Drywall is good because it allows you to quickly and efficiently align walls or ceilings. But the material has one significant drawback: it is fragile and the load in the form of a wall cabinet or shelf is not calculated. Traditional fastening methods in the case of plasterboard surfaces are unreliable: the material begins to crumble. In such a situation, a fundamentally different fastener is used - a special dowel for drywall.

Kinds

There are several types of dowels that allow you to attach hinged structures to the gypsum board:

- Butterfly.

- Driva plastic or metal screw.

- Molly.

- Dowel Fisher.

- Knauf Hartmut.

- Ordinary dowel-nail.

- Spring.

Each of these types of fasteners has advantages and disadvantages. To figure out which one is more profitable to use in a particular situation, let's get to know them better.

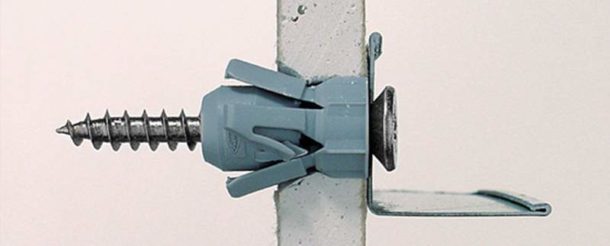

Butterfly dowel

This fastener got its name because, when tightened, it resembles a butterfly in shape. When a screw is screwed into it, the wings of the dowel open and rest against the drywall surface from the back. To prevent the element from scrolling, special cuffs are provided.

By design, the "butterfly" can be considered as a lightweight and cheaper version of the Molly dowel.

This type of fastener is designed for small lamps, cornices or baseboards, fixing electrical wiring, switches. According to the manufacturers, it is able to withstand loads up to 28 kg.

The installation instructions for the butterfly dowel are simple:

- In the right place, using a drill of the appropriate diameter, a hole is made for the dowel.

- The side "wings" are compressed by hand, after which the fastener is inserted into the hole. It should enter tightly, so it is recommended to use a hammer for drafting. In this case, the notches on the dowel body should stick into the drywall from the front side. This will prevent the element from scrolling.

- When screwing in a self-tapping screw, you need to achieve a tight pressing of the wings to the surface of the sheet on the back of the drywall.

The nuances of mounting the "butterfly" are shown in the video.

The advantages of this type of fastening:

- ease of installation;

- the possibility of extraction if necessary.

There are also disadvantages:

- To use, you need free space behind the GKL surface.

- The use of these dowels is limited to the thickness of the plasterboard coating - up to 12 mm. That is, when installing GKL in two or more layers, such fasteners will not work.

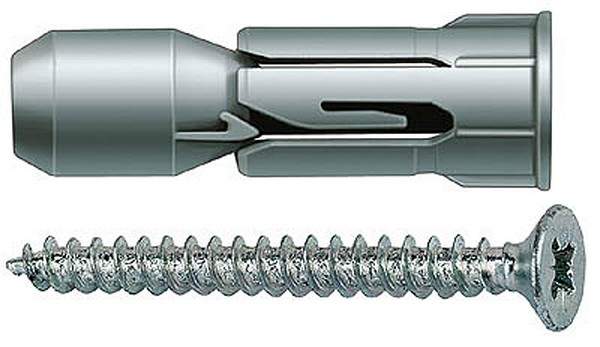

Dowel Driva

This is a metal, plastic or nylon hollow rod with a screw thread. The head has slots for a Phillips screwdriver.

It is more convenient to use a type of dowel "Driva", equipped with a drill. Then the installation is much simpler:

- Using a screwdriver, the element is screwed into the wall.

- A screw is screwed into the cross-shaped slot of the dowel, which bursts it from the inside. This guarantees a strong fixation of the element in drywall.

For the Driva variety, devoid of a drill at the end, a hole with a diameter of 6 mm is prepared in advance.

The length of the plastic dowel is 23 mm, but the size of the metal ones varies from 33 to 44 mm. Therefore, when choosing fasteners, the thickness of the wall is taken into account.

The main advantages of the Driva mount:

- Low hardware price.

- It is not necessary to have free space behind the ceiling.

- If necessary, simply dismantle.

- Plastic models are designed for a load of up to 25 kg, metal - up to 35 kg.

Dowel Molly

It resembles an umbrella in its principle of operation. Withstands significant loads - up to 35 kg.

The installation process is as follows:

- Under the diameter of the dowel (usually 8 mm), a hole is drilled in the wall or ceiling.

- The sleeve is inserted into the hole so that the teeth located on the cap cut into the surface. This will prevent the fastener from turning.

- Screw in the screw until the drop-down triangles dig into the drywall from the back of the sheet, ensuring a secure fit.

The advantages of Molly dowels are obvious: due to the formation of a cone-shaped structure from the back of the gypsum board, they increase the area of \u200b\u200bsupport and prevent the sheet from breaking under load. The disadvantages include the high cost and the need for free space behind the plasterboard.

Note! Molly cannot be dismantled: to extract it, you will have to break the wall.

And here is the video instruction for mounting Molly:

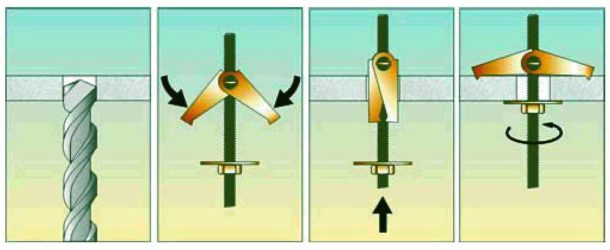

Fischer PD

One of the newest and most convenient developments in the field of drywall fasteners. The principle of operation is original in that when the self-tapping screw is screwed inside the dowel, its conical shank is pressed into the plastic sleeve, forcing the wings-stops to open. With a small sheet thickness, they carry out pressing from the back. If the thickness of the drywall is significant, they will jam the dowel in the drilled hole.

Withstands such fasteners 12-15 kg. Installing it is simple:

- Preparing a hole in the drywall.

- The dowel is inserted. Longitudinal ribs will prevent it from turning, and a reinforced flange will not allow it to fall into the hole.

- The locking screw is tightened. As it advances, the “wings” open and the dowel is fixed.

"Hartmut" from "Knauf"

Weight holding champion. Able to withstand loads up to 55 kg. It consists of a metal U-shaped bar, a locking sleeve, and two plastic guides.

Installation diagram:

- A hole with a diameter of 13 mm is drilled in drywall.

- A metal bar is inserted into it. By pulling the guides and aligning them with respect to each other, it must be brought into position.

- The guides are inserted into a colorless plastic sleeve. It is inserted into the hole until it stops.

- The ends of the guides are bred in different directions, after which they break off.

- The screw included in the delivery set is screwed into the dowel.

- Installing Hartmut fasteners: step 1

- Step 2

- Step 3

- Step 4

- Step 5

- Step 6

- Back view

The result is a very reliable fulcrum that can withstand solid loads.

Dowel-nails

Also used when hanging light objects on drywall surfaces. Such fasteners are popular because of their convenience and low price. It is usually made of plastic, but there are also aluminum varieties.

Installation is simple:

- A hole is drilled corresponding to the thickness of the hardware.

- The plastic part is carefully driven in with a hammer.

- The screw rod is also hammered with a hammer. The cross slots on it are provided in case you need to unscrew the screw. But it is almost impossible to get the plastic part out of the GKL.

With all their convenience, these hardware are used for attaching only light objects to a drywall surface.

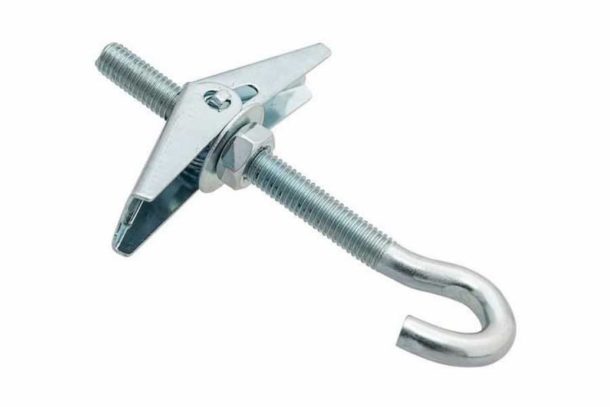

spring anchor

This fastener is also called a dowel, although this is not entirely true. It is very often used for attaching suspended structures to the ceiling, such as lamps. It is a screw equipped with two stops, which are unclenched by a spring.

Attach it like this:

- A hole of the required diameter is drilled in the ceiling.

- An anchor is inserted into it, having previously folded the blades and holding them from opening. Once behind the drywall surface, they will automatically open, providing a secure fit.

It should be noted that it is impossible to dismantle the spring suspension.

A competent choice of fasteners will not only ensure the reliability of fixing hinged structures on the surface of drywall, but also protect the plasterboard from unnecessary damage.