The problem of ceiling insulation is especially relevant for residents who have apartments on the upper floors. Due to insufficient thermal insulation of the room during its construction or the loss of quality of insulation materials under the influence of time and the external environment, heat loss through the ceiling can be very significant. The issue of thermal insulation of the ceiling also worries the owners of balconies and loggias who plan to make a warm room out of them. Let's find out how to insulate the ceiling in the apartment and on the balcony using different materials.

The need for ceiling insulation is especially acute in old panel houses. The flat roof and the absence of an attic do not allow insulation from the outside. Insufficient thermal insulation of the ceiling not only leads to the loss of a large amount of heat, but is also accompanied by the formation of mold and mildew. They develop due to drops of condensate that forms at the border of cold and warm air, which becomes the ceiling surface itself. To solve this problem, you need to take care of the insulation of the ceiling, while not forgetting to ensure its waterproofing.

Ceiling insulation materials

It is possible to insulate the ceiling in the apartment with high quality and reliability only from the inside, even if there is an attic on top. Various cables and communications can pass through the attic, to which it is necessary to provide free access. There is no guarantee that the workers serving them will not damage the insulation or its waterproofing. To save yourself from problems and worries, it is better to warm the apartment from the inside.

Please note: regardless of the material chosen, the use of insulation will reduce the height of the ceiling.

How to insulate the ceiling? The choice of material is quite diverse:

- Styrofoam. The cheapest insulation with good thermal insulation properties and low weight. At the same time, the foam is not resistant to fire and has a fairly low mechanical strength.

- Penoplex. Extruded polystyrene foam with a fine mesh structure, produced in the form of plates. Environmentally friendly and durable insulation, easy to use, has high strength, is not afraid of moisture. The disadvantage is the relatively high price.

- Penofol. Foamed polyethylene, one of the sides of which is covered with foil. The main advantage is a small thickness, but the heat-insulating characteristics are low, therefore it is used only with small heat losses.

- Insulation based on mineral or basalt wool. Resistant to fire, environmentally friendly. Under the influence of moisture, it can lose its characteristics, therefore, it needs high-quality waterproofing.

- Warm plaster. When choosing insulation for the ceiling, they often forget about this material. In fact, modern plaster mixtures, due to the addition of various fillers to them, have excellent thermal insulation properties. They do not need waterproofing and provide a beautiful appearance of the ceiling without applying an additional decorative layer. The disadvantage of this method of insulation can be called the complexity of the process and the need for certain skills.

- Cork. Great for warming rooms finished with wood. It fits well into the interior, is easily attached to the ceiling and is not afraid of moisture.

Surface preparation

Before installing the insulation, you should take care of its waterproofing from the floor side. You can treat the ceiling with special waterproofing solutions that have appeared on sale recently. They penetrate deep into concrete structures and reliably protect against moisture.

Procedure:

- The ceiling must first be cleaned and washed.

- Particular attention should be paid to seams and cracks. If necessary, cracks should be chiselled, and a filler, for example, fine gravel, should be added to the solution.

- The waterproofing solution is applied to the moistened surface of the ceiling with a brush, additional conditions for working with them can be found in the instructions.

Insulation of the ceiling with polystyrene foam or polystyrene foam

The Izolon vapor barrier is glued onto the pre-leveled surface of the ceiling, while the foil layer should look down.

Further steps to create insulation will depend on what type of ceiling finish will be chosen subsequently. Styrofoam or foam boards can be painted or covered with decorative panels or drywall.

If you choose the first method, the order of work will be as follows:

- Insulation boards are attached to the ceiling with dowels or construction adhesive. It is important that each plate has at least five attachment points, usually the corners and the middle of the sheet.

- The seams between the plates are filled with mounting foam. Foam boards often have a selected quarter, which avoids large gaps between them.

- The joints between the sheets of insulation after installation are simply glued with metallized tape.

- A paint mesh is glued onto the fixed insulation boards, after which the ceiling can be puttied and painted.

With the subsequent use of decorative panels, a suspended structure is first made of rails or profiles. The step between the rails can be selected based on the size of the foam boards, usually it is 500–700 mm.

If necessary, foam boards can be easily cut with an electric jigsaw or a sharp knife.

The height of the suspended frame depends on the thickness of the insulation boards, but should provide a gap of 1–2 mm between them and a layer of decorative trim for air circulation.

After fixing the foam on the ceiling, the necessary communications are laid in the cells of the frame and the elements of the final finish are attached.

Insulation with heat insulators based on mineral or basalt wool

To insulate the ceiling with mineral or basalt wool slabs, it is necessary to build a suspended frame. Heaters of this type absorb moisture very well, therefore, they must be reliably protected from its ingress from the external environment. The ceiling insulation algorithm in this case is as follows:

- Surface preparation: cleaning and repairing cracks.

- Bonding a vapor barrier layer ("Izolon" with foil inside).

- Marking on the ceiling of the places of fastening of the frame elements.

Tip: it is better to make the distance between the guides a couple of millimeters less than the thickness of the insulation boards: then they will be inserted into the cells with force and will not require additional fastening.

- Fastening a frame from bars or a metal profile using a perforator and dowels.

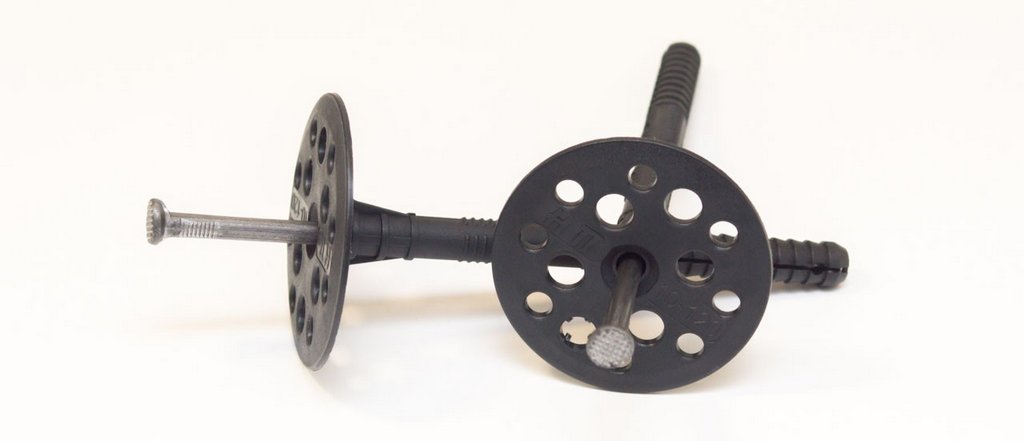

- Insertion of insulation boards. For greater reliability, you can use glue or special plastic dowels.

- Laying the necessary wires and cables.

- Laying another layer of vapor barrier over the insulation.

- Fastening to the frame of finishing elements.

When working with mineral or basalt wool, it is necessary to use personal protective equipment. Goggles and a respirator will prevent particles of insulation from entering the eyes and respiratory tract.

Exactly the same technology can be applied to insulate the ceiling on the balcony.

Features of insulation of balconies and loggias

Balconies and loggias often become additional rooms or greenhouses for indoor plants. A nice addition to a warm loggia is the reduction of heat loss in the main room.

It makes sense to insulate the ceiling on the balcony with sufficient thermal insulation of its remaining elements.That is, the floor and walls must first be insulated, high-quality glazing must be made. In this case, the insulation of the ceiling on the balcony will be the finishing operation in the process of turning it into a comfortable room.

When choosing a material for ceiling insulation, it should be noted that window frames should open freely after completion of all installation work. Therefore, between the lower border of the new ceiling and the upper edge of the window frame, a gap of at least two centimeters is required.

Sequence of work:

- With the help of a level or spirit level, markup is performed.

- All existing gaps between the ceiling and walls are filled with mounting foam. After it hardens, the excess is removed with a sharp knife.

To prevent the penetration of moisture from the outside, especially if the balcony or loggia is on the top floor, you need to take care of high-quality waterproofing.

- Using a perforator, lathing bars or metal profiles are attached. It is important that they lie in the same plane. If the surface of the ceiling plate of the balcony is uneven, then the position of the bars is adjusted by placing chips of the required thickness under them. It is better to fix these gaskets with small nails so that they do not fall out during installation.

- Insulation plates are inserted into the mounted crate. To get the right size, the plate is cut with a knife along the line, after which it breaks easily.

You can fix the insulation on glue or plastic dowels in the form of fungi. Each slab must have at least five attachment points.

- A layer of vapor barrier is attached to the insulation. For these purposes, penofol or isolon is best suited.

Now you can start finishing. The choice of the type of ceiling cladding - lining, decorative panels or drywall for painting - depends on the overall interior of the balcony and the personal tastes of the owners.