What to do if there is an old wooden floor in the room, which is inappropriate to paint or varnish? If the boards wobble and creak? You can resort to a labor-intensive and expensive method - to tear off the old coating, make a new one. coupler or put freshlags. But there is another, more practical, faster and cheaper solution - laying OSB on a wooden floor.

This method has its own nuances that are taken into account during OSB laying. Looking ahead, it is worth saying that the basis of technology is the correct preparation of the base. Below is a detailed guide, following which will allow you to achieve excellent results in terms of leveling the surface of the old wooden floor and the subsequent installation of decorative coatings: laminate, linoleum, etc.

Tools and materials for work

The list of necessary devices is minimal:

- crowbar nail puller;

- hammer;

- perforator, drill, drills;

- screwdriver;

- a large bubble or laser level (with a second tool it will be more convenient to detect irregularities).

Necessary materials:

- OSB board;

- fasteners - hardened self-tapping screws with a length of at least 45 mm;

- washers for screws (their presence is desirable, but not required).

Choosing this method of "resuscitation" of old wooden floors, you need to have an idea about the material used for these purposes in order to choose it correctly. The alignment result directly depends on this.

Characteristics of OSB boards

OSB is a building analogueplywood and chipboard. These slabs are more durable and perfectly adapted for finishing. The material appeared on the market relatively recently. OSB is made from wood chips, which are laid in 3 layers. They are glued together with special resin-based compounds. In this case, the layer in the middle is laid perpendicular to the other 2. Due to this, the resistance of the material to loads is formed.

This parameter is marked with a number. The lower the value, the lower the resistance to stress and the effects of destructive factors such as humidity. For example, index 2 means that the OSB board is not moisture resistant and is not able to withstand intense long-term loads. And the number 4 indicates that the product can be used as an overlap that will not collapse even when exposed to moisture.

The material for laying on the floor is selected on the basis of the mentioned designations in order to form an even rough surface. You should not save on the quality of OSB-plates. This is fraught with the need for laying an additional layer, which is expensive and inconvenient. The best option is OSB 3.

The question often arises: “Do I need a substrate for OSB?”. From a practical point of view, no. Wood itself is an excellent thermal insulation material, and if you consider that it is laid on wooden boards, then a substrate is not needed. But sometimes, to achieve the maximum possible soundproofing effect, it is still used.

Foundation preparation

Properly performed preparatory stage is more than half of the success of floor leveling work. First, a thorough examination of the wooden surface is carried out. This is done using a bubble or laser level. All protruding, as well as loose parts are marked, so it will be easier to strengthen them.

The next step is to securely fix the boards. Some experts recommend doing this with dowels, but a more reliable option would be to pull loose elements with self-tapping screws to the lags. It is necessary to fix the old coating as securely as possible. To do this, you can use several mounts in one area.The result is considered ideal when the “walking” floor fragments are recessed or level with the rest.

Some recommend scraping off the old layer of paint with a grinder. You need to know that this is only necessary in areas where there are obvious swellings of the paintwork. In fact, the presence of old paint is not critical, you can lay plates on it. In this case, it is necessary to remove all large contaminants.

Attention! The main part of the preparatory process is the fixation of the old wooden coating. It is this stage that should be given special attention.

OSB preparation for installation

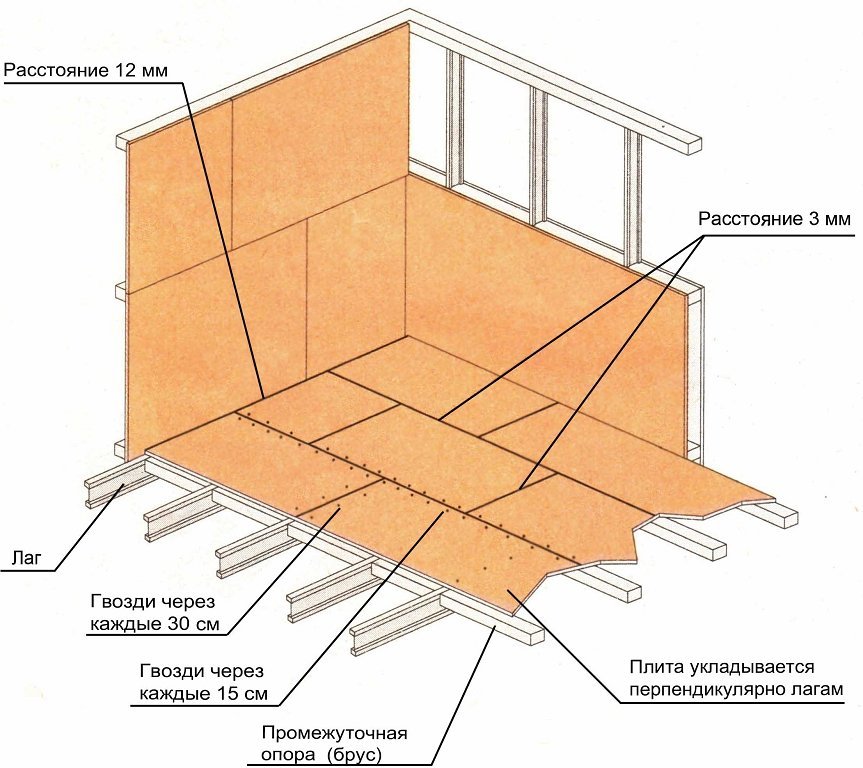

Before fixing the plates, you must first lay them on the floor in the room. In this case, 3 requirements must be met:

- There should not be straight cross-shaped seams, for which the plates are laid apart with an offset of 50%;

- The gap between the wall and the slabs must be at least 10 mm;

- Plates should not be closely adjacent to each other. The minimum gap between them is 3 mm.

Attention! Slots are needed in order to avoid the “crawling” of the plates on top of each other, the deformation of the decorative floor covering. This is due to the expansion of the material due to changes in humidity.

Laying process

After completing all the preparatory work, it remains only to tighten the slabs to the old wood flooring with self-tapping screws and fill the gap between the OSB and the wall with construction foam. After the foam dries, it is cut flush with the flooring.

The plates are fastened with self-tapping screws around the perimeter every 20–30 cm, but this distance can be reduced. Some experts recommend that you prepare the holes first, but with a screwdriver you can quickly and efficiently tighten self-tapping screws without pre-drilling.

Leveling the floor by the proposed method is the simplest, most effective and cheapest. If you follow the instructions, you can do without the help of specialists.

Cost of work

If you decide to entrust the repair to professionals, you need to calculate how much the services will cost. The price of laying OSB on a wooden floor is lower than the cost of installing these plates on logs and concrete. In Moscow, prices for this type of work vary in the range of 150–200 rubles per sq. m. m.

To decide whether to lay the slabs yourself or hire craftsmen, you need to soberly assess your strengths. This will help the following video, which clearly shows the installation process.