which they are installed.

The installation of motorized shut-off devices is advisable in places where manual flow control is difficult.

They are used:

- in places where access for manual adjustment is difficult;

- on pipelines located in places that pose a danger to human health;

- in areas requiring automatic control.

Gate valves are used to regulate, open, close the flow of liquids and gases. In construction, these are life support communications:

- water supply (DN 50, DN 32);

- water disposal (DN 50, DN 100);

- sewerage (DU 100).

Special, electric rack and pinion gate valves are used in submersible pumps to automate the regulation of water supply. The locking device is equipped with a gate valve.

In industry, electric gate valves allow you to automate the supply and discharge of liquids and gases in automatic mode. The operation of the electric valve is carried out through a communication cabinet.

Types of shut-off electrical fittings

For electric valves, there are no restrictions on the diameter of the pipe. The connection with the pipeline is flanged.

We recommend that you read: Features of the device and types of three-way valves, application in heating systems

By design, shut-off valves are distinguished:

- Disk. The barrier diaphragm is a disk that is mounted either at an angle to the flow or perpendicular (closed position).Butterfly valves are easy to install, easy to repair, and inexpensive. An economical version of such a device is combined, when the membrane is made of stainless steel, and the body is made of ordinary steel. It is not used in pipelines that are under high pressure.

- Conical or wedge. The locking mechanism is made in the form of a wedge with a retractable spindle, which is included in the wedge-shaped seat. They are used in pipelines with a "clean" carrier, since the device is easily subjected to mechanical corrosion and fails.

- Parallel. The devices have two parallel saddles with discs. Distinguish between slide and hose.

According to the location of the running gear, there are:

- with retractable spindle;

- with fixed spindle.

The fundamentally different location of the rotary mechanism affects the scope of use of the locking device.

- The thread of the rising spindle is located outside the valve body. This requires space for installation, but protects the mechanism from damage by the internal, often aggressive environment of the transported substance.

- A non-rising spindle is one in which the thread of the running assembly is in any position (open, closed) inside the body of the valve. Such fittings can be installed in a limited space, in a hard-to-reach place. However, during operation, the mechanism is subjected to the destructive action of the aggressive environment of the transported substance. This leads to breakdowns, and repairs are complicated by inaccessibility.

There are the following types of electric drive for valves:

- multi-turn;

- integrated multi-turn;

- explosion-proof;

- integrated multi-turn explosion-proof.

Shut-off electric fittings are made of both cast iron and steel. The valve is selected based on the characteristics of operating conditions (temperature, flow pressure).

Steel devices have the following advantages over cast iron ones:

- they are more resistant to work with high pressure in the pipeline (depending on the type of locking mechanism);

- durable, not subject to corrosion (stainless steel);

- resistant to water hammer, temperature extremes.

Sources

- https://StroyVopros.net/vodosnab_otopl/avtomatizatsiya-elektroprivoda-zadvizhki.html

- https://admiralzavod.com/chto_takoe_zadvizhka_s_reduktorom

- https://vseotrube.ru/ventili-i-zadvizhki/dlya-vodoprovoda

- https://vseotrube.ru/ventili-i-zadvizhki/s-elektroprivodom

- https://InfoTruby.ru/armatura/zadvizhki-s-elektroprivodom

Water supply gates

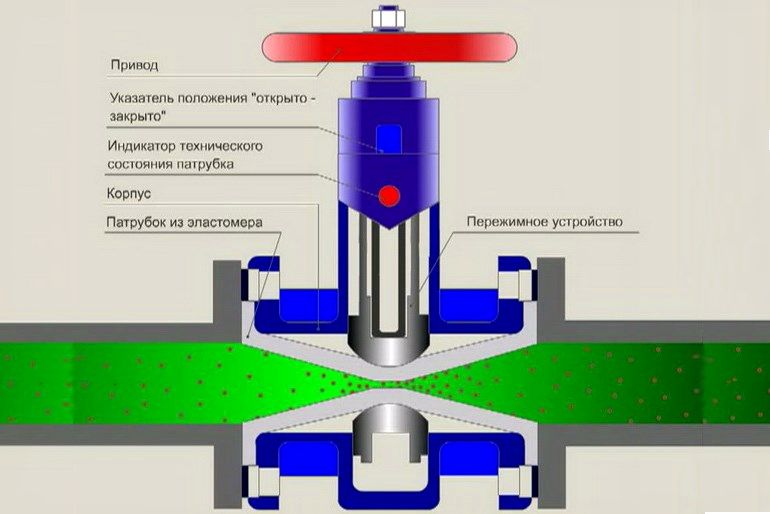

In the water supply valve, the locking element is made in the form of a disk, the diameter of which is equal to the size of the inner diameter of the pipe. During the opening and closing of the valve, the disk rotates around an axis perpendicular to the flow direction.

The valve body has a shortened cylindrical shape, it can be collapsible and monolithic (all-welded construction). It is made of cast iron alloys, different types of steels, non-ferrous metals, composite polymers. In its cavity there is a locking organ, represented by a movable part - a flat or biconvex disk and a fixed part - a saddle. Elastic rubber rings are used as seals.

Valve Selection Criteria

To choose the right water valve, it is necessary to perform a thorough analysis of the initial requirements for its technical characteristics, as well as compare the prices of products from different manufacturers.

Perform this analysis in the following sequence:

- determination of the purpose and operating conditions of valves (properties of the working medium, the value of the maximum working pressure and temperature range);

- determination of the nominal size of the conditional passage (DN);

- choice of device control method;

- choice of material for body parts;

- clarification of the function (locking or regulation);

- choice of constructive modification of the product;

- final determination of the geometric parameters of the device (building length and height, dimensions of the connecting ends, method of connection to the impulse line, number of fasteners, etc.);

- selection of the appropriate model according to the range of valves produced.

Cast iron fittings for heating and water supply systems have recently been used less frequently, mainly steel devices are used here.Cast iron valves are often installed in sewers, in compressed air, steam and bulk materials supply systems.

Principle of operation and device

The presented equipment works in different working media (water, steam, oil, oil, etc.). When choosing one or another unit, it is necessary to take into account for which environment a specific mechanism is designed. Some models of electric actuators for valves lead the structure to two positions (open or closed). But there are units designed to work in intermediate positions. The range of position of their plugs is wider.

The product has a body and flanges. The connection can be parallel or at an angle. Seals provide additional sealing.

Gate valves are equipped with an asynchronous electric motor (ASV) with a squirrel-cage rotor. The motor is articulated with a worm gear. The electric drive includes a VP-700 switch, as well as a manual override.

The mechanism is equipped with a rotary disk. It supplies or shuts off the supply of the internal medium (steam, water, oil, etc.). The control unit and sensors are responsible for this. The locking mechanism starts to move only after receiving the appropriate signal.

The movement of the plug is provided by a stem or spindle. The part forms a threaded pair together with the nut. If the spindle does not stick out, this equipment is not installed at the responsible facility. The running mechanism is located inside, which complicates its repair and maintenance.

The mechanism is activated due to changes in temperature, pressure or fluid flow of the pipeline. The signal to move the plug can be the state of pumps, fans.