When you enter an apartment after renovation, your gaze involuntarily stops at the ceiling. Plastering and whitewashing are a thing of the past. Today, stretch ceilings are gaining more and more popularity. Glossy or matte, white or colored, plain or multi-color, fabric or PVC film - they can become a real decoration of the room. Moreover, it is really possible to carry out the installation of stretch ceilings on your own, without resorting to the services of specialists.

What will be required

For installation, working tools and special accessories for stretch ceilings are required.

Most tools can be found in the arsenal of any man. The missing ones will have to be bought or rented. Their list is as follows:

- tape measure or laser meter;

- level, for greater accuracy it is better to use a laser device;

- perforator;

- hammer;

- screwdriver or screwdriver;

- angular and straight blades;

- sharp knife;

- a heat gun or a special building hair dryer (needed if a PVC structure is installed).

The list of accessories and consumables looks like this:

- aluminum or plastic profiles;

- decorative cap;

- platforms and thermal rings for mounting recessed lamps and chandeliers;

- pipe lines (if necessary);

- dowels with screws for concrete or self-tapping screws for wood;

- glue;

- canvas of the future ceiling.

The canvas can be made of two types of material:

- PVC film (polyvinyl chloride);

- made of specially woven fabric impregnated with polystyrene.

If the installation of stretch ceilings is carried out on their own without the participation of professionals, it is better to use fabric sheets. The technology of their installation does not require the use of dangerous equipment in the form of a heat gun.

Where to begin?

First you need to free the room as much as possible from furniture and household appliances. If this is not possible, move everything to the center of the room, providing unhindered access to all walls, and cover with dust protection.

Next, you need to conduct a thorough revision of the old ceiling base. Clean it of everything that can crumble, peel off and fall off. If there are floor slabs on the joint surface, the seams formed by them must be cleared, filled with mounting foam and properly processed. It is recommended to cover the entire surface of the cleaned ceiling space with a special primer that protects against mold, rot and other similar troubles.

Then you should plan the location of the lighting fixtures on the future ceiling surface. For self-installation, built-in or overhead spots for stretch ceilings are ideal. Electrical wires must be fixed on the base ceiling, they must not sag and touch the stretch ceiling material.

Measuring work

After the completion of the preparatory work, the question arises: how to measure the stretch ceiling? A number of tips will help in this responsible matter.

- Measurements should be made using tools that give the most accurate results. A laser meter is best, in extreme cases, you can use a tape measure.

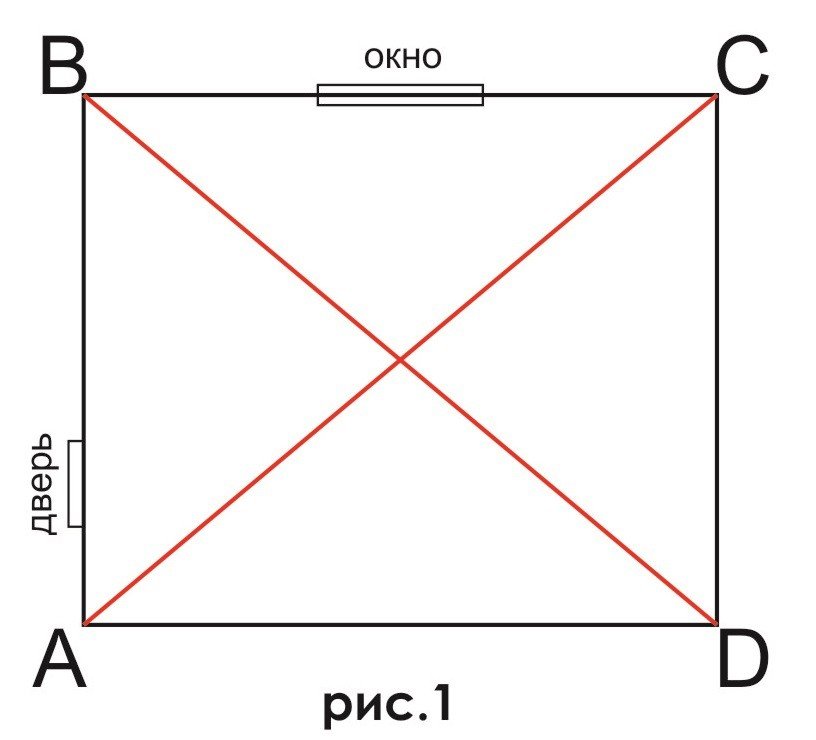

- Measurement work must be fixed on the drawing, which will look like a view of the room from above.

- Mark the corners in the drawing in Latin letters and connect them with diagonals.

- Measure the perimeter and diagonals of the room as close as possible to the ceiling and record the results on the drawing.

With the result obtained, you can go shopping for a ceiling canvas.

Stretch ceiling installation

The installation technology of a PVC tension structure is divided into stages, the sequence of which is fundamental.

- Drawing markings on the walls. To do this, you need to measure the height of the walls in all corners of the room and mark at the required level.Connect them with a straight line.

- Profile mounting. The profiles should be fixed to the wall with dowels or self-tapping screws with an interval between them of no more than 7–8 cm. The attachment point must coincide with the marking line.

- Ceiling sheet installation.

- Before unpacking the stretch ceiling, it is necessary to clean the floor from dust and debris that can damage the thin PVC material.

- According to the installation technology, the room must be warmed up to 40 degrees. This is a prerequisite that will allow you to evenly stretch the canvas and correctly assemble the entire structure.

- The canvas is hung with the help of special hanging clips, pre-installed in the corners of the room. The base corner of the canvas is attached first. It is marked on the ceiling material by the manufacturer. Then you need to fix the opposite corner. The procedure is repeated until all corners of the canvas are fixed in the clamps.

- The hung canvas is heated with a heat gun to 70–80 degrees to give it elasticity.

- Further, the ceiling material is fixed in the profiles at all corners of the room using a special tool - an angled blade. The order of fixation is the same as when hanging. Then straight sections along the walls are fixed.

- If there are seams on the canvas, it is recommended to fix them first. It should be remembered that they stretch and fix the ceiling in small pieces opposite each other.

- Installation of lamps. A thermal ring is glued to the place for mounting lighting fixtures, then a hole is cut in the stretch ceiling with a sharp tool. Spots for stretch ceilings are mounted on special racks, which are pre-attached to the base ceiling.

- Attaching a decorative cap. An alternative would be lightweight foam skirting boards that need to be attached to the wall and not to the ceiling material.

The technology for installing fabric stretch ceilings goes through the same steps, with slight differences in the process:

- the room and the canvas itself do not require heating,

- fastening of the fabric ceiling to the profiles is carried out from the middle of the wall to the corners.

Tip: before you start working for the first time, you should watch videos on how to install the master's stretch ceilings. This will help to avoid possible errors during the installation of the ceiling and comply with the entire process technology.

Types of fastening stretch fabrics

For the installation of a stretch ceiling, several types of web fastening are used:

- Harpoon - suitable for installing only PVC ceilings. Along the entire perimeter of the canvas is a special flexible element made of polyvinyl chloride, called a harpoon. The fixation of the canvas in the baguette is carried out according to the principle of the tool of the same name. For fastening, an aluminum profile specially designed for this purpose is required.

- Clip-on - used exclusively for the installation of fabric ceilings. Based on the latch principle. A special plastic profile is used for fastening.

- Bead or wedge - used for installing PVC sheets and fabrics. For their fixation, an aluminum profile in the shape of the letter P is used. The canvas is attached to the profile by means of a glazing bead (wedge) made of wood or plastic.

Schematically, the types of fastening look like this:

Tip: before you go shopping for consumables and accessories for a stretch ceiling, you should decide on the type of stretched canvas and the type of its fastening.

How to combine stretch ceilings and drywall?

Often, by design or by necessity, a stretch ceiling has to be attached to plasterboard structures. In this case, a number of features of working with this material should be taken into account.

Drywall is a rather fragile thing. Ordinary self-tapping screws and dowels will not be able to stay in it under the tension of the ceiling sheet.Therefore, the places to which the baguette will be attached to fix the stretch fabric should be reinforced with embedded profiles or wooden bars of suitable size. Also, for this purpose, it is possible to install a profile that is wider than the standard one, which is used to create a crate for plasterboard structures.

A drywall box under a stretch ceiling is mounted first. The installed structure is puttied and covered with paint of the desired shade. In the future, the installation technology of the stretch ceiling, described above, is observed.