The floor screed, being a concrete base, is subject to regular loads. As time passes coupler covered with dust, cracks, potholes and delaminations form in it. This problem is especially relevant for old Khrushchev. Repairing the floor screed by simply covering it with cement will not solve the problem, since concrete has its own physical and chemical properties: even hardened fresh concrete has differences from the old one - the coefficient of thermal expansion and shrinkage rate. Effective repair of the floor screed involves the correction of the properties of the new concrete.

Properties of concrete taken into account during repairs:

- thixotropy - a change in the structure of the medium under the influence of mechanical load, temperature, sound waves and the return of the medium to its previous state when the impact stops;

- rheology - the fluidity of a substance, which ensures the filling of small irregularities with the substance.

Preparation for repair

Mixes and repair tools:

- thixotropic repair composition;

- drill or puncher with mixer nozzle;

- Bulgarian;

- a rule 1 meter wide, factory-made is better, home-made can be rubbed off on concrete and the screed will turn out to be “humpbacked”;

- construction syringe with repair composition for injection repair;

- respirator, safety goggles, ear muffs for sawing;

- Master OK;

- hammer, large and small;

- chisel.

On the modern market there is a wide choice of repair compounds for concrete screed. The repair composition for ordinary apartments, where there are no increased loads on the floor, can be prepared independently: on an aqueous solution of PVA glue in a ratio of 1: 3, a cement-sand mortar is kneaded in a ratio of 1: 3. The composition is mixed with a drill with a mixer attachment. Kneading with a perforator - without an impact mechanism to avoid strong splashing. After mixing, the mixer should immediately be rinsed in water at high speeds.

Before starting work, you need to clean the room: remove large debris, sweep the floor 2-3 times with a wet broom, blowing cracks and pits with a vacuum cleaner after each sweeping.

Advice! For the preparation of factory repair compositions, only sifted quartz sand, also bought in the store, is suitable. Some mixtures are sold complete with the right portion of such sand.

You need to work as a grinder or puncher in goggles, earplugs, and a respirator, with open windows and a closed door to the next room, as there will be a lot of dust.

Concrete screed repair

Do-it-yourself floor screed repair is divided into several types, depending on the problem. The most common floor defects are small cracks in the screed, hidden voids and delaminations that are detected by light tapping of the hammer.

Elimination of small cracks

- Thoroughly clean the area.

- With a chisel and a hammer, punch a channel 1 cm deep along the crack, clean and remove dust.

- For high adhesion of the repair compound, treat the channel surface with an epoxy primer diluted with a solvent in a ratio of 1:10, wait for it to dry.

- Fill the gap with a repair compound, after drying, smooth, clean, and sand.

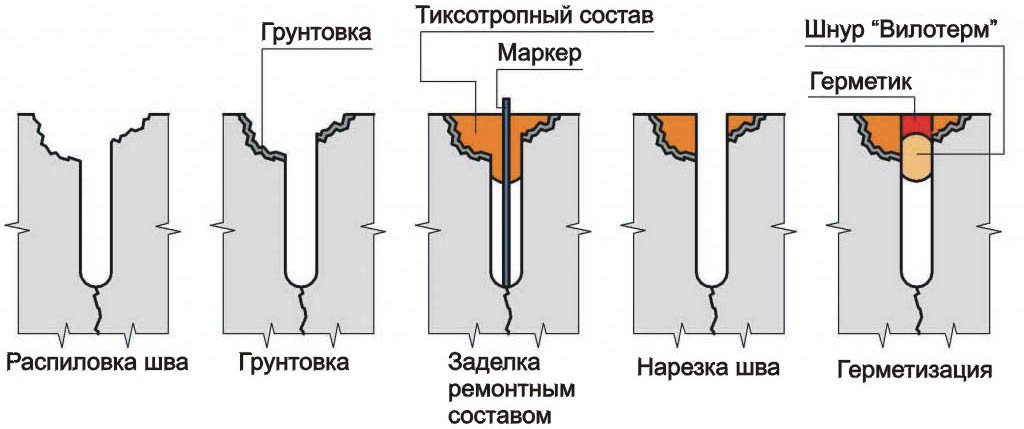

Elimination of deep cracks (more than 2 mm wide)

- Cleaning the repaired area.

- A grinder cuts a channel 2 cm wide at the surface and 5-6 cm deep.

- The edges of the channel are knocked down with a chisel (you can use a drill with a sharpening nozzle) so that there is a triangle in cross section. The edges can get brittle, you need to clean them until they are strong.

- Markers are placed in the channel perpendicular to the floor plane.

- Thoroughly blow and suck the channel, treat with a primer, wait for it to dry.

- The channel is filled with repair staff, the marker must be held by hand.

- After the repair compound hardens, the markers are removed, and a narrow seam is sawn through the holes from them to the depth of the former channel.

- A damper cord is placed in the seam. Clotheslines and synthetic ropes are not suitable!

- Over the cord, the seam is filled with silicone or polyurethane sealant, but not with mounting foam or other fully hardening substance.

Cavity repair

- The pothole is sawn with a grinder in a rectangle with a gap of 2 cm from the edge of the pit, the depth of cut is 1 cm deeper than the pothole for denser concrete, 2 cm for less dense concrete.

- A perforator with a concrete chisel attachment transforms the pothole into a rectangular niche. For shallow holes, you can use a small hammer and chisel, controlling the force of impact to avoid cracking.

- Blow out the deepening and suck it with a vacuum cleaner, treat with a primer, wait for it to dry.

- Pour the recess with a repair compound, level it with a rule to the level of the floor, and hold until completely solidified.

- Clean and sand the surface.

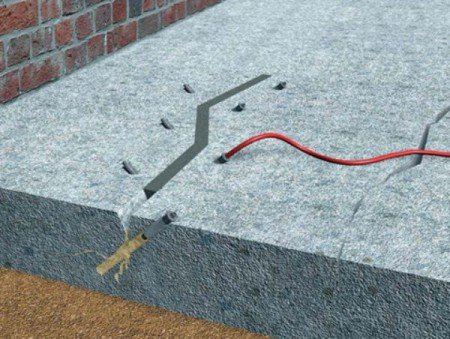

Delamination repair

Delaminations are detected quite simply: with light blows of a hammer, the entire surface of the concrete screed is tapped. In places of delamination, the sound of impact will be deaf.

Delaminations are repaired in two ways:

- Replacing the entire delaminated area is similar to repairing potholes;

- injection method.

Injection repair:

- The screed is tapped, the approximate area of the exfoliated area is determined.

- The marker indicates the approximate contour of the delamination.

- With a drill or perforator, holes with a diameter of 6-10 mm are drilled along the peeling contour with a step of 25 mm.

- With a construction syringe, a repair compound is poured into the holes - an epoxy resin of reduced viscosity. Fill the holes evenly, in several passes, to allow the resin to completely fill the cavity. Resin is pumped until the level in the holes stops dropping.

Floor repair in utility rooms

In garages, basements, pantries, where the floor finish is impractical, over time, the surface of the concrete screed crumbles, forming a lot of dust.

Too much dust indicates the need for dedusting:

- The surface is carefully vacuumed.

- If cracks or holes are found, the repair described above is carried out.

- It is necessary to treat with a deep penetration primer, wait for drying.

- Apply two layers of polymer repair compound over the entire area.

floor leveling

For laying laminate the surface of the repaired screed must be leveled. Easiest to apply self leveling compound.

Before application, the surface is cleaned of dust and washed twice with a soda solution. The composition is kneaded in small portions, applied and leveled. The resulting bubbles are removed with a spiked roller.

All work requires a conscientious approach: the service life depends on it concrete floor. Do not use frankly cheap materials. The earlier the problem is identified, the easier and cheaper the repair will be.