The ceiling is the most visible part of the interior of the room. Its slightest flaws are immediately evident, so the decoration of this part of the room should be approached especially carefully. The originality of the design will help in creating a unique entourage of the room, so recently two-level plasterboard ceilings with backlight are gaining more and more popularity.

At first glance, such designs can only be done by a team of professionals working under the guidance of an experienced designer. But bunk ceilings created using drywall, the photos of which you can see below, can be done by hand. To install them, you do not need special skills or tools, it is enough to take the work very carefully and use a few general recommendations.

Price

The average cost of installing a two-level ceiling without finishing is 600-700 rubles / m2 in Moscow and St. Petersburg, and for St. Petersburg this is rather the lower price bar, in the capital there are chances to find more budget offers.

The cost of backlighting will depend on the type and number of fixtures used, the approximate cost of installing and connecting one device is 400 rubles.

Used materials and tools

When making a double ceiling, we will use the standard list of materials used in the installation of gypsum boards:

- Metal profiles UD and CD. Of course, you can use wooden slats as a frame, but the construction of profiles is much easier. In addition, in the presence of curved surfaces, the frame of the rails will be very difficult to make.

- Drywall for ceiling thickness from 8 to 9.5 mm. Plasterboard ceiling with backlight it can also be made from ordinary GKL with a thickness of 12.5 mm, but this will only lead to unnecessary difficulties. The ceiling practically does not carry any serious load, and thin drywall is much easier to work with, especially bending.

- Fasteners: direct hangers, various profile connectors, metal screws, dowels for attaching profiles to the wall.

The tools you need are the simplest:

- Perforator.

- Screwdriver.

- Hacksaw for cutting drywall.

- Scissors for metal - they will cut or cut profiles.

- Painting knife.

- Measuring tool: level (preferably laser or water), tape measure, plumb line, chopping cord.

Options for two-level ceilings

Before you figure out how to make a two-level plasterboard ceiling, you need to decide on its design. And this is very difficult. Just look at the photo to see how many options you can consider. In technical terms, depending on the location of the levels, two can be distinguished:

- If the ceiling in the room is perfectly flat, then it can be taken as the first level. The level frame No. 2 will be attached to it.

- If the base surface is far from ideal, then it can be leveled with the first layer of drywall. In this case, the fastening of the second level will be made to the profiles of the first.

The second option is preferable in the case when the ceiling layer should hide various communications underneath. It also frees from many labor-intensive operations, bringing the preparation of the base area to a minimum.

The most common are two-level ceilings in the form of curbs or ledges placed around the perimeter of the room. In this design, it is convenient to place the backlight in them, various options for which are shown in the photo.

Installation of the second level of the ceiling

The process of leveling plasterboard ceilings well known, so there is no need to dwell on it separately.But when installing the second level, it will be useful to follow some recommendations. Let's consider them on the example of the option with borders, when the first level is the base surface of the ceiling, but all these steps and subtleties are applicable to other models of two-level ceilings.

The main installation steps are listed below.

markup

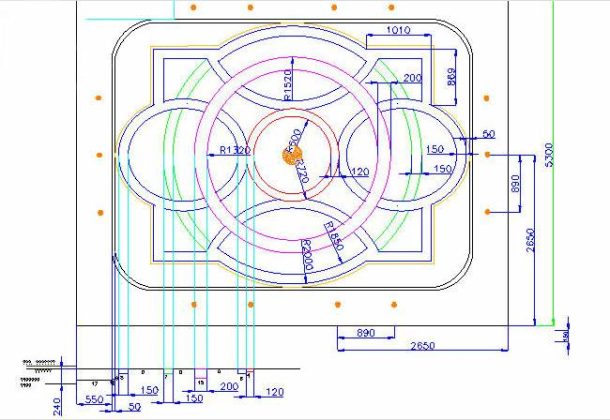

Having measured the height of the second level, a line for attaching the guide profile is drawn on the wall around the perimeter of the room. It is better to use a spirit level or a laser level. A drawing of future borders is transferred to the ceiling surface, with a step of 600 mm, the location of future jumpers and the attachment points of the suspensions are marked.

Frame installation

frame going like this:

- The guide profile UD is attached. It is attached to the wall or ceiling with dowels using a puncher. On the ceiling, the profile is attached along the drawn border line. If it has a curvilinear shape, like the design in the next photo, the profile is cut with scissors for metal, after which it can be easily bent to the desired angle.

- It is necessary to build suspensions from the CD profile. Their length should be 1 cm less than the height of the second level. At their ends, the sidewalls are cut to a depth of 2.5 cm.

You can do it even easier and screw the drywall strips that form the end of the curb directly to the ceiling profile. Then the lower guide will be attached to the drywall. But it’s better to make jumpers anyway - they will give the frame the necessary rigidity.

- Homemade suspensions are fastened with metal screws to the ceiling profile. On straight sections, the step of their fastening should coincide with the step of the jumpers and be 60 cm. They must also be mounted in places where drywall is bent.

- If necessary, holes are drilled in pre-marked places for attaching direct suspensions.

At the frame assembly stage, before installing horizontal jumpers, it is most convenient to carry out all work related to the installation and connection of fixtures. It is not always convenient to mess around with wiring with a fully assembled frame, moreover, there is a high probability of “knocking down” a level ceiling with a careless movement.

- Horizontal elements from the CD profile are cut to size. They are inserted into the guide profiles perpendicular to the wall, after which they are fixed with self-tapping screws and direct hangers. Using a level, periodically check that they are all in the same plane.

It is desirable that the attachment points of the horizontal and vertical jumpers do not coincide. After all, it is on these profiles that pieces of drywall will be joined. The spacing of the connections will reduce the gaps between the individual elements.

The result should be a fairly strong frame of the future second level of the ceiling, for example, as in the photo.

Working with drywall

After completing the installation of the frame, it remains only to cut the drywall sheets to size and attach them to the profiles with screws. Mounting step - 15–25 cm.

Often drywall needs to be bent to create curved surfaces. To do this, one of its sides is moistened with water with a sponge and rolled with a needle roller, after which it is carefully bent. If it is necessary to create a strong bend, in addition to wetting, shallow cuts can be applied to one side at regular intervals. They will help to achieve the required radius of curvature.

At the final stage, you will need to putty and paint drywall, and then finish installation of fixtures.

Thus, making a two-level illuminated ceiling on your own is not so difficult. It will not only decorate the room, but also bring the owner the joy of creativity.