Filling the gas tank

The gas tank is refueled through a filling valve using a special vehicle - a gas carrier machine (tank capacity can reach up to 55 m³), the process of filling the tank with gas is monitored by a level gauge that indicates the degree of filling the tank in percent.

The tank is filled to a level of 85% of the total volume, the remaining 15% of the tank is designed to accommodate the gaseous phase, which is formed as a result of the evaporation of the liquid.

Rice. 21 Filling the gas tank with liquefied gas

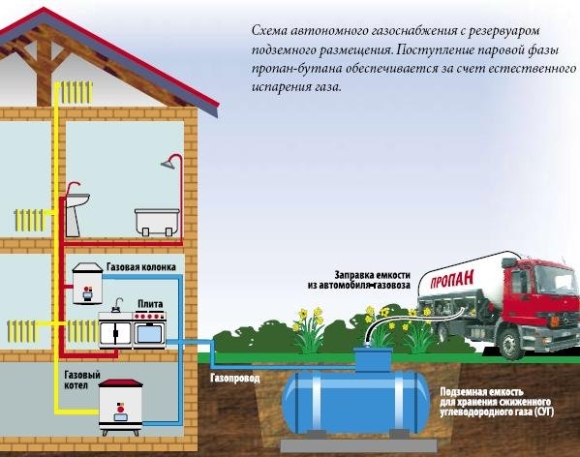

Choosing the option of autonomous gas supply for a country house, many opt for underground storage tanks for liquefied gas - gas tanks. In doing so, they will have to face not only the very high cost of the tank, but also the further costs of regular maintenance and technical inspections.

Autonomous gasification of a private house using a gas tank and cylinders

Despite the emergence of numerous new technologies for organizing autonomous heating, a gas boiler is still the most optimal and cheapest way to heat a coolant. But what if the highway runs far from home and gasification from it is impossible? In this case, you need to carefully approach the solution of the issue. The costs of using electricity will be high, and a traditional solid fuel boiler is not very convenient to use. In this case, there is only one option left - the organization of autonomous gas supply.

Currently, there are two methods of gasifying a house, which differ from each other in a number of parameters:

- Cylinder storage of gas (described here).

- Installation and operation of gas tanks - large special containers.

The choice of one of them directly depends on the following parameters:

- The area of the house and the number of gas consumption points.

- Estimated amount of expected fuel consumption.

- Land area. Will it be possible to install a gas tank in principle.

Consider both of them, starting with the cheapest, but not quite effective.

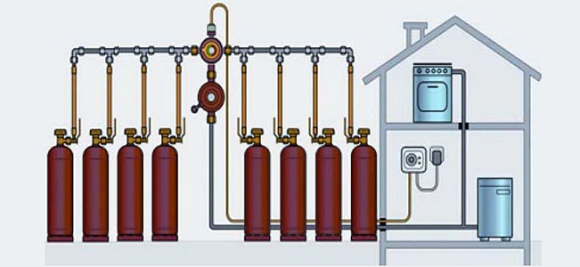

Balloon gas supply

This option is the installation of several special gas cylinders and connecting them to the gas supply system in the house. It is advisable to use it only with a relatively small consumption.

The organization of this method involves the implementation of a number of actions.

Room preparation

According to the provisions of the current SNiP, the place for storage and operation of gas-balloon equipment must comply with the following standards:

- Free standing or adjacent to the house. There must be a separate entrance and a forced ventilation system.

- A heat-resistant finishing and construction material is used.

- The area of the room directly depends on the number of cylinders and must exceed this value by at least 8 times.

- It is forbidden to operate any heating equipment or use devices with an open source of fire in the storage room.

- Cylinders should be located along the wall, on a special pallet. In this case, any distortion is prohibited - they must stand strictly vertically.

After fulfilling all these conditions, you can start organizing the connection. To do this, it is necessary to calculate the average gas consumption in order to determine the number of cylinders. Up to 50 liters of gas can be stored in one standard container.

This system must be tested by the relevant gas authorities. They will also issue permits for its operation.

Advantages:

- Small initial expenses for the purchase of equipment and components.

- The possibility of placing cylinders outside the house, but in a special steel box with a lock.

Flaws:

- A small supply of fuel requires constant replenishment.

- The complexity of replacing the used container and installing a new one.

This option will be convenient for country houses and buildings with seasonal residence.

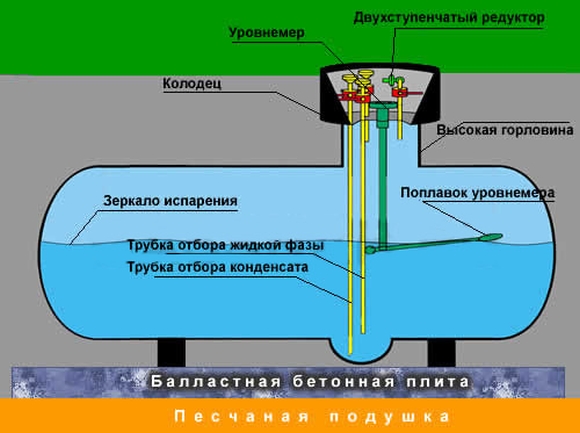

Installing a gas tank

A typical example of a gas tank design is shown in the figure.

Upon completion of its installation, a gas pipeline is laid to the house. This method is convenient because a large amount of storage allows you to work offline without refueling up to 1 year.

Rules for installing a gas tank:

- The minimum distance from the house to the structure is at least 10 m.

- Ensuring free passage of vehicles for refueling and maintenance work.

- All installation and preventive measures are carried out by representatives of a special service company that has the appropriate certificates and permits.

A typical connection scheme is underground piping to the foundation of the building.

To ensure safety, special shut-off valves and alarm sensors are installed on the structure of the gas tank and at the point of connection with the domestic gas pipeline.

Advantages:

- Economic benefit compared to the balloon option.

- Almost complete autonomy of the entire system.

- Control equipment allows you to remotely monitor the level of gas in the tank.

- Possibility to connect several houses to one storage.

Flaws:

- Possible problems with obtaining permits, rather stringent requirements for the condition of the site and the house.

- Refueling and maintenance of the gas tank can only be carried out by certified companies.

Requirements for the premises

The gas boiler, according to the regulations, can only be installed in the following rooms:

Non-residential rooms. Usually boilers are placed in the kitchen or in a specially designated room. The boiler room can be located on any floor, including the basement.

Having a volume of at least 15 m 3 (a deviation from the norm of 0.2 m up or down is allowed) and a ceiling height of at least 2.5 m.

Having a window with an opening window. In this case, the volume of the hood should be at least three times.

The above standards are provided for boilers up to 60 kW. Gas supply of a house outside the city most often involves the use of this type of equipment. More powerful boilers are rarely installed by private traders.

What are gas holders design features

According to the location, outdoor and underground gas tanks are distinguished, the former, due to too low temperatures in winter, are not used in households - they need heating, which is economically unprofitable.

Also, gas tanks can be located vertically and horizontally with respect to the ground plane, but due to the fact that vertical types have a small evaporation area compared to horizontally placed ones, they are rarely used in industrial and domestic areas.

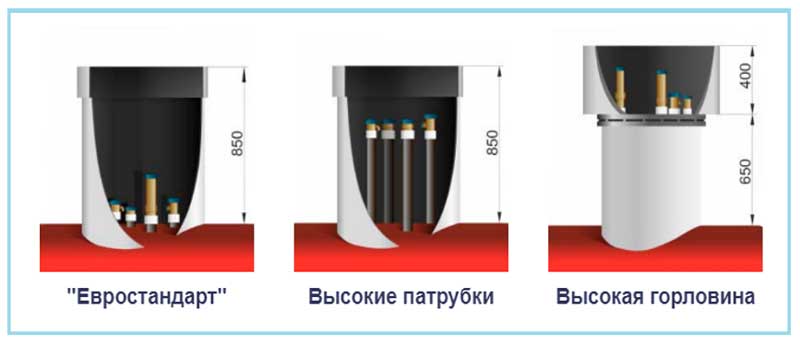

Almost all underground gas holders have the same type of tank and neck design, the minimum depth of the tank under the ground is about 600 mm, some models are equipped with a manhole.

Therefore, the domestic manufacturer supplies the market with tanks with a design (high neck) designed for operation in cold climatic conditions, but, as noted above, the material of their manufacture is significantly inferior to European steel in quality.

Rice. 19 Typical designs of reinforcement compartments of gas holders for autonomous gas supply

Use of two or more gas tanks

Sometimes, instead of one, two gas tanks are installed (in cases where there is not enough space on the site, the volume of consumption has increased, etc.), while they are connected to each other in the liquid and gaseous phases. Thus, it is possible to increase the volume of stored gas, the area of its evaporation, fill the tanks one by one or together.

When connecting them, it is more convenient to use models with high nozzles, which is one of the options for standard designs.

How to properly install a gas tank

Only specialized companies with a staff of experienced workers are engaged in the installation of a gas tank, special equipment is required for moving heavy loads, devices for welding HDPE pipes - there is practically no theoretical possibility to do the work yourself (not counting other nuances). The sequence of work carried out by a specialized company:

- In accordance with the plan of the house, a suitable site for the location of the tank is selected.

- In a given place, a pit of the required size is dug and a trench is dug to place the pipeline below the freezing depth of the soil, a sand cushion is formed at the bottom of the pit at a horizontal level.

Rice. 20 Installing a gas tank - the main stages

- A concrete slab with four protruding plates with a hole and the size of a gas tank is laid on top of the pillow; when laying it, it is additionally checked for compliance with the horizon.

- A rubber backing is placed along the axial line of the slab to protect the tank from corrosion and mechanical damage, after which the tank is unloaded and placed on the backing. It is fixed with steel cables in a protective sheath by screwing to steel plates. Some tanks are equipped with steel supports and do not require a substrate for installation.

- A pressure regulator is installed on the tank, a plastic gas pipeline pipe is connected and it is laid in a trench with a slight slope, a condensate trap is installed at the lowest point.

- A basement input is welded to the end of the underground gas pipeline HDPE pipe, the free end is brought into the house.

- At the end of the work, the system is checked by pressure testing, the pit and trench are filled up, the grass cover is restored, and the removed sod is laid in place.

Calculation of the need for liquefied gas

Preparatory measures for the installation of this type of gas equipment are very important. The miscalculations of an insufficiently qualified designer or the low professional training of builders are subsequently very costly. Heating systems do not reach passport characteristics, and in order to ensure normal living conditions, it is necessary to increase fuel consumption.

Before purchasing equipment, you need to make sure that it meets the needs of the home. To do this, you can use the practically established ratio. For high-quality heat supply, it is necessary to spend one kilowatt-hour of thermal energy for every 10 square meters of heated premises. In this way, you can get primary data on the required power of the boiler.

Considering the line of products offered on the market, you need to choose the product that is suitable for the parameter obtained.

It should be borne in mind that the value obtained in this way applies only to heating, the consumption for other gas appliances must be calculated separately, taking into account the intensity of their use.

CHOICE

“Initially, we did not plan to buy this particular system,” says Elena. “We read reviews on the Internet, compared the cost.” According to her, the option with electricity heating disappeared immediately - it is often turned off. A diesel boiler in terms of costs is about the same as a gas tank, but diesel fuel is also a smell, noise. We chose gas. The system is Russian, with installation - 400 thousand rubles.

“We have a 4,800-liter boiler with a full charge (70,000 rubles) for eight months,” Erokhina says. In winter we come here only on weekends. On weekdays, we reduce the temperature to 18 degrees so that the flowers do not die.

EVERYTHING IS NEARBY

The system consists of a gas tank (gas tank) and pipes. The gas tank is buried in the ground (or stands on the surface) and is filled with liquefied gas.At first, its use was envisaged only on farms, remote production, but about 40 years ago it was adapted for households, says Andrey Vikentiev, an expert at the Gas Distribution Safety Association.

PECULIARITIES

When installing a gas system, it is necessary to install sensors that, in the event of a gas leak, should block it. According to existing standards, the cistern must be placed at least ten meters from the house. Therefore, it is problematic to install a gas tank on a plot of six acres. However, such a system can be used for several houses, highlighting a common area away from the buildings. B

Most companies that install gas tanks require that LPG be purchased only from certain suppliers. Like, otherwise they do not guarantee the normal operation of the equipment. But unlike gasoline prices, the state does not regulate the cost of such gas.

CAREFULLY

“Approximately 20 percent of gas tanks in the country are restored,” warns Alexei Vasiliev, a representative of the Consumer Rights Protection Society. Used gas tanks are bought in Europe as scrap metal.

In Russia, the old anti-corrosion coating is removed from the tank and a new one is applied. Such a container costs two to three times cheaper.

“It is difficult for a non-specialist to distinguish an old gas tank from a new one,” says Vasiliev. “There is always a section on the shell of restored tanks, usually circular in shape, which was opened to process the inside of the tank, and then re-welded.”

But how such a gas tank will behave under the pressure of liquefied gas is always a mystery. Therefore, it is better not to take risks and not save.

The average cost of equipment and installation of an autonomous gasification system is 0.5 million rubles. 1-1.5 million is the installation of equipment and connection to the main gas pipeline. From 2 to 20 thousand liters of gas tank capacity. Depending on your needs (the house is used in the summer or all year round), you will have to fill the tank once or twice a year.

The service life of the gas tank is 30-50 years.

4 rubles/liter costs gas from the main pipeline.

Year-round heating of a house of 200 square meters will cost 30-40 thousand rubles.

Gas costs 15 rubles/liter on average when refueling an autonomous system.

Year-round heating of a house of 200 square meters will cost about 150 thousand rubles.

Equipment for gasification of a private house

- total heated area.

- Number of connection nodes (only a boiler or column, stove, etc. will work)

- Financial expenses.

Providing gas from a gas tank

- The gas is extracted from the propane-butane mixture during the process of liquid evaporation.

- After refueling into the gas tank, pressure is created during the evaporation of liquefied gas.

- The produced gas enters the reducer, which controls the supply pressure to the pipeline.

- Gas is supplied to heating units in a residential building.

Use of gas cylinders

To complete this project you will need:

- Install a special burner for liquefied gas in a gas boiler. The exception is the new generation condensing boilers of famous European brands. Units from Buderus, Viessmann often have a built-in function that allows you to switch equipment from main gas to bottled gas without changing the burner.

- Combine several cylinders into a single network.

- Connect the network to the reducer with several cylinders on each side.

There is no need to coordinate with the gas service and make a project for gasification in case of installation of bottled gas supply

The main attention should be paid to compliance with fire safety rules.

Autonomous gas heating systems

The use of natural gas is relatively inexpensive and safe compared to other heat sources.Modern gas equipment is able to automatically ensure optimal consumption of blue fuel and maintain comfortable conditions in the building.

The reasons for using autonomous gas supply systems may be the following circumstances:

- lack of access to the main gas pipeline;

- the high cost of designing and supplying gas from it to the house;

- errors in the construction of a private house, in which the connection of the main gas is impossible for security reasons. The requirements for the design and operation of autonomous systems are much softer.

For autonomous gas supply, the project is developed on an individual basis for a specific building. In this case, the developer may be offered a choice of fuel supply source: a gas tank or household gas cylinders.

Properties of liquefied gas

Cylinder gas is somewhat different from natural trunk fuel. It is characterized by:

- higher efficiency;

- low cost of fuel;

- ease of use;

- the ability to use a variety of equipment.

Such fuel is produced on the basis of propane. It is safe for human health and has no harmful effects on the environment.

The chemical formula - C 3 H 8 - indicates belonging to the hydrocarbon class of alkanes. The natural source is natural gas, which is released by the cracking of petroleum products during the separation of associated petroleum gases as a by-product.

In its pure form, propane does not have any smell, and specially introduced additives give it a well-known aroma. They are used for identification purposes when leaks form. Propane is low toxic, but has a mild narcotic effect on the central nervous system.

Scope of propane

The most extensive use of propane is as a fuel. It is used:

- in industry - to perform gas-flame work and welding of metals in non-critical structures;

- in construction - for heating industrial and facility premises;

- in road works during heating of bitumen and the surface of the roadway;

- in the food industries - in gas stoves and water heaters.

One of the new uses for propane is its use as an automotive fuel. It is cheaper than gasoline or diesel fuel and has a positive effect on increasing the resource of internal combustion engines.

The cost of autonomous gasification of a private house

To calculate the potential costs for autonomous gasification of the site, you need to know the heated area and calculate the degree of intensity of use of the gas system.

The price of a gas tank of 1000 liters is approximately 230 thousand rubles, a tank for 1650 liters will cost 260 thousand rubles, for 5000 liters - 520 thousand rubles.

Some residents unite to install an autonomous gas supply system in several neighboring areas.

Of course, the cost of buying a gas tank is not the only cost of autonomous gasification of a private house.

However, connection to the main gas pipelines may require substantial expenses.

Obviously, in this case, the main requirement is the availability of low-pressure gas networks for connection to centralized networks. If they are not available, then the possibility of connecting natural gas can be expected for years.

In this case, the only alternative is autonomous gasification, which is carried out quickly and relatively hassle-free, and at the same time can cost less.

The average cost of connecting to centralized gas supply networks in the Moscow Region to a natural gas network is 400 thousand rubles. (provided that a low-pressure gas pipeline runs close by). The presence of a medium or high pressure gas pipeline is not suitable.

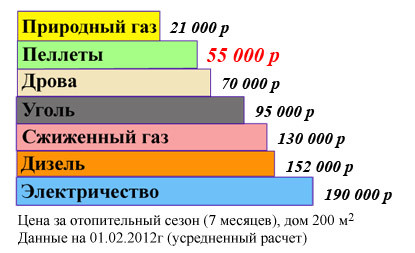

Comparison of different options for heating costs

In this table, we analyzed the costs of various types of fuel for heating a residential building with an area of 100 sq.m.

For more information about the possibility of connecting gas in a private house (to the main gas pipeline), see this article.

Still have questions? Do you want answers to them?

Here you can ask it free of charge to experts or lawyers of the portal gkh-konsultant.ru.

Price

Connecting a house to a centralized highway in our time is a pleasure, unfortunately, not too cheap. The total cost of gasification includes:

Collection of documentation. You will have to pay various kinds of state duties.

Drawing up a project. In this case, it all depends on the complexity of the work. The cost of project development can fluctuate within a fairly wide range - from 2 to 20 thousand rubles.

The layout of the gas pipeline itself. The cost of work in most cases is about 1 thousand rubles per meter.

A cut into the highway. For such work, you will have to pay about 10 thousand rubles.

And, of course, the price of the boiler, pipes, radiators, etc. should be included in the estimate. Equipment of this type cannot be called cheap either. The cost of the boiler, for example, depending on the power, can be 17,000-40,000 rubles. Modern bimetallic radiators cost 3-7 thousand rubles. Autonomous gasification will cost, of course, even more expensive. The minimum cost of a gas tank is 60 thousand rubles.

Documentation and design

The owner, who organizes an autonomous gas supply of a country house, often has a question - is it necessary to register a gas tank installed on an individual site in state organizations.

In accordance with the Federal Norms and Rules (clause 215), the following pressure vessels are not subject to registration:

- Gas carrier tanks designed to move liquid gas.

- Automobile cylinders with gas.

- Other containers, the volume of which does not exceed 100 liters.

If the owner concludes an agreement with an organization that has the right to install, service equipment with an appropriate license, its authorized representatives deal with registration issues, and all that a homeowner needs to know about LPG is to conclude an agreement.

When drawing up a contract, one should take into account the list of obligations that the contractor accepts, there are usually items:

- Submission of an application by the contractor to the supervisory authorities indicating the data on the company, the location of the gas tank and the features of its operation, if any.

- Submission of an act to the regulatory authority on the readiness of the gas supply system for operation and a copy of the order to put it into operation.

- Submission of information about the tank indicating its technical characteristics, the gas mixture used, the date of the last check.

Rice. 5 The cost of installing gas tanks - an example

The autonomous gasification system does not require complex design solutions and is quite easy to install, when placing an underground tank with a volume of up to 10 cubic meters. the following standards must be observed (SNiP 42-01-2002):

- Distance from public buildings - at least 15 m, from residential - 10 m.

- From garages and playgrounds - 10 m.

- From sewerage, thermal routes, communications and ground structures, underground wells, trees - 5 m.

- From the water supply and channelless communications, fences - 2 m.

- If there is a power line near the power line - at least half the height of the support.

When designing, the convenience of access roads, the volume of gas tanks, soil features (electrochemical activity, magnitude of stray currents) are taken into account, and based on the information obtained, the type of protection of the tank is selected.

Features of bottled gas supply

This option is usually used only for small summer cottages with modest gas consumption. Several are installed in a separate room. It is not recommended to allocate a room in a residential building for these purposes.

It is better to build a separate storage room for storing cylinders, although this room is allowed to adjoin the house.

To connect gas cylinders into a single network, a set of reducers and pressure gauges is used. As needed, empty cylinders can be replaced with filled ones.

Here you should make a separate entrance, and not a door leading from the house. The area of the room should exceed the size of the cylinders that will be installed there, eight times.

The inner surface of the room must be covered with materials that are resistant to fire. Forced ventilation is required.

Autonomous gas supply using a set of gas cylinders is preferable to use for a small summer cottage so that you do not have to worry about filling them up too often (+)

Sometimes it is allowed to store cylinders not in a separate room, but in a large metal box outside the house. It is impossible to heat the storage place for gas cylinders, any heating devices and, of course, the use of open fire are prohibited.

If the room is ready, you must perform the following operations:

-

Install cylinders

along one of the walls. -

Lay gas pipes

from the place of storage of cylinders to devices-consumers of liquefied gas. -

Assemble the system

from reducers and pressure gauges for parallel connection of cylinders. -

Connect cylinders

and appliances to the highway. -

Check the finished system

in the presence of employees of the regional gas facilities. -

Obtain official permits

documents for the operation of the balloon gas system.

Cylinders are installed on special pallets, while they need to be given a strictly vertical position. Each container contains about 50 liters of gas, based on this standard, their total amount is calculated. Such a system will cost less than a full-fledged gas supply with a gas tank, but you will have to charge the cylinders quite often.

Is there an alternative

To date, the following methods of heating private housing are known:

- natural gas coming through the main pipeline;

- electric boiler;

- solid fuel: firewood, coal;

- pellet boiler;

- liquefied gas in cylinders.

Each option has its own advantages and disadvantages. Considering that not even all urban-type settlements have a gas pipeline, it is unlikely that it is connected to a dacha settlement. And if they promise to let her down, then not as soon as we would like.

Heating costs for a house of 200 m2.

The most banal solid fuel today is also not cheap, but the main disadvantage of this type is far from the price. If you heat the cottage with wood or coal, then you must definitely be there every day.

Electricity is considered one of the most expensive ways to heat a home. Therefore, many use it in addition to solid fuel, to maintain the temperature during periods of absence in the country. The electric boiler itself is much cheaper than a gas boiler, but the price of electricity is growing every year.

Wood fuel pellets (pellets) are widely distributed in Europe, Denmark, Sweden. For Russia, this is still a rare occurrence, but it also occurs in homes where the owners care about the environmental friendliness of fuel. It is convenient that the pellets are poured into a special hopper and automatically fed into the pellet boiler, without any physical effort. Compared to pipeline gas, they will cost 3 times more, unless you include in the estimate all stages of gas pipeline, starting from the project.

What should be the gas pipeline to a private house

We all know about the explosive properties of gas, so there can be no talk of any initiative in this matter. However, you will have to collect all the necessary documents, make a project, submit applications to the appropriate authorities, etc. So, get ready to visit various services and queues. Consider all the requirements that cannot be violated.

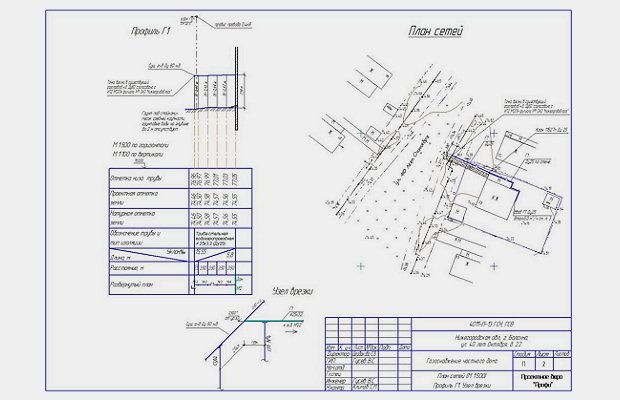

In the photo - a gas supply project for a private house

All materials, from pipes to welding electrodes, must be of high quality and have certificates

The location of all elements of the pipeline is also very important. Collapsible connections should be located only in open places

Be sure to provide free access to them. This will allow at any time to assess their condition and, if necessary, carry out repairs. It is forbidden to wall up pipes and other nodes of the gas network in the walls or foundation of the building. It is also unacceptable to run the gas pipeline through platbands, plywood walls, transoms, door and window frames and temporary partitions. True, sometimes they allow a gas pipeline to be laid through a specially made channel in the wall, but only in special cases and after the approval of the project.

Distortions are also not allowed, all pipes must run strictly vertically, horizontal sections have a slope of 0.002–0.005 m towards the instruments. If we are talking about a riser, then in this case a skew of a maximum of 2 mm per meter is allowed. They are located mainly in the stairwells or in the kitchen, but in bathrooms and living rooms it is forbidden to do this. Faucets also require special attention, they must be installed so that the cork axis is parallel to the wall. The stop nut must not be placed on the side of the wall.

Photo of gas supply pipes of a private house

It is very important to maintain distance. There must be at least 2.2 meters from the bottom of the pipe to the floor, and 10 cm of free space must be left between the upper side of the gas pipe and the ceiling

Also, pipes should not be placed close to the walls, as this will make visual control difficult. If this distance is not specified in the project, then a gap must be left, the minimum value of which will be equal to the radius of the pipe, but not exceeding 10 cm. The gas pipeline must be located on the supports rather tightly, gaps are not allowed.

Paperwork and equipment selection

But before you face the installation, you will need to run around different authorities and collect a package of documents. Prepare a passport, title documents for the land plot and the building located on it. You also need to write and submit to the gas service an application in which you express a desire to gasify the house. After that, you will receive a form of technical specifications, it is filled in by the developers. Only then can the project be started.

In the photo - gasification of a private house

You will need to conclude the following contracts:

- on the performance of work and the preparation of technical documentation;

- on gasification and installation of appropriate equipment;

- act of putting gas equipment into operation;

- for the supply and payment of natural gas.

In some cases, if you have not ventured into an autonomous gas supply, you have to pull pipes through the neighbors' plots, and then you will need written permission from them. It is necessary that specialists come to you and examine the chimney in the house, in the end they are required to issue an act. You will also have to visit the local architectural and planning department. The head of this organization is also required to issue a permit for gasification of the site.

It has already been said that absolutely all materials, especially pipes, taps, hoses, must have the appropriate certificates. Without the availability of such documentation, it is impossible to put into operation all these elements. Blue fuel flows through pipes with a diameter of 150 mm and a wall thickness of 5 mm. Basically, elements are selected from low-carbon or low-alloy steel. In principle, both seamless and welded structures can be used. Naturally, the gas pipeline is assembled from a sufficiently large number of pipes. They are connected by gas welding. Very serious requirements are also imposed on the quality of the electrodes and they cannot be neglected.

Photo of the gas pipeline of a private house

But the list of necessary materials does not end there, a number of small parts will also be needed - tees, crosses, couplings, adapters, elbows and plugs. They are usually made from cast iron or steel. To fix all threaded elements well, you should choose the right tool. For example, keys with notches and parallel jaws provide maximum grip with the part. Is it worth mentioning the boiler, column, stove and other equipment.