Despite the variety of high-tech artificial materials, natural finishing elements remain relevant to this day. People are gradually becoming convinced that cutting-edge finishes cannot replace the warmth and natural appeal of natural materials such as wood. Clapboard wall decoration, which until recently was considered the lot of country houses, is increasingly found in the apartments of city dwellers yearning for nature, not only on balconies, but also in kitchens, and even in living rooms. Wall decoration with plywood is also gaining popularity - an environmentally friendly material that is not inferior in its properties to a wooden board and allows you to get a durable and even surface.

Lining and plywood: a few words about the merits of materials

Skeptics may say that a clapboard kitchen will look like a country room or a sauna, but this statement can only be accepted by referring to the most standard material - a pine board with a golden hue. Properly selected type and color of lining, as well as competent design, will give your kitchen or bedroom a unique rustic flavor, modern or Scandinavian style features. In addition, it is not necessary to sew up the entire room or the entire kitchen with clapboard: the material can be used to finish one wall or ceiling.

Advantages of using clapboard trim in an apartment:

- Environmental friendliness and creation of an ideal microclimate. Wooden lining is a living, breathable material that absorbs moisture when it is in excess and gives it away when the air in the apartment increases dryness.

- A rich selection of shades and textures - clapboard trim made from different types of wood gives a completely different impression.

- Additional noise and heat insulation.

- Pleasant aroma of natural wood.

- Ease of installation.

- Affordable material cost.

Plywood also has many of the advantages of natural board, such as strength, environmental friendliness, ease of processing, and attractive appearance. The main difference between this material and lining is a variety of finishes: plywood sheets can be used as an independent material, or you can paint, varnish or wallpaper.

Another noteworthy wood-based material is OSB particle boards. The ceiling in the kitchen, for which OSB boards were used, will look very peculiar in its pure form, therefore, to give it a more familiar look, it can be painted with an oil or alkyd composition. If you like the structure of OSB boards, use matte or glossy impregnation to process the material.

Lining classification

Wooden lining is divided into types at once according to several criteria.

Depending on the quality of wooden elements, the following types of lining are distinguished:

- extra-class lining - there are no defects on the surface of the material;

- lining class "A" - it is permissible to have one knot per one and a half meters in length, no more than two small cracks and resin pockets;

- class "B" lining - no more than four knots can be present on one and a half meters, one contrasting area of \u200b\u200bup to 15 square meters is allowed. cm;

- lining class "C" - knots, cracks, resin pockets and other kinds of flaws come across on the surface of the material, spots and stripes can occur.

Depending on the shape of the profile, the following types of lining are distinguished:

- Standard lining, the panel of which has a groove that hides the junction of the elements during assembly.

- Eurolining that meets the highest requirements for the characteristics and decorativeness of the material. Its panels have very precise dimensions and deeper connections.

- Lining "Calm" - has a flat surface without any grooves.

- American, which, after laying on the walls of the kitchen, takes on the appearance as if the panels were mounted with an overlap.

- Block house - elements imitate a log wall due to the convex shape on the outside.

Preparation of material for installation

Wall decoration with plywood or clapboard is carried out on guides made of wood or metal. Wooden elements should be pre-impregnated with a moisture and refractory agent in order to increase the life of the finish as a whole and especially its hidden part. It is also desirable to cover the lining panels with special compounds to protect against dampness and fire.

Tip: place the finishing materials in the kitchen or in another room at least a day before the start of work. This will enable the wooden elements to adapt to the temperature regime and are guaranteed to avoid deformation.

Finishing the ceiling or walls with clapboard involves the placement of elements in various ways: the joint can be carried out diagonally, horizontally or vertically. Depending on the option chosen, the supporting bars are fixed, which should be perpendicular to the wooden panels. In the case of plywood or OSB boards, the rails are fixed in a horizontal position.

How to build a frame for lining or plywood

Consider the features of the construction of the frame with a horizontal fastening of the lining. The elements of the crate in this case will be located vertically.

- Bearing elements should be selected taking into account the quality of the walls, as well as the performance of the materials used for heat and sound insulation of the room. In any case, the load-bearing parts must be at least 40 x 20 mm. This will make it possible to build a solid frame and at the same time leave a sufficient gap for ventilation.

- The bars must be placed at a distance of no more than fifty centimeters from each other. As for the length of the bar, it is determined by the height of the room itself.

- If the base for the frame consists of wooden elements, then self-tapping screws should be used for fastening. In the presence of a concrete or brick surface, a reliable joint is provided with the help of dowels.

- Additional bars are installed near window and door openings. It is on them that decorative corners or platbands will be attached.

- Bearing beams are fixed strictly vertically. If the length of the beam is not enough, then the next one is installed at a distance of 2-3 centimeters from the previous one.

- In the process of attaching the frame, a constant step of 50 centimeters is used. If an additional heat-insulating layer is installed, then the step size is reduced by several centimeters. This will provide a tighter joint. The frame can be used for mounting communications.

Important! For laying the electrical cable, it is recommended to take a corrugated pipe, the heat-insulating layer must be protected with a vapor barrier material.

Installation of lining: stages of the procedure

For fastening lining elements can be used:

- screws;

- nails;

- kleimers.

Regardless of the option chosen, all elements are fixed from the inside; no traces of fastening should be visible on the front surface.

If nails are used to fix the lining elements, then they must be carefully hammered along an oblique line into the joint where the next plank will be inserted. In this regard, clamps are much safer, and the technology of their fastening allows both installation and dismantling of elements without any negative consequences.

It is important to properly fix the first plank of the lining, which is installed as close as possible to the corner or ceiling. The next one is inserted into a special joint and fixed with a clip. In this case, the fastening elements should be placed at the level of the carrier profile.

Tip: so that the lining does not swell at the joints with increasing humidity in the room, a gap of a couple of millimeters must be left between the joints.

Sometimes the length of the lining element is not enough and you have to increase it using trimmings from other panels. Spliced elements are recommended to be placed at the level of the carrier profile, while the joint of each element must be carefully fixed.

The last of the planks is cut to width and fastened with nails with small caps. As a result, the structure will become stable and will not be afraid of any loads.

Important! Both the finish and start strip of the lining should be located at a distance of at least 5 mm from the ceiling.

Material finishing features

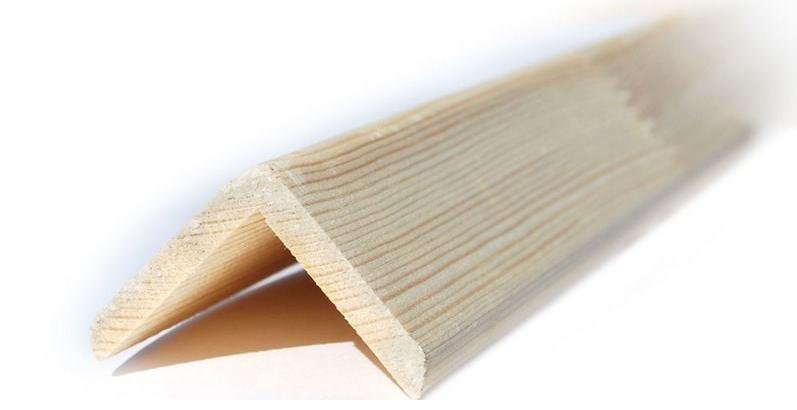

Places where nails were used must be covered with decorative plinth or slats. Special wooden corners can be used on window or door endings.

After completion of work, decorative elements should be coated with a special protective compound. This will increase the service life of the material and retain its structure for a long time.

Tip: to avoid associations with a country house, do not use glossy varnish to process the lining, choose a matte composition or wax.

It is worth noting that any wooden elements need special care: every few years it is necessary to treat the material with special means to protect it from moisture and parasites. These measures will allow you to maintain a well-groomed finish for a long time.