The underfloor heating system is gradually becoming an integral part of comfortable modern housing. From the point of view of efficiency, durability and high-quality heat distribution, the most attractive is a water-heated floor with a pipe heating system. Despite the fact that laying such a floor in an apartment is associated with certain risks and difficulties, residents of apartment buildings do not want to completely give up the opportunity to enjoy the comfort and warmth that a water system provides. Let's find out how realistic it is to implement this idea, and how the underfloor heating is laid in the screed.

Possible obstacles

As already mentioned, the arrangement of a water-heated floor in an apartment can in some cases be problematic. There are several reasons for this:

- A large length of underfloor heating pipes can lower the pressure in the entire house system, which will affect the quality of heating from neighbors.

- In some regions of the Russian Federation, including Moscow, it is forbidden by law to connect a warm floor to a common water supply and heating system.

- In those regions of Russia where such a ban does not apply, before connecting the underfloor heating to the heating system of an apartment building, an examination is required, which must establish that the system will not be impaired.

- The high temperature of the water in the heating system (50-75 degrees) is not suitable for the underfloor heating circuit; according to the norms, the surface temperature should not exceed 30 degrees.

- With any leak in the system, you risk flooding your neighbors.

Solutions

With a strong desire, any obstacles can be overcome. Laying a water-heated floor in apartments will become possible if the following steps are taken:

- Installation of an individual heating system - in this case, you are guaranteed not to disturb the thermal circuit of a multi-storey building and will manage the heat in your own apartment yourself.

- The inclusion of a circulation pump in the underfloor heating system will also help maintain normal pressure in the system and allow it to pass the necessary examination.

- To lower the water temperature in the underfloor heating pipes, it is necessary to connect through a mixing unit.

- A guarantee of reliability and protection against leaks will be provided by the use of copper pipes in the underfloor heating system. In addition, leaks are not so scary for residents of the first floors.

If difficulties do not stop you, try to approach the matter with all responsibility and strictly follow the laying technology in order to avoid subsequent defects.

Material selection

The choice of material for underfloor heating is an extremely important part. The reliability of the entire structure and service life depend on the correct choice.

Choosing pipes

The efficiency and safety of underfloor heating is based primarily on high-quality pipes, since pouring the screed will make the repair and replacement of damaged areas almost impossible.

- Metal-plastic pipes with a diameter of 16–20 mm are suitable for the underfloor heating system. They are flexible, conduct heat well, are practically not subject to thermal expansion. However, you need to choose only high-quality, expensive metal-plastic from trusted manufacturers; an inexpensive pipe can simply break due to insufficient protection of the aluminum layer.

- A good option is to use PE-X pipes. They are very elastic, but at the same time resistant to stress, they serve up to 50 years. They are produced in large bays, so that the contour is performed without additional connections.

- Copper pipes have excellent thermal conductivity, ductility, last up to 100 years and have very reliable connections. Unfortunately, they are very expensive and not suitable for everyone.

- The optimal choice is PEX-AL-PEX pipes, which have all the advantages of metal-plastic and cross-linked polyethylene. Multi-layer structure, oxygen barrier preventing corrosion of the aluminum layer, make them very reliable.

Important! Underfloor heating pipes must be designed for pressures exceeding 8 bar.

Screed material

When buying a mixture for the primary screed, you can choose any composition of a proven brand that matches the brand strength of the base.

For pouring pipes, you can use a standard cement-sand or concrete mixture, into which plasticizers are introduced to prevent cracking from temperature changes. You can choose a semi-dry ready-mix, specially designed for underfloor heating - it does not require any additional additives.

The choice of waterproofing

For a waterproofing device that protects against the formation of condensate and protects against leaks, you can choose materials of a coating or film type.

Coating waterproofing is more reliable, but more expensive. The finished mixture in buckets has a bituminous base, it is well applied with a roller and brush in several layers. Dry - cement waterproofing, requires mixing with water, then applied with a layer of up to 1 cm.

Film waterproofing materials are roofing material or a dense film. The bituminous material is spread and heated with a torch or hair dryer to firmly adhere to the base. The film is spread with an overlap, gluing the joints with adhesive tape.

Heat insulating layer

Expanded polystyrene is usually used as a heat-insulating layer, the minimum thickness of which is 30 mm. You can choose any foil heat reflector. There is a special substrate for underfloor heating with a foil layer, on which there are clips for attaching pipes.

Preparatory stage of laying

The preparatory stage of laying goes according to the following scheme:

- Calculation of the volume of necessary materials, choice of laying scheme.

- Rough leveling of the surface, sometimes with preliminary removal of the old screed.

- Waterproofing device after complete drying of the previous layer.

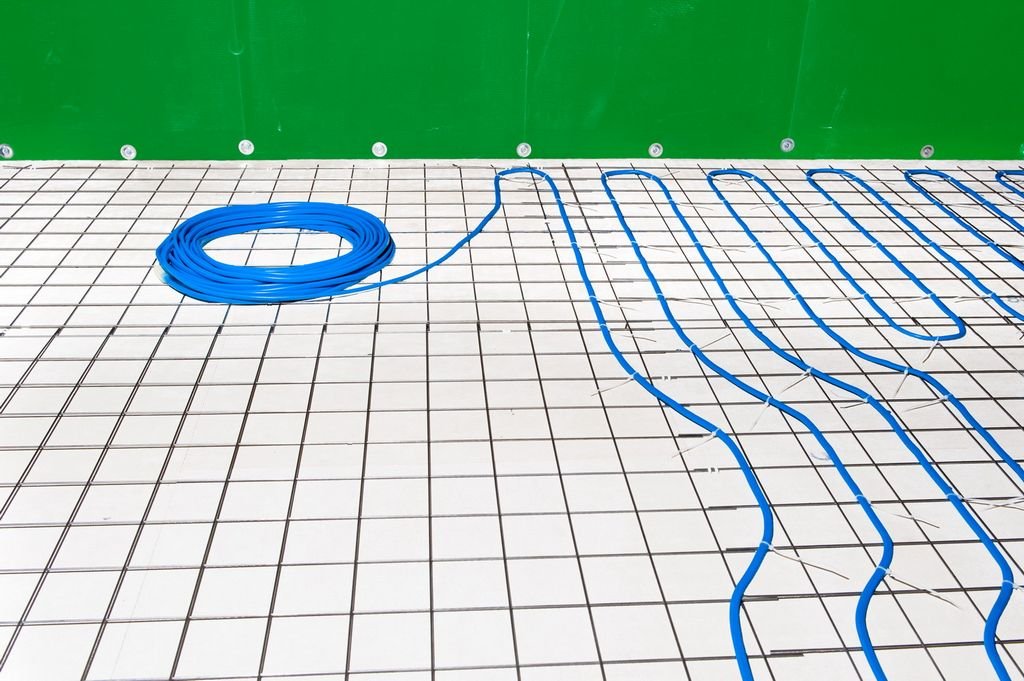

- Fastening the heat reflector and gluing pipe holders to it. If a reinforcing mesh is used, pipes can be attached to it, it itself is fixed to the floor with dowels.

- Pasting the perimeter of the room with a damper tape, for the possibility of expanding the screed without the appearance of cracks.

Choice of laying pattern

There are two popular laying patterns: snail-type and snake-type.

- For uniform heating of the floor, the “snail” scheme is better suited, since it alternates between cold and warm water flow. Hot water passes around the entire circle of the room, then goes to the second, third, fourth circle with a decrease in diameter by 20–30 cm, then changes direction in the center, and returns with an increase in the circle along the gaps left.

- According to the scheme, called the "snake", the hot water pipe runs along the edge of the room, passes under the windows, retreats 10 cm and runs parallel to the first line in the opposite direction. Another indent - another row, and so, gradually cooling down, the liquid passes through the entire room. For small rooms up to 20 sq.m. the difference in temperature is not very noticeable, unlike large ones.

Underfloor heating installation

After the completion of the preparatory stage, the laying of the warm floor begins according to the scheme selected and marked on the floor.

When laying pipes, it is necessary to adhere to the following scheme:

- retreat from the walls by 20 cm, from the windows by 15 cm;

- distance between pipes from 10 to 15 cm;

- maximum pipe length - no more than 80 meters;

- the end of the pipe goes back to the convector.

Before filling the pipes with a screed, it is necessary to check them by turning on the system.If everything is in order, you can set the beacons according to the level, then fill them with a mixture and level them, not forgetting to install a floor temperature sensor, which should be located between the pipes in the screed.

Turning on the underfloor heating

The first inclusion of a warm floor occurs immediately after its laying, without filling with a screed, to check the operation of the system. The second inclusion - only after complete drying of the screed and the finish layer. In this case, the water temperature must be increased gradually, starting from room temperature to the required one, increasing by 5◦С. A good thermostat will help with this, without it it will be difficult to choose the correct mode of operation of the system.

Finish coat

After complete drying of the screed, you can apply a top coat - self-leveling floor.

When pouring it, it is important to follow the application technology:

- divide the room into zones for pouring with the help of corners and bars;

- treat the surface with a primer;

- glue a damper tape around the perimeter;

- use self-tapping screws as beacons;

- use a needle roller to eliminate air;

- the grade strength of the finish coat should not be greater than the brand strength of the previous layer, otherwise cracks and unevenness may occur after drying.

Under tiles and porcelain stoneware, the device of the finishing layer of the fill is not required.

If all the recommendations and stages of technology have been followed, you will be able to enjoy the results of your work for many years.