Engineering network laying technology

Before installing external engineering systems underground, it is necessary to develop a project that reflects the main parameters of communications. This should take into account:

- soil characteristics;

- the area of the territory where the networks will be laid.

The technology of laying a pipeline depends on its purpose, and one of the main characteristics is the depth of occurrence. It is regulated by the provisions of SNiP, and is determined by:

- purpose of the engineering network;

- , which depends on the geographical location;

- the presence of hard rocks in the soil.

The installation of HDPE pipes for water supply must be carried out at a depth that is at least 20 cm below the freezing of the soil, since the location above can damage the network due to low temperatures. If it is not possible to lay water supply networks at this level, then they should be insulated. Sewer systems should not be buried more than 2.5-3 m.

When laying HDPE pipes in hard and dense soils, on the bottom of the trench, previously leveled and freed from stones, it is necessary to lay a sand cushion, the thickness of which should be at least 10 cm. Very loose soil needs to be strengthened.

Algorithm for laying water supply and sewerage

Work on the installation of water supply and sewerage networks begins with marking their location on the site, which is performed using pegs and twine. Then perform the following operations:

Excavation

. Depending on the volume of excavation and the capabilities of the owner of the site, it can be carried out manually or with the involvement of special equipment. In this case, a slope for sewer pipes should be provided, equal to 1-2 cm per meter of length.

Trench bottom preparation.

After removing excess soil, a sand cushion is arranged and compacted with a rammer at the junction with the inlet pipe and at a distance of 2 m from the manhole. In addition to sand, fine gravel can also be used. Laying a HDPE pipe on such a base will avoid its deformation during further operation.

Pipeline installation.

It is performed depending on the chosen method of connecting individual elements using the necessary equipment and components.

-

Pipeline insulation.

If the pipes had to be laid higher than the depth to which the soil freezes, then it is necessary to carry out work on their insulation. To protect the sewer system, you can use insulation in rolls that wrap the pipeline. Polyurethane foam is widely used as a protective shell around HDPE pipes and reliably protects them from freezing. -

Soil backfill.

The laying of the HDPE pipe in the trench is completed by closing it. To do this, you can use the excavated soil, but first you should remove large stones from it, loosen dense earthen blocks so that they cannot damage the communication network. The thickness of the layers of earth with which the trench is covered should not be more than 5 cm. Ramming is carried out between the pipe and the walls of the pit, and soil compaction is prohibited above the communications.

Cabling

Another option in the ground is trenchless technology, which uses deep drilling equipment. This method is used in the installation of power systems and communication communications. The HDPE pipe in this case serves as a protective case.

—

CAUTION 1

пÑокладка ÑÑÑбопÑоводов 1 - РРкРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРÐμ

a

пÑокладка ÑÑÑбопÑоводов 1 Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð · CAUTION.

a

пÑокладка ÑÑÑбопÑоводов 1 - РРкРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРÐ

a

пÑокладка ÑÑÑбопÑоводов оÑÑÑеÑÑвлÑеÑÑÑв лоÑкаÑ, ÐºÐ°Ð½Ð°Ð»Ð°Ñ Ð¸ ÑÑанÑеÑÑ. Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð δ Ð Ð Ð Ð Ð Ð Ел фар фар РРРРо °Ñ — — внÑÑÑиÑеÑовÑе, и межÑеÑовÑе, в ÑÑанÑеÑÑÑ — меÑÐÑеÐÐÐ

a

пÑокладка ÑÑÑбопÑоводов п Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð ° РРкÐналаÑи

a

пÑокладка ÑÑÑбопÑоводов 1 - Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μññññμð

a

пÑокладка ÑÑÑбопÑоводов РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРп treadmill.

a

пÑокладка РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРг Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ðμ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ÐμÐ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ðμ ¸Ðµ ÑÑенок ÑÑÑб или ÑпеÑиалÑнÑÑ Ð·Ð°ÑиÑÑ ÑÑÑб Ð¾Ñ ½Ð°Ð³Ð ROAKER Ð Ð Ð Ð · Ð Ð · Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ðμ ·Ð°Ð·Ð¾Ñом Ð¼ÐµÐ¶Ð´Ñ Ð½Ð¸Ð¼Ð¸ не менее 20 мм.

a

пÑокладка ÑÑÑбопÑоводов Ð ² Ð Ð Ð Ð Ð Ð · Ð 'Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μ Ð Ð ² Ð Ð Ð Ð Ð μ Ð Ð Ð Ð Ð Ð Ð Ð . Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ÐμÐ Ð Ð Ð Ðμ

a

пÑокладка ÑÑÑбопÑоводов 1 - РРкРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРÐμñññññμð

a

|

R °ññμðððð𸸾¾ðððððð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² a |

пÑокладка ÑÑÑбопÑоводов 1 - РРкРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРÐμ L. Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ðμ ¸ и воÑпламенÑÑÑимиÑÑ Ð²ÐµÑеÑÑвами.

a

пÑокладка ÑÑÑбопÑоводов 1 - Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μññññμð

a

|

Ð1кÐμÐðÐðÐ Ð Ð Ð Ð Ð Ð Ð Ð μ Ð Ð Ð Ð Ð Ð Ð Ð Ð · Ð Ð Ð Ð μ .| нимеÑÑÑÐ¿Ð¾Ð»Ð½ÐµÐ½Ð¸Ñ a |

пÑокладка ÑÑÑбопÑоводов 1 - РРкРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРÐμ

a

HDPE pipe installation methods

The main methods of fixing HDPE pipes during trench laying include:

- butt welding;

- electrofusion welding.

If the connection is required to be detachable, then the socket method or compression fittings are used. For turns, welded or cast fittings, tees, bushings for flanges and other shaped products are used. How to install HDPE pipes depends on their location and purpose.

It belongs to one of the most popular ways of fixing HDPE pipes to each other and is used in cases where there is enough space to accommodate equipment and perform work. In addition, it is indispensable for the installation of large diameter pipelines. The principle of butt welding is to heat the ends of the pipe and then fix them together. To melt the polymer, special equipment is used, and the following should be controlled:

- heating time and temperature;

- melting height HDPE;

- pressure during operation.

Electrofusion

It is carried out using special structures with a low-temperature electric spiral inside. After the voltage is applied, it is heated and the pipes are connected to the fittings. Electrofusion welding allows for high tightness and fixation strength, and is indispensable if HDPE pipes are installed in cramped conditions: wells, chambers and narrow trenches.

Connection with compression fittings

With their help, detachable pipe connections are obtained, the diameter of which does not exceed 63 mm. Therefore, most often compression fittings are used when laying internal communications. However, shaped elements with a split ring make it possible to fix pipes of a larger diameter.

Installation of fittings does not require complex equipment and can be done by hand, it is only necessary to control the applied mechanical force in order to avoid damage to pipeline parts. In addition, shaped elements should be positioned so that they have free access.

Socket connection

It is used when installing external free-flow sewage from HDPE pipes, which are equipped with a rubber sealing ring to improve tightness. To ensure the strength of fixation, it is necessary to clean the plastic from contamination and lubricate the surfaces to be joined with liquid soap or silicone.

For additional protection against moisture, the joints are treated with a sealant.

Compliance with the technology of laying HDPE pipes in the ground will ensure the long-term and efficient functioning of engineering systems without repair work. This will reduce the complexity of pipeline maintenance and reduce the cost of its operation.

Pipe selection

Experience shows that polypropylene pipes are best suited for these purposes, which:

- well extinguish water hammer;

- have little resistance to the movement of water;

- do not need thermal insulation;

- cheap and durable;

- easy to mount.

However, they also have disadvantages:

- reinforced polyethylene cannot be used in networks with a coolant temperature greater than 95 ° C;

- PPS plastic can withstand temperatures up to 110 ° C, but has a high cost.

Photo 3. Polypropylene pipes in the heating system, they do not require insulation, they are easy to install.

Pipes made of metal-plastic work well at high temperatures. But their connection is made using metal fittings, which greatly reduce the effective clearance of the pipes. As a result, the resistance to the movement of water in the system increases.

Attention! The joints of pipes and fittings are very vulnerable to leakage and must be checked periodically. Steel perfectly tolerate high temperatures, but for installation they require the use of welding and a powerful pipe bender, which is not always available when doing work on your own

In addition, steel is easily susceptible to corrosion, which over time leads to a decrease in the bore diameter of the system and a decrease in its efficiency.

Steel perfectly tolerate high temperatures, but for installation they require the use of welding and a powerful pipe bender, which is not always available when doing work on their own. In addition, steel is easily susceptible to corrosion, which over time leads to a decrease in the bore diameter of the system and a decrease in its efficiency.

Copper pipes do not have this drawback, but are very expensive, which led to their rare use for creating heating systems.

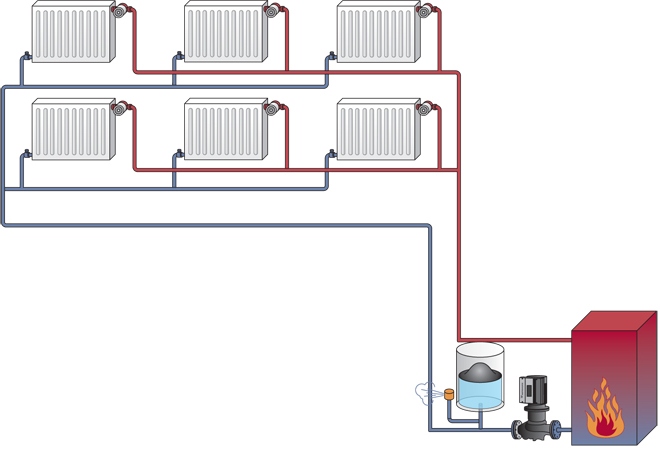

Beam wiring

For two-story buildings, as well as houses with many floors, if it is not possible to lay pipes along the walls, it is better to use radiant heating distribution.

If the radial wiring of the heating system is performed, the coolant is evenly distributed over all batteries. It does not matter how close to the room the boiler is located. All rooms heat up equally well. You can repair the system without shutting it down.

For these reasons, many users choose the beam wiring of the heating system. Especially often it is installed in houses with two floors. Such systems have another drawback - they are always made with two pipes. Therefore, their installation is quite expensive and requires more material.

Such wiring is collector, since the main element in it is the collector. Thanks to this element, the coolant is distributed along the circuits, starting from the main line.

As you can see, the distribution of heating in the house is carried out in different ways. When choosing the most suitable system, you should understand the scheme that is most suitable for a particular home.

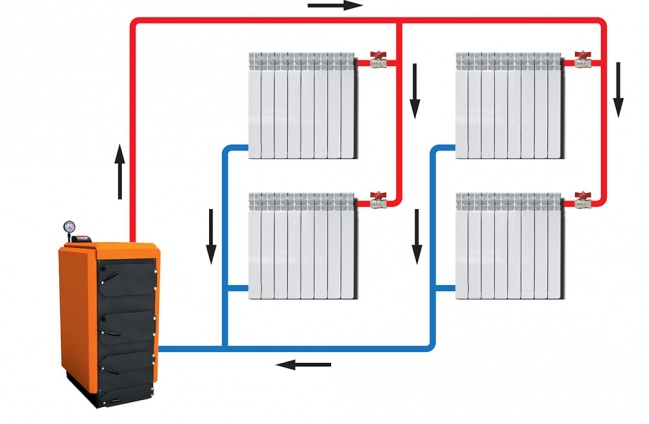

One-pipe method

When creating a single-pipe heating distribution, all its components are connected to each other. They are connected in series in one network. The result is one long pipe.

Usually single-pipe systems are filled with water. The final point where the liquid enters is the radiators. Subsequently, the heat from the heated water is given to the premises through the batteries.

Water is heated in the boiler. Then it moves through the pipes to enter the radiator. This heating system has several disadvantages. The main disadvantage is that the final radiator is located at a great distance from the boiler, due to which the water in it heats up weakly. This shortcoming can be eliminated with a slight modification of the battery. It should be done with many sections. If you follow these tips, the single-pipe type system becomes much more efficient.

Such a wiring diagram for heating a private house works great if you install it in a building with two floors. It's pretty easy to explain. If such a wiring were mounted in a one-story building, one would have to look for a suitable place for the collector. Such an element is necessary for the correct operation of the entire system.

The accelerating manifold is required to speed up the transfer of heat to the radiators. The device allows you to maintain the water temperature at the desired level and reduces the noise level.

The efficiency of work in this case is directly dependent on the location of the collector. The higher it is, the better. In the presence of a house with two floors, such problems do not arise - the collector will cope with the task of maintaining heat and at the same time not creating unnecessary noise.

Other advantages of single pipe wiring:

- When choosing a single-pipe wiring, you do not have to spend a lot of money. The low cost is ensured by the small number of pipes.

- Another advantage of this method of diluting heating is the possibility of laying even in the most inaccessible places.

- Simple installation and aesthetics can also be counted among the advantages of installing such a system.

However, this method of wiring also has its drawbacks. For example, if you need to replace broken elements, the heating in the house will have to be completely turned off. In addition, heating is uneven.It depends on the distance between the boiler and the remote battery.

However, in the case of modernization of the design and with proper installation, it will be quite effective. You can install such a system in several steps. You can do the work yourself.

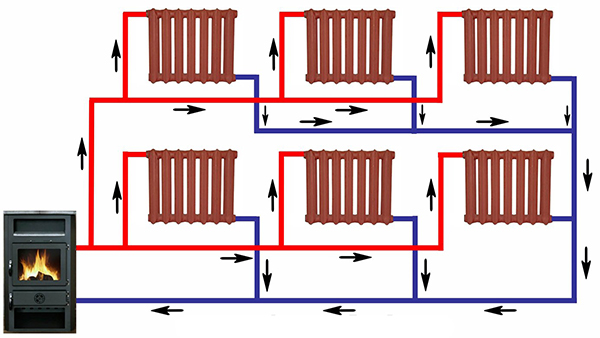

Heating system wiring options

Any type of heating system, whether it is a system with natural or forced circulation of the coolant, differs in the type of supply implementation: a system with a vertical supply and a horizontal system.

In turn, vertical systems are divided into two subspecies:

- systems with bottom wiring, in which the supply main pipeline runs along the floor of the first floor (or in the ground in the basement), from which vertical supply risers are realized;

- in a system with an upper wiring, the coolant is supplied, first of all, to the attic of the building (or under the ceiling of the upper floor, in a wooden house), passes through the main risers, then the waste liquid returns to the heating boiler through the heating radiators.

In each case, the heating boiler is installed at the lowest point of the system, on the ground floor or in the basement. Installation of the boiler directly on the ground is prohibited, the installation surface must be safe in terms of fire, especially in a wooden house. The laying of heating pipes in the ground is used if other installation options are not possible.

In multi-storey buildings, a vertical heating system is often created.

The horizontal system is divided into three subspecies, each of which works on the principle of forced circulation of the coolant.

The dead-end wiring diagram of the horizontal system is implemented according to the principle of connecting the input of each radiator to a single supply system, the return outlet of the waste coolant is also connected to a common circuit;

The system with associated circulation is different in that the coolant is supplied, as in the first case, from a single system, and the exhaust fluid is first discharged into a collector common to all radiators, which is connected to the return branch of the coolant circulation;

The most optimal option is a scheme with collector distribution, where each branch of heat supply and removal is carried out through a common collector group, separate for the heated coolant and for the cooled one. The laying of heating pipes is selected according to the best option.

The main advantage of your own heating system, implemented in a private building, is the ability to choose the optimal temperature maintained in the house.

Complex heat supply systems are characterized by a large number of control elements that allow maintaining the required temperature in each individual room. In a small private building, simple systems with natural circulation of the coolant, due to the laws of thermodynamics and gravity, are most often used. The use of simple systems in the house is justified if the heated area of \u200b\u200bthe premises is small and the total construction budget is limited.

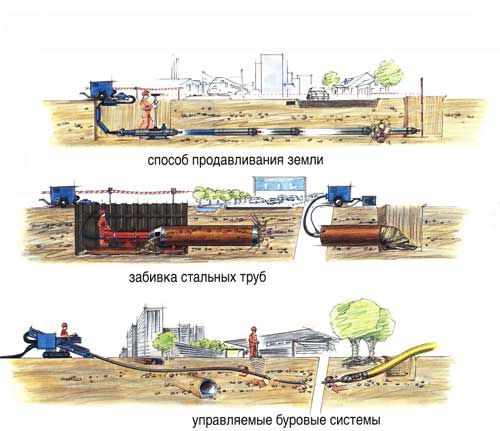

Laying underground gas pipelines

This type of installation includes laying a gas pipeline underground. As a rule, such installation requires pre-prepared dug trenches. In this case, one should take into account the depth of the dug channel and the wiring of communications according to the project, it should be at least 0.8 m. When choosing a location, it is necessary to take into account the distance to buildings, structures and other communications (sewerage, heating network). It is undesirable to lay an underground gas pipeline near trees, since their root system can make it difficult to repair and operate. When laying pipes and assembling a gas device in this way, the following points should be considered:

Scheme of laying an underground gas pipeline

Scheme of laying an underground gas pipeline

- the gap between the gas pipeline and other underground utilities must be at least 0.2 m;

- at the intersection with communication collectors, gas pipes must be pulled in cases;

- the gas main is located above other engineering networks;

- cases should be removed from the intersection at a distance of at least 0.2 m;

- with the help of waterproofing materials, the ends of the cases are processed.

Another way of underground installation is trenchless laying. This option is the least expensive. The advantages of the trenchless method of laying a gas pipeline are as follows:

- yareduces financial costs for the installation of a gas pipeline;

- reduces installation time.

The underground method of laying a gas pipeline is the safest, however, the implementation of such installation is more expensive.

Intra-house laying of sewer pipes

The installation of an internal sewage pipeline begins with the calculation and determination of the pipe material. Having calculated the required diameter for various sections of the pipeline, having calculated the number and types of elements, choosing plastic, you can proceed to laying the internal sewage system.

How to properly lay sewer pipes? The angle of inclination of the pipes must be observed.

Slope of sewer pipes

Preparatory stage

Pipes and fittings are carefully inspected for damage, wall thickness differences. Then parts of the pipeline are stored on a flat area, preventing deformation during storage.

Laying sewer pipes requires cutting the sewer pipe into parts of the required length using a special pipe cutter or a regular hacksaw. When using a hacksaw, the cutting line must be deburred with a needle file and chamfered so as not to damage the rubber cuff during installation.

Cutting a pipe with a hacksaw or a professional tool

Pipeline installation

To make it easier to connect the elements of the pipeline, silicone grease is applied to the smooth end of the pipe or fitting. The sealant extends the life of the rubber sealing rings, prevents the elements from sticking together, and reduces stress and friction within the system.

It is not allowed to use lubricants (sealants) that are not intended for sewer systems. Internal surfaces are not lubricated.

Chamfering and applying sealant

Pipes and fittings of the sewer system are assembled according to the scheme, inserting the smooth end of the element with the applied sealant into the socket of the next part. At the same time, a compensation gap of 10 mm is left.

Compensation gap

Such a gap compensates for the change in the length of the sewer pipe during temperature changes, prevents warping and relieves internal stress.

After connecting all parts of the pipeline, the sewer pipe is fixed in the floor and to the walls. Fastening is carried out with clamps, installing them under the socket to eliminate slipping.

When installing an internal sewerage system in a room without heating, it is necessary to use pipe insulation.

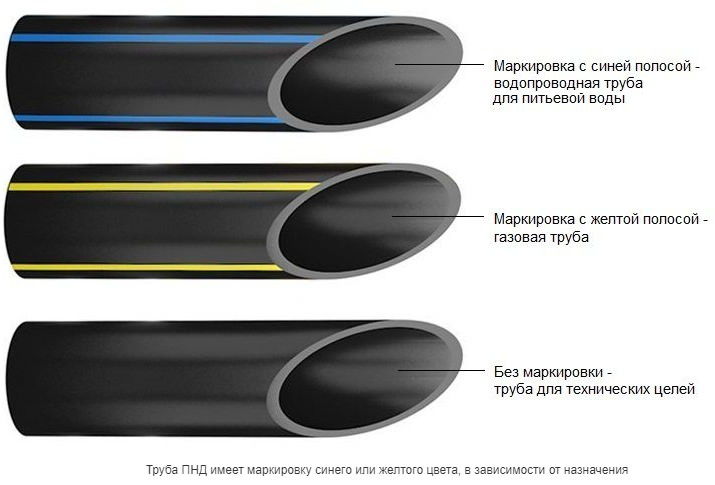

Advantages of using polyethylene pipes

Gas can be supplied in systems through steel or polyethylene lines. Steel pipes are used for all types of gas pipelines, polyethylene pipes are used only for underground laying. Polyethylene pipes are in great demand for gasification in the construction market, since they provide a lower budget for the costs necessary for the construction, maintenance and repair of a gas pipeline.

Polyethylene pipes have a number of advantages over other materials, namely:

- Not affected by aggressive environment, temperature extremes, corrosion.

- Provide ease of installation (if necessary, pipe fitting, cutting).

- It is not required to create additional protection against the occurrence of a chemical reaction with any substances.

- The polymer is not a conductor of electric current, therefore, it protects against current “wandering” in the ground, which can cause an accident.

- The inner walls of polyethylene pipes are absolutely smooth, which increases the throughput of the gas pipeline, preventing clogging.

- They have an affordable cost, lower compared to analogues.

- The weight of polymer pipes is much less, which simplifies the process of transportation, storage and installation.

- They have a long service life, up to 50 years.

Laying pipelines

The laying of pipelines at chemical enterprises can be underground - in through channels (tunnels), in impassable channels and channelless - directly in the ground; ground - on supports and above-ground - on flyovers, racks, brackets, along columns and walls of buildings.

Most often, ground and above-ground laying is used, since the service life of pipelines with such laying is approximately 2.5 times longer than with underground. In addition, when laying above ground and above ground, capital and operating costs are reduced, it is possible to constantly monitor the condition of pipelines, and their installation and repair are facilitated.

The laying of pipelines in the ground intended for the transportation of extremely hazardous and highly hazardous harmful substances and fuming acids is prohibited by the current rules and regulations.

Pipelines with flammable (including liquefied) gases, flammable and combustible liquids may, in exceptional cases, be laid underground only in passage channels equipped with reliable ventilation, hatches. In some branches of the chemical industry (for example, in the nitrogen industry), the underground laying of such pipelines is prohibited in all cases.

When laying pipelines above ground, depending on their characteristics and operating conditions, the following types of supports are used: fixed and movable (sliding, roller and suspended). Movable supports allow the pipeline to move with temperature deformations.

Pipelines are laid on supports, the distance between which is determined by the diameter and material of the pipes, as well as the mass of the pipeline (together with the transported medium and insulation). For steel pipes with nominal bore up to 250 mm, the distance between the supports is 3-6 m.

For fastening pipelines that do not require compensating devices, simple suspensions, clamps and brackets are used.

Pipelines made of fragile and ductile materials are laid in solid trays or on solid bases to protect them from sagging and destruction.

The design of supports for pipelines with compensation must be especially reliable: “dead” supports must firmly hold the pipeline, and movable supports must allow axial, and in case of self-compensation, transverse movement of the pipeline. The designs of these supports are very diverse, and often very complex.

The minimum height for laying above-ground pipelines is at least 2.2 m, and at the intersection with intra-factory roads and driveways - at least 4.5 m.

Pictures for this chapter:

| Non-freezing drain valve |

Similar chapters in other documents:

| See next: Piping |

| See next: Piping |

| See next: Piping |

The main components of the gas pipeline

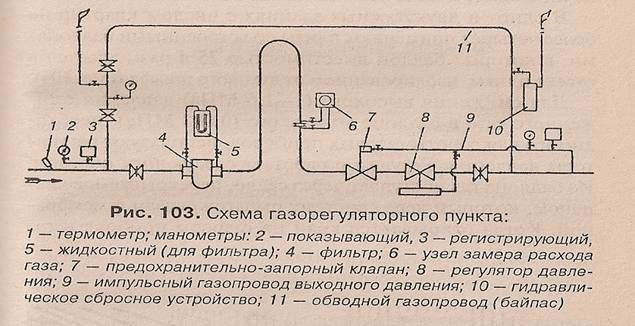

Blue fuel is supplied through gas pipelines through special distribution stations, where automatic regulator valves must reduce pressure and ensure its stable required level.

Gas pipeline networks consist of:

- internal highway;

- external highway of settlements;

- automated control systems;

- means of electrochemical protection;

- regulatory items.

There may be several options for installing a gas pipeline. The choice of mounting method depends on many parameters and the specific case.Climatic conditions, site development and other parameters are taken into account.

Two-pipe wiring

Such systems can be no less efficient than single-pipe ones. This method is suitable for heating houses with one and two floors. Its difference is that the temperature can be independently changed in any room.

Another feature of the two-pipe type system is the fact that the forward and return circuits are separated from each other.

The heated liquid is fed into the system through the supply channels. Through the inlet pipes, water begins to go to the batteries. It can also be carried out to warm floors. After the liquid has cooled down, it is automatically withdrawn back. Such systems have one positive feature - how water will pass to certain batteries can be adjusted manually.

The upper wiring can be invisible if pipes are mounted above doorways and covered with decorative elements. In this case, the pipes will be masked as much as possible.

The disadvantage of the upper wiring can be considered the fact that, in addition to installing pipes, it is necessary to install a membrane expansion tank. Such work is carried out easily, but more funds are required for this.

If the system is installed in a building with two floors, an open tank can be installed. However, it can only be placed in the attic. With the lower wiring, the pipes will be located below the windowsill.

This method is a little more difficult in terms of implementation, since, in addition to installing pipes, you will have to install an open expansion tank. It must be installed above the placement of straight pipes.

Vertical layout with top wiring

When choosing such a model, the coolant will go to the attic from the heater. The liquid then goes to all the batteries in the house.

Such schemes are more efficient lower wiring. This is due to the high pressure that is supplied through the risers.

Bottom wiring vertical type

A two-pipe heating system with a lower wiring is created sequentially:

- A main pipeline must be laid along the floor of the basement or first floor. It will take its origin from the boiler.

- It is necessary to carry out vertical pipes along the main pipe, due to which the coolant will move to the batteries.

When designing a diagram of a two-pipe heating system with a lower wiring, it is necessary to determine how air will be removed from the pipeline. This requirement can be met by installing an air pipe and an expansion tank.

Horizontal system

Quite popular is the horizontal version of the wiring, in which the coolant circulates forcibly. There are several schemes:

- Dead end. The advantages of these systems include savings in pipe consumption. Among the disadvantages included too much length of the contour. Due to this, the regulation of the operation of the system as a whole is significantly more difficult.

- Associated promotion of the coolant. Each circulation circuit is of equal length, making adjustments to the system simple and easy. The disadvantage of such a system is too high pipe consumption. In addition, the interior of the rooms deteriorates when such a system is installed.

- Beam or collector wiring of heating pipes in a private house. Each battery is connected to a central manifold. Due to this, the distribution of heat is carried out evenly.

When installing a beam system, you will have to spend money on pipes.

Horizontal heating scheme

A special case of wiring heating networks is a horizontal or collector circuit. With it, each radiator on the floor is connected to a riser or boiler with individual supply and return pipes. As a result, the coolant enters the heater along the shortest path, bypassing other consumers, and does not have time to lose its temperature.

Pipes in this case are placed, as a rule, in the floor screed.

Distribution and reception of the heat carrier is carried out with the help of collector units, which are located on each floor and regulate the heat supply to the premises located on it.

The coolant is supplied in the collector circuit due to the pressure created by the central circulation pump, but additional low-power pumps are mounted in separate branches with high resistance, for example, with underfloor heating.

Photo 2. Collector wiring diagram of pipes with a horizontal heating boiler of a two-story private house.

Advantages of horizontal wiring:

- Easy temperature control of each radiator individually.

- The minimum number of connections, which increases the reliability of the network as a whole.

- No air vents are required for radiators.

- The heating system can include devices with different hydrodynamic resistance: batteries and underfloor heating.

The main disadvantage of this scheme is the significant consumption of pipes.