Installation of drywall sheets on the frame is not the final stage in the construction of partitions in the premises of the apartment. It is also important how well the seams between the sheets of drywall will be sealed before finishing. The junction of the GKL is the most sensitive and prone to destruction place. Cracks often appear between drywall, worsening the appearance of the walls. Surfaces for painting should be especially thoroughly prepared, although cracks become noticeable under the wallpaper. How to seal the seams on drywall, will be discussed below.

Tools and materials for grouting

For work you will need:

- spatulas: wide, narrow and angular;

- abrasive grater;

- building level;

- brush;

- knife and edge planer.

Materials:

- special putty;

- primer;

- reinforcing tape.

Conditions for high-quality sealing of seams

Very important before installing drywall properly prepare the frame. To do this, it is necessary to follow the technology of its assembly, which includes the use of the required number of wooden bars or metal profiles, compliance with their pitch, proper fastening, placement of the profile exactly under the joints of the sheets, etc.

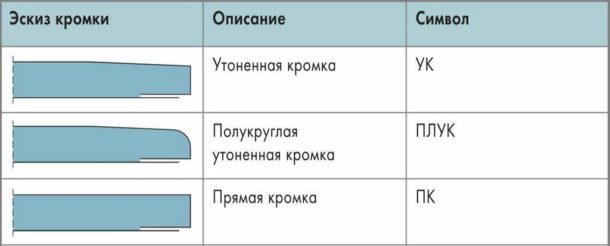

Drywall is attached to the frame with self-tapping screws. Sheets are used with chamfered edges. If drywall is installed with a cut edge at the joint or does not have a factory chamfer, it is necessary to make it using an edge planer. The angle of inclination is 45°. It is not always possible to chamfer in a timely manner, so it can be done in situ after installation using a paint knife. Putty will subsequently be laid in the resulting recess.

When there are no chamfers on the ends of the drywall sheets, the sealed joint forms a bulge. In the future, the entire surface of the sheets will have to be leveled, which will lead to significant labor and material costs.

When the joints are processed, dust is removed from them and the quality of the screw tightening is checked. They are wrapped up to a head immersion depth of 1 mm in a sheet of drywall (paper base).

It is advisable for beginners to visually familiarize themselves with the technology for preparing drywall sheets (video, photo).

What materials to choose for sealing seams?

When the home master is faced with the question of how to seal the seams in drywall, he usually tries to find cheaper putty. Such savings can go sideways, because due to low-quality material, the seams can crack, and the repair will have to be done again. You need a special putty designed for sealing drywall joints, the usual finishing composition will not work.

The choice of putty

When sealing joints between sheets of drywall, one of the best tools is Knauf gypsum putty. Depending on the purpose, one of the types of Knauf putty is used:

- Fugen Uniflot («Fugen Uniflot») - gypsum high-strength putty mixture with polymer additives. Suitable not only for GKL, but also for GVL and other types of boards from «Knauf (perforated, acoustic, floor elements).

If sheets with a semicircular thinned edge (PLUK) are used, when working with putty «Uniflot» sealing drywall seams with your own hands can be done without reinforcing tape.

- Fugen (old name - «Fugenfüller») - universal gypsum putty with excellent characteristics, used for sheets with thinned (UK) and semicircular thinned edges (PLUK).

- Fugen GF (GF) - putty mixture for gypsum-fiber sheets.

- Fugen Hydro (Hydro) - putty for sealing drywall joints with increased moisture resistance (GKL, KLVO) with a UK edge.

The basis of these dry mixes is gypsum powder, which includes plasticizers and modifiers that give each composition the appropriate qualities. For example, additives in the Fugen Hudro brand have a water-repellent effect.

Important! Gypsum putty is incompatible with chipboard, ceramic and stone cladding surfaces.

In the construction market, you can find a polymer putty that is more resistant to high humidity. This can not always be taken for dignity, since the retention of moisture in the room does not always favorably affect the microclimate. If you seal the seams between the sheets of drywall with gypsum putty, it allows you to better maintain the microclimatic conditions in the room. In addition, it has better vapor permeability, allowing the walls to "breathe". However, if there is good ventilation in the room, these advantages do not play any role.

Oil-adhesive putty is categorically not suitable for sealing joints, since it shrinks a lot.

paper tape

It is recommended to reinforce the seams with Knauf paper tape with special fiber additives that increase strength. Each leading manufacturer offers its own version of the technology with the most suitable materials for each other. Other popular brands are Sheetrock and NextBuild. The presence of a groove in the middle of the tape web makes it easier to bend the paper when finishing internal fillet welds.

To avoid the appearance of bubbles under a layer of paper with an insufficient amount of putty, it is better to purchase a tape with micro-perforations.

The sealing tape may be different - sealing drywall joints with sickle is also practiced, however, it should be borne in mind that it is inconvenient to use when processing internal corners. In addition, it has less strength compared to paper tape and is prone to stretching, so it is also not recommended to use it for transverse joints, only for longitudinal ones. The only advantage of serpyanka over paper tape is ease of use due to the self-adhesive layer.

The technology of sealing joints between drywall sheets

The sequence of work will be as follows:

- For pre-treatment of seams on drywall, a primer is used, preferably from the same company Knauf. It is sold already diluted, has good adhesion and dries quickly.

Working conditions: the temperature in the room should be at least 10 ° C, and the humidity should be within the normal range. Drafts are not allowed.

- A solution is made for sealing joints between sheets at the rate of 1 kg of dry mix per 0.5 l of cold water (proportions may vary, see package). The powder is poured evenly over the entire surface of the liquid and soaked with moisture for 2-3 minutes. Then the mixture is mixed with a mixer at low speed. At first it will be liquid, but then it will thicken to the desired consistency.

It is important that the container and tool are clean, otherwise the quality of the putty will decrease by 2 times, and its hardening will also accelerate. The properties of the solution are retained for no more than 40 minutes, and it is impossible to maintain the required viscosity by diluting with water, so portions are prepared in small quantities. After the putty mixture has hardened, the seam is rubbed with a grater with sandpaper and primed again.

- A layer of putty is applied to the seam. In places with a cut edge, it is made a little thinner, but the filling should be of high quality. Until the solution has set, a reinforcing tape is applied to it and pressed into the putty with a spatula. It must be closed completely so that the edges do not protrude. Then the surface is corrected and leveled. You should leave a place in thickness for applying the second layer.

- At the same time close up the places where the heads of the self-tapping screws are recessed.

- The next layer is applied to the seam no earlier than 12 hours later.Application is carried out with a wide spatula so that the surface is flush with the sheets. The second layer dries very quickly. Then the protrusions are again cleaned with sandpaper.

The sealing of drywall joints on the ceiling and on the walls is carried out using the same technology. Only processing the ceiling is more difficult, and all defects are more noticeable.

Conclusion

When building partitions in rooms, it is extremely important to understand how to properly seal the seams between sheets of drywall. Competent seaming technology will prevent the appearance of cracks, due to which the appearance of the finish is significantly affected.