How to choose a storm water inlet

When choosing the right type of storm water inlet, you need to take into account various factors that, with the right approach, will provide you with a long service life and reliability.

The most important of these factors are:

- intensity and amount of precipitation on the site, climatic conditions;

- storm sewer area;

- terrain;

With the correct calculation of these features of your site, you will be able to choose the right type of storm water inlet itself.

For the backyard of a small private house, you can choose a rain well, which is lighter in weight and design, but if the climatic conditions are rainy and there is a lot of precipitation at different times of the year, then it is better to take the cast-iron option.

It will be able to withstand a large load and hold a lot of debris and leaves in it so that they do not clog underground sewer pipes.

Features of the design of storm water inlets for storm sewers

All types of storm water inlets differ in that they have different weights and depths. A standard storm water inlet has a depth of about 40 centimeters and is light in weight, but if the material for its manufacture is cast iron, then the weight is much greater.

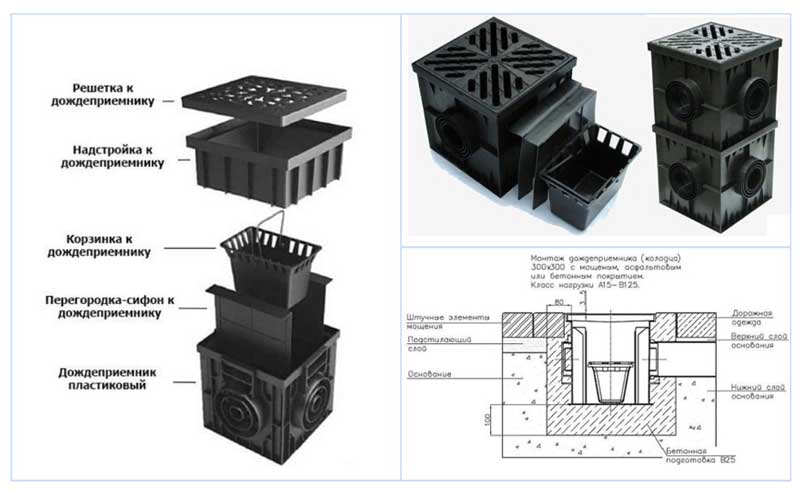

The storm water inlet itself can be sold both separately and in a set with other elements for it.

The complete set consists of:

- the storm water inlet itself;

- baskets for storm water inlets of different sizes;

- partitions - siphon;

- external grid.

All these elements can be different in quality and price. They are selected depending on the choice of the storm water inlet itself.

You can see the standard kit in the picture below.

The grid for a point catchment can also be made of materials of different quality, its choice depends on the load that will be applied to the grid in the future.

Materials for storm water inlets: which is better cast iron or plastic?

Previously, storm water inlets were made only of concrete or cast iron, but now another modification has been added to them - plastic storm water inlets for storm sewers.

At first glance, it may seem that it is better to choose a cast iron material, as it is stronger.

But modern technologies make it possible to make the device of a plastic storm water inlet highly durable and reliable.

The advantages of plastic materials are that they are light in weight and easy to install, protected from corrosion and external mechanical and chemical influences.

If you are still afraid that it will not withstand the load, then in the kit you can take a grate made of cast iron or other metal, this will reliably strengthen and protect the storm water inlet.

You can see an example of a plastic point water collector in the image below.

The size of a standard plastic water collector for the house will be 300x300x300. You can also use this type of water collector as an independent collector well, since plastic storm water inlets have the ability to install several layers, laying them on top of each other to the desired height.

Cast iron storm water inlets are most often used either on roads that are often used by vehicles, or in places of constant accumulation of water.

It can also be said that the cast-iron drain is able to withstand a weight of about 90 tons, it is suitable for places with constant traffic and heavy traffic, it can withstand a huge amount of wastewater.

What a cast iron gutter looks like, you can see below.

Such a storm water inlet can be quite large, it is suitable for the highest loads and ensures the reliability of storm sewers.

Cast iron storm water inlets

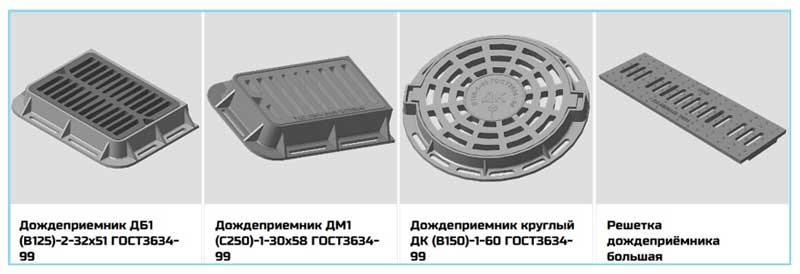

Varieties and parameters of rectangular cast iron storm water inlets are regulated by GOST 3634-99, which subdivides all products into the following categories:

- D - small storm water inlets weighing no more than 30 kg. and a rated load of up to 15 kilonewtons (kN.), Which in terms of kilograms is equal to 1500 kg.

- DB1, DB2 - large storm water inlets with a total weight of about 50 kg. and 80 kg. accordingly, they are installed on the canvas of urban roads and parking lots, hold a load of up to 12,500 kg.

- DM1, DM2 - models of the main type with a rated load of up to 25000 kg., have a mass of 60 and 100 kg. respectively, are used on highways with heavy traffic.

- DS1, DS2 - super-heavy modifications, designed to hold a nominal weight of 40,000 kg, product weights of 80 and 130 kg. accordingly, they are used in areas of increased loads (airfields, ship docks).

In addition to the rectangular products specified in the standard, the industry produces round varieties with the DK marking weighing about 100 kg, which can withstand a rated load of about 15,000 kg.

Rice. 7 Drainage systems made of cast iron - examples of location

Cast iron structures have the following features:

- High drainage capacity due to the presence of wide-section grooves, which ensures the drainage of significant volumes of water.

- Durability to withstand significant loads of heavy vehicles.

- A long period of technical operation that does not require frequent and complex maintenance of the water collection unit.

- High resistance to the action of the aqueous medium in the case of coating the surface of cast iron with special corrosion-resistant components

- Environmental cleanliness and safety for people.

- Acceptable cost for the consumer.

- The large mass of the product makes it difficult to install, requiring the installation of a high-strength reinforced concrete well.

- Lattices and frameworks made of cheap raw cast iron are highly susceptible to corrosion.

- In connection with the widespread facts of theft of ferrous and non-ferrous metals, many devices are equipped with special fasteners from elements that lock the grille.

In individual areas, such structures are rarely used due to their large dimensions and weight; for private areas, DB1 products with overall dimensions of 695x470x120 mm are most suitable.

Rice. 8 Plastic storm water inlets - modifications

Features of installation of surface drainage systems

Often, on an individual site near a private house, it is required to collect water from paving slabs, if the slope does not allow it to be taken outside the site, and direct it to a drainage well or outside the site. For these purposes, surface systems are used, consisting of storm water inlets and trays made do-it-yourself concrete, or factory products made of plastic, concrete or polymer concrete.

Surface drainage is easier and faster to assemble from semicircular trays made of concrete or plastic, work is carried out in the following order:

- They draw up a drainage scheme tied to the site plan, indicating the slopes and the direction of water movement along the trays.

- Prepare the necessary tools, the main of which are the building level, grinder, rubber mallet, spatula, bayonet shovel.

- An outlet hole is made in the concrete-polymer sand trap and a place is prepared for installing the trays, observing the necessary slopes. To do this, he marks a line with a cord along which he digs a ditch of the required depth so that there is a free space of about 10 cm below and on the sides of the tray.

- The trays are laid out along the dug channels, starting from the highest point of the drain and connecting to each other, if necessary, use a grinder to fit.

- A concrete pad is laid at the bottom of the pit and the trays are lowered onto it, checking the slope with the level and the straightness of the direction with the previously stretched cord.The position is adjusted using a rubber mallet.

- Joints in concrete-polymer trays are sealed with a sealant that comes with the kit; in the last section, a plug is glued to the end.

- After the concrete has hardened, the system is closed with gratings, then the channels are lined with paving slabs; during installation, the depth of the grating by 3–5 mm should be observed. below the level of the pavement surface.

Rice. 14 Contour map of precipitation intensity depending on the terrain

Installation of storm water inlets installation features

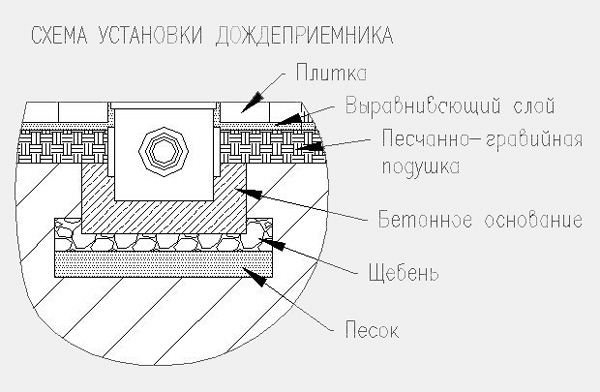

If you choose a square design of a plastic storm water inlet through which water will be drained, then the process of installing it under the downpipes of the house will consist of the following steps:

- At the location of the storm water inlet, a pit is dug to a depth of 30-40 cm more than its height with a gap of 3-5 cm between the side walls and the surface of the pit.

- The body is prepared for the installation of pipes, having previously cut holes of the required diameter according to the template with an electric jigsaw, the standard cross-section of sewer pipes is 110 mm. It should be noted that orange pipes are always used for outdoor work, designed for lower temperatures than the gray indoor pipe.

- The bottom of the pit is covered with a layer of sand and rammed in such a way that 5–10 cm remain to the bottom surface of a properly installed storm water inlet. rested against the poured concrete layer. The element can be installed at the bottom of the pit even after the concrete cushion has hardened, the main thing in solving this problem is to avoid the housing sinking into the ground over time.

- After installing the box, a pipeline is connected to it, located in pre-dug trenches with a slope of at least 2 cm per 1 running meter.

- After the installation of the last element is completed, the system is checked for operability by a stream of water from a watering hose and then buried, usually the next stage of work is a blind area and laying paving slabs.

Rice. 13 Installation of a storm water inlet from polymer concrete trays

Rainwater inlets for storm sewers types

All varieties of melt runoff and precipitation disposal systems are divided according to the materials of manufacture of their main element - a storm water inlet, which is a round or rectangular body with outlets for gutters or pipe connections. The scope of sewage systems, their cost and installation methods depend on the material of manufacture of the grate and housing.

All gutter gratings, depending on the load they can withstand, are marked with the following letter symbols:

- A - hold a weight of about 1500 kg., Suitable for drain sewerage in individual territories.

- B - the maximum load that the device can withstand is no more than 12,500 kg. The grate carries the weight of vehicles, can be placed outside and inside garages.

- C - the element holds the weight up to 25000 kg., is installed on highways with heavy traffic.

- F - the product holds a weight of up to 90,000 kg., It is located on the route of heavy special equipment, at airports and ship repair docks.

Rice. 5 Design features of storm water inlets for a storm drain system made of concrete

concrete structures

Conventional concrete catch basins are commonly used in road construction, they are capable of carrying high loads and are made of reinforced concrete or fiber reinforced concrete. There are several varieties of products of this type, depending on the scope of application - light, heavy or trunk.

Light types are a model of a small size (no more than 400x400 mm.) Of a cubic shape with a wall thickness of about 20 mm. For a greater depth of the branch pipeline, they can be installed in a vertical position on top of each other. Products have a low cost, high service life, and are resistant to temperature fluctuations over a wide range.

Heavy storm water inlets can withstand a weight of up to 3000 kg. They are installed in places with a low load on the roadway - on pedestrian sidewalks, exits from buildings, in the subway and pedestrian crossings.

The body is made of fiber-reinforced concrete, the gratings are cast from black or zinc-coated cast iron.

Another type of heavy storm water inlets is made of reinforced concrete, the structure is placed along the edges of the roadbed of highways and is able to withstand a long-term vehicle load of up to 90 tons.

Another common option for storm water inlets is the main ones, they are assembled from ready-made concrete gutters or by casting them on site, which are then covered with cast-iron grates on top. The design is widely used in road and individual construction to collect large flows of water from urban and private areas.

Rice. 6 Cast iron structures - appearance

Location rules

When installing storm water inlets, the following rules must be observed:

- Drainage surface systems are installed in places where water accumulates on the site; when placing a drainage pipeline, a slope of at least 20 mm is observed. for products with a standard diameter of 110 mm, the indicator increases with small diameters and heavily polluted drains.

- A surface drainage system is placed 3–5 mm below the coating level, and a point storm drainage system is installed in the same way.

- The storm pipe of the house should be located in the center of the drainage grate and at such a height that it is possible to remove the cover and lift the grit basket without obstruction.

Rice. 12 Installation of a storm water inlet under downspouts

Storm water volume calculator

Usually, the determination of the volume of storm drains is carried out when designing storm sewers in public utilities; in individual housing construction, calculations are not relevant if water is drained outside the site. It is clear that the standard diameter of the outlet pipes is 110 mm. in a set with industrially produced storm water inlets, will ensure the transportation of any water volumes that may appear on the site after a rainstorm or spring flood.

The calculation of the amount of storm drains is important if they are drained into a storage tank, the volume of which must be determined in order to avoid overflow. For calculations, the easiest way is to use an online calculator, in this case, the amount of water collected from the entire site is calculated using the following formula:

Q \u003d q x F x Y, where

Q is the total volume of storm water on an individual site;

q is a coefficient characterizing the intensity of precipitation in a given area. It is determined according to the tabular data of metrological or design organizations, as well as according to special maps-schemes for a given area, measured in liters per second per unit area (hectare).

F is the surface area of the site from which water is collected, it can be the roofs of houses and outbuildings or a landscaped area around a private house. For the convenience of calculations on calculators, this parameter is entered in square meters.

Y is a tabular coefficient characterizing the absorbent properties of the surface from which drainage is carried out. The standard calculator for calculations instead of this indicator Y includes a list of various surfaces: roofing, asphalt, paving slabs, turf.

After entering the data, the desired value is obtained in liters per second, minute, or cubic meters per hour.

Rice. 15 Drainage maintenance - examples

Plastic storm water inlets

Modern plastic storm water inlets have no competitors when used in domestic households, they are made of frost-resistant polymers (special heat-resistant polypropylene) and have the following features:

- The plastic storm water inlet is lightweight, easy to install and assemble even by an unprepared homeowner. The device is easy to connect to a pipeline of any diameter thanks to the built-in cylindrical baffles.

- Standard modifications of an equilateral cubic storm water inlet have a face length of 300, 400 and 500 mm.

- The manufacturing material is resistant to temperature changes in the range from -40 to +90 C., withstands the corrosive effects of most aggressive chemicals, and has a long service life.

- The device is easy to maintain and provides high-quality cleaning, thanks to the smooth, hard plastic surface, which has low hydraulic resistance and low absorbency.

- The design is made in such a way that allows you to install storm water boxes on top of each other, to make pipes of any standard section at different levels.

- Depending on the expected load, gratings made of cast iron, galvanized steel, stainless steel, and plastic are installed in plastic boxes.

Rice. 9 Plastic drainage systems - design and correct installation diagram

The correct plastic storm water inlet, unlike other types, has a more complex design, the main elements of which are:

- Lattice. Depending on the chosen model, it has a round or square shape; drains enter the drainage system through its slots.

- Waste basket. Prevents heavy debris and sand particles that collect on its bottom surface from entering the pipeline channel.

- Protective siphon. The rubber element prevents the spread of polluted air from the baskets.

- Water seal. The partition is placed at the entrance to the pipeline and stops the flow of wastewater in the opposite direction.

- Protective cover. The element closes the storm water inlet in winter, preventing it from clogging with snow and ice from frozen water.

- Extension. Allows you to increase the height of the structure and, accordingly, the depth of its immersion in the ground together with the pipeline system, it is used as a means of protecting pipes from freezing in winter.

- Luke. It is installed instead of the grill if the device is used as an inspection or maintenance hatch.

Rice. 10 Rain gutter system from trays - layout diagram

Installation of storm water inlets

As a rule, storm water inlets are installed under sewers, and in places of puddles or accumulation of rain and melt water.

During installation, an important point is to take into account the depth at which the storm water inlet will be located, as well as its size.

If you carry out all the installation steps correctly, you can be sure that the storm sewer will last a long time and will not be clogged with debris.

Location rules

If the storm water inlet is not properly positioned, then most of the water will remain on the surface and the storm sewer device will be useless.

To remove as much wastewater as possible, you need to install drains in low-lying points of the area or make a recess for them so that the water itself flows to the storm water inlet.

This rule also applies to those drains that are installed under the sewer.

You also need to choose a place for the drain under the pipe so that the water jets fall clearly into the center of the storm water inlet.

An example of the correct installation of a drainage system under a sewer can be seen in the photo below.

Drainpipe under sewer

After choosing a place for the storm water inlet, you can proceed with its installation.

Features of the installation of storm water inlets

First of all, when installing storm water inlets, it should be remembered that the drain must be provided with a solid foundation and well fixed underground.

Consider the main steps in the installation of a storm water inlet:

- first you need to dig a pit, measuring the depth of the storm water inlet itself and adding 30-40 cm to it, and also leaving 3 cm on the sides for pouring concrete;

- a sand cushion is poured at the bottom of the pit, which is filled with water and tightly rammed;

- the storm water inlet must be connected to the sewer pipes leading to the collector and the entire structure must be leveled in height;

- pour a thin layer of concrete mortar on the bottom and tightly lay the storm water inlet;

- now the concrete must be carefully poured on the sides of the drain;

- after that, you can install partitions and a storm water basket.

After installation, the surface gap around the drain can be covered with sand or gravel.

You can view the general scheme for installing a storm water inlet below.

Scheme of installation of a storm water inlet

Next, the storm sewer itself is connected and the storm water inlet is ready for use.

Once every 2-3 months, its basket must be cleaned of debris, if you do this regularly, then your storm sewer will last you a very long time.

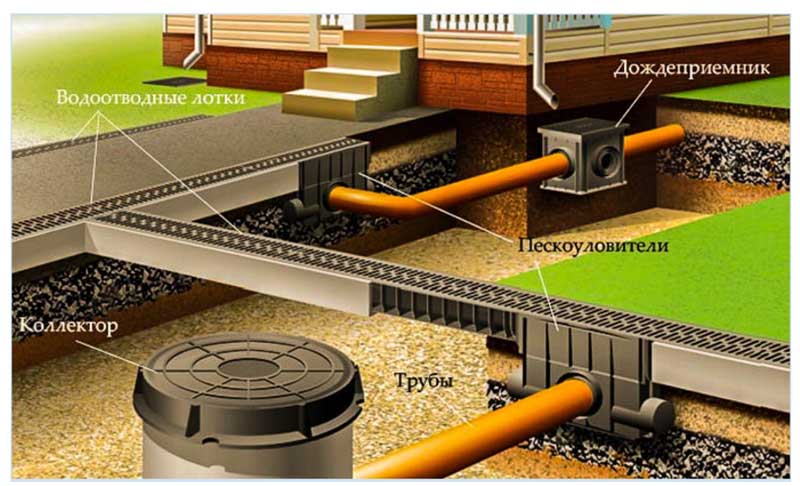

What is storm sewer and its components

The storm drain has a fairly simple structural device - the water that enters through its grate is filtered and flows down inclined pipes into a sewer well.

The main components of the storm sewer system are the following components:

- Lattice. Water enters the system through the element, serves to ensure safe passage and passage, to screen out large objects and debris that clog the channel. It is made of galvanized or stainless steel, cast iron, high-strength plastic.

- Sand trap. The main purpose of the sand filter is to collect sand and other heavy fine debris that clogs the underground pipeline channel. Structurally, it is made in the form of a basket with a handle, on the bottom of which heavy sand settles, and water enters the channel through a hole located above, according to the principle of operation, it resembles a siphon under a kitchen sink. The element is placed under the cover and does not carry a large load, therefore it is most often made of plastic, during operation it must be regularly cleaned of sand. In other similar models, the debris settles into a rectangular tray without a handle, which is also easily accessible after removing the top cover.

- Rain inlet. The basis of the whole structure, the grate rests on it and a filter is installed inside, accumulates the collected water and directs it through the outlet holes into the pipeline channel. The element is made in the form of a square or cylindrical container, the materials of manufacture are high-strength polymers, cast iron, concrete.

- Pipes. The drainage of water from the body of the storm drain is usually carried out using smooth sewer PVC pipes that are resistant to low temperatures. Less commonly used pipes made of asbestos cement, cast iron, ceramics. The cross section of the pipelines corresponds to the outlet openings in the body of the storm water inlet. In popular inexpensive plastic models, the outlet usually has a size of 110 mm, but in the construction of, for example, parking lots, wells with an outlet for a pipe of 160, 200 mm can be used.

- View manifolds. As in any sewer line, inspection outlets are needed to monitor the performance and clean the pipeline from blockages.

Rice. 2 Storm water inlet device

Purpose, classification and design

Water inlets used for drainage, when placed in the zone of an individual residential building, perform the following functions:

- They protect the walls and foundation of the house from getting wet by water flowing from the roof.

- Protect basements and basements in cases where spring flooding may occur.

- They allow you to save water by collecting it in drain wells for further use for household purposes.

- They protect elements of the landscape and the garden (paths, flower beds, beds) in the backyard from erosion by water, and help to prevent puddles from forming on the site.

- When falling from pipes, the drain destroys the material of the blind area, this can be avoided by protecting it from destruction while simultaneously draining water by installing storm water inlets.

Rice. 3 Gutters for the drainage system - installation diagram

The storm sewer system works as follows:

Through a high-strength decorative grate, which fulfills the main condition necessary for aesthetics - an attractive appearance, water enters the pre-cleaning element in the form of a sand settling basket. Heavy dirt and sand remain at the bottom of the storm water inlet basket, while the liquid enters the channels and gutters through the holes located above in the housing in which the filter device is located. The further path of water lies along an underground pipeline laid with a slight slope, it enters a storage well, where it is collected for further use or disposal.

The main differences between all systems lies in the design of the storm water inlet, which has the following body designs:

- Rectangular. Rectangular design can be found on the street of any city - such heavy cast-iron gratings of a standard size are located along city roads. Such a drainage design often has a large length and is assembled into a main line from several buildings, installed along separate sections of roads, streets, pedestrian crossings. It is used in cases where the collected water flow has a large distribution area, sometimes devices are also installed under sewers to collect water from several points into one channel.

- Square. These devices are used in a small area of \u200b\u200bthe territory from which it is necessary to divert wastewater, they are usually located directly under the downspouts of houses. Square models are widely used in individual households, as a result of low loads on the lattice of their cases, they are produced in a polymer version.

- Framed. Such types are used in places of high loads on surface lattice elements, they are mainly located on roads. When installed, their grate rests on a solid metal frame that prevents the well from deforming and destroying, and immersing it under the roadway.

Rice. 4 Designs of storm water inlets with different shapes of gratings

Construction care

Like the sewer system, the storm drain needs maintenance, and the following cleaning methods are used:

- Sand catcher baskets located under the downpipes of the house should be regularly cleaned of sand as they fill up, the same operation is carried out with surface drainage baskets with a higher frequency (once every 2 - 3 months.)

- For cleaning, the storm water inlet, basket and trays also need to be washed with a stream of water under strong pressure, using a hose connected to the water supply system, while all contaminants are washed off and drained out through the channel.

- To clean the drain from mold, plaque, algae, which are sources of microbes and unpleasant odors, you can use construction or gardening tools (spatulas, scrapers) in combination with household chemicals for cleaning water pipes.

Usually, the design of the house and the adjacent territory includes a storm sewer layout, which serves to drain rainwater from the roofs of houses and outbuildings, as well as from the sidewalk area outside the site. In everyday life, when choosing the right storm water inlet, they often prefer a drain from a wide range of plastic models - the devices are low cost, good physical parameters, aesthetic appearance, easy to install and install with your own hands.

How to choose a storm water inlet for a private house

In everyday life, stormwater pipes made of concrete or cast iron are rarely used due to the complexity of installation and heavy weight; their use is inefficient due to the lack of high loads. Cast iron gratings of class D1, D2 are sometimes located in the places where cars drive, at the entrance to the garage or on the driveways to the house.

Under the drainpipes of houses, the overwhelming majority of plastic structures are installed, which are distinguished by functionality, high technical characteristics and ease of installation. In addition, the price of such devices is quite democratic and affordable for any homeowner.

A plastic model of a small size, installed under the downpipes of the house, has an aesthetic appearance and modern design, it does an excellent job of filtering and draining rainfall into the pipeline and then into the storage well. In addition, the device is easy to maintain - periodic cleaning of the sand catcher basket is quite rare and takes a minimum of time.

In order to cope with surface runoff throughout the site, drainage lines are used in everyday life, which are prefabricated trays or semicircular guides cast from concrete, located on the same level as the ground and covered with gratings. Such a system allows you to divert water from the laid paving slabs or other coverings over a large area, transporting it along underground concrete or plastic guides outside the site or into catchment tanks.

Rice. 11 Storm drain installation tool