Warm floor

The main function of such heating floors is to heat the floor and / or the room directly. There are two types of such heaters: water and electric. The first involves laying pipes in the base of the floor, through which warm water flows. This is a cheaper and not entirely safe option, since in case of damage to the pipes, not only will you have to remove the entire coating in order to repair the leak, but there is a very real risk of ruining the repair completely.

Read also: about the features of the operation of an electric underfloor heating.

As for the electrical variation, everything is much more favorable here, although the cost of such a heating project will be more expensive. However, the costs will quickly pay off, because such a system:

- safe;

- very comfortable;

- economical;

- in the event of a breakdown, repair is much easier.

Some are afraid that electric heating options consume a lot of electricity, but in reality this is not the case. After all, it should be borne in mind that the main expense is only for heating. Further, electricity is required only to maintain the set temperature. And a high-quality and competently mounted and tuned heater will not be a very greedy consumer.

A mixed type of heating will allow to further reduce electricity consumption, that is, when both the floor with heating and the main heating will be present in the room. Although without the latter, power consumption will not be a big problem.

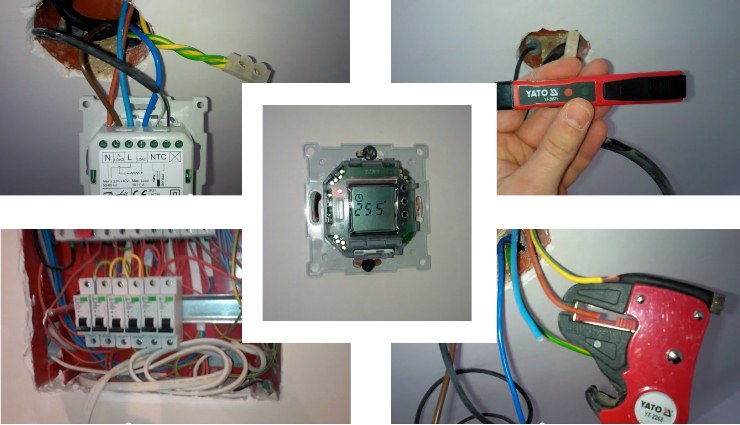

In this video you will learn how to connect a cable underfloor heating to a thermostat:

Features of the device and installation

Despite the apparent complexity of underfloor heating, in reality it is extremely simple, like the installation itself. The basis of its work is the conversion of electricity into heat through a conductor with high resistance. As such, a cable or mat can be used, which are connected to a 220 volt network. The thermostat monitors the degree of heating and temperature.

The thermostat will help maintain the required temperature without overheating the floor

The selected conductor is laid on a foil, which covers a rough screed 1 cm thick. Under it, in turn, there is a heat insulator, which can be placed directly on the ceiling. The wire itself is fixed with a special mounting tape and connected to the thermostat. A temperature sensor is also attached to it, which will record the degree of heating.

After laying and fixing, it is possible to apply the main screed with a thickness of 2 to 5 cm, on which the finishing coat will subsequently be laid.

When choosing it, you should pay attention to the admissibility of using it with the “warm floor” system.

Thus, the floor heating device includes:

- heater;

- thermostat;

- temperature sensor.

All installation and adjustment work can be carried out even by a person who does not have special knowledge in this area.

Types of thermostats

According to the type of functions, they can be divided into several groups:

– with one function (temperature maintenance);

Thermostat with one function

– with a large number of functions (programmable).

Programmable temperature controller

By design, thermostats are divided into types: wireless and with wires for communication with the boiler. Install the thermostats in a convenient place, connect the temperature sensor, connect it to the boiler control system and use it.

Room thermostats need a constant supply of air to function properly, so they should not be covered by curtains or blocked by furniture. Appliances adjacent to the electric thermostat may interfere with the correct operation of the device: lamps, televisions, heaters located nearby.

Connecting the thermostat to the underfloor heating system

Depending on the type of heating cable in the underfloor heating system, the connection scheme will be different. There are two types of floor: with a single-core and two-core bundle, the principle of operation between them is similar, but the multi-core cable has a much higher service life, as well as technical indicators for heating speed and height.

Connecting a thermostat to a single-core system is easier - just connect two neutral cables to one terminal, and a phase to the appropriate socket. In this case, the current will pass through the entire length in series along the ring of the bundle.

In a two-core cable, all wires exit from one side, so the connection is made in series - one wire to one terminal. The current in this circuit passes along the entire length of the heating element and returns along the same path in one direction.

Thus, subject to all the rules and the algorithm for connecting the thermostat to any circuit, all that remains is to set the device to the desired parameters by rotating the wheel on the temperature scale.

Thermostatic control valves

A thermostatic valve is a simple solution to the problem of obtaining a coolant of a given temperature by mixing colder water with warmer water. The view of the three-way valve is shown below:

Three-way valve

Scheme of including a three-way valve in the heating system:

Scheme of including a three-way valve in the heating system

Piping scheme for a solid fuel boiler using a thermostatic three-way valve:

Piping scheme for a solid fuel boiler using a thermostatic three-way valve

Gas boiler piping scheme using a thermostatic three-way valve:

Gas boiler piping scheme using a thermostatic three-way valve

The thermostatic radiator valve allows you to control the temperature in the room by changing the flow of hot water through the radiator. They regulate the flow of hot water through the radiator, but do not control the boiler. Such devices must be installed in order to adjust the temperature that is needed in each individual room.

This idea should be considered as an addition to a thermal control plant. Also, such devices need periodic readjustment and regular performance checks (every six months during the change of operating modes).

Preparatory work

Before proceeding with the connection of the regulator, it is necessary to carry out a number of preparatory steps. To begin with, they determine where it will be located, taking into account a number of nuances:

- The device is not installed where it can be exposed to direct sunlight; installation in drafts is also not recommended. This is especially true for models with a built-in sensor that will regulate the temperature according to the air flow of the room.

- It is undesirable to install the regulator on external walls that are in contact with the street, as this can lead to incorrect readings.

- The installation height of the device is an equally important point. Installation at a height of at least 400 mm is prescribed.

- It is forbidden to install temperature control devices in rooms with high humidity, since almost no model is equipped with a moisture-proof housing. Therefore, if the heated floor is located in a bathroom, shower or bath, then the regulator itself must be moved to the next room, where it will not be exposed to excess moisture.

- The temperature sensor must be placed no closer than 500 mm from the wall, in the case of a cable floor model - between the turns in the center. If the film version is used, then the thermometer head is located in the center of the carbon heating strip.

For more convenient and comfortable installation, it is recommended to use an elongated 60 mm socket. This will allow you to freely arrange all the wires connected to the device.

For a heated floor, it is recommended to run a separate dedicated power line with a copper cable with a wire cross section of 2.5 mm, which can withstand a load of up to 3.5 kilowatts. Moreover, the line must be equipped with a separate circuit breaker for 16 amperes.

Before starting the connection, it is necessary to make a strobe from the installation site of the device to the floor. It should fit two corrugated pipes with a diameter of 10 mm. In one of them, wires to the "cold ends" will pass, in the other - the temperature sensor line. It is especially useful to place a sensor in a corrugated tube, since they can often fail, and in order not to open the coating every time, it will be enough just to pull out the old one and insert a new one just as easily.

If the screed is supposed to be made quite thick (35-50 mm), then the corrugated tubes can not be immersed in the strobe on the floor. Otherwise, you will have to prepare an appropriate groove here as well. The ends of the corrugations should be plugged so that the solution does not get there during the process.

When the thermostat is connected to a film-type warm floor, corrugated tubes are not used, since here the temperature measurement principle will be different.

Central thermostat

Such a thermostat is located far from your boiler and usually allows you to turn the heating on or off throughout the house. Older versions are wired to the boiler, newer systems tend to send signals to the device's command post. It is with devices of a new type that quite expensive, but effective devices are equipped: double-circuit boilers Ferroli, Beretta and domestic AOGV.

The most famous are room thermostats for a double-circuit boiler of the Gsm and Protherm trademark. They have a built-in dilatometric thermostat for the boiler, which, depending on the model, can work remotely, often this technology is used for an electric boiler or solid fuel units.

The room thermostat turns off the heating of the system as needed. It works by measuring the air temperature and turning the heating on when the air temperature drops below the thermostat setting and turning it off when the set temperature is reached.

Advice:

- It is recommended to set the thermostat at 20°C;

- At night, the set temperature should be between 19-21 ° C.

- It is desirable that in the children's room it was about 22 ° C.

- The temperature should not fall below 22°C in a room for the elderly and people with disabilities.

As a rule, the temperature of the whole house or individual rooms is based on only one climate microcontroller in the heating system. The best option for its location in the living room or bedroom, which should probably be the most visited place in the house.

Room thermostats need a free flow of air to sense the temperature, so they should not be covered by curtains or blocked by furniture. Appliances adjacent to the electric thermostat may interfere with the correct operation of the device. These include lamps, televisions, neighbor's boilers through the wall, touch switches.

Areas of application of temperature controllers

Thermostats are widely used in various fields, both in industry and in everyday life. Most often, these devices can be found in underfloor heating systems with a heating element in the form of a heating bundle, which is located in the screed. When power is applied to the electrodes, the wires heat up and give off heat to all surrounding layers; for proper operation, the system is equipped with a temperature sensor built into the screed. The controller can be used for electric or water underfloor heating, the principle of its operation does not change from this.

Thermostat with sensor for underfloor heating

The thermostat is also used in heating or heating boilers to automatically adjust the level of heating of the internal environment. Many manufacturers equip heating devices with these devices already at the manufacturing stage, but even if this is not provided for by the boiler design, the controller can be installed on the line yourself.

Programmable room thermostat

The programmable electronic room thermostat allows you to select the desired and comfortable temperature at any time, it is easy to reconfigure and change the operating mode. The timer allows you to set a different heating pattern for weekdays and weekends. Some timers allow you to set different settings for each day of the week, which can be useful for people who work part-time or in shifts. Many Terneo and KChM models are equipped with such thermostats.

Programmable room thermostat

A programmable room thermostat allows you to set individual heating standards for each day in accordance with your lifestyle and maintain the temperature at home all the time, regardless of the presence or departure of the owners. Video: Connecting a room thermostat to a gas boiler

If a boiler with a radiator is responsible for the heating system, as a rule, only one programmable room thermostat is needed to control the entire house. Some patterns need to be adjusted in the spring and fall when the clocks go back and forth or there is a certain change in climate. We also recommend changing the temperature settings when changing day and night.

Such a climate controller has several options that expand its capabilities:

- "Party", which stops heating for several hours, then resumes;

- "Override" allows you to temporarily change the programmed temperatures during one of the configured periods;

- "Holiday", increases the intensity of heating or reduces it for a certain number of days.

Connecting a thermostat

Since temperature controllers can be used both to control heating elements and to control a cooler, there are two types of contacts and terminals in the design of the device. During the independent connection of the device to the system, it is necessary to strictly observe the polarity of the contacts and avoid contradictions in the circuit.

Thermostat connection diagram

No electrical connection is required to connect a mechanical thermostat, since all control and opening of the switch is done by physically changing the characteristics of the heating plate. To connect this device, you need to follow the algorithm below:

- In the documentation for the devices, there is a designation of the terminals by numbers; in accordance with these indicators, it is necessary to assemble the system. First of all, you need to connect the zero cable to the box electrodes and lead it immediately to the consumed heating elements, for example, a warm floor;

- The phase is brought into the controller directly, without connection to household appliances. The box itself will distribute electricity at the moment the contacts are turned on. In some devices, it is necessary to lay a jumper inside the thermostat from the positive wire to the operation indicator, which shows a signal at the moment the heater is turned on and throughout the entire period of operation;

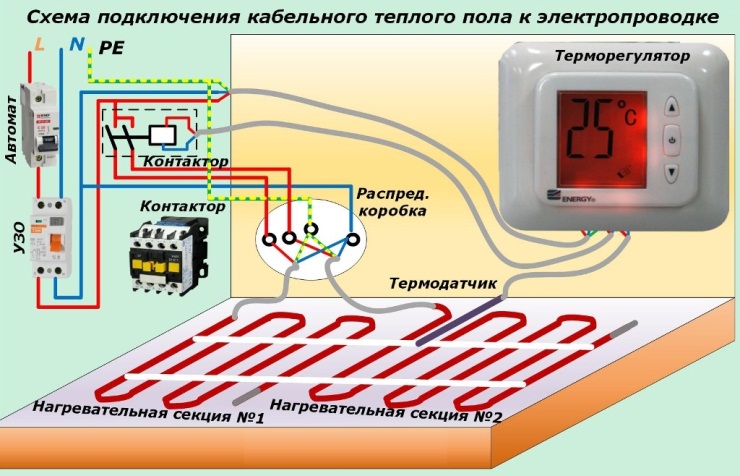

- The control unit contains terminals for connecting a cooling heating element, as well as for an external temperature sensor. All devices must be connected in series, the current must be completely disconnected. This is a typical thermostat connection scheme, which is most common in underfloor heating or infrared space heating systems;

- The temperature sensor is connected last, after which a test run of the system and a voltage check on all elements are performed.

Scheme using the machine

There is also a thermostat connection scheme using a magnetic circuit breaker, most often this scheme is used when there are several controlled devices that require high voltage current for operation. In this case, the machine is connected to an open network of a positive cable in parallel with a thermostat, in addition there is a connecting cable with a control device. Current is supplied to consumer devices through a circuit breaker, but it is controlled by a thermostat. The heating elements are connected to the controller only on a parallel line and through the machine, this allows the system to be operated with high voltage without interruption and in a safe mode. In the event of an emergency, the switch will trip and completely de-energize all devices.

Thus, it can be seen from the diagram that the thermostat is connected to heating or cooling devices immediately before applying voltage to them, that is, the controller will be the first element in the system. Many thermostats are equipped with an electronic microcircuit and a processor that, in addition to temperature readings, provide additional data on various indicators, such as the state of humidity in the room, pressure and the time required to reach the set parameters. Such devices have a cost much higher than mechanical household thermostats.

Types of thermostats

The floor temperature controller can be of three types:

Electro-mechanical thermostats. In appearance and principle of operation, they resemble a similar device on an iron: there is a switch, by turning which you set the required temperature. These are the cheapest and easiest to use devices.

Electromechanical thermostat for electric floor heating

Digital. More expensive models. They are controlled not with the help of a wheel with graduation, but with the help of buttons (tactile or touch - depends on the model). Usually they also have a digital panel that displays the current temperature and / or the set value.

Digital controls - have a slightly more "advanced" look

Types of thermostats

There are two main types of thermostats, which differ depending on the principle of operation:

- Mechanical devices are thermostats that regulate the temperature of the actuator by opening a contact between two plates of different density. When the sensor is heated, the signal enters the contactor housing and transmits an impulse to open or close the plates;

Electronic thermostat

- Electronic thermostat. In this case, the information coming from the temperature sensor is analyzed in a digital processor, only after that a command is executed to supply power to the heating element.

In both cases, the control is carried out manually, by setting the required temperature on the controller case. You can also distinguish the classification of thermostats based on visualization and control keys. Thermostats are available with rotary dials with a scale, setting buttons or a touch screen. The principle of operation of all these products is not significantly different from each other.

There is also a classification of thermostats according to the type of placement: external or internal. Depending on the task to be solved, the device can be installed into the wall in a pre-made niche. The construction size of such a device coincides with an ordinary socket, so it is often mounted in a hole cut by a crown.

The outdoor thermostat has a thicker body, which is closed on all sides with plastic plates.The disadvantage of such a device is its size, due to the impossibility of placing the device inside the wall, it will protrude on a plane, moreover, when connecting a cable to it, it will be necessary to arrange an additional channel from a corrugated pipe or canister.

Connection Recommendations

To increase the service life of the electronic thermal sensor, it is not recommended to install it in a draft zone or in places of active exposure to direct sunlight. Thanks to a simple thermostat connection diagram, almost any home craftsman can handle this job. However, first you should decide on the connection method:

- Classical.

- Using a magnetic starter.

Both options are worth considering in detail.

Standard scheme

One of the important parameters of any thermostat is the power indicator. One device can be used to control several space heating devices. It is from the power of the thermostat that the number of heating devices that can be connected to it depends. At home, it is quite enough to use appliances with a power of no more than 3 kW.

Most often, thermostats have four contacts - two for input and output. To connect the device, it is necessary to extend two conductors from the junction box and connect them to the input terminals. After that, the output contacts are connected to the heating system using two other wires.

If it became necessary to connect two heating devices to the thermostat at once, then you need to decide on the type of connection:

- Sequential.

- Parallel.

Using a magnetic starter

Such a connection scheme for a mechanical thermostat is most often used to control several heaters. The magnetic starter is an electromagnetic type switching device. It is designed for use in networks with high loads. There are quite a few options for connecting a thermostat through a magnetic starter, but it is enough for a home master to know only one.

If everything was done correctly, then it remains only to set the regulator to the desired mode of operation. Connecting the thermostat should not be difficult if you follow the instructions. However, you should not overestimate your strength, because the safety of family members depends on the quality of the connection.

Principle of operation

Most often, thermal sensors operate cyclically, and at the same time, a circuit is closed-opened. As the temperature rises, the resistance of the thermostat's internal sensor drops. As soon as the set parameter is reached, the device operates and turns off the circuit. During a decrease in temperature, the reverse process occurs - the resistance increases, and as a result, the thermostat turns on the electrical circuit.

With the help of a temperature sensor, you can easily control the microclimate in the room. It is enough just to set the desired temperature in the apartment, after which the device will do everything on its own. Infrared heated floors have now appeared on the market, which are able to heat not only the air, but also the surrounding objects. For the system to work in automatic mode, a thermostat must be connected to it.

Electric boilers

A fairly common alternative to gas and solid fuel boilers. A lot of advantages, high efficiency, but a long payback period. The connection is simple, like with gas boilers, but without a cold water supply. Temperature control and overheating protection are provided.

Boiler mechanical timer

With a simple mechanical timer for an electric boiler, there are three options for starting the central heating system:

- The boiler is off;

- The boiler supplies hot water;

- The boiler turns on and off at the set time.

Mechanical timers usually have a large round dial with a 24-hour scale in the center.By turning the dial, you can set the desired time and then leave it at that position. The boiler will turn on at the right time. The outer part consists of a set of tabs with a 15-minute period, which are inserted for the convenience of adjusting the operation and setting modes. An emergency reconfiguration is possible, which is performed when the boiler is connected to the network.

Mechanical timers are easy to set, but the boiler always turns on and off at the same time every day, and this may not satisfy the owners if the family is large and bath procedures are performed several times a day at different times.

Purpose of thermostats

Depending on the purpose of the room, it may be different, but not higher than + 27 ° С. Although in some cases, when heating large rooms, heating up to + 33 ° C is allowed.

The thermostat can be connected even by a novice specialist

There are several main reasons for maintaining the temperature within such limits:

- Ensuring comfortable conditions for a person, because when the floor is heated above + 27 ° C, the sensations for the legs can be far from pleasant.

- Floor covering also requires the maintenance of certain temperatures, non-compliance with which can lead to various unpleasant moments - deformation, drying out, divergence of seams.

- And the constant unregulated operation of the heating element will result in a significant waste of electricity.

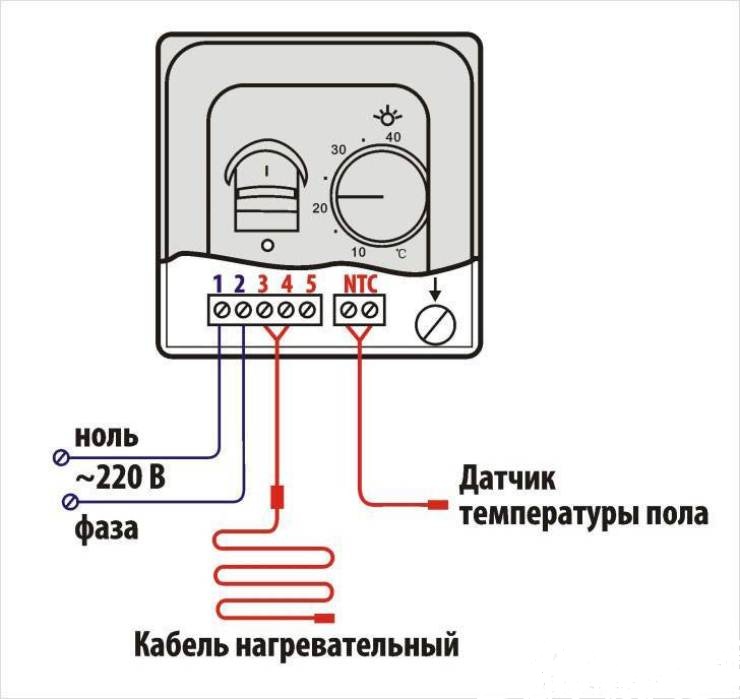

It is in order to maintain the temperature within certain parameters that electric floor heating systems are equipped with thermostats. Moreover, the scheme for connecting a warm floor to a thermostat is quite simple and will not cause problems even for a person who first encountered such a need. This is clearly visible in the figure.

Scheme of connecting the floor to the thermostat

Main types of boilers and temperature control

There are several types of boilers: solid fuel, gas, electric and liquid fuel.

Boilers are widely used all over the world. There are domestic samples, there are boilers and imported ones. The material of manufacture is steel or cast iron. Easy to operate, economical, with the function of adjusting the temperature of the coolant. In cheaper models, this function is implemented using a special device - a thermocouple.

Structurally, a thermoelement is a metal product, the geometric dimensions of which, under the influence of temperatures, decrease or increase (depending on the degree of heating). And this, in turn, changes the position of a special lever that closes and opens the draft damper. The photo shows an example of such a regulator:

Photo: sample thermostat

The more the damper is open, the stronger the combustion process, and vice versa. Thus, the volume of air that enters the closed-type combustion chamber is fully controlled by the thermostat, and if necessary, its supply is stopped and the combustion process dies out. In more modern models, controllers are installed that, depending on the specified thermal conditions, control the air flow, turning on (or turning off) a special fan (see photo below):

Boiler with temperature controller

Gas boilers are the most common and cheapest units to operate. Boilers are single-circuit and double-circuit. Single-circuit boilers have one heat exchanger and are intended for heating only. The switching circuit is shown in the figure below:

Scheme of switching on a single-circuit boiler

Double-circuit boilers have two heat exchangers and are designed for heating and hot water production. The boiler connection diagram is shown below:

Scheme of switching on a double-circuit boiler

Some boilers have separate controllers for heating temperature and hot water.

Wiring diagram

When the floor itself is laid, and all the preparatory work has been completed, you can begin to connect the electric floor heating to the thermostat. It's easy to do. As a rule, if you buy a device in a store, an instruction is always attached to it describing the features, settings and installation. A diagram of how to connect a warm floor to a thermostat is also located on the back of the device.

The scheme for connecting a warm floor is simple, even an inexperienced person can figure it out

As can be seen from the figure, the first two contacts are used to connect the 220 volt power supply. In this case, it is highly desirable to connect the phase and zero as indicated on the device diagram.

Contacts numbered 3 and 4 are designed to connect directly to the consumer. Here you should be extremely careful, since inexperienced craftsmen often connect power wires to these terminals, which always leads to the failure of the device.

Terminal number 5 (for this example) remains free, but 6 and 7 are used to connect a temperature sensor to them. Here, too, it would be useful to check it first. To do this, with a tester (multimeter) in the resistance measurement mode, you need to see what readings the temperature sensor gives. For this example, this value should be 10 kΩ with a possible deviation of 5-10%. If the sensor shows a short circuit or other values \u200b\u200bthat are very different from the indicated values, then it is clearly faulty.

In this video you will learn how to connect a thermostat: