How to make underfloor heating

To arrange floor heating, it is necessary to clean the base of the floor from debris, it is recommended to make a concrete screed so that the surface is even

This is important for the normal circulation of fluid in the system: the water pressure in all sections of the pipeline must be the same

On an uneven surface, the load on the pipes will be uneven. In areas that experience greater coolant pressure, a rupture may occur. This will lead to serious complications. You will have to open the flooring and completely change the water circuit in the room.

- Thermal insulation "Knauf Therm POL PRO" is laid on the base. Mats do not strengthen. They are installed side by side. Sheets should fit snugly against each other.

- I remove debris and dust from the insulating surface.

- A damping tape is strengthened along the perimeter of the room. It must fit snugly against the polystyrene insulating material.

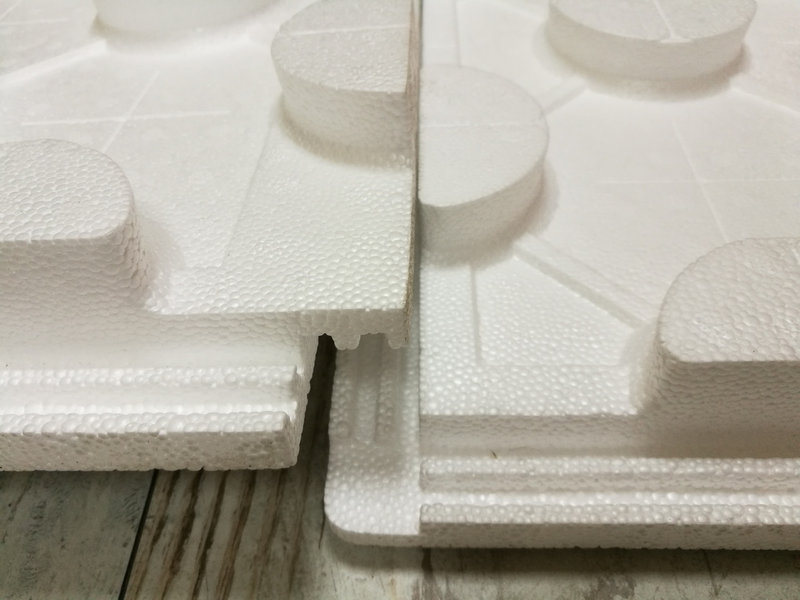

- Lay mats "Knauf Therm Warm floor". Leave no gaps between sheets. You don't need to glue them to the subfloor. The mats are laid in such a way that the upper surface of the bosses throughout the site has the original shape of a tablet. Sheets on which incorrectly formed bosses remain are installed from the side of the walls.

- Along the perimeter of the room, a water pipe is laid with a “snail”. It is recommended to use Knauf Therm PERT EVOH pipes. They are specially adapted for the heating system, made of metal-plastic. The outer and inner surfaces are protected by a special anti-diffusion coating that creates an oxygen barrier. The metal parts of the plumbing are not subject to oxidation. On the surface of the plastic there is a marking of the footage. There is no need to use a tape measure.

- The water circuit is fixed between the bosses. During installation, a certain step is observed, 40 cm; each turn of the pipe is fixed through 4 bosses.

- "Snail" is brought to the center of the room. The pipe is turned and directed along the reverse contour. Use the same technique "snail".

- Now the water supply is laid every 2 bosses. The distance between the turns should be 20 cm. The circuit is taken out of the room and connected to the outlet pipe on the boiler or on the furnace.

- Installation of the underfloor heating system is completed with the arrangement of the screed. To do this, you can use the Knauf building mixture, make the screed bulk, in a dry way. The advantage of a dry screed is that in an emergency, you can easily remove the filler and fix problems in the heating system. When arranging a concrete screed, it is difficult to repair the water supply.

Thermal insulation "Knauf" has poor sound conductivity. This property of the material makes it possible to reduce the penetration of noise into the room. Expanded polystyrene is recommended to be laid on the floor in apartment buildings. The material is used if there are small children in the apartment who like to actively move.

Superpol in 3 hours (dry screed installation)

- header

- Superpol in 3 hours (dry screed installation)

- header

- Installation of a dry screed floor base Knauf-superpol

- header

- Water heated floor without screed. Lightweight foil system.

Mat for underfloor heating with bosses Knauf Therm S0.72 m2

Delivery

Own delivery service - we work seven days a week

On-line 24/7

You can contact our online chat at any time of the day

Guarantee

All products are covered by a manufacturer's warranty

- Manufacturers Knauf

- Availability: In Stock

- Product code: KnaufTherm

KNAUF Therm Warm floor (Knauf Therm Warm floor) 1200x600x47 mm S=0.72 sq. m.

Pack of 10

The flagship for the production of energy-saving materials is the Russian company KNAUF. The brand is famous for manufacturing products based on expanded polystyrene.The use of innovative technologies and scientific achievements allowed Knauf engineers to create a unique heat-insulating material KNAUF Therm Underfloor heating. It is a molded mat that is widely used in underfloor heating systems.

The advantages of a warm floor include excellent thermal insulation and compressive strength - 140 kPa. In addition, expanded polystyrene has a low level of moisture absorption and excellent sound insulation. The development of the company meets the strict requirements and standards of European and Russian standards.

Brand engineers made knauf therm underfloor heating mats absolutely safe and environmentally friendly. The composition of the material does not include harmful chemicals such as phenol-formaldehyde and chlorine. Knauf slabs for underfloor heating are characterized by low flammability. This property is achieved through surface treatment with modern flame retardants. Knauf floor heating mats, the price of which is always affordable on the SantekhMarka website, are not subject to deformation and are not afraid of mechanical damage.

Technical and operational advantages

1. The manufacturer has made anti-vandal bosses, which are used for laying pipes of various sizes. Bosses make it possible to lay pipes with the required pattern. There is no need to additionally use metal meshes. This prevents chafing of pipes.

2. The special shape of the boss with a reverse slope helps to securely fix the pipes.

3. Maximum convenience and speed of laying provides a lock around the entire perimeter of the mats. It guarantees a tight fixation of all constituent elements to create a single monolithic surface.

4. The mats are marked on both sides, which greatly simplifies cutting. Also cutting minimizes the amount of residue.

5. The company gives a guarantee for its products for a period of 100 years.

Technical features

The combination of technical parameters makes knauf floor slabs an irreproachable sales leader in the Russian market. The thermal conductivity of the product in the dry state is up to 0.038 W/mK. At the same time, the water absorption rate per day is not more than 1.8% per volume.

Application area

Styrofoam boards

As a heater for the floor, the Knauf company suggests using polystyrene boards: polystyrene foam. They are laid on a concrete base under the screed. Next, form the substrate, lay the lining for the floor. Suitable for any material, hard or soft texture.

Polyfoam "Knauf Therm POL PRO" is used for floor insulation in any premises, even in rooms with high humidity and low temperatures: loggias, verandas, outbuildings. What are the main characteristics of this material?

- Insulation is produced in the form of a mat of a certain size: length 1 m, width 1.2 m. Sheet thickness 5-10 cm. For the best effect, several layers of foam are laid on a concrete base.

- The material has low thermal conductivity, does not freeze, does not absorb moisture. Styrofoam is inert to chemicals in concrete mortar or tile adhesive.

- Thermal insulation belongs to the 3rd group of flammability.

- It's easy to use. Using a construction knife, you can cut out any contour necessary for a particular room.

When installing thermal insulation, it should be foreseen that the level of the floor will rise by the thickness of the sheet. If the insulation has been laid in several levels, then the floor can rise to a considerable height. The material is used to insulate the base not only in residential premises, but also on verandas and in gazebos.

Insulation "Knauf Therm Warm floor" is used to equip a liquid or steam heating system "warm floor". Styrofoam differs from standard insulation in the shape of its surface and functionality.

- Thermal insulation from expanded polystyrene for water heating is produced in the form of a mat. Dimensions: length 150 cm, width 50 cm, thickness 1 cm. Bosses are located on the surface.Outwardly, they look like round tablets with a leg. There is a chamfer on the top flat surface. The leg has an arcuate shape with a small angle of deviation.

- The boots are elastic. With pressure, they shrink a little, but quickly return to their original shape. The relief is located in increments of 10 cm. It is designed for laying water pipes for the "warm floor" system.

- The contour is laid between the bosses. At the same time, the legs are compressed, clasping the pipe, securely fixing it, as in a castle.

- Installation of the heating system is carried out in a short time. There is no need to install a metal frame for pipes on the surface of the base floor.

- Knauf insulation is easy to install. A thorn-groove lock runs along the mat. If there is no need for a lock, then it is easy to cut it off with a construction knife. The contour necessary for the warm floor is cut out of the mat.

- Thermal insulation has low thermal conductivity, does not absorb moisture. The insulation is resistant to low and high temperatures. According to the passport for the material, polystyrene foam for the "warm floor" system belongs to the 3rd class of flammability.

Together with the Knauf Therm Warm Floor thermal insulation, the kit may include a damping tape, self-tapping screws for fixing it, and material for making a screed. Despite the fact that the company does not produce heating systems, it can offer products that will facilitate the installation of water floor heating and help maintain an optimal microclimate in the room.

Underfloor heating Knauf features, characteristics and benefits

The article will talk about innovative products created using German technology - Knauf warm floor. Two-component products are made using fine expanded clay sand and gypsum fiber sheet. Below is information about what are the design features, technical parameters, pros and cons of the floor.

general information

The prefabricated Super floor from Knauf is a simple structure in terms of design and installation. It is a factory Superfloor Knauf warm floor, consisting of two sheets of moisture-resistant gypsum fiber glued together. The sheets measure 150x50x1 cm and are joined with a double offset of 5 cm.

Offset floor sheets Knauf

Paul Knauf is designed for installation in any room with dry and normal humidity levels, as well as in a non-aggressive environment. In the case of using waterproofing during installation, it is allowed to use the floor in rooms with high humidity, for example, a bathroom.

- The useful area of the sheet is 0.75 m 2 .

- The level of thermal conductivity ranges from 0.22 to 0.36 W / m ° C

- The compressive strength exceeds 10 MPa.

- The hardness of the material on the Brinell scale is more than 20 MPa.

- High fire-technical indicators according to GOST: combustibility group - P, flammability - B1, toxicity - T1 and so on.

Construction using Super floors includes:

- separating layer

- edge damping tape,

- leveling insulation

- floor base as Knauf sheets,

- adhesive solution between adjacent parts of the Super floor,

- screws for gypsum boards.

Construction Super floor Knauf

Benefits of Super floor

Innovative German technology has made it possible to create a product with high technical performance, which leads to a lot of advantages over analogues in the building materials market.

Advantages of the Knauf Super floor:

Ease of installation can significantly reduce the cost of both labor and consumables.

Knauf floor installation

- Technological aspects make it possible to speed up the installation process due to the elimination of wet laying processes.

- The low weight of the floors reduces the static load.

- High level of thermal insulation.

- Optimum soundproofing.

- The possibility of building prefabricated floors in rooms that have a complex configuration.

Moderate mechanical impact is allowed on this design, they can be cut, sawn.Sufficiently oversized products are easily transported and easy to set up even by one person.

Important! Knauf floors are laid at a distance of 10 mm from the walls, the gap is filled with mounting foam, which creates effective waterproofing. Floors are used both on reinforced concrete and on top of a wooden base under any coating

Installation is carried out by means of adhesive solutions and screws for GVL sheets. After the Superpol device, you can walk on it immediately after the adhesive mixture dries

Floors are used both on reinforced concrete and on top of a wooden base under any coating. Installation is carried out by means of adhesive solutions and screws for GVL sheets. After the Superpol device, you can walk on it immediately after the adhesive mixture has dried.