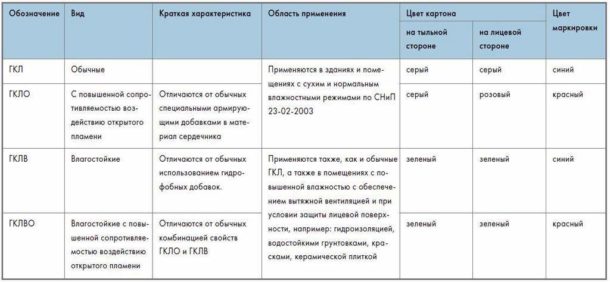

An important advantage of drywall is its versatility. But this does not mean that an ordinary GKL sheet can be used in conditions close to extreme. For a humid environment, a moisture-resistant variety is used, and to create structures that can withstand open fire and withstand elevated temperatures, fire-resistant drywall is used.

What is fire resistant drywall

Heat-resistant material is produced in the form of flat building sheets of rectangular shape. They are a gypsum core lined with durable cardboard on both sides. From standard GKL The fire-resistant variety is distinguished by the following features:

- The gypsum core is additionally reinforced with fiberglass. It is not afraid of high temperatures, and prevents the destruction of the material when exposed to fire.

- The core contains water of crystallization, which increases the level of fire protection. In the process of heating, the material, as it were, extinguishes itself.

- The sheet is reinforced from the inside with chamotte clay, which sinters under the influence of fire and keeps the gypsum from scattering.

- The cardboard shell is glued to the core with special compounds that increase strength and turn the coating into a reinforcing frame. It is an excellent base for applying any kind of finishing material.

All additional components of fire-resistant drywall allow it to withstand exposure to open flames without spreading combustion, without emitting smoke and without deteriorating for a long time.

Characteristics and properties of GKLO

The fire-resistant type of GKL has the following technical parameters:

- The standard size is 2500 × 1200 × 12.5.

- Weight - 30 kg.

- Density - 850 kg / m3 (for comparison: for ordinary Gyproc drywall - 800 kg / m3).

- Combustibility class - G1 (low combustible material).

- Flammability index - B1 (low flammability).

- Toxicity group - T1 (low-hazardous).

- Thermal conductivity - 0.22 W / Mk.

- Thickness - 6.5, 9.5, 12.5, 14, 15, 16 mm.

- Width - from 0.5 to 1.3 m.

- Length - from 3 to 5 m.

In addition to high fire resistance, GKLO has the following properties:

- Excellent sound and heat insulation.

- Durability - due to increased strength, it lasts longer than conventional GCR.

- The ability to absorb excess moisture and release it into the environment in case of deficiency.

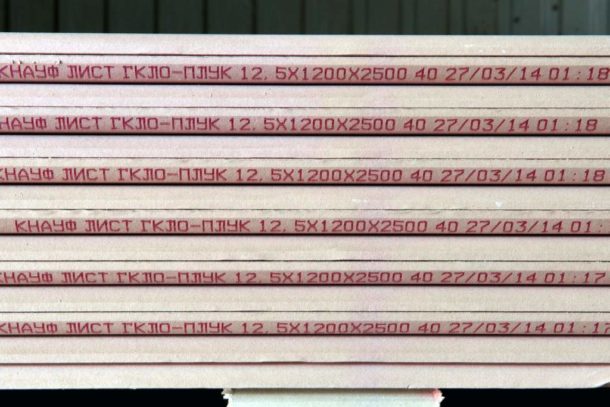

GKLO has a pink or red color, less often - gray with red markings, so heat-resistant GKL is easy to recognize by its appearance.

Interaction with open fire

When exposed to high temperatures, refractory drywall does not deform. The material is able to withstand an open flame for a long time. In the end, the cardboard shell will burn anyway, and the gypsum core will crack. However, this process will be slow.

The fire resistance limit is 25–45 minutes, depending on the manufacturer. During this time, the material will fully retain its bearing capacity and original integrity, preventing the fire from moving in the opposite direction. Then the gradual destruction of the drywall sheet begins, which will end in about an hour. Ordinary GCR disintegrates after 18–20 minutes.

The next video is a crash test of different types of drywall, thanks to which you can clearly see the resistance of GKLO.

Scope of application

The scope of fire-resistant drywall is quite wide and includes:

- Carrying out finishing work in rooms with high air temperature. These are boiler rooms, boiler houses, production shops, for which there are special requirements for finishing heat-resistant material.

- Installation of frame partitions, which contain basalt-based wool fibers with heat-resistant properties.

- Repair in children's rooms.

- Finishing work in the premises of public buildings with increased traffic.

- Arrangement of walls and load-bearing elements in educational institutions.

- Manufacture of fireplaces.

- Sheathing of wooden buildings in order to prevent fire.

- Installation of domestic ventilation systems.

- Fireplace box lined with GKLO

- Chimney lining

Marking

Each sheet of fire-resistant GKL has a symbol, consisting of:

- letter code of plate type;

- standard markings;

- indication of the type of longitudinal edges of the sheet plate;

- digital indicators that display the nominal length, width, and thickness in mm.

For example, a Knauf gypsum fire-resistant building board with a rounded edge 2500 mm long, 1200 mm wide and 14 mm thick would be designated as follows:

Fire-resistant drywall GKLO type DF- GOST 32614-2012 (EN 520:2009) ЗК 14-1200-2500

Mounting Features

Fundamental differences from technology for installing standard gypsum boards not available, but the procedure itself is somewhat complicated by the increased rigidity of the coating. For installation, a reinforced profile of the guide type is used, which can withstand higher loads compared to standard drywall.

Stages of work:

- Preparation of load-bearing elements. The ceiling is cleaned and the old finish is removed, the primer is applied. If necessary, the wall surface is leveled. Experts advise additionally covering the base with fire-resistant compounds, which make it possible to protect housing from a fire.

- Marking the area for attaching cardboard. The installation of the profile must be carried out at a distance of about 100 mm from the ceiling and up to 50 mm from the floor (depending on the type of frame). The profile is fastened with elongated dowels.

- Installation of heat-resistant drywall. It is carried out using special load-bearing elements. The distance between the screws is 20 cm.

Mandatory requirement: all fasteners must be made of refractory materials (alloy steel) and have high torsion resistance. This will increase the rigidity of the supporting structure.

- surface priming, sealing seams using reinforcing paper tape.

Important! When installing heat-resistant sheets, only a metal profile should be used to prevent deformation of the material.

- Installation of GKLO

- Ceiling made of fire-resistant plasterboard

Price

You can buy fire-retardant GCR in any region of the country, the price varies depending on the manufacturer and size. A well-established manufacturer of heat-resistant drywall, which has a quality certificate and meets international standards, is the Knauf company. The approximate price of a fire-retardant GKL of this company measuring 12.5 × 1200 × 2500 varies from 350 to 450 rubles per sheet. Most manufacturing companies provide customers with the opportunity to order material directly from the warehouse or design it according to individual sizes.