For the arrangement of floors in rooms with a large area, a mechanized floor screed is widely used. The traditional way pouring cement screed provides for the preliminary preparation of a special solution with its subsequent application to the base base. At the same time, all work is done manually, which not only takes a lot of time, but also does not provide the ideal quality of the resulting surface.

A mechanical screed involves the use of special equipment that helps to cope much faster and better with the preparation of a cement mortar, applying it to the work surface and leveling it to perfect condition.

Advantages of a mechanized screed

- Machine screed allows you to get a flat surface in rooms with a large area.

- A mechanized screed reduces the time for repair work, as well as labor costs. This is achieved not only by accelerating the process of filling the floor in the room, but also through the use of semi-dry screed technology, which very quickly gains strength and becomes serviceable.

- Due to the fact that the entire floor in the room can be filled in one day, it dries evenly. This makes it possible to achieve an unprecedented high strength of the concrete obtained in this way.

- For the preparation of the solution in a mechanized way, environmentally friendly and cheap materials are used.

- The use of special equipment allows you to control the level of the floor, as well as to perform various slopes of its surface provided for by the project.

A mechanized semi-dry floor screed is very common when performing machine leveling work. Due to the fact that there is practically no water in the composition of the mixture used in this technological process, it is possible to achieve accelerated drying and hardening of the surface. After 1-2 days, you can walk on it fearlessly, and on the 4th or 5th day, the screed becomes completely ready for laying the final layer of flooring on it.

Equipment for mechanized floor screed

For the preparation of the building mixture, as well as pouring and leveling the surface of the concrete pouring of the floor by mechanical means, special equipment is used, which includes:

- Pneumosupercharger - a device that provides simultaneous preparation of the solution and its supply to the place of laying the concrete screed.

- A compressor used to create the pressure necessary to supply the resulting mixture. It can be included in the design of the air blower or used as a separate device.

- Betonovod - a hose for supplying concrete.

The use of such equipment in construction work allows you to achieve the simultaneous performance of several operations at once: preparing a building mixture, applying it to the floor surface and leveling. Due to the small weight and size indicators of the products used, their high mobility and ease of use are achieved.

The leveling of the mechanically applied building mixture on the floor surface is also carried out using special equipment, which includes smoothing machines.

This is a disk device, which includes a motor mounted vertically and equipped with a special handle for ease of use. Depending on the purpose, smoothing machines differ in weight, size, and also in power.

Construction mixtures for mechanized application

A mechanized floor screed involves the use of a building mixture, for the preparation of which the following materials are required:

- Fine sand.

- plasticizers.

- Cement.

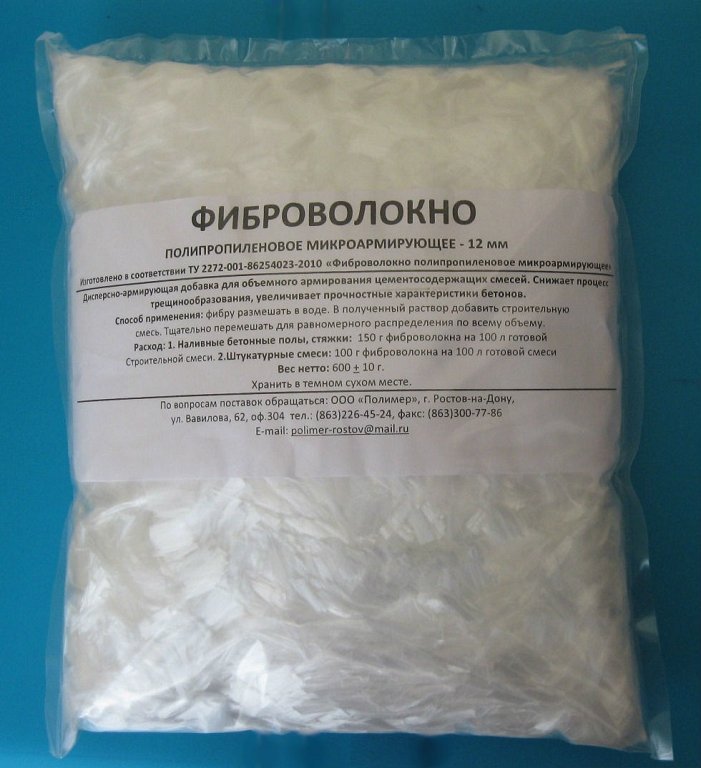

- Fiberglass (polypropylene fiber).

Fiber is a building material consisting of very thin (about 18 microns thick) threads of small length (from 2 to 4 cm). Mixed with concrete mortar, these threads provide it with additional strength and lightness. These qualities are especially important in cases where technical conditions do not allow using too heavy concrete to level the floor.

Floor screed mechanically provides for the following work:

- Preparatory stage. The work on preparing the floor for applying a cement screed to it by mechanized method does not differ from the work performed when pouring it manually. At the same time, the base is checked for the presence of minor flaws, thoroughly cleaned of debris and primed. Using the building level, the height of the future floor surface is determined. To do this, special marks are applied to the walls, and on the floor beacons are installed. To ensure the strength of the structure and prevent its destruction as a result of temperature fluctuations, damper tape.

- Preparation of the mixture and pouring the floor. The components of the concrete mixture are poured into the working capacity of the pneumatic blower in the required proportions. After turning on the device in the network and preparing a solution of the required consistency, the floor is poured. At the same time, it is necessary to start it from the corner farthest from the entrance doors, gradually moving towards the exit from the room. In parallel with the performance of these works, the floor surface is leveled using a smoothing machine. The work on pouring the screed in each room must be completed within one day, this is necessary to ensure its maximum uniformity and strength.

- Laying the final cladding.

Thus, mechanized floor screed can significantly reduce the time of work and improve the quality of the result. However, when carrying out repairs in apartments with a small area, such a solution is not always appropriate.