By investing a lot of money in the installation of plastic windows, people expect to seriously increase the comfort level of their apartment. They carefully study the model range, compare the advantages of profiles used in various designs. But all the advantages of PVC windows can be crossed out by mistakes made during their installation. Most of the claims against companies that install PVC windows are made specifically to the quality of the work of the installers. Plastic windows will last a long time and will not lose their qualities if the installers are guided during installation on GOST, and not on purely personal considerations.

What document regulates the process of installing plastic windows?

In March 2003, GOST 30971–2002 was developed and adopted, which ensured the formalization of installation work. The adoption of this document was facilitated by the state program to increase energy efficiency and energy saving.

But not all companies in their work are guided by the provisions of this document. The high requirements imposed by GOST 30971–2002 increase the costs of firms operating in the PVC window market. Therefore, small companies often ignore its provisions, saving on the quality of services provided. This is facilitated by the low professional level of employees of such enterprises.

To the average layman, familiarity with this document will bring tangible benefits. Knowing the rules for installing PVC windows, he will be able to control the entire installation process, and after its completion he will be able to receive detailed technical documentation on the work performed and full warranty service.

What documents are issued during installation?

The owner of new PVC windows should have two documents on hand, one of them - before installation, the other - after the completion of work on replacing window blocks.

- A contract is drawn up in advance, which must contain the necessary calculations for the thermophysical properties of the window installed in a specific wall opening. Based on them, the best installation scheme is selected, which is agreed with the customer.

- After the installation of plastic windows is completed, the technical passport of the installation with the installation scheme is handed over to the customer. It should also list the materials used to seal the field joints and the contractor's warranty obligations.

Room preparation

The process of replacing window blocks is accompanied by the release of a large amount of dust. Therefore, before starting work, it is necessary to free the room as much as possible from furniture and household appliances. What cannot be taken out, as well as the walls and floor, must be covered with film or newspapers to prevent contamination.

Tip: you can use an old bedspread as a kind of screen by pulling it wet at a distance of two to three meters from the window opening. It will take on a significant proportion of the dust, and later it can simply be thrown away.

Preparation of window openings

Before installing plastic windows, it is necessary to remove the old frames from the wall opening. To do this, installers use a puncher, an electric jigsaw and a crowbar. GOST 30971–2002 requires the contractor to pre-prepare openings for window blocks: fully clean the surface and eliminate existing defects. Also, GOST requires the presence of false quarters at the openings into which plastic windows are installed. They are necessary for the formation of a three-layer assembly seam.

Reference: quarters are protrusions designed to protect the seams from external adverse effects. In their absence, so-called false quarters are created, usually made from metal or plastic corners.

Three layers of mounting seam when installing PVC windows

Regardless of the materials chosen by the installers of plastic window units, the rule is that any installation seam must contain three layers.

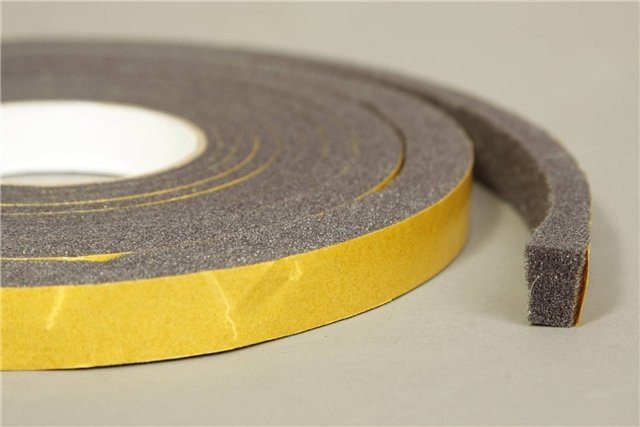

- The outer layer must protect the rest of the joint materials from moisture. At the same time, it must allow air to pass through to ventilate the insulation. In most cases, pre-compressed sealing tapes (PSUL) are used to form this layer. Before mounting the window frame in the opening, it is pasted over with these tapes. In the future, they expand and close all the gaps between the box and the wall opening. PSUL are ideal for installation work in new homes, where the geometry of the wall openings is not broken. But if the slopes are uneven or plastered, then certain problems may arise when using such a protective material. According to GOST 30971–2002, when installing PVC window blocks, it is allowed to use various types of sealants, for example, silicone.

Important! The sealant must not be applied directly to the mounting foam and must cover only two sides of the joint.

- The middle layer provides thermal insulation. To fill it, polyurethane foam is used, which is selected based on the climate of the area. It is necessary to fill the seam with it in such a way that later you do not have to cut off the excess from the side of the street: such manipulations make it easier for moisture to enter this layer. If there is a need to apply several layers of foam, then the time interval between the formation of each of them should be maintained in accordance with the rules defined by GOST.

- The inner layer protects the insulation from moisture from the room. It consists of vapor barrier tapes. It is necessary to follow the correct calculation of the overlap of such a tape, which should be at least half the width of the material. Wrinkling should also be avoided when laying the tape. Most often, installers use tape with a protective coating applied on the inside, but if window openings are plastered, then it is better to choose tape with an external coating.

How should the window block be attached

When installing the window block, it is necessary to ensure a sufficient gap between the window profile and the wall opening. The gap will not only allow you to perform all work on filling the seams with high quality, but also compensates for possible changes in the geometry of the window caused by temperature fluctuations.

There are rules for the location of fasteners:

- for white PVC window boxes, the maximum distance between them is no more than 700 mm;

- if the window box is colored, then this distance is reduced to 600 mm;

- fastening elements must be located at a distance of at least 150 mm from corners and joints;

- wooden blocks used for pre-fixing the window must be pre-treated with antiseptic materials, their height must be at least 20 mm;

- in most cases, window frames are fastened with dowels and anchors, which are driven into the wall to a depth of 40 mm.

Important! All fasteners must have an anti-corrosion coating, usually stainless or chrome steel.

What else should the contractor do after installing the window

Not knowing the GOST standards, many customers believe that the contractor's duties end after the installation of the window block is completed. And companies that install PVC windows take advantage of this, making their work easier. In fact, the contractor is required to additionally perform the following actions:

- Check the operation of the window sashes, if necessary, adjust them and eliminate possible distortions.

- Check the operation of all fittings installed on the window.

- Remove protective film.

- Collect and take out the debris generated during the removal of old window frames and the installation of a plastic window block.

The importance of proper window installation

Proper installation of a plastic window will avoid the typical problems that arise from improper installation. These include:

- Insufficient thermal insulation of the structure, the formation of so-called cold bridges.

- The appearance of mold and fungus due to poor waterproofing or insufficient vapor permeability of the installation seam.

- The appearance of distortions of the sashes or the window box, caused by an insufficient thermal gap or improper placement of fasteners.

Subject to all the rules prescribed in GOST, a plastic window can last up to 20 years and still not lose its characteristics.