About induction

An induction boiler has absolutely no advantages over conventional, equipped with heating elements. All talk about this is the fantasy of marketers and sellers in order to sell their goods to gullible buyers. The percentage of electricity converted into thermal form is almost the same for all types of heating devices. Do not compare boilers with stoves - indeed, the induction surface is more economical than steel "pancakes", there are no heat transfer losses through the surface of the stove to the dishes, the heating spot exactly matches the size of the pan, it does not matter the tightness. In heating boilers, the coolant immediately heats up, there are no intermediate elements. There are no advantages, the efficiency of the boilers is the same. The rest of the "arguments" about reliability, security are also sucked from the finger. Among the disadvantages: increased wear of the winding due to interturn short circuits, increased aging of the insulation, vibration during heating, labor-intensive repair.

Induction heating systems are by no means a novelty, they have been used in industry for more than 70 years, but only some domestic kulibins offer to use them for heating buildings.

Electric boiler on heating elements, fully equipped, adequately controlled

Types of boilers for heating

There are several types of boilers that can be used to heat a greenhouse.

Gas. How to connect registers correctly?

A gas boiler consists of various components, in particular, a steel or cast iron heat exchanger, an atmospheric burner (sometimes), a control system, a water circulation pump, an expansion tank and a safety valve.

Photo 2. Gas boiler for heating the greenhouse. The device is quite large, often it is located outside the greenhouse.

The device works on the basis of natural or liquefied gas, is unpretentious to water quality and can be installed anywhere in the greenhouse.

Specifications of the greenhouse boiler:

- Efficiency minimum 93%;

- power - from 40 kW;

- the volume of water in the boiler is at least 6 liters;

- the height of the device is about a meter;

- width - 54-60 cm;

- length - 90 cm;

- gas consumption - at least 5.0 kb. m/hour.

After turning on the boiler, the water flowing through it is heated in the heat exchanger to the required temperature and pumped into the system circuit. This is a single-circuit option that is used only for heating. To heat the greenhouse and supply hot water, two-circuit devices with a built-in hot water heating circuit are used. Basically, single-circuit models are used for greenhouses. Smoke is removed through a specially equipped chimney or through a steel pipe.

In order to connect the register to the water circuit, it is necessary to find out where hot water will be supplied and where cold water will leave. Further, holes for threaded couplings are made at the ends of the register, on which fittings are then attached, connecting the heat exchanger with the water circuit. An air vent is welded on the opposite side from the supply. It can be at the end, but it is better that the valve is at the top.

Since the register is heavy, it is necessary to provide reliable fastenings. There are two ways to place the heat exchanger: wall and floor.

In order to install the register on the floor, it is necessary to make legs, as well as additionally fix the device against the wall.

Also, do not forget that the distance from the surface of the register to the walls and floor should be about 25 centimeters.

Advantages: the gas boiler is unpretentious in maintenance and does not require constant human intervention. It heats up instantly and ensures even heat distribution inside the greenhouse.

Disadvantages: high price for models for heating a large area, gas supply costs, the need to coordinate the connection of the boiler.

Electric boilers

Electrical systems are used to heat air and soil. Most often, an electric boiler is bought for heating large-area greenhouses, in which plants demanding light and temperature grow. An electric boiler allows you to accurately set the temperature that must be maintained inside the greenhouse, and use electricity to additionally illuminate the plantings.

Types of electric boilers:

- The simplest convectors will be a great choice for a polycarbonate greenhouse. The heating coil, through which the air flow passes, consumes little energy, but cools down quickly and is not suitable for heating the soil;

- Heaters are distinguished by the fact that air circulates through the heating coil forcibly and in large volumes. The heater is equipped with a thermal fan, and the heated air goes not only into the space inside the greenhouse, but also into pipes laid underground and along the walls;

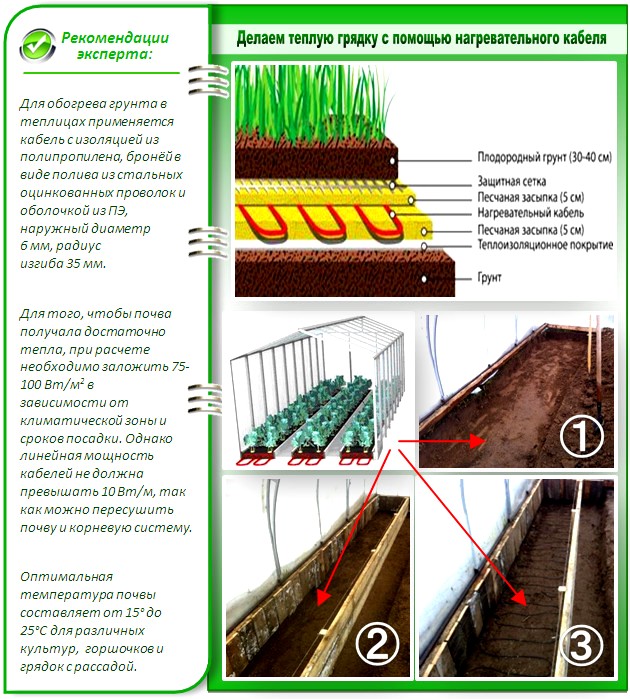

- Heating cables are laid in the soil and heat it, and this, in turn, increases the air temperature;

- Water for water heating is also heated by electricity. Such a system is used both for heating the soil and for increasing the overall temperature in the greenhouse. This heating option is recommended to be used in large rooms, since electric boilers for water heating are usually sold powerful, designed for farms and private houses. An alternative option is to make a wall-mounted greenhouse, and lay heating to it from the common boiler of a private house.

An alternative way to heat a greenhouse with electricity is to use infrared heaters. These devices are shaped like conventional ceiling lights, but they emit a bright light that does not heat the air, but the objects it falls on. Infrared heaters work from the network, and they can be used in greenhouses of any size and type. The only drawback of this heating option is the high cost of the device and the small area on which the light falls. Attaching a do-it-yourself ceiling IR heater is no more difficult than hanging and connecting a regular lamp.

A separate category of heating systems for greenhouses is combined boilers. They tend to run on two fuels at once, such as gas and solid fuel or gas and electricity. Such complex systems are used to save one of the resources or for greater security. For example, at night, electricity can cost less than during the day, and not every summer resident decides to leave a gas or coal boiler for several days. In addition, combined systems are useful in areas where power outages occur frequently.

Choosing the most suitable boiler for heating a greenhouse is a difficult task. Its decision depends not only on the size and conditions of use of the greenhouse, but also on the preferences of the gardener. Someone chooses for themselves simple gas stoves, and someone chooses a complex and expensive long-burning system. But in any case, the installation of a convector allows you to increase productivity and extend the use of the greenhouse at least twice.

Types of boilers for heating greenhouses

The main criteria for choosing a suitable boiler model for heating a greenhouse are its cost, the need for monitoring on an ongoing basis, performance indicators and availability:

- Solid fuel boilers. Firewood, sawdust or special briquettes are used as fuel material. Efficiency = 75%.

- liquid fuel models. Gasoline, kerosene or diesel fuel are used as fuel. Efficiency=about 96%.

- Gas boilers. This includes devices that run on natural or liquefied gas. Efficiency = max 98%.

- Electric boilers. The power source is the power grid, solar panels or wind turbines. Efficiency at the level of 95-97%.

Operation of a solid fuel boiler

The appearance of a solid fuel generator is similar to a stove, but the difference is that the functional state is ensured by the gas released during the combustion of the fuel.

The photo shows a solid fuel boiler for a greenhouse

The design of the boiler has several sections. One of the sections is provided for fuel placement. The combustion process is provided by the supply of oxygen through the bottom blowing system.

The blowing system has an adjustable damper, when the fuel burns out sufficiently, the damper is closed, after which the oxygen supply is blunted to a minimum. Due to the absence of air, a chemical process begins to occur and forms pyrolysis gas. It enters the second compartment, in which heat is generated.

Pyrolysis boilers are one of the most economical models for heating greenhouses with a small area. Thus, the recommended amount of fuel per 100 m2 of premises is only 11 kg / day.

Heating a greenhouse with a pyrolysis boiler has one more positive quality: inPossibility of heating not only air, but also water. This makes it possible to develop several options for the greenhouse heating system (for example, install radiators around the perimeter or place pipes under the fertile layer). Also, when using a pyrolysis boiler, the amount of smoke becomes less by 95%, and the cinder is collected in a special compartment and does not poison the atmosphere with harmful emissions.

The disadvantage of the pyrolysis boiler is its high cost.

Gas and liquid fuel boilers

Gas can be supplied to such boilers both in a stationary way (natural gas) and mobile - that is, fuel is supplied from an installed cylinder, which requires periodic replacement.

Gas flows through pipes

An important point when equipping a greenhouse with a gas boiler is the mandatory presence of ventilation.

This is necessary to ensure normal conditions for plants and greenhouse workers, since the carbon dioxide produced during the combustion process is extremely dangerous in both cases. The same situation is with the use of liquid fuel models of boilers. However, it will not be difficult to convert a gas boiler into a liquid fuel boiler and vice versa. One has only to change the burner to another, with a nozzle of a suitable diameter.

Electric boilers - their advantages and features

The use of electric heating boilers for greenhouses is allowed only if it is not possible to install a different type of installation.

This is due to the cost of electricity and the availability of alternative energy sources. The only possible exception would be the use of heat accumulators. Such projects are part of a multi-tariff electricity consumption plan and allow saving up to 60% of electricity costs. At the same time, the heating, ventilation and heating system is fully automated.

The video clip shows how you can heat the greenhouse with a converted boiler (from mine to pyrosine). At a temperature outside the window of minus 21 degrees, the greenhouse warms up to + 25 degrees. Interestingly, the heat generator is literally assembled from scrap metal. We recommend to look.

We hope that the material of the article was useful to you. If not difficult, please click on the social network buttons below.

About the efficiency of various electric heating systems

As for heating with electricity, direct heating systems are more economical: fan heaters, convectors, heating cables and film heated floors. The lower efficiency of the water system with an electric boiler is explained by losses in the delivery of the coolant: overcoming the hydraulic resistance of the liquid, the operation of the circulation pump. Warm floors have the best performance due to the optimal temperature distribution. How to ensure their safe operation in a greenhouse is a separate issue.But the difference between different types of electric heating is small, we are talking about only a few percent.

http://vasha-teplitsa.ru/wp-content/uploads/2014/05/banya18430.jpg - It is quite possible to arrange a warm floor using a heating cable in a greenhouse. It can be protected from possible damage by a strong mesh laid on top.

How to choose boilers for greenhouses advice from farmers

When choosing between solid fuel, electric, coal, or steam boilers, it is necessary to take into account the area of the greenhouse, financial capabilities, type of cover and types of plants grown.

The recommendations of experienced farmers will help you navigate and make the right decision:

- If there is a gas pipeline on the site, it is more profitable to install a gas boiler. This statement is true for buildings of any size.

- For year-round heating of an area over 50 sq. m and if there is available firewood, it is better to choose a solid fuel unit for long-term combustion. The purchase and installation costs will pay off within two to three years. Payback in small greenhouses (15-20 sq. m.) - about 10 years.

- When heating is turned on seasonally (in early spring), it is advisable to use a low-power suspended electric boiler without a chimney outlet. However, during severe frosts, they are not effective, as they heat the air above, and the soil remains cold - this is fraught with freezing of plants.

Some gardeners consider solid-fuel models of direct combustion like bourgeois stoves to be optimal heating boilers for small greenhouses. The efficiency of the system can be significantly increased by connecting a water circuit and installing a pump for pumping coolant.

Features of using the oven

Long-burning stoves are an improved version of the Russian stove, economically consuming a variety of solid fuels (wood, old furniture, sawdust, cones, various garbage, coal). They were actively used during the Civil War and the Great Patriotic War, when even ordinary firewood was in short supply and boiler houses were idle.

In them, the fuel burns from top to bottom, and as it burns out, the fire sinks lower and lower. This increases the burning time and contributes to the release of more heat. The fuel in such furnaces slowly smolders at high temperatures and burns out to the end (pyrolysis). This process is regulated by the intake of air through a blower or blower.

Did you know? Americans attribute the invention of the potbelly stove to the famous American politician Benjamin Franklin. In the USA, such stoves are called "fat belly".

At the beginning of work, the stove is well heated. Otherwise, the combustion process may stop. The chimney in these designs must be straight and free from bends, as it will need to be periodically cleaned of soot, and it must be accessible for such work.

Such devices should be used when there is the possibility of constant control, because firewood must be periodically thrown into them. Under them, it is good to make a foundation and overlay with brickwork.

The stove should not be placed close to rapidly flammable and unprepared materials, as metal parts become very hot and can cause a fire. The firewood used must not be damp.

Gas heating boilers

Boilers using gas as fuel are considered the most convenient and economical. Installing them with your own hands is not difficult, and even the largest buildings can be heated using such a system.

Gas boilers can be:

- Single-circuit, designed to heat only air or soil;

- Double-circuit, capable of warming both the soil and the air to the required level.

For small rooms that are not used in winter, or built in regions where there are no frosts, a single-circuit gas stove will suffice, which will warm the soil or warm the air, extending the life of the greenhouse.Double-circuit systems are useful in large, permanent buildings, in which the cultivation of fresh herbs does not stop all year round. If a double-circuit gas boiler is used in the greenhouse, then one pipe, through which smoke from the combustion of fuel flows, is laid underground, and the second, with hot air, along the top and walls of the greenhouse.

Depending on the size of the room, a direct or forced draft boiler can be installed in the greenhouse. The first type is based on air circulation inside the greenhouse itself, and the second type is based on forced air intake from the outside and, accordingly, an increase in the volume of air flow.

Infrared gas heaters are a great option for quickly raising and maintaining the temperature for a short time if the main heating in the greenhouse has failed. The device consists of two parts - an infrared heater, with tubes in which gas burns and reflectors, and a small gas cylinder. Inside the tubes of the device, the fuel burns and is converted into infrared radiation, which heats the soil, plants and greenhouse walls. Constantly using such a device is irrational due to the relatively low power and fuel supply, but in case of frost, turning on the gas infrared heater will help save plants from the cold.

Gas boilers are considered the most popular in their class. Fuel for them is cheap and easy to buy, the system does not depend on the supply of electricity and does not consume it, and you can install such a boiler even in a small greenhouse. But at the same time, the boiler is not considered fireproof, like any gas appliances, it has large dimensions and requires the installation of a chimney.

With the help of gas, not only air, but also water can be heated. Water in water boilers and heating systems is often heated with this type of fuel.

About alternatives

Of course, there are alternatives:

Use other, less expensive types of fuel. In the presence of a resource base, solid fuel is the cheapest: firewood, coal. Pellets make sense only if the plant for their production is nearby. They are inexpensive, unlike other types of solid fuels, they allow you to fully automate the combustion process, but due to the low volumetric weight, delivery costs a good penny. The winning option is to find a source of supplies of used technical oils. Natural gas is convenient and relatively inexpensive, but it looks like your backyard is not gasified. Liquefied gas is unprofitable, especially considering the installation of a gas tank. Heating with petroleum heating oil (oil) is on the verge of profitability. Diesel fuel will definitely not pay off, you will go into a serious minus.

A wood-burning stove is a troublesome, but the cheapest and most effective way to heat a greenhouse. For a more even distribution of heat, there is a fan nearby

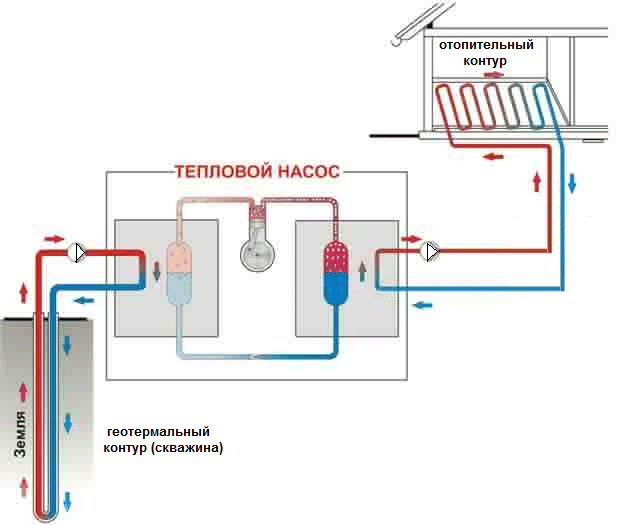

Use renewable heat sources. The heat pump is unlikely to justify itself, the operation is extremely cheap, but the equipment itself is very expensive. In many European countries, the state subsidizes such installations, we do not have such a practice.

Heat pump - environmentally friendly, economical to operate, but very expensive to install

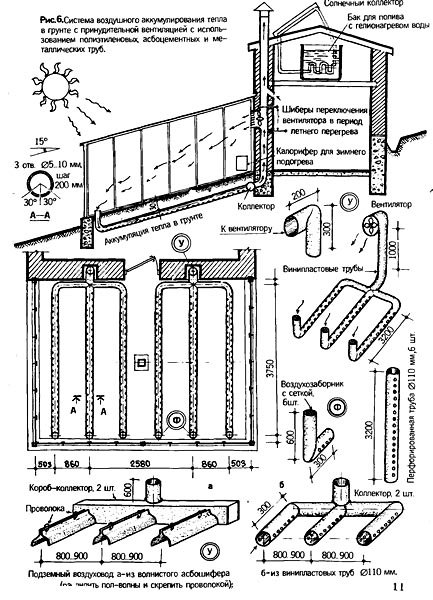

It makes sense to pay attention to the heating system of Ivanov's vegetable garden, which can be read about in the series of popular science books "Smart Garden" by Kurdyumov or on his website: http://kurdyumov.ru/knigi/teplica/teplica08.php. This is not to say that it is very effective, but still some kind of savings

The arrangement of a small greenhouse using all the elements of Ivanov's solar vegetation hardly makes sense. Solar panels, automatic control of the gates are unlikely to pay for themselves. But the location of the greenhouse on the southern slope, the deaf insulated northern wall and the ground heat exchanger are sound ideas. And the gates can also be turned manually.Due to the constant movement of air, the flow of which is created by fans, heat is accumulated in the ground during the day, and energy is given back at night. This solution will not increase the average daily temperature in the greenhouse, but will help to level the difference between day and night. Containers filled with stones or water can also be used as a heat exchanger.

Vegetarian Ivanov's device

If the greenhouse has not yet been erected, it is worth applying rational construction solutions that reduce heat loss and allow more efficient use of solar radiation: correctly orient the greenhouse to the sunny side; attach it to the south side of the house; make the north side deaf, insulate well and line the inside with reflective material, foil; partially buried in the ground; provide for the possibility of installing an additional layer of greenhouse film during the cold period, etc.

A set of simple measures applied during construction will reduce the cost of heating the greenhouse by 1.5-2 times

Partial (by 0.5-1.5 m) deepening of the greenhouse into the ground justifies itself. Sunlight in sufficient quantities penetrates through the roof, the walls should be well insulated and lined with foil

The photo clearly shows additional rolls of film rolled up to the ridge of the greenhouse, which are unfolded in frosts

Use traditional methods of heating greenhouses, for example, a mixture of manure and straw laid in the autumn stays all winter, releasing a lot of heat.

Greenhouse heating methods

To maintain a temperature of at least 25 degrees Celsius inside the greenhouse, powerful equipment is required.

The peculiarity of his choice is that heating is required for a fairly large area - sometimes up to 1000-5000 square meters. m.

For this use:

- gas boilers;

- solid fuel stoves;

- electric boilers;

- diesel and combined models;

- IR heaters.

Reference. The most inexpensive option in terms of maintenance is gas boilers. Having spent money once on the purchase of the device itself, in the future you will have lower costs for utility bills for gas, maintenance and repairs.

Diesel fuel and electricity are costly ways to heat a large greenhouse area. Coal, firewood, sawdust, briquettes are a little cheaper, however, they need to be constantly purchased, brought and laid manually.

The power of gas heaters for greenhouses with an area of up to 400-600 sq. m should be at least 40-60 kW. This is a rather heavy equipment (from 100 kg), which is often controlled by automation.

Air

This heating method is usually used with solid fuel stoves. A “potbelly stove” can be used as a stove, which is installed outside the greenhouse and connected to a flue gas pipe. To ensure uniform heating of the room, a horizontal chimney is made along the length of the greenhouse.

Photo 1. Air heating of the greenhouse: several convectors are installed around the perimeter of the room, which heat the air.

For air heating use:

- electric, gas boiler, stove or regular outdoor fire;

- Heating elements / convectors;

- radiators and blowers.

Sometimes infrared heaters, which are mounted in the walls or ceiling of a building, are also referred to as air heating. They are completely dependent on the electrical network, but are able to heat a large area of the greenhouse.

Air heating is also considered to be air heating with a heat pump (a temporary way to solve the problem), as well as heating with steam, which is supplied inside the table through external pipes, and returns back to the boiler through others - subsoil.

Advantages: easy installation, volumetric air heating (from below, from above, from the side).

Disadvantages: low efficiency, sometimes dry air.

Water

It implies the supply of water through radiators and pipes along the walls or in the center of the greenhouse. Due to this, a large area of \u200b\u200bthe room is heated.This can be single pipe wiring or other types of piping.

The source of heat is a boiler (usually gas, electric or solid fuel), to which the pipes are connected.

For water heating use:

- chimney for waste disposal;

- system for automatic addition of coolant (to maintain a constant temperature);

- external and internal pipelines, boiler.

Water heating may well work due to the natural circulation of water. You can buy a pump and use it as needed.

Reference. It is best to choose cast iron radiators or bimetallic, aluminum devices that are easily connected to the heating system.

Advantages: the ability to install with your own hands, warming up not only the air, but also the soil.

Cons: Not suitable for large areas.

DIY heating sources

Simple heating boilers for a greenhouse can be assembled and installed by hand. For implementation, you can use metal sheets, an old barrel or an empty gas cylinder.

Boiler for a greenhouse from a gas cylinder

Necessary materials:

- empty gas cylinder;

- metal grating;

- latch on the door;

- handles and hinges;

- U-shaped metal pipe - water circuit coil;

- steel plate and chimney.

Step-by-step progress in the manufacture of a heating boiler for a greenhouse:

-

Cut the balloon in half. One hemisphere is the body of the furnace, the second is the ash tank.

- Prepare a grate-grate corresponding to the size of the cylinder.

-

Insert the grate into the body and grab it by welding - the grate should divide the space into 1/3 and 2/3 parts.

- Cut out a circle from a steel plate, the diameter of which is equal to the size of the section of the cylinder.

-

Cut off 1/3 of the circle. For the most part, prepare a rectangular hole. Weld fittings to the door (latch, hinges, handle).

- From the smaller segment of the circle, make the ash pan door.

-

Cut the bottom of the ash pan from the second half of the cylinder and connect it to the end - the door.

- Inside the boiler, mark the place of installation of the ash pan and drill two holes at the top of the body.

-

Weld the coil to the inner surface of the furnace by passing the ends of the pipes through the holes. For reliable fastening, you can put a metal sheet.

- At the top of the boiler, cut a hole for the pipe and weld the pipe. The chimney must pass through the greenhouse at an inclination of 20°, the exit through the back wall. The height of the pipe is equal to the height of the greenhouse plus 1 m.

- Connect the chimney to the pipe using a coupling and sheet asbestos.

When connecting the boiler, it is important to ensure reliable thermal insulation of the contact area between the chimney and the building cover.

Video: greenhouse heating system

The proposed videos demonstrate the features of the organization and operation of various methods of heating country greenhouses.

Option 1. Water circuit: connection through the Zhukovsky gas boiler, exhaust - galvanized pipe 15 mm, laying method - combined (at the top and bottom of the greenhouse). The circulation of the coolant is forced by means of a pump.

Video: Water system

Option 2. Furnace heating. The use of two types of wood-burning stoves in the greenhouse: brick and metal, the chimney lining is horizontal. Recommendations for the choice of wood for kindling.

Video: Furnace heating

Video: greenhouse boilers

Video: Assembly technology for a pyrolysis boiler for a greenhouse, installation, connection and operation

Video: Transformation of a wood-burning stove into a water boiler

About greenhouse heating

The most effective way is to heat the soil. Do-it-yourself winter greenhouse is created in several ways.

By laying the heating circuit in the ground, it is possible to provide acceptable conditions for the normal growth of plant roots and the supply of nutrients to them.Simply heating the air can also create a comfortable environment for most crops, especially in the climate zone in which the European part of Russia lies.

When heating greenhouses, a large amount of heat is consumed through the walls and the ground. Therefore, it is customary to lay 250 - 350 W of heating system power per 1 m2. Given the different heights of greenhouses, you can use a different rate - 100 W per 1 m3.

Elements of the water heating system provide air heating due to convection and should be located as low as possible. The air heating system is fixed from above, at a height of at least 2 m from the ground. The temperature of the air supplied through the ducts should not exceed 40°C.

Greenhouse in the garden

Optimal choice

The best option for heating greenhouses is to install a potbelly stove, which is considered the most economical and easy to operate. The heater consists of a barrel with a door for the firebox, a chimney, a pipe for the heat to escape to the outside, a jumper in the upper part.

Heating occurs due to the movement of smoke:

- Hot smoke moves through the pipe, the pipe is installed either on the sides of the greenhouse or in the center.

- The surface of the oven radiates heat.

- Warm air is formed above the jumper and exits through the pipe.

Waste lumber, coal or firewood can be used as fuel. The quality of combustion depends on the type of fuel and the penetration of air into the furnace space of the furnace. This method of heating is suitable for those who can often control the combustion process. This is the only drawback of the potbelly stove.

For long-burning stoves, this minus is an advantage: fuel can be added to them much less often. They also use less fuel and reduce the heating of the furnace walls without reducing heat transfer. They are very similar in characteristics to infrared heaters.

The long burning furnace has two chambers, one of which completely burns the residual fuel, and the other burns only the main part. Oxygen access to the chamber is limited, as a result of which the fuel does not burn immediately, but smolders for a long time with the release of a large amount of heat.

Various household waste can be used as fuel for long-burning stoves, but without harm to plants. The constancy of temperature in the greenhouse provides the necessary conditions for the growth of crops.

About boiler power

Excuse me, but your post is akin to the question “I want to take a walk, what clothes should I wear”? To advise panties or a sheepskin coat, you need to know whether it is winter on the street or summer, heat or frost, sun or rain. The same with the greenhouse. Where do you live, in the Krasnodar Territory or in the Northern Urals? What kind of cellular polycarbonate is covered with a greenhouse? The cheapest 4 mm (thermal conductivity 3.8 W/(m K)) or 25 mm (1.6 W/(m K))? How are you going to heat: only in the spring, to drive out the seedlings, or do you want to have fresh vegetables all year round? What temperature should be maintained? What is the average height of the greenhouse - after all, we heat not the area, but the volume? What proportions does it have, the floor area does not matter, heat is lost through the outer walls - it is their area that you need to know. How is the structure oriented to the cardinal points, does it get direct sunlight in winter? Since we do not know any of this, we cannot give you any advice on the power of the boiler.

About the economics of agriculture

Heating a greenhouse with electricity is by no means a cheap thing. In the agro-industrial sector, such solutions are not used, it is unprofitable. You are not the first to get excited about this idea, but if you are interested in the economic side of the issue, calculate the costs and compare with the possible benefits. All your predecessors abandoned the idea of heating greenhouses with electricity, it is much cheaper to buy vegetables and fruits.

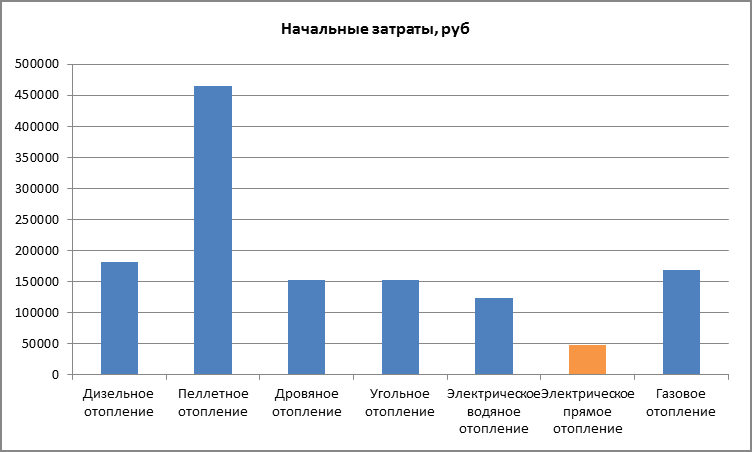

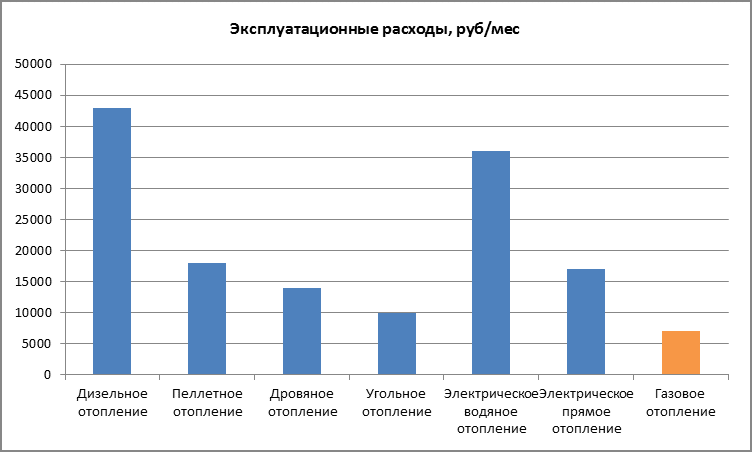

For comparison - comparison of the cost of installing heating equipment using different energy sources. Using different energy sources

And operating costs. The data are given for the Moscow region, in a particular area the cost of solid fuel can be much lower. Heating with electricity at low initial cost is extremely expensive to use