Purpose

The name of this device has Greek roots and comes from the word rotten. In simple terms, these are special underground chambers, which consist of one or more compartments through which various organic liquids and wastes enter. Concrete septic tanks do not function as independent structures, they are used together with special post-treatment. Post-treatment is carried out inside the earth. It follows from this that it cannot be said that this facility cannot cope with the tasks of treating wastewater and waste.

At summer cottages, concrete septic tanks are used to collect and treat organic waste and sewage.

The resulting sediment after cleaning is mineralized and can be used as a fertilizer for plants and trees that grow in the country.

Concrete septic tank design features

The main difference between a concrete septic tank and some other options is its integrity - in the sense that everything that is necessary for its operation is located in close proximity to each other. This monoblock product, placed in one large pit, is both an advantage and a disadvantage. The plus is that you don’t need to dig several holes, as is done in the case of making a septic tank from concrete rings, and the minus is that you will have to dig a very large hole - at least 3 by 2 m in size and 2 meters deep. Basically, it doesn't matter.

More importantly, formwork will be needed for its manufacture, and this is at least additional costs and labor costs for its manufacture.

Like any other septic tank, a concrete product of this type is divided by partitions into two or three parts - three is better, since three-stage water purification is better, and such septic tanks last much longer.

- First hole. Drainage coming out of the house gets into it. Here, heavy human waste is separated from the total mass of wastewater - they settle to the bottom, and more or less purified liquid is poured into the next pit.

- Second hole. So to speak, after-cleaning - at its bottom everything remains that did not have time to settle at the bottom of the first pit. Almost one liquid gets into the third compartment of a concrete septic tank for a summer residence, which was what was required to be achieved.

- Third hole. This is a pit for water disposal - without impurities, the liquid simply soaks into the soil through the bottom and holes in the walls, without clogging the pores in the soil. This is the whole point of such treatment plants. Due to the absence of impurities, the ability of the soil to absorb water does not disappear for a very long time.

You can see how a septic tank made of monolithic concrete works in this video.

As a rule, septic tanks, unlike ordinary drain pits, serve faithfully for at least fifty years. And if, in addition to everything else, biological preparations are also used, the task of which is to decompose solid waste, and even more. In principle, this nuance concerns not only the principle of operation and construction of a concrete septic tank - it is typical for any treatment plant of this type. We will continue to build such a durable drain pit.

How to make a device with your own hands

In addition to the above tips, there are many more recommendations that are especially important to consider during construction, since only this will help to do the installation correctly, efficiently and without violating technology. When installing rings, you must follow the safety rules

When installing rings, you must follow the safety rules

When installing rings, you must follow the safety rules

Namely:

Pouring is carried out using concrete of exactly such grades as B15 and higher.For mixing, you need to follow the proportion for 1 m3: crushed stone - 1200 kg, sand - 600 kg, cement - 400 kg, water - 200 l, superplasticizer C3 - 5 l.

Before concreting the bottom, a sand cushion is laid at the very bottom of the pit. The sand is laid in a layer of 20 cm. Next, you need to make reinforcement, for which a special mesh is used. The mesh is taken the one for the manufacture of which reinforcement with a rod diameter of 10 mm was used. The optimal cell size is 20x20 cm.

Concrete is laid above the surface of the reinforcement by at least 3 cm, and it is possible to proceed with the subsequent arrangement of the walls only after 2 weeks, so that the base is frozen as firmly as possible.

The walls should be no more than 20 cm thick, and the thickness of the partition between the chambers should be 15 cm.

When equipping a rectangular septic tank, it is worth considering that high pressure will be exerted on it, so you need to increase stability with a degree of soil resistance. For this, reinforcement is carried out not only of the bottom, but also of the walls.

In order to compact concrete during laying, it is necessary to use a deep manual vibrator, since the usual bayonet method will not give the desired result in the form of maximum level compaction.

Formwork should be assembled from edged boards, which will be cheaper and more convenient.

The pouring of the walls should be completed at one time, however, if this is not possible, then before starting to pour the next layer, the first one must be covered with Penerat. This allows you to make adhesion between the layers at the highest level and eliminate the formation of a gap at the junction.

Once the walls are filled, you need to wait at least 14 days, after which the formwork is removed.

The structure is inspected for integrity, and if no defects are found, then work continues, and if there are any, it is necessary to grout with cement mortar and apply a waterproofing layer using special mastic.

Next, it remains to make the roof of the septic tank, for which the formwork is assembled from the boards

It is important to remember that concrete has a considerable weight, and therefore the spans between the boards are supplemented with props. This must be done every 1.5 m.

The ceiling is reinforced in the same way as other parts of the tank, but reinforcement with a rod thickness of 12 mm is used here.

The minimum amount of concrete on top is applied at 3 cm.

Before filling up the container that will be used for sewage, you need to wait 3 weeks, remove the props and cover with a layer of polyethylene for the drying period of the concrete.

The work requires a considerable investment of time and effort, but in the end you can get a high-quality concrete septic tank. If you want to equip it in a private house, and with your own hands, then the concrete and reinforced concrete option is what you need. Such designs are thoughtful, comfortable, and most importantly - durable, stable and strong.

We make a septic tank out of concrete with our own hands step by step

Consider the sequence of making a septic tank from concrete with your own hands.

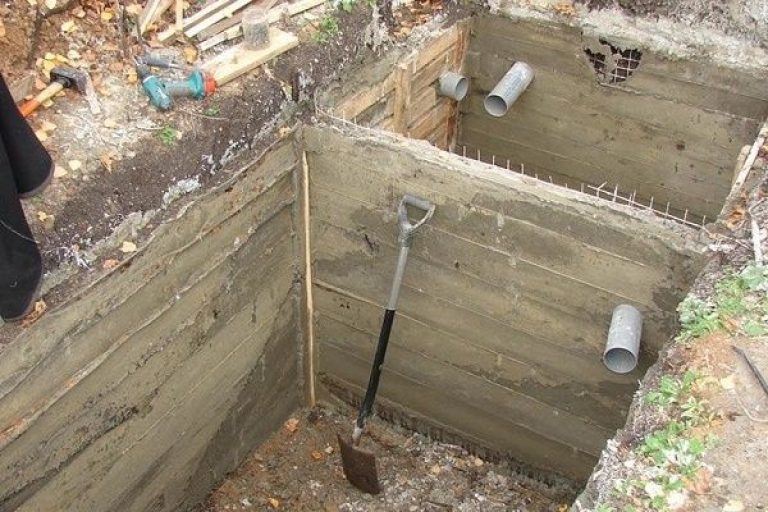

In the selected place, a pit of the required volume is dug:

If the soil is clayey, then around the perimeter you can do without external formwork, but simply lay a film to prevent water from leaving the concrete. If the soil is sandy and the walls of the pit crumble, then you will have to put up the outer formwork from the boards.

You will also need fittings, for which you can take any suitable iron trash: cuttings of pipes, angles, fittings, etc. If nothing was found in the yard, it is not necessary to spend money on new fittings, you can buy by weight at a scrap metal collection point ...

So, we laid a film around the perimeter of the pit and installed reinforcement:

We connect the fittings with a special knitting wire, and not by welding.

From any improvised materials (boards, plywood, OSB, chipboard, flat slate, old doors, etc., etc.) we put the formwork:

If the partition nevertheless decided to also pour concrete, then in the formwork of the partition we immediately lay pipes for air and overflow, and in the side walls - for the sewer inlet and outlet:

We put spacers between the opposite walls of the formwork and pour concrete into the formwork to the top.

Important! When pouring concrete, it must be bayoneted - rammed with a crowbar or a wooden stick of a suitable section, for example, a shovel handle, a bar, etc.

It is necessary to bayonet concrete so that there are no shells with air in it, which make the wall loose, porous, because of which it can collapse ... well, or it will simply let water through.

At least two weeks, your concrete septic tank should stand in the formwork. At this time, we pour water on the exposed parts of the concrete to prevent it from drying out and, as a result, cracking.

After two weeks, we remove the formwork, continuing to pour concrete for another week, you can cover it with a film:

At the same time, we concrete the bottom.

If you have porous walls:

- this is bad, as already mentioned above! Fix it! How? Well, at least get it right. (Although, I assume that you are reading this article before you started making a septic tank with your own hands, so do not allow poor quality work.)

After all of the above, we make a cover for the septic tank. We use any improvised means. In the photo, the frame is welded from the corner:

Steel sheets can be laid on top:

And on top, reinforce and pour concrete, having previously arranged formwork for hatches and installing a ventilation pipe:

But we managed without welding, using all the suitable iron that was available on the site: pipes, pieces of reinforcement, corners and backs from an iron bed (but not a mesh - it has too small cells, the solution almost does not pass through them, and those the very pores to be avoided!). They laid all this across the pit and tied it together with steel (not copper and not aluminum!) Wire. From below, to the resulting reinforcing cage, we tied old doors, you can put together shields from unnecessary boards. It is clear that we have left the doors below forever, and the plank shield can then be dismantled and the boards pulled out through the hatch. There must be gaps between the reinforcement and formwork panels so that the concrete covers the reinforcement from all sides; gaps are achieved by laying stones, pieces of bricks (red), tiles, etc.

The size of hatches is not regulated by any norms, except for those that in the future will allow you, if necessary, to climb into them.

Hatches rise above ground level with red brick masonry or, if desired, formwork can be made and cast from concrete:

As a result, we get something like this:

We make the height of the hatches taking into account the likelihood of raising the soil level (perhaps you want to bring black soil to the site, or you will concrete the area around, or you want to arrange a flower bed on top, or simply pour earth to insulate the septic tank ... or all of the above together).

This is how it is quite easy to make a septic tank out of concrete with your own hands.

do-it-yourself concrete septic tank

Types of concrete septic tanks

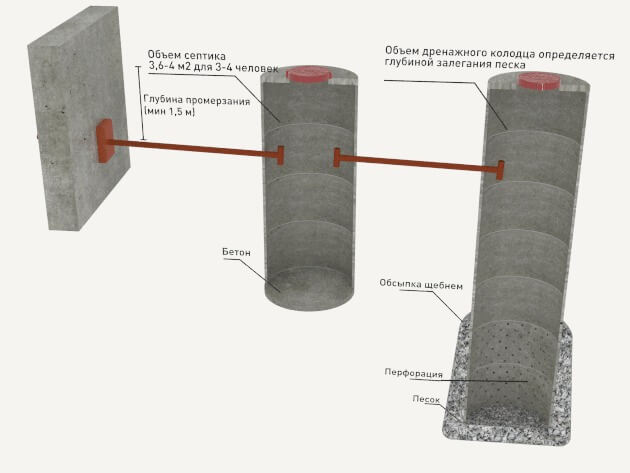

Designs for the accumulation of wastewater differ in the number of chambers. When choosing, take into account the dimensions of the containers into which sewage flows

The intensity of operation of wastewater systems should be taken into account. This makes it possible to correctly calculate the volume of chambers.

single chamber

This design option is called a drain pit. This is the simplest septic tank, it is characterized by small dimensions. The main function is to store sewage. The drain pit is cleaned regularly. The design is simple: a hatch for servicing the system is installed on top, in the side wall there is a hole for connecting a pipe through which drains enter the pit.

In most cases, this option is used if 2 people live at the facility. It is enough to build a small-sized concrete septic tank

with your own hands: 1.5 m - wall width, 2 m - depth.

Double chamber

A pipe passes between the 2 tanks, through which the treated effluents move. The first of the chambers is used as a sump, where the separation of solid fractions occurs naturally (they settle to the bottom). Sewage with a smaller amount of pollution enters the second container through the pipe. Such effluents are allowed to be dumped into the soil.

The first chamber is larger than the second. In addition, the overflow at the outlet of the structure should be located lower than at the inlet. Due to this, the possibility of treated effluents getting back into the first chamber is excluded. Such designs provide for the possibility of warning about overflow of the tank, for which a critical liquid level indicator is used, and at the same time a float switch.

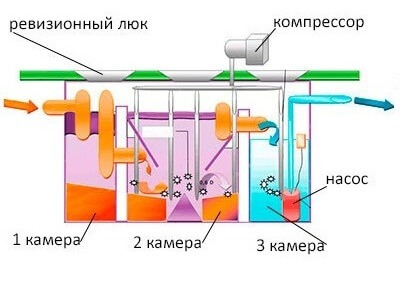

Three-chamber

These are more complex septic tanks. They are equipped with a forced aeration system. As a result, the process of cleaning and disposal of sewage is accelerated. It is difficult to equip a septic tank of this type on your own, because the volume of installation work increases, equipment costs increase. Main knots:

- compressor;

- aerator;

- submersible pump for pumping out treated wastewater.

In two- and three-chamber septic tanks, a ventilation system is provided, as well as inspection hatches. In the first chamber, cleaning is carried out with the participation of anaerobic microorganisms, in the second - through aeration and aerobic microbes. The pump is located in the third compartment.

Construction technology

In order for the structure to be durable and of high quality, before starting construction, it is necessary to carefully prepare. To begin with, it is worth familiarizing yourself with the list of requirements that the sanitary and epidemiological station imposes on such installations:

- the installation should be no closer than 6 meters to the house;

- be sure to install rubber tanks;

- the pipe through which the waste flows must be below the ground freezing level;

- the pipe must have a slope for every 2 cm of each meter of pipe.

- the total amount of organic waste and sewage for 1 day;

- the installation volume must be at least 3 times the total amount of incoming wastewater;

- if the water consumption per day is not more than 1 cubic meter, then a single-chamber installation is sufficient.

For the installation of a septic tank, a certain list of materials and tools is required:

- cement mortar for concreting;

- sewer pipes;

- bitumen;

- tee;

- ventilation pipes;

- crushed stone;

- slate;

- hacksaw for cutting pipes;

- shovel;

- Master OK;

- stairs;

- container for mixing the solution.

To use a concrete septic tank, it is important to follow the construction technology. First you need to dig a pit

For the installation of the structure, it is necessary to equip a special pit. The dimensions of the pit must meet the required data. In such a situation, dig one hole. After it is divided in two. Each of the parts will be a specific component in the treatment of organic waste

Just in this process, it is worth taking into account the level of freezing of the earth. To prevent soil shedding, you need to use plastic wrap

In addition to the pit, it is also necessary to dig trenches of a certain size for laying pipes. Drain pipes must be placed at an angle.

The next step is to strengthen the walls of the pit. To save resources, you can do this with a sliding formwork.

It is performed for half of the pit, and then, after pouring and drying, it is transported to another compartment of the pit. Shields made of wood are mounted and fastened to each other with a beam. They are fixed in the ground by about 5-10 centimeters. They make holes for mounting pipes that are laid from housing. Installation takes place over a length of about 35 centimeters. Before proceeding with the filling of the pit with mortar, the formwork must be strengthened with reinforcing bars. This is necessary so that the future installation is more durable. Metal bars for fittings can be replaced with pipes made of different materials or wooden beams.

Next, you need to fill with concrete mortar. Filling can begin after the pit has been reinforced with reinforcement. To start mixing the solution, the following components are needed - plasticizer, cement, water, sand. In order for the concrete mixture to dry and harden, it is worth waiting a few weeks.If cracks appear on the surface, they can be covered with concrete mix.

Now you can start installing the partition. This partition is made from the existing building material - stone, brick. A pipe is installed between the compartments. With its help, waste will be transferred from one compartment to another. The first compartment is engaged in the sedimentation of solid wastewater components. In the second compartment, organic waste is filtered and discharged into the soil. In order for the drain pit to work better, it is advisable to install a tee in the overflow.

We must not forget about the overlap of the installation. In order to provide a solid support for the ceiling, it is necessary to mount metal channels inside.

Above them is a wooden shield. The shield should have small sides, they outline the limit of the hatch clearance above the ceiling. Slate is placed on top of the shield. Only after that, pipes for ventilation are installed. How the final work is performed. The quality of the completed septic tank can be found out in a couple of weeks.

What is required for construction

It is quite possible to build a monolithic septic tank made of concrete or concrete blocks with your own hands, but you need to take into account the nuances.

Several people are required to install a septic tank from concrete rings.

Several people are required to install a septic tank from concrete rings.

Required on your own:

- Make a volume calculation;

- Prepare a hole;

- Do all the rough work.

As for the capacity of the tank, this is a purely individual parameter, and when choosing it, you need to be guided by the volume of water that will be used.

Particular attention should be paid to where exactly this object will be located on the site. The main thing is that the level of the septic tank should not be higher than the house

How to make a monolithic septic tank with your own hands

For work you will need:

- sand;

- gravel;

- cement;

- plasticizer;

- molten bitumen;

- metal reinforcement elements: sheets, corners;

- polyethylene film;

- pipes;

- brick;

- boards, bars;

- fastening elements of wooden metal products;

- reinforcing wire and rods;

- Sander.

How to calculate volume?

First you need to decide on the dimensions of each camera. It is required to know the depth and width of the walls. The calculation principle is the same for a rectangular and square septic tank. It is necessary to multiply 3 values: the depth and width of 2 walls. According to this scheme

each camera is calculated.

How to choose the right place?

At the same time, the location of surrounding objects is taken into account:

- the distance between the septic tank and the residential building should not be less than 5 m;

- if there is a well or a well on the site, then the drain pit is equipped much further (20 m between objects);

- leave 4 m to the border of the site;

- a septic tank is being built at a distance of 5 m from the roadside;

- to green spaces - 3 m;

- to a flowing reservoir - 5 m, and to a reservoir with stagnant water - 30 m;

- if there is a gas main nearby, you need to retreat 5 m.

Installation of a concrete septic tank

Installation instructions:

- Prepare the pit. Its walls must be even. In the process of digging, a building level is used.

- Close the pit with plastic wrap on all surfaces.

- Reinforcement of the inner perimeter is in progress.

- Formwork is being installed.

- In a wooden structure, holes are made for connecting communications.

- The solution is kneaded using Portland cement, gravel, sand and a plasticizer.

- Work continues after 28 days.

- The frame is mounted using metal corners, which are attached to concrete with anchors.

- The frame is sheathed with flat slate, sealed with bitumen.

- Then the formwork is installed to fill the floor with concrete. Provide a hole for the ventilation pipe.

Manhole covers can be metal or wood. In both cases, the frame from the corners is first mounted. The hatch is installed with hinges.In order for the construction of the septic tank to serve for a long time, concrete is poured in 1 day. This eliminates the possibility of its delamination. Separately, a pit is dug for a filter well. The installation principle is the same as for the drain pit, but the bottom is not concreted. Instead, a sand and gravel cushion is equipped.

Comfortable housing is the desire of any person, but not everyone can buy a ready-made house with everything you need. But this does not mean that everything you want cannot be done on your own, it requires quite a bit of money and patience. Any construction begins, first of all, with sewerage planning. With the presence of sewerage in the country, it will not be difficult to connect all the necessary plumbing. The best choice would be to install a concrete septic tank with your own hands. In this article we will try to analyze all the nuances and subtleties of a concrete septic tank from.

Views and schemes

Such structures can be of different types - completely monolithic or prefabricated, from separate rings. Both options have both advantages and disadvantages. Despite the fact that with the correct organization of the installation, it is not difficult to do the job, yet many specialists and consumers prefer monolithic structures.

It is not difficult to mount concrete septic tanks on your own, however, it is important not to forget about the presence of a wastewater treatment system in them.

Everything that gets inside the chambers is sent for cleaning. When the cleaning is completed, the effluent will either go to a special tank or to fertilize the plants.

All this must be taken into account when designing the future site.

A monolithic concrete septic tank, in turn, also comes in different types:

- single chamber installations;

- two-chamber structures;

- three-chamber concrete structure.

A large number of compartments in the septic tank is not used, as this is not rational. All septic tanks have their own nuances and features.

In a single-chamber septic tank, heavy suspensions that enter the chamber sink down. They break down into organic waste due to the influence of anaerobic microbes. Air gas vapors and individual chemical elements form a special separating crust on the surface. This crust clogs the pipes through which everything flows. Therefore, during installation, it is necessary to place tees there.

Due to the fact that the decomposition of wastewater is carried out together with the release of gas fumes, there must be ventilation of the septic tank from concrete rings.

The filling level is controlled by a special float indicator:

- The single chamber unit is easy to install and quite easy to use. However, it must be remembered that its cleaning system often becomes clogged, especially the pipes.

- A monolithic concrete septic tank of a two-chamber type does not have such a disadvantage; its drainage structure can work much longer without additional cleaning. There is also ventilation installed. The bottom of the second compartment can be filled with crushed stone, this will help protect the filters from clogging with solid parts of organic waste.

- A three-chamber septic tank needs a more complex device. In the first compartment, wastewater treatment is carried out. Waste of organic origin breaks down under the influence of anaerobic microbes, and the harder parts sink down. Biological purification takes place already in the second compartment. Thanks to the air pressure created by the compressor, the waste is mixed with special bacteria, and with the help of this maneuver, the organic matter decomposes faster. The third compartment is necessary for more thorough additional treatment of the remaining wastewater. The resulting liquid eventually enters the earth aftertreatment.

Advantages

A concrete septic tank has a huge list of advantages. A person who enjoys the advantages of concrete septic tanks does not need to constantly clean sewage pits.It is enough to perform such an operation once every couple of years. Concrete septic tanks do not need electricity, their operation takes place in a completely autonomous manner.

For such a structure, it is not required to buy and install special pumps or drainage installations. The device of such a concrete structure is so simple that even a person with minimal building experience can mount it. It is possible to mount reinforced concrete rings of any diameter and volume, it all depends on the desire and needs of the consumer.

This concrete installation has a much longer period of operation than its plastic or steel counterparts. A concrete septic tank performs waste filtration much better than other similar systems. The costs associated with the purchase of material and installation of the system are absolutely negligible.

Advantages and disadvantages of a concrete septic tank

When choosing a variant of similar structures that are different in material (plastic, metal), positive and negative qualities are taken into account. A concrete monolithic septic tank has the following advantages:

- relatively low price, and the option of concrete rings is considered more affordable, but it is not monolithic and requires work to ensure the tightness of the structure;

- such products do not provide for the possibility of connecting to electrical equipment (automatic filtration systems, pumping stations, compressor), which allows them to be operated in any conditions;

- you can build a septic tank with your own hands: when erecting a monolithic chamber, a concrete solution is prepared;

- long-term operation;

- resistance to the negative effects of external factors: mechanical stress, chemicals;

- due to the absence of seams, the possibility of penetration of sewage into the soil is excluded;

- a monolithic concrete septic tank is characterized by significant weight, it is much heavier than concrete and metal structures, which allows you to skip the stage of strengthening in the soil; for comparison, plastic analogues are characterized by a much lower weight and tend to rise above the soil surface when the soil is heaving.

There are few disadvantages of such structures. So, note the complexity of the work. Do-it-yourself monolithic concrete septic tank is built over a long period, since it uses the technology of pouring cement mortar, which implies the need to dry the walls and floor of the pit for 1 month.

Characteristics of the reinforced concrete structure

You will have to work hard on your own, and first you need to decide where the object will be installed

It is important to pay attention to sanitary standards and geological features of the site.

For example, if the groundwater level is too high, then this makes installation difficult:

- A distance of at least 5 m from the foundation of the house is required.

- Putting a septic tank far enough from home will be irrational, as additional difficulties will be created during the construction of the drainage system, and there will also be a need for additional costs.

- Despite the fact that the object has the maximum tightness, it is necessary that the location be as far as possible from the drinking water intake point.

When choosing a location, the way the groundwater is located is taken into account, and if its level is too high, then a complex system of filtration fields is selected.

Concrete rings should be lowered very carefully so as not to damage them.

Concrete rings should be lowered very carefully so as not to damage them.

If it is necessary to install the structure at a significant distance from the house, it is necessary to install an inspection well on straight sections every 12-15 m. They are also placed at each turn of the drainage system.