How to properly flush the heat exchanger of a double-circuit boiler

Mikhail, Yekaterinburg asks a question:

Good day! 3 years ago we put ourselves a double-circuit boiler. This is a very convenient device, since the apartment is now warm, and there is always hot water. At the time of purchase, I was told in the store that it is necessary to clean the boiler once a year if the tap water is very hard. To clean, you need to call specialists, but it costs a lot of money. In fact, that's why we didn't clean the unit for so long. Can you tell me how long it takes to clean? And how to flush the heat exchanger of a double-circuit boiler from lime deposits? Thank you very much in advance for your help!

Hello! You should not worry too much, since modern models of double-circuit boilers do not deteriorate at all if they are cleaned every 3 years (even if the water is very hard). The main thing at the same time #8211 is not to start the process until 5 years of use. The fact that the store told you to clean once a year is only partially correct. But this does not make sense, since you will only spend money once again. The ideal option #8211 is to perform such work once every 3 years, subject to constant use of the boiler.

It is necessary to understand how to flush the heat exchanger under a double-circuit boiler correctly. There are several cleaning methods. The most effective is standard flushing using a special liquid that is able to peel off limescale from the inner walls of this installation.

Before you get to work, you need to turn everything off. First, turn on the tap at the bottom of the boiler, which ensures the flow of cold water into it. Next, you need to drop the pressure to zero. If there is no such relief valve, skip this step. Now without fail disconnect the boiler from gas and electricity. This must be done to ensure your safety. If possible, immediately drain the water from the boiler.

Now you need to remove the casing from the boiler. To do this, at the bottom you need to unscrew the four nuts. Please note that water may flow from below. Therefore, it is recommended to do this over a large basin or even take the boiler outside, removing it from the eyelets on the wall before that. Slowly unscrew the heat exchanger so as not to damage the parts.

Next, the heat exchangers are flushed. You can do this with ordinary running water. You will see for yourself when the water after washing will become cleaner. Absolute transparency will indicate that the main part of the washing was successful. Now you can rinse everything with boiled cold water.

Now it's time to use the cleanser. A special liquid for flushing circuits is purchased in advance, which eliminates deposits on parts. Such a liquid is poured into two basins, then contours are placed in these basins so that their entire surface is covered with the agent. Leave it all for 15-20 minutes. But before that, carefully read the instructions. After all, some funds may require more or, conversely, less time for acidification.

After that, the contours are pulled out of the containers. Now, instead of liquid, it is necessary to pour boiling water with washing powder diluted in it into the basins. The amount of powder must be sufficient. Place the heat exchangers in this solution for 3-5 minutes.

Now you just have to rinse the contours several times so that there are no traces of concentrate and powder left.

Flushing of a double-circuit boiler can be considered completed. You now have to install the heat exchanger in place. To do this, you must first install new rubber gaskets, even if the old ones are still quite suitable.

Then everything needs to be returned to its place, trying to tighten the nuts as tightly as possible. It is good to use a wrench for this. When everything is assembled, hang the cauldron back on the hooks. Then you can connect the installation to gas, electricity and water. You have seen that it is not so difficult to understand everything. And if there are difficulties during assembly or disassembly of the circuits, you need to refer to the instructions. There is a diagram where everything is shown in detail, so it is almost impossible to get confused.

How to clean

Many ordinary people who decide to flush the heat exchanger with their own hands, as a rule, ask two questions. How to clean this device? How to clean it? To begin with, we will tell you what chemicals are used to flush the heat exchanger.

Cleaning products

The modern market for household chemicals is very well saturated with all kinds of cleaning products for a gas boiler.

Therefore, you need to be very careful when choosing a washing agent. First of all, you need to consider the following factors:

- the degree of contamination of the heat exchanger;

- how the reagent will affect the material from which the heat exchanger is made.

At home, it is most advisable to use the following chemicals to flush this boiler element:

- citric acid, which is a fairly effective remedy for removing scale;

- sulfamic and adipic acids are practical for regular flushing of the heat exchanger, when pollution is not so significant;

- hydrochloric acid is designed to remove sufficiently strong scale, but when using it, it is worth considering the properties of the heat exchanger material;

- gels that dissolve in water - they are not as aggressive as acid reagents, but no less effective.

An important point: you must follow all safety measures when working with chemicals.

Washing methods

To clean this structural element of the boiler from scale with your own hands, it is best to use the following two methods:

The essence of the mechanical method is as follows:

- the gas boiler is disconnected from the gas supply and power supply;

- the heat exchanger is disconnected from all lines and carefully removed;

- the device is soaked for 3–7 hours (depending on the degree of contamination) in a container with an acid solution of low concentration;

- the heat exchanger is thoroughly washed with running water and installed in place.

Tip: when rinsing with running water, the appliance can be gently tapped with a mallet at the same time to increase the cleaning effect.

The procedure for this is as follows:

- two nozzles of the device are disconnected from the common boiler system;

- a booster hose is connected to one of them, through which the flushing fluid will be supplied;

- we also connect a hose to the second branch pipe, from which the reagent will exit to the booster - thus, the flushing agent will circulate between the heat exchanger and the booster;

- after cleaning, the spent chemical solution is drained and then washed well with water.

Expert note: to successfully descale the heat exchanger with a booster, flushing should be done several times.

And in conclusion, I would like to note that we really indicated two effective ways to clean a gas boiler from pollution. We hope that our recommendations will help you do your own washing of the heat exchanger at home.

Watch a video in which an experienced user clearly explains the features of flushing a gas boiler heat exchanger:

How to clean a gas boiler: a procedure for each node and a do-it-yourself cleaning video

Flushing the heating boiler from scale: features of the procedure and do-it-yourself video

Replacing a gas boiler in a private house: documents, rules and procedures

Disassembly and removal of soot

For efficient operation of the equipment, it is necessary to clean the gas column. The deposits formed on the walls can disrupt the smooth operation of the device, so you do not have to wait for a complete failure of the equipment, you should periodically carry out preventive cleaning.

Before starting dismantling, it is necessary to cut off access to gas and water. Do-it-yourself cleaning of the geyser begins with removing the boiler doors and disconnecting the auto-ignition wire. Then the thermocouple, piezoelectric element and burner tube are removed

Carefully remove the nozzle and the burner itself

The thermometer sleeve, the boiler cover, and the flue are removed. The gas column is cleaned using a brush and brushes, which clean all internal and external elements. The nozzle hole is cleaned with a needle with a smaller diameter in order to avoid an increase in the hole and a violation of the combustion regime. The internal channels of the heat exchanger are blown with a vacuum cleaner and wiped with a damp cloth.

At the same time, you can carry out minor repairs to the heat exchanger with your own hands: replace the gasket under the pilot burner, check the thermocouple, which is prone to breakage due to the specifics of operation, and so on. Such work does not require large investments, but maintains the performance of the boiler at a high level, and the thermocouple device is quite simple, and replacing the element is not difficult.

The structure of the gas boiler

Assembly is carried out in reverse order. When connecting the piezoelectric element, it is recommended not to use a tool in order to avoid damage to the ceramic base, it is better to tighten it by hand.

When installing, it is necessary to check the thermocouple on the gas boiler, you need to know that the end of the conductors must be at the level of the place where the flame appears.

Classification

Currently, manufacturers manufacture heat exchangers from:

Steel heat exchanger

This is the most common option, especially when it comes to devices manufactured at domestic factories. It's all about the availability of steel and its easy processing. Hence the low cost of this device. We add that steel heat exchangers have excellent ductility and high strength when exposed to mechanical loads.

The ductility of the material plays one of the main roles when the metal is subjected to heat. In the zone of direct action of the burner, so-called thermal stresses are formed inside the metal, which can lead to the appearance of cracks. It is plasticity that prevents this from happening.

But steel heat exchangers have their drawbacks.

- First, steel is subject to metal corrosion processes. This shortens the service life. By the way, both the outer side of the device and the inner one begin to corrode.

- Secondly, in order to achieve a high degree of inertia, manufacturers increase the thickness of the heat exchanger wall and the size of its internal cavities. And this, in turn, increases its weight and dimensions, plus the fuel consumption for heating a large amount of coolant.

What are the features of combined gas-firewood heating boilers

But the cast-iron heat exchanger practically does not corrode when in contact with water. Hence its longevity. But this metal makes quite stringent requirements for the operation of gas equipment. The thing is that the boundary between the highly heated and warm part of the heat exchanger is a zone of increased danger. It is in this place that the metal usually bursts.

To avoid this, it is necessary to flush the gas boiler heat exchanger more often. Thus, getting rid of deposits in the internal cavities of the device. There are zones inside the device where hot and warm water meet. This is the place where the coolant enters from the return circuit of the heating system. This is where the so-called low-temperature corrosion occurs.Today, this problem is solved by installing a three-way mixing valve. It is installed on the return line near the heat exchanger. The valve connects the heat exchanger, return and supply circuit. That is, inside there is a mixing of hot water and cooled. The coolant enters the heat exchanger at an acceptable temperature.

Attention! In this regard, imported gas boilers with a cast-iron heat exchanger are very vulnerable. The cast iron is cast using the latest technology, which allows the use of a thin-walled structure.

But they are not adapted to Russian conditions.

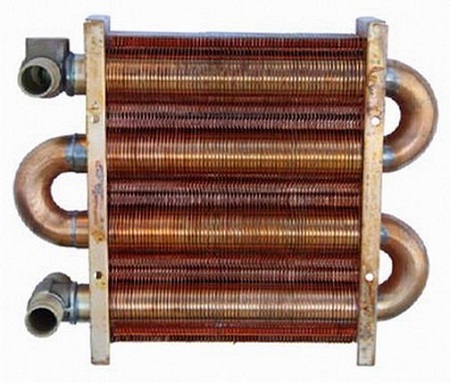

The advantages of a copper heat exchanger are many:

- Small specific weight.

- Small capacity of the device.

- Compact dimensions.

- High resistance to corrosion processes.

- Heating requires less fuel.

There are also disadvantages:

- High price.

- Low reliability when heating the element.

The last drawback is being solved today. Manufacturers, using additional functional devices, seek to reduce the effect of thermal energy on the metal. For example, by reducing the volume of internal cavities, it is possible to reduce the gas supply and thereby reduce the size of the flame.

How to clean interior surfaces

Flushing of the inner surface of a plate, fire-tube or bithermic heat exchanger is possible only with the help of special equipment.

- High pressure pump - hydrodynamic flushing. Used to remove small deposits. Advantages - the speed of the procedure and the possibility of cleaning without removing the heat exchanger.

- Booster (acid-resistant pump) - acid (chemical) flushing. Removes even old scale. Benefits - removes scale that cannot be removed by other methods. Disadvantages - with the wrong selection of reagents (acids and neutralizers), it reduces the service life of the heat exchanger.

- Complex "Streamer" for electric discharge cleaning. Used to remove scale of any strength. Advantages - the metal of the heat exchanger is not destroyed, a high degree of purification is provided. Disadvantages - noise and duration of the procedure.

Of all the methods listed at home, only chemical cleaning is possible, since the factory booster can be replaced with a low-pressure pump. The rest of the equipment is both expensive and bulky, so such washing of boilers can only be done by service centers.

Regular cleaning of the boiler heat exchangers guarantees its efficient operation.

Thanks to the information presented here, you can independently, without the involvement of specialists, carry out preventive maintenance of a gas boiler, single or double-circuit. The work performed by you in accordance with the recommendations below will be of no less quality than the preventive maintenance carried out by qualified personnel of service companies.

In addition, you can save a considerable amount, since the cost of specialist services can reach several hundred US dollars. In addition, waiting for the arrival of the master for several days, or even weeks, may not suit every owner of an individual heating system, especially shortly before the start of the heating season.

Fluids for flushing heat exchangers

In conclusion, consider the question of how to flush the heat exchanger of a gas boiler

Despite the abundance of recommendations in various sources, some care must be taken in choosing a cleaning agent.

Many experts recommend using hydrochloric acid for flushing. It removes scale really well, but it is a rather aggressive compound that can break the protective coating of the inner surface of the heat exchanger.

In addition, there is evidence that washing with hydrochloric acid can cause metal brittleness.

Less dangerous for the heat exchanger material is citric acid.It perfectly copes with all types of deposits, as well as special reagents: DETEX, Cillit, Sanaks and others.

Timely and proper care of the elements of the heating system will increase its service life and reduce the cost of maintaining performance. Cleaning the heat exchanger, as one of the most important operations performed in the maintenance of boilers, will make the most significant contribution to this process.

Depending on the design of the boiler, the following operations must be performed:

- Using a long screwdriver, remove the front cover of the unit, the protective cover and the combustion chamber baffles.

- Disconnect the interfering wires of flow sensors, temperature sensors, etc., as well as pressure pipelines (in order not to forget how they are connected, you can photograph the internal filling of the unit).

- Remove fan and exhaust deflector.

- The plate heat exchanger itself is similar to the radiator of an automobile stove and is mounted on latches.

- When removing the device, avoid sudden movements and mechanical impact - it is very easy to damage the heat exchanger.

- When disconnecting copper pipes from the radiator, be sure to hold the nuts located at the base of the device with a second wrench, otherwise the outlet pipes of the device may be damaged. After cleaning the heat exchanger, install it in the reverse order.

Cleaning is needed in the following cases:

- The calculated indicators of the device differ significantly from those stated in the passport - the heat exchanger consumes more heat, but at the same time works with less efficiency.

- The deadline for the scheduled replacement of the rubber seals of the heat exchanger has come.

- Such a dense build-up of dirt, scale, and scale has formed on the heat exchanger plates that it can only be removed mechanically.

Based on my own experience, I can say: before choosing a method for flushing a heat exchanger, it is necessary to take into account all its technical characteristics, analyze the degree of contamination, the intensity of work in order to stop at an option that will allow you to put the heat exchanger in order as carefully as possible without causing damage to either the plates or seals with chemicals .

Chemical

In this case, water is completely drained from the heating system so that the concentration of the reagents used does not decrease. Then a do-it-yourself booster is connected to the boiler for flushing the heat exchanger, a special apparatus equipped with a pump to ensure constant circulation of the solution.

Dry powder mixtures containing sulfamic acid are used to clean the element. Reagents are able to destroy carbonate, calcium and iron oxide deposits, they effectively fight scale, limescale, rust. Powders are diluted with water at a temperature of 10–60°C, the solution is run through a heat exchanger for several hours. The composition of the reagents does not destroy the metal and material of the sealing elements.

Chemical flushing of heat exchangers allows you to clean such hard-to-reach places of devices that cannot be reached without disassembling the unit, or that cannot be manually cleaned

It is possible to flush the device with hydrochloric acid solution, but this must be done with caution, it is quite aggressive, and toxic waste is difficult to dispose of.

A good effect is given by flushing the gas boiler heat exchanger with citric acid, it acts more sparingly than hydrochloric acid. After washing, a neutralizing solution is poured into the system.

To completely remove the sediment products, the fluid for washing the heat exchangers of gas boilers must circulate in the system all the time, stopping and stagnation will lead to clogging of the pipes with fallen and compressed scale particles.

Heat exchanger for gas boiler

It is not difficult to guess that the quality of heating in the future depends to a large extent on the boiler.A cheap boiler can quickly require repairs: cleaning pipes from limescale or replacing components.

In addition, gas heating is quite dangerous, a malfunction in the system can cause an emergency in the apartment. Unfortunately, it is the heat exchanger that most often causes malfunctions in the boiler.

There are three types of heat exchanger for a gas boiler:

In primary heat exchangers, heat transfer occurs from gas to liquid. It is a copper pipe, bent like a coil in one plane. The surface of the pipe is covered with copper plates.

The power of such a heat exchanger is determined by the length of this pipe and the number of its bends. At best, the design is covered with an anti-corrosion coating that protects the system from the damaging effects of hot water.

However, the protective layer does not save the heat exchanger from precipitation in the form of dirt, soot, salt and other products. They settle on the surface of the element and make it difficult to work.

The more dirt has settled on the surface of the heat exchanger, the worse its work, and the sooner the boiler will fail. In this case, even at maximum load, the radiators will remain barely warm.

In secondary heat exchangers, heat is transferred from liquid to liquid. This design is made of thin stainless steel plates.

Such a heat exchanger is much more reliable. The heat exchange area is much larger here, and the rate of heat exchange and heat transfer is much higher.

Due to this, salts and dirt do not have time to settle on the surface of the components, thereby slowing down its wear.

Accordingly, the more steel plates in the design of the heat exchanger, the higher its power and efficiency in performing the task.

Finally, combined heat exchangers are the most perfect in their structure. They combine in their design the process of transferring heat from gas to coolant, and from there to water in batteries.

By structure, such heat exchangers are a pipe on which copper fins are soldered. The pipe itself is double - the inner one is for water, and the outer one is for the coolant.

The cost of the boiler, where there is a combined heat exchanger, is much lower. This is because the need for additional hydraulic units is simply eliminated.

However, such a heat exchanger may suffer from the salts contained in the water. They quickly settle on its surface, making further successful operation of the system impossible.

When choosing solid fuel boilers or gas heating boilers, you should not pay attention only to their appearance. This is the last thing to think about when buying.

It is optimal if you analyze the water that will be used for heating before buying in order to make the right choice of the boiler and its components.

How to clean the fire tube heat exchanger of a single-circuit boiler

Cleaning floor-standing boilers with a fire-tube heat exchanger is different from a similar procedure for attachments. Here, for the procedure, the heat exchanger is not removed, but only access to it is provided.

To perform the work you will need the following tools:

- wrenches;

- metal brush-ruff;

- manual brush for metal;

- screwdriver;

- brush made of natural pile or nylon.

The first mandatory action is to turn off the gas supply valve. Next, you need to perform three stages of work - providing access to the heat exchanger, cleaning parts, assembling the boiler. The disassembly / assembly steps depend on the specific model. How to clean the boilers of the MAYAK model - 12 KS, you can see in detail in the video.

How to clean the heat exchanger

The heat exchanger is cleaned according to end of the heating season. To carry out the work, it is enough to have a standard set of tools available.Before starting work, it is necessary to disconnect the boiler unit from the gas network (main or local) and electricity.

Consider, how to clean a floor standing gas boiler :

- first of all, the burner is dismantled;

- it is required to disconnect all wires from the gas valve;

- a thermocouple is removed from the combustion chamber, which is connected to the gas valve by a capillary tube;

- the fuel supply pipe is disconnected;

- the bolts or nuts (4 pcs) are unscrewed, fixing the stove with the burner, the assembly assembly is taken out.

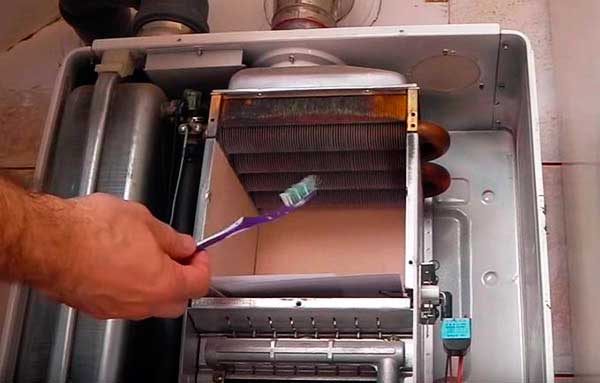

It is convenient to clean the burner of a gas boiler with an old toothbrush. Soot must also be removed from the flame control sensor, igniter, piezoelectric device for automatic ignition.

To get to the boiler heat exchanger, remove the top cover of the unit, disconnect the draft sensor and the chimney, remove the insulation, dismantle the casing fasteners and the casing itself. Having gained access to the heat exchanger, it is necessary to remove the turbulators from it.

A soft metal brush is suitable for cleaning the turbulators, and the heat exchanger itself is freed from soot deposits with a miniature scraper made of thin metal. A brush with a long handle is also used. First of all, the smoke pipes are cleaned and swept, then the soot that has fallen on the bottom should be removed.

Cleaning the wall-mounted boiler is done with a toothbrush

Cleaning the wall-mounted heat generator. After turning off the gas supply, it is necessary to dismantle the front panel of the boiler. Then the front cover is unscrewed, which closes the combustion chamber. It is recommended to cover the nozzles with a sheet of thick paper so that the burner does not become clogged with falling soot. Do-it-yourself cleaning of the heat exchanger of a double-circuit boiler is carried out using an old toothbrush or a brush with metal bristles. After the cleaning is completed, it is necessary to sweep the heat exchanger with a brush and carefully remove the paper with the collected soot. How the procedure is performed, see the video below.

Flushing of a single-circuit and double-circuit gas boiler

Flushing the gas boiler heat exchanger is necessary to remove internal deposits that can disrupt the normal circulation of the coolant in the heating system and cause problems with the supply of hot water to the local DHW system. Substances that destroy the metal may also be present in the deposits.

How often this measure is required depends on the type of coolant. If purified water circulates in the system, it is enough to do prophylaxis every four years, removing deposits. The system with antifreeze should be flushed every two years and the coolant should be changed regularly - under the influence of high temperatures, it changes properties over time and can become dangerous for the metal elements of the system.

How much does it cost to clean a chimney

If you clean the chimney at home, it turns out much more economically. So in a chemical way, you only need to buy a product and 30 g of dry powder is enough for one application. The average volume of a can of powder is 500 g, therefore it can be used up to 17 times. But if you can’t clean it yourself for a number of reasons, you should use the services of professional craftsmen.

The accumulation of soot on the walls of the chimney can ignite, which in turn will lead to a fire or heavy smoke.

If for self-cleaning, on average, 1,000 rubles are spent for one jar of composition, then calling specialists at home will cost an average of 6,000 rubles at a time. Although the difference is obvious, it is not always possible to give a 100% guarantee for quality work on your own, and besides, without special skills, you can only aggravate the situation.

It is up to you to call the masters or to clean the chimneys and boilers yourself, but do not forget: the miser pays twice.

Chimneys can also be cleaned by adding special substances to the fuel, in which during the combustion process they will partially remove soot from the inner surface. Available in the form of powder, liquid and even solid briquettes. They must be used regularly to keep the chimney in good condition.

1. Means "Chimney sweep" - a chemical agent. Helps eliminate soot and soot in chimneys. The average price is 159 rubles.

2. Means "Grillkoff" - contains salts which in the course of burning react with pitches and destroy their structure. Price from 157 rubles.

3. "Forte Plus" burnt fat and soot cleaner - foaming agent suitable for cleaning AOGV boilers. Price from 519 rubles.

Keeping the boiler and chimney in perfect condition is a time-consuming process that often requires the help of specialists. But even at home, having certain skills, you can easily apply knowledge in practice and deal with problems when heating systems are clogged.

To prevent severe clogging, it is necessary to conduct an independent inspection once a month. This will help extend the operation of the heating system, and give you warmth and comfort in the house!

How to flush the heat exchanger of a double-circuit boiler

The method of descaling the DHW path depends on the type of heat exchanger installed in your heat generator. There are only two of them:

- bithermic, it combines the heating of the coolant and water for hot water supply;

- secondary heater in stainless steel.

It is better to clean the units of the first type with the help of a booster, since it can be quite difficult to remove such a unit. The hoses leading from the tank are connected instead of supplying cold water and exiting hot, after which the circulation pump and the boiler itself are started. The heating temperature should be limited to 50-55 degrees.

If there is a secondary heat exchanger in the double-circuit boiler, the latter can in most cases be removed. To do this, the front panel is removed, and then the control unit is unscrewed and moved aside. The secondary heat exchanger is located at the bottom and is fixed with 2 bolts. After removing it, it is immersed in a saucepan with citric acid dissolved in water and boiled on a gas stove, which is described in detail in the video:

Cleaning plate heat exchangers

The heat exchanger disconnected from the system should be cleaned from the outside and inside of the formed dirt, rust and scale. It will be most convenient to start cleaning the outer part of it.

Having cleaned the outer surface, you can begin to put in order the inside of the heat exchanger, that is, the inner walls of the curved pipe. There may be a fairly thick layer of scale in it, especially if the previous prevention was carried out a long time ago or was not carried out at all, or if the water in your house is quite hard. There may also be dirt coming from the tap water inside, especially if you do not have a filter installed to purify it.

Gas heat exchanger

The main heating function in the boiler is performed by a gas heat exchanger. Its design determines the structure and functionality of the boiler itself.

It is the heat exchanger that transfers heat between the coolants. From the hot carrier, heat is transferred to the cold one, and from there directly to the water.

There are a large number of types of heat exchangers for gas equipment. They determine the cost of the boiler, its characteristics and functions.

Gas equipment differs in cost, this is no secret to anyone. In most cases, the high price is determined by the quality and features of the heat exchanger.

It turns out that the greater the weight of the gas boiler, the greater the likelihood that it will last you as long as possible. The weight of the structure depends on the material from which it is made.

Both shell-and-tube heat exchangers and their other variants are usually made of durable steel.The thick walls of such an exchanger allow it to effectively cope with the load, without collapsing for a long time.

And the impact he experiences is not weak. Judge for yourself:

- outside, the heat exchanger is exposed to high temperatures, which rise as a result of the combustion of the fuel. Heat exchangers tend to "burn out" because of this;

- inside the system there is also very hot water - its temperature reaches ninety degrees. Boiling water causes the formation of scale on the surface of the boiler parts;

- sudden changes in the temperature of the heat exchanger can cause cracks on the surface of the material from which it is made.

Thus, we can conclude that only a particularly strong material of great thickness is capable of withstanding such loads. It follows that the more weighty the boiler, the larger and thicker the heat exchanger in it, and it makes up more than ninety percent of the weight of the boiler.

How to clean the boiler from soot

Cleaning the boiler from soot

Although gas is a clean fuel, still, when it is burned, unburned heavy oil products are released, which are black layered films. This is the soot that sticks to the surface of the combustion chamber, to the heat exchanger, thereby reducing the thermal conductivity of metals. That is, soot is a barrier to the penetration of heat into the heat exchanger. So, it is necessary to get rid of it, which is included in the procedure for cleaning gas boilers.

As with the heat exchanger, cleaning can be done by hand. As a rule, they clean the internal surfaces of the firebox, the external heat exchanger and the chimney.

With a firebox and a heat exchanger, everything is simple. If the soot layer does not exceed 2 mm, then it can be removed with a scraper or a damp sponge. If the layer exceeds this indicator, then chemical solutions cannot be dispensed with. For this, as in the case of the internal cavities of the heat exchanger, it is better to use acid-based solutions.

As for the chimney, this is a topic for a separate article. The only thing to say is that there are a lot of ways to clean this pipe - after all, our ancestors have been doing this for many centuries in a row, so colossal experience has been accumulated here.

Chimney cleaning methods

What can be offered?

- Burn soot with high temperatures. Let's face it, it's not the safest way. To do this, you can use aspen firewood, which emit huge thermal energy.

- You can use potatoes that are burned in the firebox. The starch released during combustion softens the soot, which falls off in chunks on its own. So there is no need to clean up afterwards. It is necessary to accurately calculate the number of potatoes per furnace volume. Usually it is not less than a bucket.

- There is an option in which table salt is thrown into the fire. Most likely, this is not a method of cleaning soot, but a method of preventing its formation.

- You can clean the chimney mechanically. To do this, you will have to close all the openings of the gas boiler, climb onto the roof and clean the pipe from above with a brush. After that, the furnace and heat exchanger are cleaned.

- And the last option is chemical cleaning.

Chimney cleaning

Well, if the chimney in your house is a collapsible structure, consisting of several parts. If it is easily and quickly disassembled, then the best option is to disassemble the pipe and clean its parts.

Here are a few methods that answer the question of how to clean the boiler from soot. All of them show that such processes can be carried out with your own hands. Some of them are very simple, and some require skills and information. There are also those that are carried out with the help of special tools and equipment. But in any case, using our information and understanding all the intricacies, you can not wait for specialists, but start cleaning yourself.