Plaster can be simple, improved and high quality. Contrary to popular belief, these definitions do not refer to the quality of the material, but to the technology of work and finishing characteristics, which are regulated by the requirements and rules of SNiP and GOST. Consider the differences between improved plaster and other types of plaster finishes and the requirements that it must meet.

Differences between different types of plaster

Doing a simple plastering possible in cases where the requirements for the quality of the finished coating are not too high. This type of finish requires the application of only two layers - spray and primer - and is most often used in non-residential premises.

When medium to high demands are placed on the wall covering, improved plastering is performed. It is used in cases where a perfectly smooth base is not required, and a structured finish coat or stacked tiles. The technology of work assumes the presence of three layers: spray, soil and coating.

High-quality plaster has a similar application technology to the improved one, but requires at least one additional layer of primer. Plaster coating of this level allows you to get a perfectly aligned vertically and horizontally surface.

Improved plaster: layer thickness

All requirements for the performance of work and the quality of the resulting coating are prescribed in the document SNiP 3.04.01-87 "Insulating and finishing coatings".

According to the technology, improved plastering is performed in 3 layers. The thickness of each of them depends on the material of the base and mortar and is prescribed in the rules of SNiP.

- Spraying is necessary to increase the adhesion of materials. For it, a solution of the consistency of liquid sour cream is used. The thickness of a continuous layer thrown on brick or concrete bases must be within 5 mm. For wooden bases, the maximum layer thickness increases to 9 mm, taking into account shingles or mesh.

- The soil serves to level the walls. With significant unevenness of the walls, it is allowed to apply the soil in several stages. The thickness of each individual layer of soil should be within 5 mm for mortars based on cement and 7 mm for light compositions based on lime and gypsum.

- Covering layer is the finishing stage of the plaster finish, which is rubbed with a trowel and serves to obtain a smooth and even coating. Its thickness can be no more than 2 mm. When using decorative plaster, the coating can have a thickness of up to 7 mm.

Tip: improved plastering technology does not require mandatory use lighthouses, but to facilitate the work of leveling the surface and controlling the thickness of the layers, it is still recommended for beginners to work on beacons.

Each layer applied only after the previous one has set. The total thickness of the material varies within 2 cm. When this figure needs to be exceeded, a metal mesh is stuffed onto the base. Experts recommend using it also when plastering foam concrete walls, when working on wood and metal. Reinforcing mesh in all cases helps prevent cracking.

In the current SNiP there is no regulation for fixing the plaster mesh, and its mention in the documents is advisory.

Tolerances for improved plaster

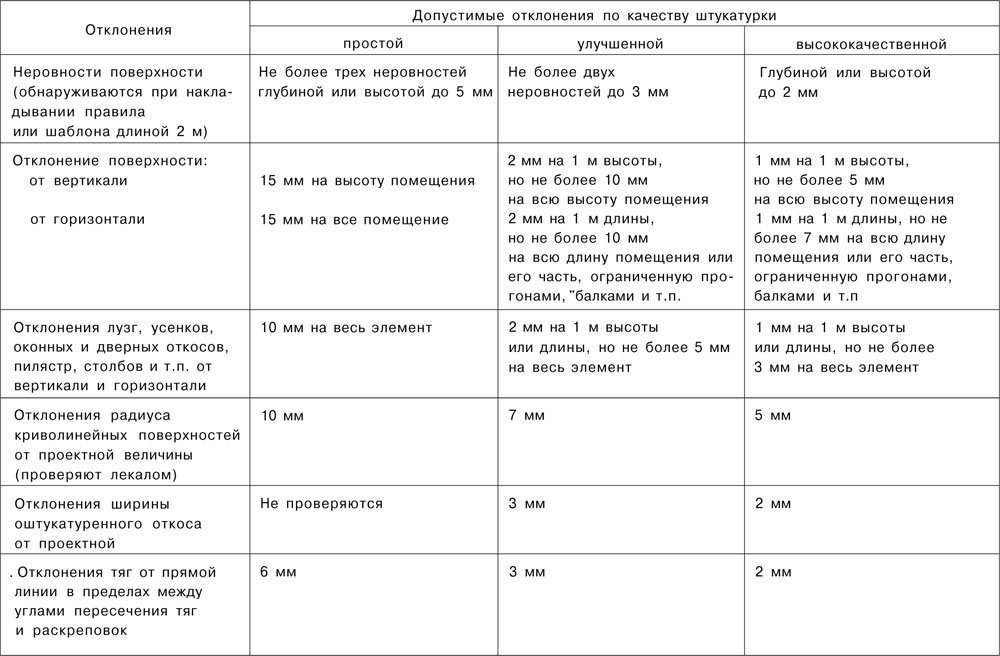

In accordance with SNiP 3.04.01-87, plastered surfaces may have deviations that are not a violation of the norm:

- from the vertical and horizontal, the coating may have a deviation of no more than 2 mm per 1 m of length;

- for the entire height of the wall, the surface can be deflected by no more than 10 mm;

- slopes of windows and doors, pillars, pilasters, husks can be deviated by no more than 2 mm from the vertical and horizontal per 1 m of length;

- the radius of curved surfaces can be deviated by 7 mm from the value specified in the project (control is carried out using a pattern);

- the width of the slope may differ from the design by 3 mm.

Important! SNiP for improved plaster does not allow the presence of delaminations, cracks, shells, efflorescence on the surface, as well as visible traces of the tool that was used for grouting.

Requirements for the quality of used plaster compositions

The quality control of the material and mortar used is carried out on the basis of GOST 28013-98 “Construction mortars. General technical conditions".

According to GOST, the solution for improved plaster must meet the following requirements:

- The solution intended for spraying and soil must pass through a mesh with a mesh diameter of 3 mm.

- The solution for the coating layer must pass through the mesh, which has a mesh size of 1.5 mm.

- The sand used for the preparation of the mortar must contain grains, the size of which does not exceed 2.5 mm in solutions for soil and spray and 1.25 mm for finishing.

- GOST also regulates technical parameters such as mobility, delamination, water retention and strength.

An additional requirement of GOST is the presence of a document in the solution, which indicates:

- date and time of preparation;

- brand of solution;

- number;

- mobility;

- binder component;

- standard.

Quality control of plaster works

Control over compliance with the requirements of SNiP and GOST is carried out at three stages: at the stage of preparation, in the process of work and at the stage of inspection and acceptance of the finished base.

For control at the preparatory stage, it is necessary:

- check the quality of the solution;

- determine the humidity of the walls and temperature;

- make sure the walls are cleaned of dirt.

In the process of performing plastering works, control of verticality and horizontality, as well as the quality of the resulting coatings, is carried out.

At the last stage, the control consists in checking the adhesion strength of the dried mortar with the wall and the quality of the surface that has undergone sanding.