Manufacturers

| Manufacturer | Characteristic |

|---|---|

| Vektor JSD 20-W (Russia) | Power - 20 kW. Water consumption during heating 25 ° C - 10 l / min. Weight - 10.5 kg. Dimensions (H*W*D) - 580*330*208 mm. Automatic independent electric ignition, powered by batteries. To start, just open the tap of the mixer. Operates at water pressure from 0.2 to 7.5 atm. Multi-level security system. Automation protection and safety system turns off the water heater when: - lack of sufficient draft in the chimney; - extinction of the flame on the burner; — reduction of water flow; - overheating of the heat exchanger. Existence of the digital display displaying temperature of hot water at the exit from a water heater. The presence of the "Winter-Summer" mode, which allows you to save gas up to 40% in the warm season. Instability of operation when the water pressure changes, auto-ignition skips and heat exchanger leaks due to thin walls. Possible occurrence of a problem after a year of operation. Low price - about 4,500-4,800 rubles. |

| Neva 4510-M (Russia) | Affordable price and great functionality. Work on natural and liquefied gas. Power - 17.9 kW. Productivity — 10 l/min. Ability to connect multiple points of consumption. Lower gas supply. Quiet work. The presence of a thermometer and electric ignition on batteries. Works at a water pressure of 0.1 atm. There are problems with the quality of the materials used and reliability. |

| Bosch WR 10-2P (Germany) | Power - 17.4 kW. Productivity — 10 l/min. Water heating up to 60 °С. Convenient mechanical rotary switches for temperature adjustment. Two versions of the column are available - P23 for natural gas and P31 for liquefied from a cylinder. Work at pressure from 0.1 to 12 atm. The combustion chamber is open type, requiring the installation of an air outlet. Easy to use and install, small size, quiet operation. Installation vertical, on a wall. Lower gas supply. The presence of piezo ignition . Thermometer for monitoring water temperature. The model is sensitive to water quality. Relatively high price. |

| Electrolux GWH 265 ERN Nano Plus (Sweden) | Power - 20 kW. Productivity — 10 l/min that allows to take a shower comfortably. The average cost of the model. Work at water pressure from 0.15 to 10 atm. Convenient management. Installation - vertical, on the wall. Liner communications - from below. The presence of electric ignition. The presence of the "gas-control" function, which prevents any leakage of combustible substance. Fine temperature adjustment and high pressure sensitivity. |

As a result, the operation of an instantaneous water heater on liquefied gas will allow you to autonomously supply a house or cottage with hot water.

Connecting equipment to the cylinder

Before you start connecting the equipment yourself, make sure that the model really fits.

Other brands of acceptable equipment:, (almost all the latest models). The instructions for the Bosch speakers indicate that a 50-liter cylinder is enough for 10 hours of stable operation at a power of 25 kW. A conversion kit for Bosch speakers is available from an authorized service center.

If it is necessary to carry out work on the readjustment of equipment, the replacement of collector nozzles and the assessment of the tightness of the joints, they must be done strictly according to the rules. Nozzles should be smaller in diameter: as in gas stoves, the pressure given out by liquefied gas reducers is 2-3 times higher than when natural gas is supplied through pipes. At the same time, the calorific value of liquid fuel is 1.5 higher than that of natural gas.

On the equipment, you need to put the date of the rework - the day, month and year. The type of gas suitable for use is also indicated.

The scheme for connecting the cylinder to the GC requires it to have a reducer with pressure stabilization of 300 mm of water. Art. and a minimum vapor phase capacity of one cubic meter per hour.

Parameters of the hose connecting the gas equipment with the fuel tank:

- 250 cm - minimum length;

- 1.2 cm is the least acceptable internal diameter of the tube.

Please note that the forums on the network contain information of the following nature: if you reconfigure the column correctly and carry out the work without flaws, problems with water pressure may occur and the column will not start. Then you will need an additional installation of a pressure pump

When installing a shut-off valve, remember that it must be easily accessible so that the user can quickly close it in the event of an emergency.

After completing the installation work, check the tightness of the connections and conduct a test run of the equipment.

Instruction. Transfer of the gas column Neva 4511 to liquefied gas

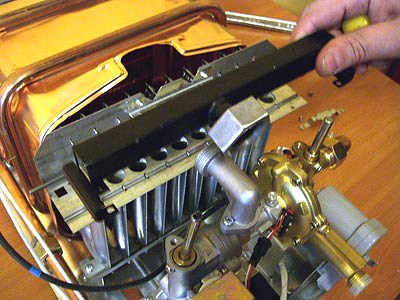

Jets with a diameter of 1.28 mm are installed in the gas column. This set of nozzles is installed in the burner rail for natural gas operation with a pressure of 130 mm. water. Art. (130 mbar). The ramp at the gas column Neva 4511 is ten-section, i.e. The ramp includes 10 nozzles.

Our LPG nozzle kit contains 10 nozzles with a diameter of 0.75 mm.

This kit is only suitable for this model,

because, for example, the Neva 4510 gas column has a ramp of a different design. Moreover, this model of the Neva 4511 is quite well studied by us. It is easy to install, repair and maintain. When converted to liquefied gas, the column consumes about a kilogram of gas per hour of operation. You will now see for yourself that altering the ramp will not take much time. To translate the column, we need a Phillips screwdriver and an adjustable wrench (38 mm). The column itself does not need to be dismantled at all.

Begin

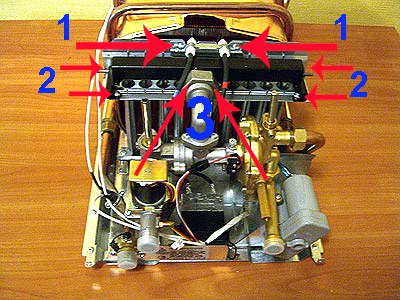

First you need to separate the ramp. An ignition electrode (candle) and a flame presence (ionization) sensor are fixed on the ramp. Separate them by unscrewing two screws.

They are numbered 1 in the photo. After separating the sensor and the candle from the ramp, it is necessary to unscrew the four screws (No. 2), which secure the burner ramp.

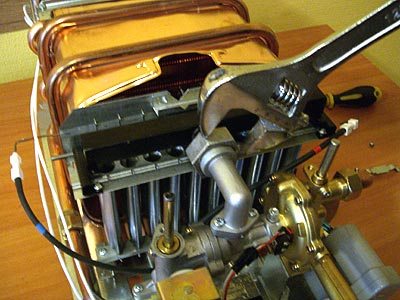

After separating them, we take an adjustable wrench and unscrew the ramp nut from the column gas unit.

The ramp is in our hands. After the ramp is in our hands, it is best to turn the jets with a head (7 mm) so as not to damage the slots when tightening new nozzles with pliers or an open-end wrench (a key, like a 7 mm head). As you can see, almost nothing is required from your brain to replace the nozzles.

Now we will understand the principle of operation of a flowing gas water heater on liquefied gas (aka balloon). Let's see what advantages such boilers have and how to install them (perform installation). In the end, let's look at the rating of manufacturers who produce the best models on the market.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery across all territory of the Russian Federation and the CIS countries.

Owners of private houses, summer cottages constantly select the best option for supplying users with hot water. One of these options is a flowing water heater that operates on.

Flowing water heater Vektor JSD

Are there turbocharged models

A turbocharged water heater can be used to heat water. Such devices do not need a traditional vertical chimney, the combustion products are discharged through a coaxial pipe led through the wall. Through it, air enters the closed furnace - to maintain the combustion process. Turbocharged speakers have disadvantages: you need to make a hole in the pipe, ask the consent of the neighbors from above to install the equipment, the device makes noise due to the operation of the turbine.Plus, when working on propane-butane, you will also need to place a cylinder in the room. An important plus of turbocharged versions is versatility, they can be placed in any room, since a chimney is not needed.

The second important advantage is that they do not “eat up” home air.

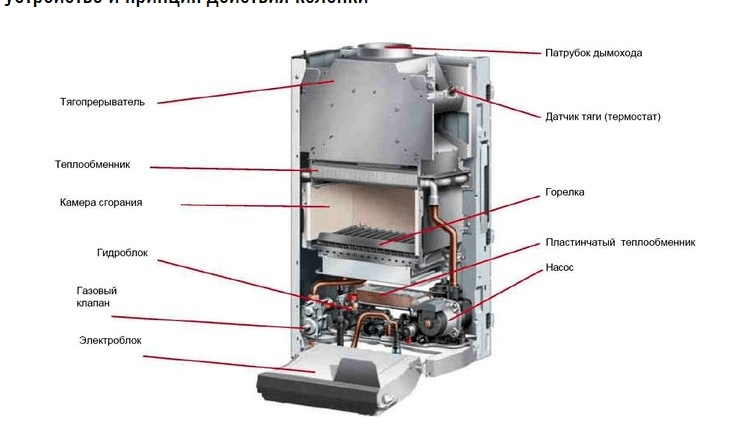

1 The device and principle of operation of a geyser without a chimney

Before you buy a geyser without a chimney, you should understand the principle of its operation, and the removal of exhaust gas, as well as understand the principle of operation of such devices.

For example, a geyser vector without a chimney consists of the following parts:

- The body of the device is made of metal alloy. It also has a control panel and a display with information about the water temperature;

- The device of the primary heat exchanger, together with a thermal module;

- Recirculation pump, through which water is supplied to the heat exchanger;

- Sealed combustion chamber.

A geyser without a closed chimney has a unique design of the combustion chamber, characteristic only for this type of device; - Burner, usually with piezo ignition, or with electric;

- The fan is the mechanism by which the system functions without natural draft to remove the exhaust gas;

- Plate (secondary) heat exchanger;

- Condenser and thermostat;

- Expansion tank (for primary water storage);

- Hydraulic module;

- Cold water inlet line, gas supply valve, relief valve;

- Outlet hot water line;

- Coaxial chimney.

You should consider the principle of operation of a gas column without a chimney:

First of all, when the hot water tap is turned on, the burner is ignited. Simultaneously with this process, gas and cold water are fed into the system using individual valves and a pump.

Further, in the combustion chamber, the gas is converted (under the influence of temperature) into thermal energy, which passes into the heat exchanger. The latter is equipped with special pipes through which water circulates, which turns into warm water in a few moments. It is she who lends herself further to the water supply system, after which we can use it for domestic purposes.

As you can see, in general, the principle of operation of a gas column system without a chimney does not differ fundamentally from conventional columns. But it should be noted about the features of the exhaust gas exhaust system: Firstly, the coaxial chimney is an exhaust system that does not require additional installation work.

For its functioning, it is necessary to provide a special cutout (compartment) in the wall, in which this system will be installed. In this device, gas is removed from one side, and clean air is supplied from the other, which is necessary for the combustion chamber. Secondly, the presence of a fan and a closed-type combustion chamber eliminates the need for natural draft (and, of course, the installation of a chimney).

Gas consumption

The average user is interested in how much fuel his column consumes. If the device is powered by a centralized gas supply, you need to know how many cubes are consumed per unit of time; if on propane, I wonder how long one cylinder will last? The costs depend on various characteristics and, above all, on the thermal power. An example of calculating the consumption of propane-butane. Initial data:

- specific heat of combustion - 14 kW / h;

- Efficiency - about 92%;

- burning 1 kg of a mixture of propane-butane gives 12.9 kW / h.

Suppose we have a heater that produces 5 liters of hot water per minute, and the fuel consumption is 1.5 kg per hour. A 50 liter cylinder contains 42 liters or 23 kg of propane-butane. Having made simple mathematical calculations, you can find out that one cylinder is enough to heat 4,600 liters of water. In terms of hours - a little more than 15 hours of continuous heating. If you use hot water for 2 hours a day, then 4 cylinders will be needed per month.

How to choose

Instantaneous water heaters running on gas - natural or liquefied, have almost the same device. Differences in nuances - materials, control method, degree of automation. Important parameters when choosing a gas water heater:

- Ignition method. Older versions were kindled by hand - with matches and lighters. Today, manufacturers offer three ignition options - piezo, electric and from a hydro generator.

- heat exchanger material. The life of the device depends on the quality of this part. If you buy a cheap Chinese device, the heat exchanger in it may turn out to be tin. Such water heaters do not last longer than three years.

- The inner diameter of the tubes in the heat exchanger. Wide tubes do not need to be descaled as often as narrow tubes.

- Water block. Preferably metal. A cheaper alternative is plastic.

- Performance. When choosing this parameter, it is necessary to take into account the volume of water flowing from the tap per unit of time. The easiest way is to record the time and see the result on the water meter. If the flow is less than 10 L/min, why choose a model with a capacity of 15 L/min or more?

- Temperature control - manual or automatic. The first ones are cheaper. Adjustment is made by valves. In modifications with power modulation, the temperature is maintained at a given level automatically.

- Removal of combustion products. Safer output through a coaxial chimney. Along with the power of the device, the diameter of the pipe increases. The second option is the output through a traditional chimney. The third is without a chimney. The latter cannot be installed in a confined space and without ventilation. These are usually mini-speakers - devices with low power.

- Supply of oxygen. In cheap versions, air is supplied through the vents. Minus - combustion products penetrate back into the room. Expensive devices are equipped with a pipe removed from the bottom of the device. The body is additionally closed with covers - from below and from above, so that combustion products do not penetrate into the room.

- Power. Mini-heaters for 17-19 kW are suitable for systems with low pressure and one point of water intake. Powerful devices should be taken for a pressure of more than 10 l / min and with several points of water intake. Versions for 21-31 kW are not installed in apartments, these are options for country houses.

Switching to alternative fuel

Most columns can be converted to an alternative type of gas - from natural to liquefied and vice versa. The changeover must be carried out by a service department that has the appropriate certificate. Manufacturer's parts kits must be used. When changing over, the manifold jets are replaced: nozzles with a diameter suitable for the type of fuel used and its pressure must be installed. When performing work, the device is turned off, the gas valve is closed. After completion of work, check the tightness of the connections. On the device itself and in its instructions, they write what it works on, the date of the work, the organization that performs the work.

Vector

"" - budget speakers assembled from Chinese components. Many consider them “of the last century”, but our consumers value them for their simplicity and low cost - the lineup consists of devices whose price does not exceed 4,000 rubles.

Despite the cheapness, this equipment works properly, providing houses and apartments with hot water. All models have a stylish design, they can even become an element of decor. A distinctive feature is compactness. Chinese spare parts, if necessary, are easy to find in any market.

Control - knobs for adjusting the gas and water passing through the heat exchanger. Some versions are equipped with a mode switch - winter and summer. The disadvantage is the accelerated wear of spare parts. So, for example, the walls of the heat exchanger are made of copper, but this layer is so thin that they burn out over time. There is no flame control module.

Vector JSD 20

Like all representatives of the Vector lineup, the column is cheap - it costs about 4,000 rubles. Compact, fits in the smallest kitchen. There is a digital display and auto ignition. Color - white, gold and silver. Closed chamber. Electric ignition.

Vector JSD 11-N

Compact version for a small space. There is an automatic fire extinguishing sensor and overheating protection. Heats up 5 l/min. It weighs only 4.5 kg, but it is also designed for only one water intake point. Parameters:

Vektor Lux Eco 20-3

This new product from Vector has advanced protection that reduces the risk of overheating. The closed furnace is cooled by water. Selecting and setting the temperature regime. There is a digital display. Case with mirror panel. The model was developed taking into account the change in pressure in water pipes. The average cost is 8,000 rubles.

Now we will understand the principle of operation of a flowing gas water heater on liquefied gas (aka balloon). Let's see what advantages such boilers have and how to install them (perform installation). In the end, let's look at the rating of manufacturers who produce the best models on the market.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery across all territory of the Russian Federation and the CIS countries.

Owners of private houses, summer cottages constantly select the best option for supplying users with hot water. One of these options is a flowing water heater that operates on.

Flowing water heater Vektor JSD

Principle of operation

The main function of gas water heaters is to heat water as soon as possible. It looks like a housing in which there are, a combustion chamber,.

In a column powered by liquefied gas, water is heated while it flows through a heat exchanger, which in turn is heated by a burner. In addition, the device has such elements as: a water cooling system, a control unit, temperature, pressure and thrust sensors. Thanks to the electronic security system, the operation of the column is controlled throughout the entire operation.

Water heater Electrolux GWH 265 ERN NanoPlus

Geysers powered by gas cylinders

If there is no centralized gas supply, it is necessary to heat water and cook food using gas water heaters and stoves that can run on a gas cylinder.

The gas cylinder used to heat water contains gases such as propane and butane. They are by-products of oil, gasoline and gas processing. The cylinders may contain only technical butane or a mixture of butane and propane, which is summer and winter.

The compression of these gases converts them into a liquid of a smaller volume (and therefore such a gas is called liquefied), and when the pressure decreases, this liquid begins to turn into a vapor state. Since an increase in temperature causes a strong expansion of liquefied gases, the cylinder is usually filled to 85% of its volume, so there is always a layer of vaporous gas above liquid gases.

For summer cottages, the choice of a heater that uses gas from a cylinder as an energy source is often the only way to get hot water in summer cottages. In situations where the main gas pipeline is not connected to the dacha, and there are also problems with the power grid, a gas water heater of this type will be a real salvation.

When a water heater is connected to a gas cylinder, on average, one gas cylinder with a capacity of 50 liters is enough to provide two or three people with hot water daily for a month.

First of all, you need to make sure that your geyser is set to use the gas that is present in the cylinder. If required, carry out work on the reconfiguration of the column with the replacement of the collector nozzles and the assessment of the tightness of the connections.At the same time, the date of the reconfiguration and the type of gas that can be used in the apparatus must be marked on the equipment.

The cylinder that will be connected to the geyser must be equipped with a reducer with a stabilization pressure of 300 mm of water column, as well as a minimum vapor phase capacity of 1 m³ per hour

They also pay attention to the selection of the hose - its length should be up to two and a half meters, and the inner diameter should be from 12 millimeters

It is important to purchase a hose that will withstand working with a column on a gas cylinder

When installing the hose, it must not be bent or twisted. If the hose has to be installed with a bend, adapters are used for this and the bend radius is monitored (it should not be less than 90 mm along its outer line). In addition, the hose must not be bent within 50 mm of the ends of the tips.

The installation of a gas shut-off valve must be carried out in front of the dispenser so that this valve is easily accessible. After completion of installation work, the hose and other connections should be checked for timely detection of leaks. Only after that the column can be used to heat water.

www.o-vannoy.ru

2 Types of columns without a chimney and their differences, prices

First of all, geysers without a chimney vary by manufacturer. There are enough models on the market both from representatives of foreign brands (geyser power without a chimney) and domestic brands (geyser Vector 11n without a chimney). The main difference between the representatives of these two groups is the cost and quality of products. According to generally accepted stereotypes, imported models are of higher quality than ours. Sometimes this is so, but not always. Moreover, if we take into account the prices for gas water heaters without a closed chimney of foreign manufacturers, and compare them with Russian models, the difference can reach 30%.

If you pay attention to reviews of a gas water heater without a national-made chimney, you can trace the trend according to which people are increasingly supporting just such models, due to the improvement in the quality of the latter, against the backdrop of rapidly growing competition.

The next criterion that differentiates gas water heaters without a chimney is the location of key mechanisms. This classification affects the ease of operation and installation of the device.

Geysers without a chimney can have a horizontal arrangement, as well as a vertical one.

Next, you should decide on the type of gas column: storage or flow. Storage water heaters without a chimney are less common, as they are more expensive, usually take up a lot of space and are less versatile. Whereas flowing gas water heaters without a chimney (Neva gas water heaters without a chimney) are the leaders in the segment and heat water immediately after the latter passes through the system.

Most gas water heaters are designed to function when assisted with natural gas. At the same time, sometimes it is advisable to use a liquefied gas water heater without a chimney. Such a device can use as fuel not only gas from the system, but also liquefied gas from special cylinders, which is very convenient and relevant for regions and districts where, for certain reasons, there is no access to a gas pipeline (dacha, in a remote area, etc.) .

The price of a geyser without a chimney is approximately on the same level as water heaters that have an open combustion chamber. Speaking specifically, medium-power models have a cost of 8 thousand rubles (domestic manufacturer) and 10 thousand for imported models.