Sprayed insulation composition and features

Spray foam is supplied in the form of two components - A and B:

- Substance A - is intended to support the reaction of component B. It includes: foaming components, foam regulators, catalysts, polyesters, flame retardants. Supplied as a brown or yellow liquid.

- Substance B is an isocyanate, which begins to polymerize upon contact with air. It is a brown liquid with a pungent odor.

When substances A and B are mixed, a chemical reaction begins, accompanied by the release of a large volume of carbon dioxide, foaming the material. After solidification in air, a layer of insulation is formed with a large number of closed small cells that contain carbon dioxide. Spraying the mixture is carried out using special equipment.

Having all the advantages of polyurethane, PPU provides:

- Easy application of the mixture on any surface in a continuous sealed layer without the formation of seams. Thus, you do not have to worry about possible cold bridges.

- Possessing hydrophobicity, it perfectly protects against corrosion any structures, including metal ones (they do not even need to be painted).

- Excellent adhesion allows the material to be applied to any surface, even smooth (cleaned of debris, dust and grease stains).

- After polymerization, polyurethane foam acquires high strength, which allows its use, among other things, for the insulation of basement floors and foundations.

- Although polyurethane foam is not a non-flammable substance, the addition of flame retardants to component A made it possible to assign it a G2 fire certificate (poorly flammable self-extinguishing materials).

But, having decided to use polyurethane foam for thermal insulation at home, you need to know and take into account its shortcomings.

The disadvantages include:

- The need to use special equipment for work.

- Low resistance to UV rays, dictating the need to protect the insulation layer.

- When applying the material, a large amount of carbon dioxide is released, which is harmful to humans, so during work you will have to use a respirator and skin protection.

- Relatively high cost of thermal insulation.

- Due to the large number of closed pores, the material practically does not "breathe", so natural air filtration through the structures of the house will become impossible.

Description

Polynor sprayed polyurethane insulation is a completely new class of materials designed for insulation and sound insulation. It is very reliable, environmentally friendly, easy to use - it is often used to process areas of complex shape and the most inaccessible places. Packaging in cylinders allows you to purchase exactly as much insulation as you need for the required work. The speed of insulation of one square meter is 2 minutes by one person

Advantages:

- seamless insulation, no cold bridges;

- surface leveling is not required;

- 100% adhesion to all building materials;

- adjustable thickness of the insulation layer from 1.5 cm;

- surface protection against fungus and mold;

- maximum penetration into joints and cracks;

- no weighting of the supporting structure;

- does not pass or absorb moisture.

GZhU installation and foam generator

- The first thing we will consider in the video instructions is a schematic diagram of the technology and drawings of equipment for the production of carbamide foam (penoizol and its analogues).

- I will tell you about important technical nuances, mistakes or misunderstandings of unscrupulous manufacturers, including those who can call their urea foam penoizol. What absolutely can not save.

- From many years of experience, I will demonstrate the device of a simple, but reliable and efficient foam generator in operation, visual photos, videos, diagrams, drawings and instructions will help you easily make such an apparatus with your own hands. My foam generator, if necessary, is easy and quick to maintain and clean. If it is clogged, you can disassemble and assemble it in 10 minutes!

- How to make simple and reliable dispensers for accurate solution delivery and quick adjustment of the amount of resin for the production of foam of different densities and characteristics.

- Required installation maintenance.

Stages of foam insulation sheet production technology

- Preparation of forms.

- Pouring liquid penoizol.

- Exposure 2-3 hours.

- Dismantling of forms and exposure of "cubes" of material within 3 hours.

- Primary cutting into sheets.

- Drying.

- Finishing, packaging, warehousing, shipping.

It would seem that everything is simple and clear. Nevertheless, the production of sheet penoizol is a more complex technology than pouring at the facility, requiring careful observance of the consumption of components, temperature and drying conditions.

Approximate consumption rate of penoizol components for filling out the form, volume 1 m3

- Urea-formaldehyde resin - 22 kg.

- Foaming agent - 0.2 kg.

- Curing catalyst (orthophosphoric acid) - 0.3 kg.

- Tap or process water - empirically.

The first thing you need to start producing sheet penoizol is a suitable room. If industrial production volumes are planned, a room with an area of 250-500m2 will be required, which should accommodate the following production areas:

- Warehouse of raw materials.

- Mold filling area.

- Drying area.

- Section of preliminary and finishing cutting and packing.

- Finished goods warehouse.

Features of the production process

To implement the technological process (filling, disassembling molds, cutting, stacking on racks, cutting to size, packaging, etc.), a staff of three people will be required.

In addition, the production room must be "warm". Special requirements for the temperature regime are imposed on the drying section. So, at the pouring site, the temperature should be maintained at least 15 degrees Celsius, and at the drying site at least 20-28 degrees Celsius.

Since the drying process lasts for three days, the temperature in the drying compartment should rise gradually, starting from 20 degrees on the first day and reaching 28 degrees on the last day. There must be effective supply and exhaust ventilation in the pouring and drying areas.

Ready-made penoizol slabs, when drying on racks, should not have “closed” zones. That is, air access is provided from all sides of the plates. High-quality drying is necessary so that subsequently shrinkage does not appear, and the smell of formaldehyde is completely weathered. Its duration depends on the air temperature in the room, relative humidity, the degree of air exchange and the amount of water used for the production of penoizol.

Forms for pouring slabs are four walls of galvanized steel, connected to each other by means of quick-release locks. The bottom of the mold is a pallet on which a sheet of galvanized steel is laid, after which the walls are installed on it. Inside the form is not lubricated with anything.

Penoizol has one drawback - shrinkage is possible during intensive drying, therefore, initially the "cube" of the finished material is cut into sheets of larger sizes than required. And after the final drying, each sheet is passed through a special cutter, adjusted “to size”, which removes “tolerances” (surpluses) with an accuracy of one millimeter.

Thus, approximately 7 sheets with dimensions of 1200x600x100 millimeters - 0.5 m3 of finished insulation are obtained from the initial block, which are packed in thermal film in packs of 7 pieces.

Trimmings and other residues formed during the cutting and production of foam insulation sheets are crushed into crumbs, packaged in bags and used for heat-insulating backfill. That is, it is possible to characterize the production of sheet penoizol. How completely wasteless.

It should be noted that if liquid penoizol can be used, including in the repair and reconstruction of buildings and structures, then sheet material is used mainly in the construction of new buildings.

Polyurethane foam its properties and scope

In the production of the material at the dawn of its origin, two substances were used: polyisocyanate and polyol. Depending on the proportion in which these components are used, and the rate of reaction, the technical characteristics of the final material can vary quite a lot.

There are two types of PPU:

- Perlon U - flexible, elastic, but poorly resistant to tearing forces (foam rubber);

- Igamid U is hard, strong, but cannot withstand bending loads.

Modern polyurethane foam is a material with a cellular structure, in which 85-97% of the volume is occupied by pores filled with gas or air.

The very substance that forms these pores is only 3-15% of the total volume of the insulation. Therefore, PPU is a very light material.

Varieties

Thermal insulation of houses is carried out using different types:

1. Liquid. It is the most common, manufactured directly at the construction site.

2. Sheet penoizol. The basis for it is a liquid semi-finished product, poured into a regular cubic form. After hardening, the array is cut into sheets of the required thickness. Cutting is carried out manually (string) or on machines. Then the sheets are dried, finishing mechanical processing is performed.

3. Granular (crumb, thermal wool). For its manufacture, polymerized penoizol is crushed to a fraction of 10-15 mm - this size allows you to maintain elasticity.

Outwardly similar to expanded polystyrene, it is a white material with a fine-meshed structure. But the technical characteristics of the two polymers differ significantly - this is clearly shown in the table.

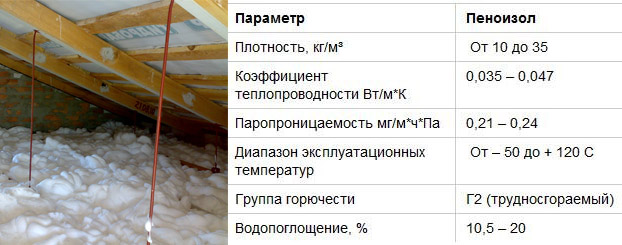

| Parameter, unit of measure | Penoizol | Styrofoam |

| Density, kg/m3 | 6-35 | 10-50 |

| Thermal conductivity, W/(m*K) | 0,012-0,041 | 0,037-0,042 |

| Operating temperature limits, °C | -50/+120 | -50/+80 |

| Compressive strength, kg/cm2 (with linear deformation of 10%) | 0,07-0,5 | 0,14-0,75 |

| Water absorption per day,% by weight | 5,5-10 | up to 2.0 |

| Shrinkage, % (liquid penoizol) | up to 4 | |

| Flammability group | G1-G2 | G1- G4 |

Types of penoizol

The material is supplied in several commercial forms:

Liquid

Represents the solution ready for drawing on the warmed surfaces. The shelf life of the solution is limited. Before purchasing, you should make sure that the product is suitable and the packaging is tight.

Granulated

Granules are supplied in bags. Their shelf life is practically unlimited, such raw materials can be stocked up for future use. Before applying, you will have to spend time diluting the solution and bringing it to the desired consistency.

Granular penoizol

Granular penoizol

Sheet

This is a heater, foamed and molded into molds at the factory. The sheets have a standard size for insulation of 1200 * 600 mm and are convenient for laying in guides or end-to-end on horizontal surfaces. Also available in rolls of various widths.

The main consumers of polyurethane foam are

- construction industry - about 50%;

- instrumentation and refrigeration industry - 20%;

- space, rocket, automotive, furniture and other industries - the remaining 30%.

The material has become very popular as a thermal insulation for main pipelines of large diameter and length. In this area, it not only reliably protects pipes, but is rarely subjected to vandal destruction - because it is simply impossible to steal it for reuse.In the medical industry, the material is used for the production of orthopedic shoes and prostheses.

Material Features

Penoizol was developed at the end of the 20th century as a modern alternative to foamed polyurethane, a proven insulation that had a number of operational disadvantages. The main difference between the physicochemical properties of penoizol is that it retains its elasticity after foaming. This greatly increases its strength and useful life when insulating and soundproofing loaded structures, such as floors and ceilings. There are other features of the material:

- resistance to temperature and humidity changes;

- immunity to biological threats: microbes, mold, insects, rodents;

- fine porous structure contributes to high vapor permeability;

- resistance to fire and high temperatures;

- environmental friendliness: does not emit harmful substances even when smoldering.

The elasticity of the material facilitates its installation in sheet form. When sprayed, the high adhesion and penetrating ability of the solution makes it possible to insulate both large surfaces and hidden cavities and hard-to-reach places.

Separately, it is worth noting the excellent sound insulation. Penoizol copes with both airborne noise and sounds transmitted through building structures.

The production of penoizol does not require special technical knowledge and especially sophisticated equipment and can be set up by hand.

Pros and cons

Outwardly, penoizol is similar to marshmallow cookies. Pleasant to the touch, light porous white material retains elasticity and strength for several decades. Construction experts note the following advantages of the material:

- Low thermal conductivity. This indicator brings penoizol to a number of the best heaters on the market.

- High adhesion to most building materials and excellent foam penetration. These factors make it easier to apply insulation both to large areas and to various hard-to-reach places, including hidden cavities in walls and roofs. The material fits well on horizontal, vertical and inclined surfaces.

- Estimated service life is 55-75 years. The result was obtained by calculations and large-scale tests, but the analysis of control samples that have served for 10-20 years confirms it.

- High vapor permeability. This property allows the insulation to "breathe", removing excess moisture from its volume. This prevents the accumulation of moisture - a breeding ground for mold and pathogens. At the same time, a comfortable microclimate is maintained in the premises.

- Unattractive to pests: insects and rodents. Penoizol becomes a natural barrier to their spread.

- Resistant to open fire and high temperature. When heated, penoizol does not emit toxic substances, unlike other foamed materials.

- Resistant to solvents and other chemically active substances.

Inherent insulation and a number of disadvantages.

- Over time, prone to bulk shrinkage;

- May produce an unpleasant odor upon application and drying. This indicates the low quality of the solvents and binders used, but does not affect the final quality of the insulation. Just for the time of work on thermal insulation, the dwelling will have to be left.

It is better to pay attention to the smell before buying a spray composition.

Varieties of sprayed polyurethane foam

Polyurethane foam insulation, which is applied by spraying, is divided into two categories: industrial - sold in barrels and used by specialists to insulate large structures and surfaces, and in 1 liter cylinders, which is intended for independent use. Industrial PPU is represented by several brands of different manufacturers.

The most famous are:

- Sealection 500 is an American-made material. It has an open structure and fire safety class G2.

- "Ecothermix" - produced on the basis of vegetable oils, contains a minimum amount of harmful substances. There are two varieties of it on sale: grade 300 - with a closed structure to protect external surfaces from the cold, and grade 600 - with an open structure for interior work.

- Healtok Soy 200 is a closed structure insulation made from soybean oil and polymer waste. Perfectly adheres to any surfaces, densely fills all cracks and pores.

PPU in cylinders is made from polymer components. The cylinder has a spray tip or an adapter for use with a mounting gun. Currently, this heater is represented on the market by two brands - Polynor and TEPLIS. The material in its appearance resembles a polyurethane foam. After hardening, it forms a fine-meshed coating with low thermal conductivity. One bottle is enough for 1 sq. m of surface when applied with a layer of 40 mm.

Application technology is simple:

- Surfaces must be cleaned of dust and dirt and slightly moistened.

- A nozzle must be screwed onto the balloon.

- Then it is shaken and the nozzle is directed to the right place.

- By pressing the trigger of the gun, the material is sprayed.

Currently, the insulation in cylinders is heavily advertised, but experts do not advise trusting advertising too much.

Although the manufacturers of Polynor claim that its service life is 35 years, it has not yet passed the test of time.

Manufacturers of industrial two-component insulation believe that one-component polyurethane foam in cylinders is practically no different from ordinary polyurethane foam, but it costs several times more. The material has a large number of open pores, therefore it is unsuitable as a hydro and vapor barrier.

Therefore, having decided to insulate your house with high quality, you should not rely on an unprofessional heater. If you wish, you can use a spray can to process small sections of structures or internal partitions, but it is hardly suitable for warming large surfaces.

Scope of application

Penoizol is suitable for insulation and sound insulation of all types of building structures and elements. It is used for items such as:

- floors and ceilings;

- walls, including frame;

- roofs and truss systems;

- ground floors, foundations and blind areas.

Roof foam insulation

Roof foam insulation

Sprayed penoizol is perfect for correcting mistakes made at previous stages of construction. He can isolate the so-called. "cold bridges" through which intense heat leaks from heated rooms occur.

In addition to construction, the material is also popular in the manufacture and thermal insulation of refrigeration equipment - from household models to industrial installations.

Separately, it is worth mentioning the use of penoizol as sound insulation in buildings located near highways or in noisy industries. A 50-mm layer of penoizol allows you to reduce the noise level several times and create more comfortable conditions for your stay.

Penoizol is used both for residential premises and for warming household and outbuildings: garages, baths, sheds for keeping farm animals, cellars.

A somewhat unusual scope of penoizol is fire fighting: foam is used to extinguish chemically active substances and energized installations. The atomized material blocks the access of air and prevents further combustion.

Features of the material used

Liquid foam for warming procedures is an excellent and reliable product. The most popular material is polyurethane foam.

Before you begin the thermal insulation procedure yourself, you must wear specially designed clothing.

After spraying can begin, spraying needs a special tool, spraying should be carried out carefully. The main distinguishing feature of polyurethane foam is rapid hardening.

After that, the material fills the entire space between the rafters or beams, which are located vertically.

Consider a brief description of this rapid product:

- foam for wall insulation stably tolerates high temperatures (about 80 degrees Celsius);

- it is able to pass water;

- has excellent vapor barrier performance;

- the material is strong enough to mechanical damage;

- some liquid heat insulators are able to increase in volume. For example, the heat insulator Corundum.

In addition to wall insulation, liquid polyurethane foam is great for sealing various cracks on the surface. Therefore, with its help, you can easily mount plastic windows.

Also, this insulating material has excellent refractory parameters. The main disadvantage of this product is that it cannot be used in rooms that are not ventilated at all. Under such conditions, it is simply not able to harden.

Do-it-yourself foam insulation with your own hands will allow you to achieve a monolithic coating. On such a surface there will be no seams and joints.

One balloon can hold 700 milliliters of foam. It is used for one square meter of insulated surface, the thickness of which is about four centimeters.

For operation, the foam cylinder must be installed in a specially designed gun for installation. The principle of operation is that you press the trigger of a construction gun, and direct a tight jet of material onto the surface of the wall.

After a day, the product will be able to completely harden.

A tool such as an air gun is used for thermal insulation:

- external walls of the apartment;

- balconies and loggias;

- foundations of the house (foundation);

- various pipes.

Self-installation of the installation

Foamer drawing. (Click to enlarge)

Foamer drawing. (Click to enlarge)

On the websites of manufacturers involved in the manufacture of equipment for the production of penoizol, you can purchase installation drawings and find out the production technology.

By purchasing such a package of documents, you can assemble this device yourself, especially since spare parts are always available.

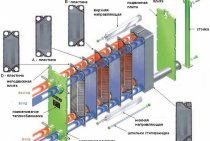

The budget option would be a do-it-yourself design and consisting of:

- gas-liquid installation;

- set of cranes;

- supply hose;

- compressor, for the production of compressed air;

- plastic barrels up to 300 l.

The process of obtaining insulation is based on the principle of foaming solutions with a catalyst and mixing it with carbamide resin. With the help of a pump, the components enter the plant, where they foam under the influence of compressed air.

One of the main components of the system in a gas-liquid installation is a pump, so it is better to purchase a quality pump.

We do not recommend pumps of the type NSh 6 (gear pump) and NSh 10, as they can fail in dosages when supplying one of the components - resin.

There are problems with these pumps also with an electric motor. The declared power may not be enough when supplying the finished product to fill voids.

Please note: when choosing pumps for installation, it is necessary to take into account dosing errors, errors in engine speed instability due to voltage and load.

It is more advantageous to use plunger or vortex pumps. Here it will no longer be possible to make a mistake with the dosage, but if solid particles enter, a violation of the entire work process can occur, from a failure in the dosage to a breakdown of the unit.

Keep in mind: when choosing a plunger or vortex pump, be sure to consult about the material from which the internal parts are made.It is desirable that it be nickel-plated, stainless steel, ceramic or plastic.

It is also desirable to purchase a high-quality plunger pump for foam supply. The foam is generated by a high expansion foam generator at low pressure. At the exit, we get foam with a beautiful fine-meshed structure.

The most effective method by far is double foaming. Penoizol at the exit appears as a dry mass, which makes it possible not to flow out of the filled cavity.

The compressor on the equipment must be set to a certain capacity

Be sure to pay attention to the consumption of resin, it should be no more than 25 kg in order to get a quality product.

In the installation for the production of penoizol, it is necessary to create the optimal ratio of all components for the distribution of insulation throughout the filling volume.

The final product should be white in color and, when pressed, return to its original shape.

As an insulating material with low cost and high insulating properties, penoizol is beneficial for our own production.

Having assembled equipment according to the drawings, you can open your own small business and start earning. With the expansion of the scope of penoizol, its production can be called promising.

Watch the video, which shows in detail the stages of work on the equipment for penoizol with your own hands:

Production of carbamide foam

In the video tutorial, we will discuss the necessary components and raw materials.

The correct recipe for preparing a solution for foam. Because even here there are very important points and mistakes that novice manufacturers or scammers make.

Which carbamide resin and hardener to choose in order to get the highest quality foam. After all, there is a strong odor and secretions that absolutely can not be used. After all, it’s not just that there are various rumors and rumors, after the work of hackers, penoizol is harmful

I remind you, as in any other production, anything, it is important to correctly and accurately follow the technology. Only in this case there will always be positive reviews about penoizol.

The influence of different proportions of components, including compressed air, on the characteristics of liquid foam (penoizol and any other brands of carbamide foam).

Solving possible problems with electricity or unsuitable water on site at the customer.