An impeccably flat ceiling, to which there are no complaints, is rather an exception to the rule, the dream of any owner, the crown of a successful repair. One of the options for an ideal ceiling surface can be a slatted suspended ceiling.

Slatted ceilings are a type-setting structure of narrow long slats. Rails are most often made of aluminum and steel alloys.

Advantages of rack ceilings

Even at the stage of deciding on the design of the ceiling, there are many advantages that allow you to make a choice in favor of the rack:

- ease of installation will allow you to mount the rack ceiling with your own hands and save you from the invasion of workers;

- not all base surface defects are amenable to simple correction, so it is easier to cover them with a false ceiling;

- high fire safety;

- ease of care and environmental friendliness (safe materials on which mold and fungus will not start);

- long service life - due to resistance to moisture and temperature extremes, such a ceiling will serve for many years in a row;

- The state of emergency in the form of flooding by neighbors from above does not pose any threat to the rack aluminum ceiling;

- ventilation, gas pipes, air conditioning mains and other everyday prose will be hidden from your eyes;

- worthy appearance and elegant execution of any design idea;

- the lightness of the suspended structure gives a minimum load on the walls.

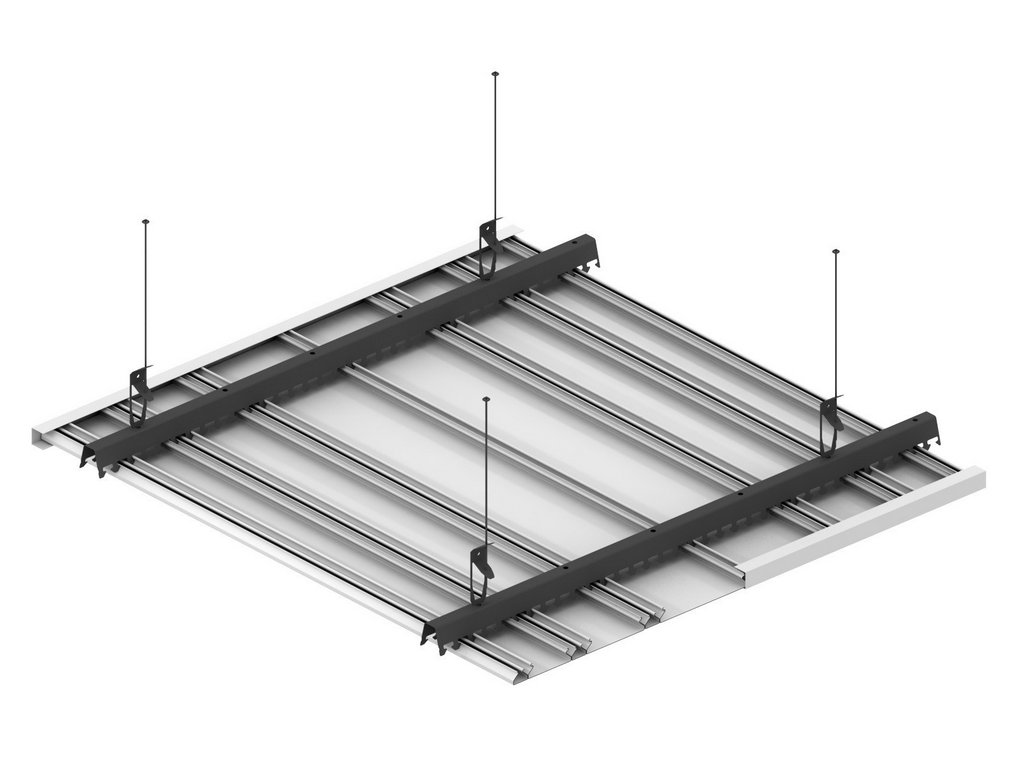

Components of the rack structure

The suspension system of this type consists of the following elements:

- Carrier rail (stringers, traverses or combs) - steel strips on which the rails are attached.

- Adjustable hangers with which the stringers are attached to the ceiling.

- Reiki - panels, most often aluminum or metal.

- Inserts for grouting gaps between slats.

- Corner - a profile for masking joints.

Types of rack ceilings

Depending on the joints between the rails, the ceilings are:

- open type;

- closed type;

- gapless type.

Open ceilings

When installing open-type ceilings, the rails do not fit closely to each other, there is a gap of about 15 mm between them. Usually, the gap is formed with an insert, which serves as an additional decorative element, but can also remain open. Such a slatted ceiling in the kitchen, bathroom or toilet is a great solution. It is functional, unpretentious in operation and has a very attractive appearance.

According to the profile of the rails, open-type ceiling structures are divided into:

- ceilings of Italian design - slats 84 mm wide have rounded edges;

- German design ceilings - slats 85–185 mm wide with rectangular edges;

- designer ceilings - slats from figured profile panels (V-, S-, U-shaped).

Designer slatted ceilings deserve special attention. Drop-shaped or cube-shaped slats, in the shape of the letter V or U, will help to give individuality to any room and satisfy the most sophisticated taste.

Rack structures of a closed type

Installation of ceilings of this type comes from rails with a special "tongue" that closes the space between the rails. When finished, the ceiling is a solid plane, and the different size of the panels allows you to create a non-standard rhythm in the design of the ceiling surface.

Gapless ceilings

These are suspended structures, the installation of rails in which takes place closely, without insertion. They are widely used in non-residential industrial premises.

Tips for choosing slatted panels

Reiki can have different facing surfaces: matte, glossy, mirror, laminated, perforated. To make a competent choice, it is useful to know the nuances of each type of rail. Namely:

- The matte surface of the rails does not reflect light reflections, so any type of lighting is acceptable in this case - built-in lamps or traditional chandeliers.

- A glossy or mirror surface implies the use of built-in lights.

- Laminated panels look elegant and noble, but are not suitable for rooms with high humidity - it is better not to use them in the bathroom and kitchen.

Ceiling installation

Installing a suspended rack ceiling does not require high skill and special tools. The question "how to make a rack ceiling" will not puzzle you for a long time, because the whole process comes down to a few simple operations.

Following the instructions below, you can assemble the rack ceiling with your own hands.

You will need:

- roulette;

- drill;

- screwdriver;

- level;

- pencil;

- metal scissors;

- profiles;

- dowels;

- self-tapping screws.

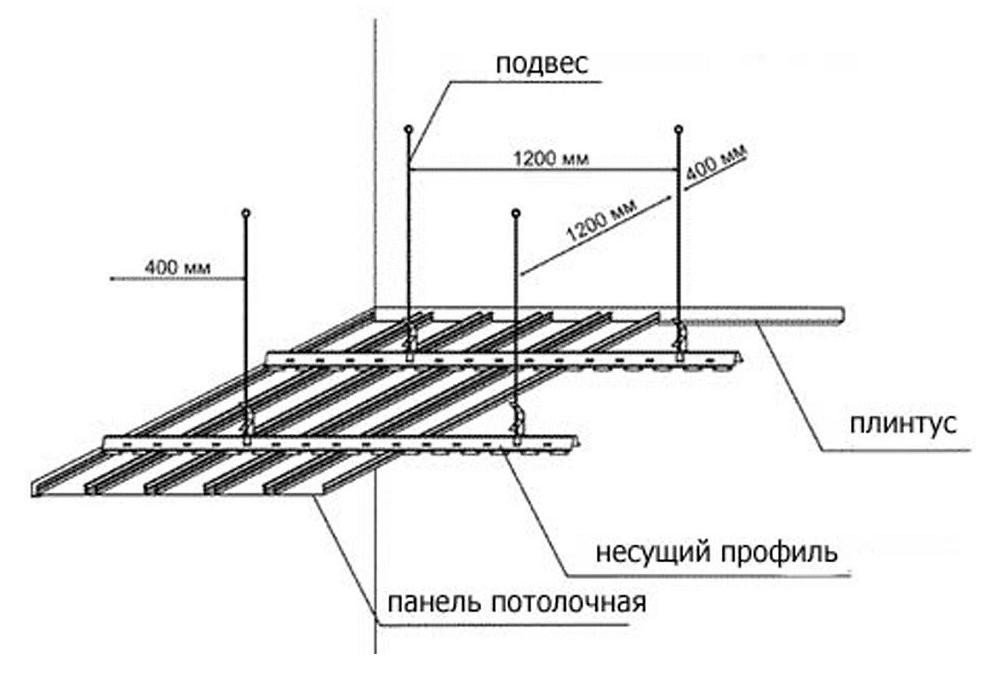

Installation instructions for rack ceiling:

- Decide on the height at which the ceiling will be mounted. It is chosen arbitrarily, but if lamps are built into the structure, at least 1 cm must be added to their size to calculate the height.

- Using a level and a pencil, mark the installation line of the end profile along the entire ceiling.

- Every 30–40 cm, drill holes for the dowels with a drill.

- Secure the profile with dowels and screws. The corner profile can also be mounted simply on self-tapping screws, without dowels: the design is quite light and does not have a large load.

- Mark the ceiling for the installation of suspensions to which the stringers will be attached. In order to correctly calculate the required number of stringers, you need to know that you need to install the first of them at a distance of no more than 30 cm from the wall. Subsequent gaps between tires should be no more than 120 cm.

- Install a stringer hanger on the ceiling in 100 cm increments.

- Cut the guide bar to the desired length with metal shears.

- Fasten the tires to the hangers with self-tapping screws.

- Cut the aluminum rail to the desired length.

- Insert the rails one at a time into the rails and snap into place. The last rail is inserted above the end profile.

Important! Usually the last rail needs to be cut to width. To do this, mark the cut line and draw it deeply with a knife. Then bend and unbend the rail along this line until it breaks off.

How to cut holes for lights

To make neat holes for the lights in the slatted panels, you need to follow the instructions:

- draw a contour of the lamp on the surface of the metal rail with a pencil;

- using a drill with a cut-off crown or by hand with small scissors, carefully cut the hole, starting from the center.

What else is good to know

When choosing rack panels, you should understand that only a quality product from a serious manufacturer can embody all the advantages. A short guide will help you make the right choice:

- The thickness of the rack panels affects the durability and strength of the suspended structure. The denser the rail, the less likely it is to be damaged during installation, as well as the ceiling to sag. The optimal thickness of the rail is 0.5–0.8 mm.

- Pay attention to packaging. Quality products are always packed in a protective film.

- Luminaires that are planned to be used when installing a slatted ceiling must be purchased together with slatted panels.

In order to navigate the abundance of the products offered, it will be useful to know the leading manufacturers of slatted panels:

- The firm "HUNTER DOUGLAS" (Holland) produces a wide range of metal rails of different colors and sizes.

- PROMETAL (Italy) is a respected manufacturer of high quality slatted panels.

- Russian manufacturer "ALBES". Competitive cost while maintaining the excellent quality of aluminum slatted panels is an advantageous feature of the products of this manufacturer.

In conclusion, you can try to bring the disadvantages of slatted suspended ceilings. But let's be adequate: isn't a slight decrease in the height of the ceiling due to the suspended structure and some relative high cost (compared, for example, with plastic panels) more than offset by the unique appearance of the new ceiling, individual design nuances, not to mention its purely technical advantages?

Let your ceiling be the best version of itself - choose slatted panels.