How does corrosion in pipes appear and what does it lead to?

For every 10 °C increase in water temperature, its ability to cause corrosion doubles and its ability to dissolve CaCO3 and CaSO4 salts decreases, which leads to accelerated scale formation.

However, heating systems are harmed not only by reactions between various chemical elements. Substances that are dissolved in any water have the ability to settle and attach to the walls of watercourses.

These chemical processes contribute to the formation of rust and scale in the heating system, which reduces the clearance of pipes and their heat transfer.

A corrosion inhibitor is used to prevent or slow down corrosion processes in heating systems. To reduce the formation of scale, various additives and reagents are used.

Sodium hydroxide

Alkali is one of the most effective products in the fight against rust. To wash plumbing from smudges of rust, you can use alkaline products. They are applied directly to the spots, and left for about 20 - 25 minutes to act. If the size of the smudges is too large and conventional household chemicals cannot cope, it is recommended to use an active alkali - caustic soda. In a saucepan with boiling water (2 liters), dissolve 50 grams of caustic soda. The resulting solution is poured onto the rust spot and left for 10 minutes. Such products remove rust without mechanical action and are unable to damage surfaces.

Consequences of clogging

- after a certain point, the pipes become clogged;

- the movement of water in the pipes is reduced and later even the water pump will not be able to pump water through this system.

Things are much worse for thermosiphon heating, where there is no such pump. As a rule, after clogging, heat is not passed through, and the pipes remain cold. And that's only part of the trouble. In addition, the boiler itself begins to heat up very much, which can lead to its breakdown.

Some owners carry out an annual cleaning of blockages in such a system by changing the water. In other words, the old impure, rusty water is drained and filled with new water. And this is reasonable, because when the old water is drained, a small amount of chips and rust leaves it. But there is also an opposite side. Rust requires iron and oxygen. If the pipe is metal, then iron is always present in it, but oxygen is contained in water. As a rule, when you do not change the liquid in the heating system for a long time, the oxygen content in it decreases significantly, which means that the rusting process stops. With a constant change of water, on the contrary, it is activated. Summing up a little, one thing can be said - this method helps to get rid of a small amount of rust, but, on the other hand, we only accelerate the new process of its formation.

How can I clean the pipes internally?

To remove various deposits in plumbing or heating systems, internal pipe cleaning is performed. Many experts recommend that preventive cleaning and flushing of pipes from scale and rust be carried out at regular intervals.

Currently, there are several methods aimed at increasing the throughput of pipes, with the help of which it will be possible to carry out preventive and cleaning measures:

- hydraulic shock;

- with the help of special chemicals;

- with the help of sandblasting;

- using abrasives.

Pipe cleaning with water hammer

Using this technique, high-quality cleaning of water and heating pipes from rust and scale is performed.Only specialists should carry out such work. They also use the appropriate equipment, through which rust is removed from the internal surfaces. It is connected to the system, after which compressed air is released into the pipes.

Being under high pressure, the air stream most effectively cleans any contaminants. Thanks to the hydraulic shock, there is no need to dismantle the entire communication, so cleaning activities can be carried out under any weather conditions and temperature conditions.

When carrying out these activities, you should follow the safety rules that are regulated by the relevant regulations, so it is better to entrust the performance of such work to professionals.

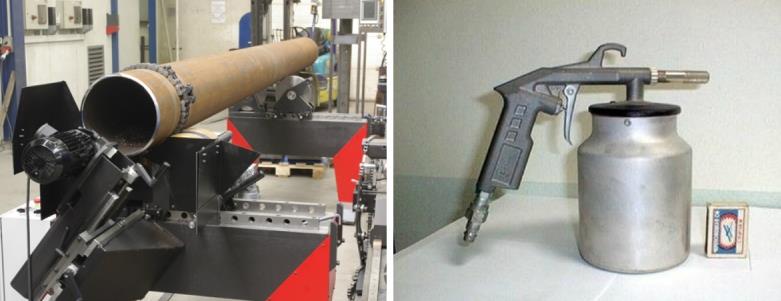

With the help of this device, a hydraulic shock is applied

Internal cleaning of pipes with special tools

Since during the active operation of pipes, rust and scale accumulate on their internal surfaces, which significantly reduces their throughput, and also has a negative impact on water quality, some specialists clean communications using special tools (citric acid, chemicals). With their help, pipes are cleaned from scale in communications of any length.

Cleaning pipes with chemicals

Chemical elements can, if used improperly, damage the integrity of the pipes, so they must be used in full accordance with the instructions.

Cleaning the internal surfaces of pipes using sandblasting techniques

Cleaning the inner surface of pipes from scale and rust and other contaminants can be done by sandblasting. This procedure is carried out under controlled pressure, using a continuous air stream mixed with the abrasive. To apply this cleaning method, it is necessary to dismantle the heating or plumbing communications, which is very problematic when they are located in hard-to-reach places.

However, for small layers, hand guns equipped with a sand tank are on sale. It is worth noting that they will not be able to cope with serious deposits.

Sandblasting machines - professional and manual

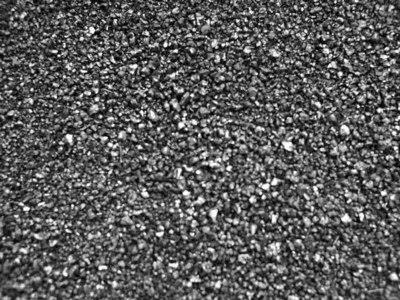

Cleaning the internal surfaces of pipes with abrasives

This method involves the addition of special abrasives to the water streams passing through the pipes, which remove rust and other deposits from the internal surfaces, and in fact is an analogue of sandblasting.

It has its advantages and disadvantages:

- high consumption of abrasive;

- a large amount of time is required to complete the work;

- as an abrasive, it is necessary to use special materials with certain parameters.

Special powder for abrasive pipe cleaning

Before you clean the pipes from rust, you should decide on the methodology according to which these events will be carried out. Some specialists also use for these purposes such devices as cables, the diameter of which is an order of magnitude smaller than pipes. The movement of the cable through the communication is carried out using an electric or pneumatic drill.

The choice of high-quality means for flushing the heating system

Today, there are many special products for flushing heating systems on the domestic market, however, not all of them are of high quality.

By choosing a low-quality reagent, you risk not only not getting the proper result, but even harming your pipes, since some components can cause significant damage to their surface.

When buying a composition, you need to make sure that the manufacturer has a good reputation and be sure to check all the necessary quality certificates.If they are available, you can be sure that the cleaner will certainly show good efficiency and will get rid of rust and sludge in one treatment.

The composition of such products, as a rule, includes acid and special inhibitors that prevent etching of the metal and, as a result, the formation of corrosion on it. They will not only wash the pipes, but also reliably protect them from rust for a long time.

Recommended

DOCKER THERMO is an effective heating system flushing agent. Recommended for treatment of boilers, high and low pressure boilers, condensers, heat exchangers, pipelines, for flushing household water heaters. The selectively active composition of the substance allows you to flush systems not only with metal, but also with plastic or rubber tubes. Concentrate.

Photo: Bosch. Regular maintenance is required to ensure long-term operation of the heating system. In addition to checking the pressure, the pH value of the water in the heating system should also be monitored and, if necessary, adjusted.

Among all the dangerous phenomena, the most “popular” is, perhaps, scaling - this is the name of the solid insoluble precipitate of calcium, magnesium and some other metal salts. It is formed as a result of heating tap water to 60-65 ° C, in which these salts are contained in the form of ions. All parts of heating and hot water supply systems that come into contact with water can suffer from scale, but most of all the sediment forms on the heating elements of storage-type electric water heaters. They also need additional protection. Most storage devices are equipped with a magnesium anode, which, gradually breaking down during the oxidative reaction, protects the heating element from scale formation, and the tank walls from corrosion.

Photo: Buderus. To prevent corrosion of the boiler, the combustion air must not contain any aggressive substances. Contribute to corrosion halogenated hydrocarbons, chlorine and fluorine compounds

The magnesium anode must be replaced if it is severely worn. The condition of the rod is assessed visually during the annual service inspection. Usually the anode is supposed to be changed every 1-2 years, so when buying it is worth clarifying where you can buy the part and how exactly it needs to be replaced. However, at present, models of water heaters with a titanium anode connected to a protective current source (“with superimposed current”) have become widespread and do not require replacement.

As for the heating systems of country houses, in well-equipped closed circuits in small volumes of circulating coolant (several tens of liters), the risk of scale formation is small. And in order to avoid it, it is enough, as water enters the house, to carry out its general preparation, aimed at reducing hardness, reducing the content of calcium and magnesium ions (we talked about this in detail in the article “Water - and nothing more”, No. ). Another thing is communal boilers, where there are much larger volumes and constant leaks that have to be compensated. In such cases, both additional softener filters in the water make-up system and magnetic water activators popular today can be used.

Photo: De Dietrich. Titan Activ System (De Dietrich) set of superimposed current titanium anode and power supply. Its advantage is that the anode is not consumed during operation.

Much more dangerous for domestic heating systems is the corrosion of the metal of the heating installation. It can occur due to the ingress of oxygen from the air into the heating system. Possible ways for oxygen to penetrate are leaks in the heating system, rarefaction zones, an expansion tank of insufficient size or plastic pipes without a protective layer.It is difficult to fight corrosion, it is much easier to ensure the tightness of the system in advance by correctly designing the circuit and using pipes with a protective layer.

Corrosion damage usually occurs when oxygen is continuously introduced into the heating circuit water. To avoid this, the heating system must always be closed. In cases where it is not possible to create a closed system, it is necessary to provide special measures to protect against corrosion when treating the water used for heating. In addition to filling the heating system with demineralized water, special chemicals can also be added. They bind free oxygen or form a film on the surface of materials that protects against corrosion. In addition to checking the pressure, the pH value of the water in the heating system should also be monitored and, if necessary, adjusted. It should be between 8.2 and 9.5.

Sales Support Engineer, Bosch Thermotechnika

Features of the use of inhibitors

Specially designed reagents for heating systems have the following features:

- Protect all types of metals from corrosion;

- Reduce the adhesion of water-soluble components;

- Do not allow the formation of precipitation of insoluble substances in the heating system;

- Designed for use at temperatures above 100 °C;

- The term of effective protection is 5 years;

- The regent should occupy 2 - 2.5% of the total volume of the coolant in the heating system. This significantly reduces the cost of protecting heating systems;

- Additives contain volatile substances, which, when evaporated from water, create a protective layer on surfaces that do not come into direct contact with the coolant;

- Additives do not contain harmful substances;

- Slow down the development of bacteria and algae.

Rust control

The entire cleaning step is relatively simple and does not require the use of complex techniques. The process will take place as follows:

- pipe cleaning;

- cleaning the boiler itself.

Pipe cleaning

Ordinary citric acid, which every housewife has, can act as such a remedy. It must be dissolved in water, it is advisable to use a three-liter jar, since a large amount gives a greater effect. All this solution must be poured into the heating system. Subsequently, it is immediately necessary to light the boiler, set the temperature to a high level, and it remains to wait twenty-four hours. We drain this water later. We flush pipes by filling and re-draining clean water.

Another similar technique is the use of food vinegar. To achieve the best effect, you need a lot of it. But there is also a more win-win option - this is the use of hydrochloric acid, mainly 10 or 20%. This chemical is great for cleaning pipes. But you need to be careful with this substance, since too high a concentration can significantly damage the heating system.

The process will take place as follows:

- we connect the compressor to the heating system;

- we connect the compressor with the pipe and start it;

- flushing begins with a simultaneous combination with pneumatic shocks;

- disconnect the pipe going to the boiler (bottom);

- we put some container near it so that dirty water flows there;

- clean water must constantly flow into the riser (unclean water during draining).

The compressor is expensive and if you don’t want to spend money, then you can apply the dismantling of radiators (each separately). That is, washing them under huge water pressure.

Boiler cleaning

Deposits can also be in the boiler itself. In addition, there are more of them here than in pipes. The fact is that it warms up very much, due to which the process accelerates.

This is where chemicals are used. All the work is quite simple: you need to disconnect the heating pipes, take a pump that is combined with a boiler and water is let in through it, with pre-added chemistry. Drain all the dirty water and then rinse with clean water.

Having learned all the tips discussed, you will be able to independently flush the heating system with full confidence.

Due to the peculiarities of operation, heating pipes and radiators constantly have to be in contact with water. And, as you know, the metal, when interacting with a liquid, is prone to oxidation and, as a result, the formation of rust.

Corroded areas can gradually become the cause of a leak. But first of all, this phenomenon is fraught with a decrease in heat transfer of the entire heating system as a whole.

In combination with lime deposits, rust clogs the patency of pipes and creates plaque on their inner surface, which prevents the room from heating normally. At the same time, fuel consumption does not decrease, but rather only increases. That is, you spend more money on heating and at the same time do not get the proper result.

Based on the foregoing, it follows that it is extremely necessary to take timely care of how to flush the heating system from rust.

When to clean pipes

Corrosive changes can also occur in heating systems. When they appear, the efficiency of space heating will significantly decrease, and operating costs will greatly increase. The expediency of cleaning depends on the degree of damage:

- Cleaning pipes in those areas that are heavily rusted is not advisable, since during this procedure the pipe can be damaged. The best solution would be to completely or partially replace the pipes in the system so that it can be operated with maximum efficiency in the future.

- In the event that slight accumulations of rust and scale are found, a series of cleaning measures can be carried out and the pipes can be restored to their previous performance.

Carry out external rust removal

The outer part of the pipe usually suffers only from the appearance of rust. You can remove an unwanted problem using the following tools:

- Fine sandpaper. This manual cleaning process is quite laborious, so it should only be used on small areas. A sheet of "sandpaper" is wrapped around the desired section of the pipe, hands are protected with gloves and, embracing the pipe, make movements from side to side.

- brushes. You can use a brush with a metal bristle or put a cable brush on the grinder.

A suitable brush should have a spiral cable weave

- Special chemicals. There is a wide range of corrosion converters and rust modifiers on the market. The principle of their action is often the transformation of corrosion products into metal-safe compounds.

"Tsinkar" - the most famous remedy for combating external rust

Selection and recommendations for the use of an inhibitor for a heating system

One or another inhibitor must be selected based on several indicators:

1 An open or closed type expansion tank is used;

2Type of structural materials used: ferrous metals, alloys based on copper or aluminum;

3 Water pH indicators;

4Indicators of "hardness" of water (the amount of dissolved salts in the coolant).

Depending on the hardness and acidity of the coolant, as well as the characteristics of the heating system, it is necessary to choose an inhibitor of a certain composition. The following compositions of additives are distinguished:

- Orthophosphate. The reagent forms a protective film, causes the precipitation of salts, with their large quantities. It is necessary to add to the coolant based on the proportion of 10 - 20 mg / l. It is used in heating systems where the elements are made of ferrous metals at a pH level of water less than 7.5 units. The concentration of chlorine in water of 300 mg/l and more levels the effectiveness of orthophosphate and leads to corrosion of the metal. Can be used in combination with zinc polyphosphate or phosphonate additive;

- Polyphosphates. They are used to protect pipelines made of ferrous metals with Ph water up to 7.5 units. During the use of polyphosphate, water softening is not required. The amount of chlorine also does not affect the properties of this inhibitor. The effectiveness of the action of polyphosphates is increased with the help of zinc. The optimal amount is 10 - 20 mg / l .;

- Phosphonates. Apply only in combination with zinc, orthophosphates or polyphosphates. The composition will be effective at a concentration of 10 - 20 mg / l and at Ph 7 - 9. Protection of ferrous metals is provided by the addition of calcium;

- Molybdate. The reagent protects ferrous and aluminum alloys. It is necessary to add to the coolant at the rate of 75 - 150 mg / l, in order to reduce the amount of the composition without reducing efficiency, the addition of phosphorus components is required. The recommended pH of water is 5.5 - 8.5. Hard water causes molybdate to precipitate. Chlorine and sulfur impurities level the use of molybdate, but without the occurrence of pitting corrosion;

- Silicate. It is used for soft water at a concentration of 10 - 20 mg / l. Provides protection for ferrous and copper alloy systems with Ph 7 and higher water. A protective coating forms on surfaces over several weeks;

- Zinc. It is used as an additive to other additives: orthophosphates, polyphosphates, phosphonates, molybdates. And also with combinations of inhibitors that do not contain zinc: orthophosphate / polyphosphate, orthophosphate / molybdate, a mixture of phosphonates in an amount of 0.5 - 2 mg / l. Zinc strengthens the protective film and reduces the amount of the main inhibitor. When water pH exceeds 7.5, it is necessary to use zinc stabilizers;

- Benzotriazole. Required concentration - 1 - 2 mg / l in water with Ph 6 - 9 to protect copper alloys;

- Tolitriazole. Analogue of benzotriazole;

- calcium orthophosphate. Used to eliminate the sticking of precipitation of calcium phosphates. The content of calcium orthophosphate in water should be 10-15 mg/l.;

- Polyacrylates, polymaleates, hydrolyzed polyacrylamides and acrylate substances. Used for biological contamination. The optimal concentration is 2-3 mg / l .;

- Chlorine and bromine are used to kill microorganisms. A concentration of 0.1 - 0.5 mg / l is sufficient. Chlorine is only effective in water with a pH below 8. If the pH is higher than this, bromine is used;

- Zeolites. Used to soften water;

- Nitrite. Used in closed systems, it causes the formation of a stable film of iron oxide on the surface. Effective in concentrations of 250-1000 mg / l and an increase in Ph to 9 - 9.5, by adding borax. The amount of nitrite can be reduced to 300 mg/l if the same amount of molybdate is used. Nitrite is susceptible to bacterial degradation, so it is also necessary to use a non-oxidizing bactericide, copper corrosion inhibitors and a polymeric dispersant in combination;

- Alkalis (caustic soda, ash). Used to increase the pH of water to 9 - 10.5 units.

Best Answers

Soggy,(it means ❝wet❞):

Soda ash (not to be confused with caustic!). .It is added for washing.

Drinker in the Blackthorn:

and how is the sage from above going to drive soda into the pipes if it is a water pipe? yes nothing! it was necessary to put metal and not plastic! metal at least 20 years old.

ENLIGHTENED:

and it’s not fate to put a filter, so as not to suffer later? In general, the solution to such issues lies in the sphere of swirling water. Read the work of Viktor Schauberger, he offers methods for cleaning pipes there. The thing is that in nature, water always runs with swirls, but it is absent in pipes, and plaque is formed from this.

Alexander:

You go to the grocery store, you buy a lot of citric acid. You dilute 50-70g per 10 liters of water. Now the questions are whether there is something to drive it into the pipes and why it is needed. A raid that significantly blocked the cross section? - I doubt. And the advice is to reduce, if possible, the temperature of the boiler just below 55 - less scale will form.

Nicholas Pg:

you look at the rust with pipes, you won’t dissolve it, if you can change them it’s easier to change, You can iron out the water, there’s something I heard, like filters, they replace iron if you put it after the well