Problems and malfunctions of pumping stations and their correction

All pumping stations consist of the same parts and their breakdowns are mostly typical. It makes no difference whether the equipment is Grundfos, Jumbo, Alco or any other company. Diseases and their treatment are the same. The difference is how often these malfunctions occur, but their list and causes are usually identical.

The pumping station does not turn off (does not gain pressure)

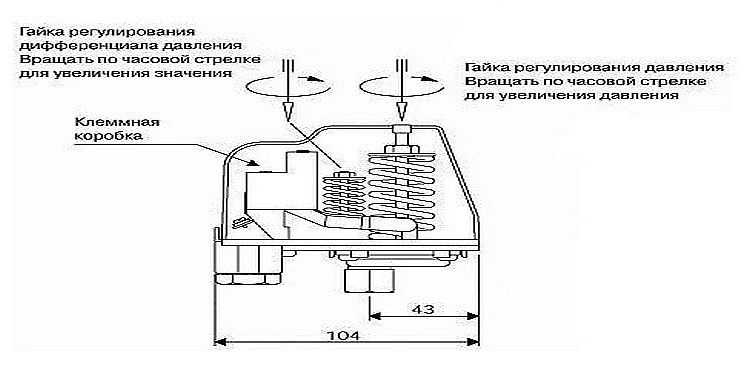

Sometimes you notice that the pump has been running for a long time and will not turn off in any way. If you look at the pressure gauge, you can see that the pumping station is not gaining pressure. In this case, the repair of the pumping station is a lengthy business - you will have to sort out a large number of reasons:

If the shutdown limit of the pressure switch is much lower than the maximum pressure that the pump can create, and for some time it worked normally, but then it stopped, the reason is different. Possibly the pump the impeller worked

. Immediately after the purchase, he coped, but during the operation the impeller was worn out and "now there is not enough strength." Repair of the pumping station in this case is the replacement of the pump impeller or the purchase of a new unit.

Another possible reason is low voltage in the network

. Maybe the pump is still working at this voltage, but the pressure switch is no longer working. The solution is a voltage stabilizer. These are the main reasons that the pumping station does not turn off and does not build up pressure. There are quite a few of them, so the repair of the pumping station may be delayed.

Repair of the pumping station: often included

Frequent switching on of the pump and short periods of its operation lead to rapid wear of the equipment, which is very undesirable. Therefore, the repair of the pumping station should be carried out immediately after the discovery of the "symptom". This situation occurs for the following reasons:

Now you know why the pumping station often turns on and what to do about it. By the way, there is another possible reason - pipeline leakage

or some connection, so if all of the above does not apply to your case, check if the joint is leaking somewhere.

Air in water

There is always a small amount of air in the water, but when the faucet starts to “spit”, something is not working properly. There can also be several reasons:

The pump station does not turn on

The first thing to check is voltage. Pumps are very demanding on voltage, they simply do not work at low voltage. If everything is fine with the voltage, things are worse - most likely the motor is faulty. In this case, the station is carried to a service center or a new pump is installed.

If the system does not work, you need to check the electrical part

Other reasons include a plug / socket malfunction, a frayed cord, burnt / oxidized contacts at the point where the electrical cable is attached to the motor. This is something you can check and fix yourself. A more serious repair of the electrical part of the pumping station is carried out by specialists.

The motor hums but does not pump water (the impeller does not rotate)

This error may be caused low voltage in the network

. Check it, if everything is normal, move on. You need to check if it's burned out. capacitor in terminal block

. We take, check, change if necessary. If this is not the reason, go to the mechanical part.

First you should check if there is water in the well or well. Next, check the filter and check valve. Maybe they are clogged or defective. Clean, check the performance, lower the pipeline into place, start the pumping station again.

We check the impeller - this is already a serious repair of the pumping station

If that doesn't help, the impeller may be jammed. Then try manually turning the shaft.Sometimes, after a long period of inactivity, it “sticks” - it becomes overgrown with salts and cannot move itself. If you cannot move the blades by hand, the impeller may have jammed. Then we continue the repair of the pumping station by removing the protective cover and unlocking the impeller.

Next step

You checked the device for contamination and for the electrical system, so why is the pump still not pumping water? Now inspect and carefully check the device itself. The pump has a filter device that may be clogged. In this case, clean it or replace it. This clogging problem can also occur with a pumping station check valve.

If everything is in order, then a more unfavorable option follows. If the pump suddenly worked while there was no liquid in the tank, then the sensor inside the device could simply burn out due to overheating. In this case, you can't do anything with your own hands. It is not recommended to even go to a specialist, because the water pump will no longer show as reliable results as in the old days.

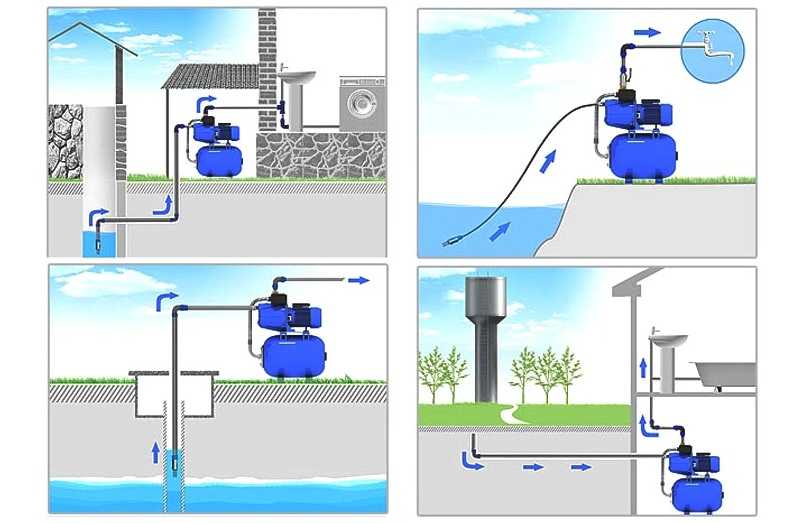

The composition of the pumping station and the purpose of the parts

A pumping station is a collection of separate devices interconnected. To understand how to repair a pumping station, you need to know what it consists of, how each of the parts works. Then troubleshooting is easier. The composition of the pumping station:

Each of the parts is responsible for a certain parameter, but one type of malfunction can be caused by the failure of various devices.

The principle of operation of the pumping station

Now let's look at how all these devices work. When the system is first started, the pump pumps water into the accumulator until the pressure in it (and in the system) equals the upper threshold set on the pressure switch. While there is no water flow, the pressure is stable, the pump is off.

A faucet was opened somewhere, the water was drained, etc. For a while, water comes from the accumulator. When its quantity decreases so much that the pressure in the accumulator drops below the threshold, the pressure switch is activated and turns on the pump, which pumps water again. It turns off again, the pressure switch, when the upper threshold is reached - the shutdown threshold.

If there is a constant flow of water (a bath is taken, watering the garden / vegetable garden is turned on), the pump works for a long time: until the required pressure is created in the accumulator. This happens periodically even when all taps are open, since the pump supplies less water than flows out of all points of analysis. After the flow has stopped, the station works for some time, creating the required reserve in the gyroaccumulator, then turns off and turns on after the water flow appears again.

Malfunctions of protective systems of pumps

Usually, a properly assembled water supply system and quality pumps have devices that prevent them from idling.

In the event of a malfunction of such protective devices: a dry-running relay for a well and float switches for drainage, a well or fecal pump, the devices can work in the absence of water.

Sometimes the float switch of well or drainage pumps, due to improper installation, does not lower along with a drop in the water level (it falls on a hillock or clings to a protruding object) - this leads to the operation of the electric pump in idling mode and its further failure.

Vibrating pumps, which usually do not have external protective devices connected in the system, working for a long time without water after a drop in its level, can fail if there is no built-in thermal protection.