Leveling various surfaces with plasters ─ one of the popular ways to prepare walls and ceilings for painting or wallpapering. However, plaster does not always lie flat, without defects. Some surfaces have low adhesion, so the solution applied to them begins to crumble and peel off. Especially quickly the destruction of the protective and decorative layer is manifested on the facades of buildings that are exposed to the negative effects of climate and moisture. Using mesh for wall plastering, you can ensure a firm fixation of the mortar with the surface and improve the quality of the finish.

Application

The mesh is used for outdoor and indoor work, and helps to achieve the following results:

- Increase the durability of decorative finishes by properly distributing the load and reducing its impact on 1 m2. The grid is fixed pointwise on the base, and with its help the weight of the solution is kept.

- Avoid cracking of the plaster by reinforcing the surface layer. Walls and partitions made of blocks and bricks are prone to shrinkage and deformation. The reinforcing fabric gives the finish plasticity and prevents the appearance of cracks and other defects on the surface.

Mesh types

For the manufacture of the mesh, different materials are used, which, along with other parameters, determine its type, characteristics and scope.

If plaster thickness on the surface should be 30 mm or more, it is advisable to choose a metal mesh. It is used for rough wall finishing with compounds containing cement or clay, and ensures the strength of their connection to the surface due to additional fasteners:

- to a metal base ─ by welding;

- to wood - self-tapping screws;

- to a wall made of bricks or concrete blocks ─ dowels with a large washer.

Depending on the manufacturing method and design features, a metal mesh can be:

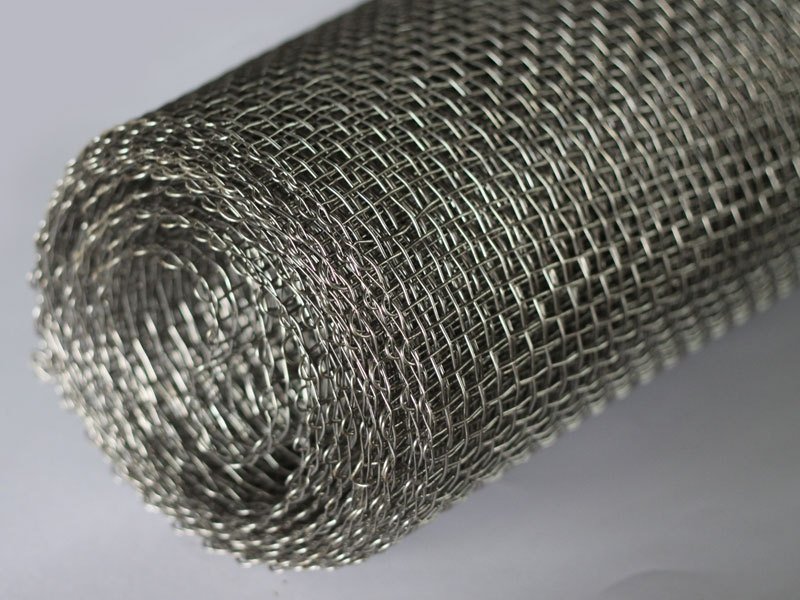

- Woven. It has a cell size of 1 × 1 cm2 and is made by woven method from thin and durable wire with different sections, most often galvanized. It is produced in the form of rolls and is used as a reinforcing layer for plastering exterior walls.

- Rabitsa. It is made from low-carbon steel wire by weaving and is a canvas with square or diamond-shaped cells and a size of 20 × 20 mm2. To protect against moisture and aggressive substances, the mesh is coated with a layer of zinc or polymer. The chain-link is used to work on surfaces of a large area, including wood or brick.

- Welded. It is made from steel wire, which is superimposed at right angles on each other, and then fixed at the joints using spot welding. The result is a strong mesh with square cells of different sizes. It is used to strengthen plaster with strong wall shrinkage, which is important for finishing new buildings or houses located on unstable soil.

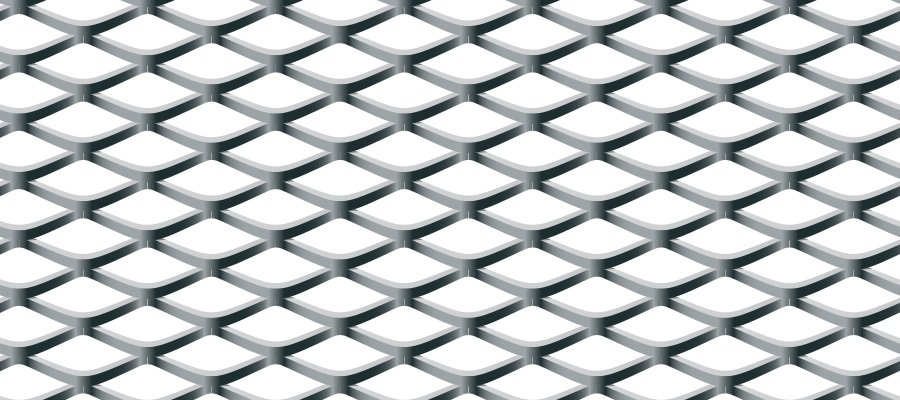

- Cut-and-draw. It is a sheet material with diamond-shaped cells and is intended for reinforcing walls with a small consumption of plaster. Expanded metal is made by cutting holes of the same shape and size into a sheet of metal, which is then stretched and formed into a plaster mesh.

If it is necessary to apply the solution as thinly as possible, it is advisable to use a plastic or fiberglass mesh.

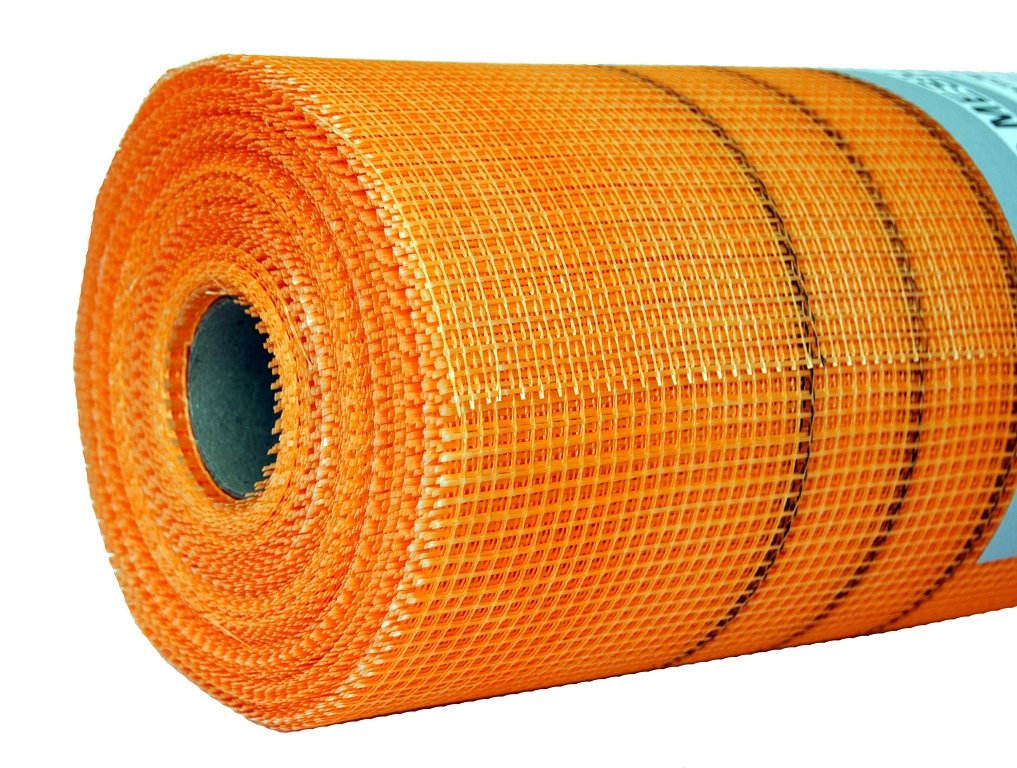

- Fiberglass. It is indispensable for finishing ceilings, facades and walls in the presence of depressions, grooves and depressions on their surface.It is lightweight, durable and resistant to temperature changes, and can be used for facades. Fiberglass mesh is not susceptible to moisture, so it is used for reinforcing roofs and plastering bathrooms and pools.

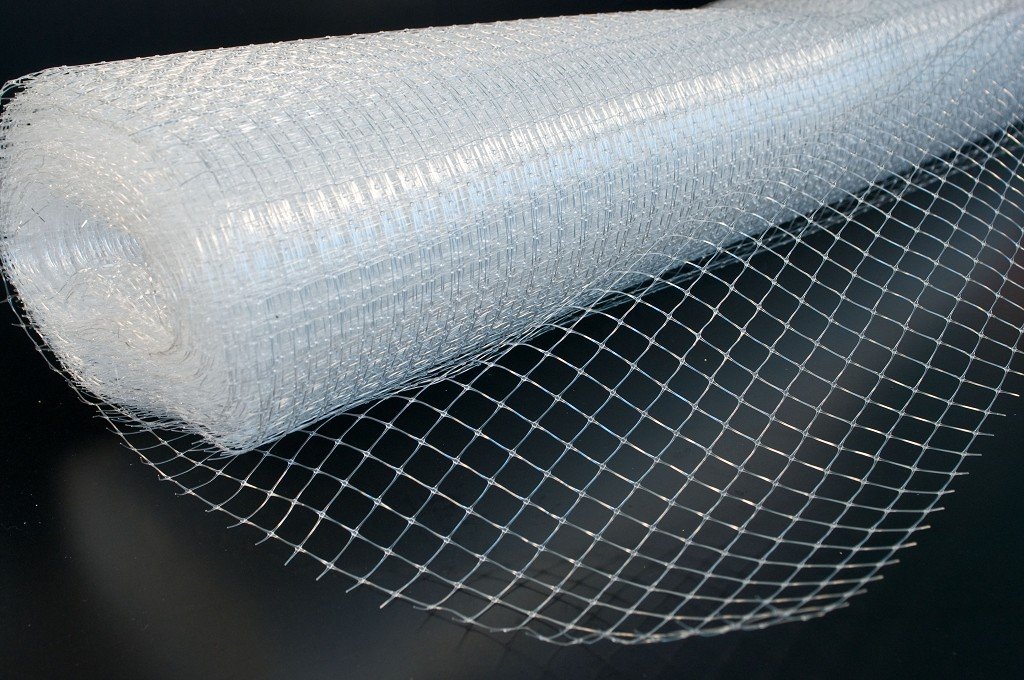

- polymer mesh. It is produced by extrusion from polymer raw materials, which is most often used as polypropylene. With the help of molding machines, the plastic melt is converted into a mesh fabric, the cell size of which is determined by the modification of the material. Plastic mesh is used for plastering work on the surface of facades and internal partitions. Since over time a mixture of sand and cement destroys the polymer sheet, it is advisable to use for finishing gypsum-based mixtures. Grid with cells 2×2 mm2 is indispensable for applying finishing putty.

Mesh laying technology

For finishing work, several types of plaster mixtures are used, which differ in composition, application nuances and the degree of impact on various materials. In addition, when choosing a mesh, you should consider:

- the thickness of the applied layer;

- base material;

- conditions for finishing and operating the coating.

metal

When choosing a metal mesh for reinforcement, it is worth giving preference to galvanized mesh: it prevents corrosion and prevents the appearance of rust spots on the walls. In addition, it is easy to cut and simple enough to fix on the surface. Before work, the metal mesh should be degreased, and the galvanized mesh should be simply rinsed with water. The formation of the reinforcing layer occurs as follows:

- Using scissors for metal, the mesh is cut into separate sheets, the size of which depends on the orientation of the material on the surface. In the presence of rusts, a reinforcing layer for plaster is placed along each seam with a solid sheet.

- Drill holes with a diameter of 6 mm using a puncher. Their depth should exceed the length of the dowel by 2-3 mm, and the step should be 25-30 cm.

- Dowels are inserted into the holes obtained, and then the mesh is fixed to the surface of the walls with mounting tape and screws. For reliable fixation, the canvases are overlapped, overlapping each other by about 10 mm.

- Beacons are installed, and the first layer of plaster is thrown using a trowel. In this case, the solution must be pressed in such a way that it passes through the reinforcing fabric and is fixed on the surface. After that, the finishing layer is evenly distributed over the surface of the wall or ceiling.

- The second layer of plaster is applied when the first one dries. If the basis is a facade with insulation, then it is advisable to use a chain-link to reinforce the surface. It is also necessary for the decoration of wooden walls.

plastic

If necessary, to protect the plaster from cracking, use a plastic mesh. It is especially in demand in those cases of interior decoration, when shrinkage of the base is possible. The algorithm of actions is as follows:

- prepare the base, and with the help of a toothed trowel, a layer of plaster is applied to it;

- put the canvas on top of the solution and smooth it so that the mixture protrudes from the cells;

- smooth the plastic mesh with a spatula, and if necessary, apply a second layer.

Separate parts of the canvas are overlapped on the wall.

fiberglass mesh

It is fixed on a wall made of brick or concrete blocks with a layer of plaster. If desired, you can fix the grid in several places with self-tapping screws. Fiberglass is attached to wooden surfaces with a construction stapler.