How to insulate a panel house from the inside

A simpler method is the internal insulation of the house. It can also be produced after construction is completed.

Now, liquid foam (penoizol) is often used for these purposes, which has many advantages over foam plastic slabs, which were widely used in building insulation until recently. Such plates could inaccurately adhere to surfaces, due to which heat losses occurred, and liquid foam does not have this disadvantage. With this method of insulation, heating costs are reduced significantly, and the service life of these materials is over 50 years. According to its parameters, a 10-centimeter layer of penoizol is equal to 30 centimeters of ordinary foam.

Shield house insulation technology

- Before insulating, it is necessary to carefully prepare the surfaces: clean the walls of dirt and remnants of the old coating, eliminate defects (irregularities, old nails, protrusions, etc.), plaster the surfaces for greater evenness. Then the walls must be primed to ensure a better setting of the base and the thermal insulation layer.

- Then proceed to fixing the insulation. If sheet materials are used, they are mounted on a pre-mounted frame. The distance between wooden or metal profiles is calculated from the width of the plates or rolls of insulation.

- The insulation itself is fixed either with glue or with the use of fasteners. If the gluing method is chosen, then you should choose an adhesive that will withstand the conditions of outdoor use (high humidity, temperature changes, etc.). Sheet materials are glued from top to bottom, placing the insulation strictly horizontally.

- When fixing with dowels in the facade of the house, holes are first made and then the fasteners are hammered there. Plastic fasteners are more often chosen, since metal ones can oxidize over time or create cold bridges. Usually five dowels are used to secure the insulation sheet - four in the corners and one in the center. You can replace special dowels with self-tapping screws with wide caps.

- After that, a reinforcing layer is created. For it, a special aluminum fiberglass mesh is used, and a layer of plaster is placed on top.

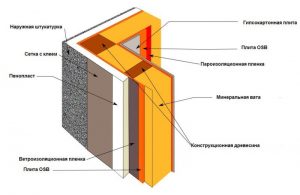

- Walls insulated in this way require the creation of a vapor barrier layer - a film that will create a reliable barrier against moisture entering the insulation.

- It is possible to lay two layers of insulation, while the second layer is laid with an offset and thus there are no seams in the structure. If the option of insulation in one layer is chosen and gaps have formed, then they can be filled with liquid foam or construction (mounting) foam. A layer of protective mastic or plaster is applied over the hardened composition.

How to make an economical version of a greenhouse for the winter

If finances do not allow you to build a capital greenhouse, do not despair. With proper ingenuity, you can achieve excellent results with minimal cash outlay. We invite you to see for yourself. How easy and inexpensive it is to build a winter greenhouse with your own hands will tell the video from the program "Four acres":

The owners of such a building in the summer should think about how to insulate the panel house for winter living. Such a house is usually built in a fairly short time, and if it happens in the warm season, there is a chance to temporarily not pay due attention to it and forget that it will look quite significant during the winter cold and winds.

Such buildings are often placed in suburban areas: they are cheap, quick to manufacture and fully meet all the requirements of country life. But - only when it's warm and even hot outside. In winter, a typical frame house is very cold, even if you have provided some kind of heating in it (which, without insulation, is usually a waste of money). The underfloor heating system, which many consider a panacea, will not save either.

It's all about very poor thermal insulation; turning on the boiler, you actually heat the street. Of course, there are options for panel buildings designed for year-round living in them. But at summer cottages, the simplest, summer modification is usually put - for the most part, people do not intend to return to gardens and vegetable gardens until spring. And if you have new interests, circumstances and hobbies that urge you to live in the country in the cold, you need to take care of its comfort. At least in terms of the amount of work done on insulation.

How to insulate a panel house for winter living?

The process can be broken down into three equally important steps.

We remove the cracks

Inspection starts from the walls

. The most likely places for the formation of cracks are the corners of the room, the joints of the walls and the floor (often here the cracks are covered with skirting boards, but it still blows from under them), window openings (the entire perimeter is checked here, but especially meticulously - below, under the windowsill, if it is installed , or under the lower casing). On the planes of the walls, if the house is not too old, there are usually no gaps.

Found gaps are caulked. You can use antiquated materials for this, that is, tow or jute rope. A little PVA glue is applied, and the chopstick is driven tightly into the hole found.

The ceiling is also subject to verification: warm air, as is known from physics lessons, tends to rise. And if the ceiling is full of holes, he will heat an unnecessary attic, instead of staying in the room. The integrity of the ceiling is easy to check in winter: put a bowl of snow under the roof, if it doesn’t melt, it means that there is no access from the lower room. If cracks are found, they are blown from the side of the roof with polystyrene foam from a sprayer.

Having eliminated such defects, you can proceed to the thermal insulation itself. And first you need to choose an insulating material.

What is suitable for thermal insulation

External insulation

- The walls are cleaned, the defects found are caulked, the surface is impregnated with antiseptics.

- The crate is stuffed. If the insulation is sheet, it will be cellular, and the dimensions of the nest between the slats correspond to the dimensions of the plate.

- If rolled, the planks are stuffed without jumpers along the entire length or height of the house with a distance of the width of the roll. The evenness of the laying of the crate is controlled by the level: the smoothness of the wall after finishing depends on it.

- Waterproofing is laid over the entire surface. Its role will be perfectly performed by construction polyethylene attached with a gun.

- The panels should go on top of each other and not stretch so as not to interfere with the subsequent laying of the insulator. The joints are sealed with tape.

- The heat insulator is placed inside the crate and fastened either with glue or with dowels. If glue is chosen, it is advised to grind the wall for better adhesion of materials.

Internal insulation

If it seems to you that only chipboard and drywall are not enough, you can use calcium silicate boards. They are approved for internal insulation work (since they are breathable lining), have high thermal insulation characteristics and are thicker than conventional materials. Yes, and do not believe those who assure you that a frame dwelling is only for summer, since it is not only possible to insulate a panel house for winter living, but also quite inexpensive.

Insulation of a panel house for winter living - the choice of materials and technologies

In the first case, the insulation is attached to the facade with glue, a reinforcing mesh is glued on top of the insulation and facade plaster is applied.In the second case, the thermal insulation is fastened between the rails of the bars, then the insulation is covered with a vapor barrier film and sheathed with siding.

Insulation of a garden house with foam plastic from the outside

Insulation of the garden house from the inside

In addition to insulating floors and walls, do not forget about protection against heat loss through doors and windows in a summer house.

Window openings, especially window slopes and window sills, require careful insulation. Well, if you have a small vestibule, then the cold will not penetrate the house, but it is better to insulate the front door in the country house. To do this, you can use dermantin, synthetic winterizer and furniture nails.

Insulation of a garden house with mineral wool from the inside

Expert answers

Ruff:

Try to enter “calculation of heat loss” into the search box, find the calculation calculator, set your parameters - the material and thickness of the walls, the area of \u200b\u200bwindows and doors, get the thickness of the insulation. But I advise you to entrust the implementation to specialists. It is correctly written here that both the ceiling and the floor must be insulated, the creation of “cold bridges” should be avoided, etc. etc. In general, it’s not just a “fur coat” to put on at home, it’s more difficult. You also need a “hat” and “boots”, and fasten all the “buttons”)

Nicholas V:

such houses do not exist. you are confusing something.

Cat Walking by itself:

Insulate the walls with polyethylene foam or polypropylene foam. For starters, 20 mm. It won't be enough, sew more. Don't forget the floor and ceiling.

TRAMP:

I think it's impossible! Justify - as a rule, the height of the ceiling is 2 meters! It is necessary to open the floor and make insulation 20cm. The floors will rise - the ceiling will be lower! Roof overhangs are usually short and will not allow you to increase the wall from the street.

GOD DANDELION:

my house has a wall thickness of 100mm ... insulation is Rockwool basalt slab ... walls are made of OSB slabs 12mm from the street ... hypocardium inside ... I live all year round ... it's cold in summer in winter ... the area of \u200b\u200bthe house is 75 sq m ... heating is an electric boiler

Olga:

We have timber 90 + insulation 100mm and siding on top Inside it is sheathed with clapboard. In winter, we live there on vacation and heat the stove once a day

Drinker in the Blackthorn:

Well, my friend has a frame house. sandwich panel walls b. y. did not freeze last winter. decided to insulate this one. fastened with osb screws and on top of the dowel five styropol. in the spring they will throw a net and tighten it with glue.

Irina Dedushenko:

If the frame house is built correctly, then it is warm in winter. The thickness of the insulation 15 cm is sufficient if the insulation is foam plastic and the joints are airtight. If the insulation is mineral wool boards, then it is also acceptable, but it is better (to save fuel) to make 20 cm. The mistake that we made earlier was to insulate the floor with mineral wool 10 cm thick. With a ventilated underground, this is not enough - you need 15 cm or add polystyrene foam. As a heater, mineral wool boards are better, but they must be laid carefully so that over time they do not slip and do not form gaps between themselves. The frame, if it is wooden, must be treated with an antiseptic

And be sure to pay attention to waterproofing. Often, rolled waterproofing is used to waterproof walls from the foundation - one layer of roofing material

It is necessary to use hydroisol, and if roofing material, then glued on bituminous mastic in two layers. The advantage of a frame-panel house is that it is not necessary to wait for precipitation, as in chopped and timber houses, to caulk it, etc.

Andrey Enyutin:

at the price of a bar that we now have, a frame-panel house for our climate is a perversion. however, a house made of timber trimmed with rokla turns into a so-called. 0 house.

Lion Heart:

Any building is good by itself. Finishing has always been the most important. The frame house is cleverly and efficiently insulated, finished and it will be super. Each material has its pros and cons. But again, the most important thing is finishing. A lot of friends have bought frame houses and do not regret it.

Alexei:

Girl, factory-made glued timber, dried, cut into a spike to size,

grooved (for example, 2 grooves), albeit with a rokla (we have a jute insulating gasket between the beams), and even a year later, an industrial gun, compressor, sealant in soft packaging go through the seams with a sealant ...

This is for a century.

Skeleton is a barracks that used to be built, I have one like this for dachas, it has already withstood 3 crossings, oblique, crooked, the shields are already crumbling. barrack

Insulation of other structures

You can usually insulate the floor using the same material as for the walls - polystyrene, polystyrene, mineral wool. In addition to them, expanded clay is a good solution - a porous reddish-brown material obtained by firing clay or shale.

If it is planned to live in the attic or store something that excessive cold is harmful, then the attic must also be insulated. Insulation material is laid between the roof rafters. If the attic is non-residential, it is enough to insulate the attic floor. Due to the low cost, low weight and good thermal insulation performance, expanded clay or sawdust is often used for this purpose.

Sometimes expanded clay (and other similar bulk materials) are also used for vertical structures - walls

In this case, special attention must be paid to compacting the materials so that they do not sag over time.

In addition to round timber, timber can also be used for the construction of wooden houses. Such buildings, subject to the construction technology, will last for decades and remain comfortable even in severe frosts.

What material for construction to choose

The beam does not have to be square or rectangular; a beam with a rounded surface is also widely used in construction. The price of lumber can vary significantly, but choosing the cheapest option is not always justified, it can simply turn into big problems in the future.

For construction, this type of timber can be used as:

whole

- the cheapest option, get it from tree trunks. And the main disadvantage can be considered large deformations of the house. The main difficulty at the production stage is to achieve acceptable humidity. If there are no special problems with a section of 15x15 cm (it is enough just to keep it in a drying chamber), then larger sizes, for example, 25x25 cm, are more difficult to dry;

if the budget allows, then it is better to stay on glued laminated timber

. It differs from a solid one in that it is assembled from several boards that are glued along the entire length. Due to this, it is possible to achieve the required level of humidity, and the profiled surface will make the joint of the individual bars very durable and reliable.

Winter houses made of glued laminated timber are much less shrinkage. And if it is recommended to withstand about 1-2 years before proceeding with interior decoration, then glued laminated timber allows you to remove this pause. Shrinkage does not exceed 0.5-1.0%, moreover, the probability of cracking is reduced to a minimum.

As for the length and thickness, the dimensions can vary over a wide range. Typically, the thickness of glued beams is up to 30 cm, and the minimum value is 7.5 cm, the length, as a rule, does not exceed 12 m.

Execution process

Do-it-yourself thermal insulation of such houses outside occurs in the same way when using any insulation:

- First you need to clean the walls and treat the surface with an antiseptic.

- After that, the crate is stuffed. When using sheet insulation, it is made cellular according to the size of the plates, and if rolled, then the strips need to be stuffed along the width of the roll.

- The entire area must be waterproofed. In this case, construction polyethylene is perfect, which is attached with a gun, the joints are glued with adhesive tape (while they must overlap).

- After that, the heat insulator itself is attached inside the crate made using glue or dowels.

Expert advice: it is recommended to close the thermal insulation from the inside with a vapor barrier. This is necessary so that the steam generated in the house does not fall on the insulation, which, because of this, loses its properties.

In the case of using chipboard sheets, they are fixed to the wall with self-tapping screws, which greatly reduces the level of insulation, since it does not create an air gap between the insulation and the wall. If GKL or chipboard sheets are not enough, calcium silicate boards can also be used. They are recommended to be used for insulation from the inside.

Therefore, if someone tells you that you can use a panel house only in summer, do not believe him. After warming such a frame building, it will be suitable for living even in harsh winters.

Watch the video in which the specialist explains the features of the insulation of a frame-panel house:

Is it damn cold in the new house, not only in winter, but even in autumn? Then it will have to be insulated, and as soon as possible. And you need to insulate the outside. Firstly, it is the economy of internal space. Secondly, external insulation is much more effective, because it prevents the walls from cooling, and not just keeps the heat inside.

Since this procedure is within the power of even a novice builder, you can insulate the panel house from the outside with your own hands. And this is saving on the cost of insulation up to 50%! The main thing is to choose the right material.

How to insulate

According to the technology, the heat-insulating material is placed in the gaps of the wall frame. The bearing elements of the wall can be made of wood or steel. The work is carried out in several stages.

Preparatory

It will not take much time, but it will significantly increase the quality of work. Before starting work, the wall frame is cleaned of construction debris, dirt and dust. Next, the walls are inspected for the presence of protruding fasteners that can damage the heat-insulating material. Protruding nails are driven in with a hammer.

All slots in the frame are insulated with mounting foam. The moisture content of the wood is checked, if the elements of the wall frame are damp, they should be dried with a building hair dryer. Then proceed with the next stage of work.

Waterproofing and vapor barrier

Protection of the wall frame from moisture is required in the following places:

- wall support on foundations (at the junction of elements from materials of different properties, horizontal waterproofing);

- on the outside of the wall, on top of the insulation to protect against atmospheric moisture;

- a vapor barrier is laid on the inside of the wall to protect it from moisture coming from inside the room (warm steam).

thermal insulation

Insulation is placed between the racks of the wall frame. The distance between the supporting elements is selected so as to ensure easy installation, namely:

- 580 mm clear between mineral wool posts;

- 600 mm for foam and extruded polystyrene foam;

- for polyurethane foam, the distance does not matter much.

Fastening of mineral wool is carried out on dowels

At the same time, it is important that there are no gaps between the racks and the heat insulator through which cold can penetrate. For foam, you can use special nails or glue

Polyurethane foam is held due to its own adhesion to the surface and penetration into small gaps in the structure.

sheathing

At this stage, there are discrepancies in technology for different materials. Unlike all the others, mineral wool does not allow fastening the sheathing directly to it. It is necessary to provide an air-ventilated layer of the wall to remove excess moisture. The layer is located after waterproofing, its thickness is 5-10 cm.

Frame house sheathing scheme

Polyurethane and polystyrene allow wall cladding to be mounted without a ventilation gap. After the cladding of the frame house was completed, the thermal insulation work was completed.

Thermal insulation of floors and roofs

To build a frame house for winter living, it is also important not to forget about the reliable insulation of the ground floor and the attic roof. If the house has a cold attic, then the thermal insulation is mounted in the ceiling pie of the upper floor

Rigid slabs of mineral wool are most often used for roofing. To ensure ease of installation, the pitch of the rafters is predetermined so that there is a clean distance of 580 mm between them. Thermal insulation is fixed after installation of waterproofing and battens.

Insulation of the floor of the first floor must be carried out using a durable indelible material. An excellent solution would be penoplex. If the insulation does not have high rigidity and strength, choose installation between the lags. To do this, boards or bars are fixed on the floor, which will take the load from people and furniture, and a heat insulator is laid between them. Proper insulation of the frame will make the house a comfortable and economical home.

Such houses are built quite quickly and often in the warm season, so thermal insulation is often forgotten.

However, in winter, during winds and cold weather, it will be significantly noticeable.

The choice of materials how not to harm the structures of the house

Considering that initially the frame house is quite light, it is often built on light foundations - columnar, shallow tape and pile. They are initially calculated for structures of low weight. Therefore, the weighting of the finished house may require strengthening the foundation. Yes, and the additional load on the floors must be taken into account.

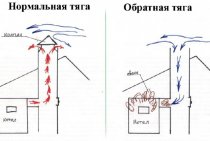

Dew point - why the heater does not "work"?

The main reason for the deterioration of the qualities of all hygroscopic heaters is the moisture that accumulates inside. After all, water is an excellent conductor of heat - water-cooled units are much more efficient than air-cooled ones. Moisture microparticles in the insulation layer work in the same way - they absorb heat and release it to a colder external environment.

And even perfect vapor and waterproofing will not save the insulation from moisture if the dew point at which condensation begins to form is incorrectly calculated. So, the image clearly shows what an insufficient layer of external insulation will lead to, in this case expanded clay with a density of 200 kg / m3 and a layer thickness of 10 cm.

The black graph illustrates the temperature drop of the wall pie from 20 degrees inside the building to -25 degrees outside. With such strong drops, an insufficient layer of outer insulation will lead to cooling of the inner layer, at the point of contact of which steam will begin to condense.

The ideal solution is to increase the thickness of the insulation, in this case up to 20 cm.

This option will either completely remove condensation, or shift it to the outer layers. Then, if there is a ventilation gap between the insulation and waterproofing, excess moisture will simply evaporate without affecting the characteristics of the material.

Thermal insulation boards and mats

The simplest and most affordable types of materials for external insulation are mineral wool and glass wool. To reduce heat loss by almost half, ten centimeters of insulation with a density of 25 kg / m3, laid from the outside, is enough.

Thanks to this, it is possible to reduce heat losses from 42.09 kW/h to 23.37 kW/h during the heating season.

Approximately the same effect can be achieved with 10 cm of polystyrene foam. But the disadvantage of polymer insulation is their almost complete vapor impermeability, which significantly worsens the natural microclimate.In other words, in such a house there will always be high humidity, unless forced ventilation is done. And this is a direct path to the formation of mold and fungi.

But natural insulation, for example, reed slabs, must be laid in a layer of at least 15 cm to ensure a similar level of heat loss

Of course, eco-friendly material is always preferable, but the financial side of the issue should also be taken into account.

Thermal insulation backfills

Bulk heaters are difficult to install. Often they require special equipment, but if the hand is not stuffed, it is rather difficult to do such insulation.

Although it is quite feasible. According to its characteristics, 10 cm of ecowool with a density of 35 kg/cu.m. are in no way inferior to mineral wool. But the density is 60 kg/cu.m. will already lead to an increase in heat loss to 25.43 kWh.

When insulating walls with expanded clay, you need to be prepared for the fact that you will have to increase the thickness of the walls by 25 cm. It is better to use expanded clay crushed stone with a density of 200 kg / cubic meter. Density increase up to 600 kg/cu.m. will lead to an increase in heat loss with a similar thickness of the insulation layer up to 27.22 kW / h. Also, do not forget about the weight of the building - such an amount of expanded clay will significantly make the building heavier.

15 cm of expanded vermiculite as an external insulation will reduce heat loss to 25.18 kWh. This is a good option if there is a vermiculite production nearby. Otherwise, the delivery of the material will negate all the cheapness of the insulation itself.

If there is a sawmill nearby that is ready to give away sawdust for free, the walls can be insulated in a rather economical way. In addition, 15 cm of sawdust with a density of 250 kg/cu.m. provide only 24.48 kWh of ash loss during the heating season. And so that the sawdust does not rot and gain sufficient protection against fire, they make a clay or cement mixture.

For example, for the manufacture of "home" wood concrete, you will need 100 kg of sawdust, 25 kg of sand, 6 kg of slaked lime and 200 kg of cement. You need to mix everything in one container, adding water in an amount sufficient for normal mixing. The final mixture should not crumble when compacted, but water should not flow out either.

Design features of a warm winter house made of timber

Quite often, wooden houses are considered exclusively as an option for temporary residence, for example, in the country. In this case, living in it is planned only in the warm season for a relatively short period of time.

But log houses may well be used for permanent residence, and due to the low thermal conductivity of wood, even a relatively small wall thickness will provide comfort in the house.

Optimal wall thickness

The thickness of the timber for the winter house should be selected based on the normative value of the heat transfer resistance of the wall. In this case, you can be guided by the requirements of the SNiP 23-02-2003 standard (dedicated to the thermal protection of buildings and structures).

Of the entire document, we will be interested in only 2 points:

for seasonal living, you need to take into account sanitary and hygienic requirements and comfort in the house. In this case, the heat transfer resistance should be about 1.26 m2∙ᵒC/W, that is, the wall thickness should be at least 17 cm;

A wall thickness of 50 cm from a bar is absolutely meaningless, so the builders use a different approach - they use a layer of heat insulator outside the house. Thanks to this, a winter house made of timber becomes warm even with a small wall thickness. For example, with a wall thickness of 15 cm and the use of a heat-insulating layer (10 cm), the heat transfer resistance coefficient will already be 3.1 m2∙ᵒС / W, which is even slightly more than the requirement of the standard.

Insulation of a house from a bar

You can insulate the house both outside and inside. But when using a heat insulator inside, the usable area decreases, so they are often limited only to the outer layer of the heat insulator.And if a beginner may have problems with building a house, then everyone can do it with their own warming of the house.

The work is performed in the following sequence:

- first, the wall is cleaned of dust and dirt;

- then the crate bars are installed (their thickness is selected depending on the thickness of the insulation layer). As for the step between the individual bars, it can be taken at the level of 60 cm. The crate can be carried out using only vertical bars, and bars can also be installed in a horizontal direction;

then a vapor barrier film is placed on top of the insulation layer, this is necessary so that the heat-insulating material does not dampen. If this happens, then the tree will rot faster and the heat insulator itself will lose its characteristics. The vapor barrier film differs from conventional polyethylene in that it allows moisture to pass through only in one direction, so that moisture will leave in the direction from the wall and will not get back;

Material selection

According to their composition, all heaters are divided into:

- loose;

- woody;

- foam;

- mineral wool (for example,).

- blocks;

- plates;

- rolls;

- mixtures.

And in appearance, these materials can be divided into the following:

- blocks;

- plates;

- rolls;

- mixtures.

When choosing a heat-insulating material, it is necessary to pay attention to its specific properties. The fact is that there are a lot of manufacturers of materials for building insulation on the market now, and even seemingly identical mats or slabs can have different performance.

Consider the most basic of them:

- the coefficient of thermal conductivity, the lower it is, the thinner the layer of insulation can be dispensed with;

- moisture absorption coefficient, the lowest is needed;

- fire resistance, depends on the ignition temperature, the higher it is, the less combustible it is and is more suitable for you;

- durability, it is clear that we choose the one with the longest service life;

- environmental friendliness, mandatory for indoor use, insulation must comply with safety standards for human health.

Only after studying what properties the material you like has, comparing it with others, it will be possible to decide how to insulate the house in the country.

And in appearance, these materials can be divided into the following:

- blocks;

- plates;

- rolls;

- mixtures.

When choosing a heat-insulating material, it is necessary to pay attention to its specific properties. The fact is that there are a lot of manufacturers of materials for building insulation on the market now, and even seemingly identical mats or slabs can have different performance.

Consider the most basic of them:

- the coefficient of thermal conductivity, the lower it is, the thinner the layer of insulation can be dispensed with;

- moisture absorption coefficient, the lowest is needed;

- fire resistance, depends on the ignition temperature, the higher it is, the less combustible it is and is more suitable for you;

- durability, it is clear that we choose the one with the longest service life;

- environmental friendliness, mandatory for indoor use, insulation must comply with safety standards for human health.

Only after studying what properties the material you like has, comparing it with others, it will be possible to decide how to insulate the house in the country.

Rockwool insulation - technologies on guard of comfort "href="http://pro-uteplenie.ru/neorganicheskie/minvata/53-uteplitel-rockwool">Rockwool insulation).

And in appearance, these materials can be divided into the following:

- blocks;

- plates;

- rolls;

- mixtures.

When choosing a heat-insulating material, it is necessary to pay attention to its specific properties. The fact is that there are a lot of manufacturers of materials for building insulation on the market now, and even seemingly identical mats or slabs can have different performance.

Consider the most basic of them:

- the coefficient of thermal conductivity, the lower it is, the thinner the layer of insulation can be dispensed with;

- moisture absorption coefficient, the lowest is needed;

- fire resistance, depends on the ignition temperature, the higher it is, the less combustible it is and is more suitable for you;

- durability, it is clear that we choose the one with the longest service life;

- environmental friendliness, mandatory for indoor use, insulation must comply with safety standards for human health.

Only after studying what properties the material you like has, comparing it with others, it will be possible to decide how to insulate the house in the country.

Panel house insulation technology outside

The advantage of frame-panel houses is the possibility of their insulation without removing the outer skin.

But if the walls are decorated with siding and are in good condition, it can be dismantled beforehand. This will save you a lot of money on new upholstery.

The main thing when laying insulation from the outside is not to leave a ventilated gap between it and the wall. This will nullify all insulation efforts, since cold air will freely contact the wall.

General scheme of external insulation

Regardless of the chosen material, the initial scheme is always the same:

- The walls of the house are cleared of hanging elements - visors, antennas and drains.

- A frame is made where the insulation will be invested. A beam of this size is used to provide the desired thickness of the insulation. Unlike the insulation of a wooden house, it is not necessary to make a ventilation gap between the insulation and the wall, since the vapor barrier has already been laid from the inside of the house and moisture does not need to evaporate through the insulation to the outside.

A cornice is fixed along the bottom in the area of \u200b\u200bthe base - it will hold the insulation boards.

After laying the insulation, it is closed with a windproof film. The membrane can be fixed on the frame with a construction stapler or nails. Joints and attachment points to the frame are glued with butyl rubber tape. It is important not to cover the insulation with impermeable waterproofing - possible condensate from the insulation must evaporate freely!

A 25 mm thick counter rail or siding profile is attached over the waterproofing to provide the necessary ventilation gap between the windproof membrane and the exterior trim.

External finishing can be done with both siding and edged board with subsequent processing.

If the insulation is laid under the plaster, a layer of reinforcing mesh is required on top, otherwise the plaster will soon crack.

For insulation with foam plastic, the frame does not need to be built. The plates are attached to a special glue and fixed with dowels with umbrellas.

All cracks are filled with foam

It is important not to forget to walk on the foam sheets with a special grater - to improve adhesion. Otherwise, the plaster layer can be easily removed along with the reinforcing mesh.

About the same, how to properly insulate your facade with mineral wool, is available on the video:

Warming the house with bulk materials

The technology of home insulation with bulk materials also requires the construction of a frame. After that, the frame is sewn up with an edged board to a height of up to 30 cm. An unedged board is not used - the insulation will spill out through cracks and irregularities. Consider insulation using sawdust as an example.

A layer of sawdust is poured around the entire perimeter of the house and compacted well. Uncompacted sawdust in the future caking and the resulting voids no longer insulate anything. So gradually the skin is raised under the roof.

The last layer under the roof is laid wet - so it will not need to be tamped, and thanks to natural ventilation, the sawdust will dry quickly.

If the insulation is planned with sawdust concrete, a special formwork is constructed, into which the mixture will be laid.The lesson is quite long - each layer must have time to dry before you can proceed to the next. Thus, only 50 cm of the facade can be insulated per day.