polyurethane foam

Recently, polyurethane foam is gaining popularity. It is considered one of the most reliable heaters.

The presented material has positive properties:

- Withstand mechanical stress;

- Withstand thermal stress;

- Fire resistant;

- Durable;

- There are no seams and joints that need to be sealed.

In other words, this insulation does not have the disadvantages that mineral wool and polystyrene have.

In other words, this insulation does not have the disadvantages that mineral wool and polystyrene have.

If you look from the side of the properties of this product, then we can say that it has no drawbacks.

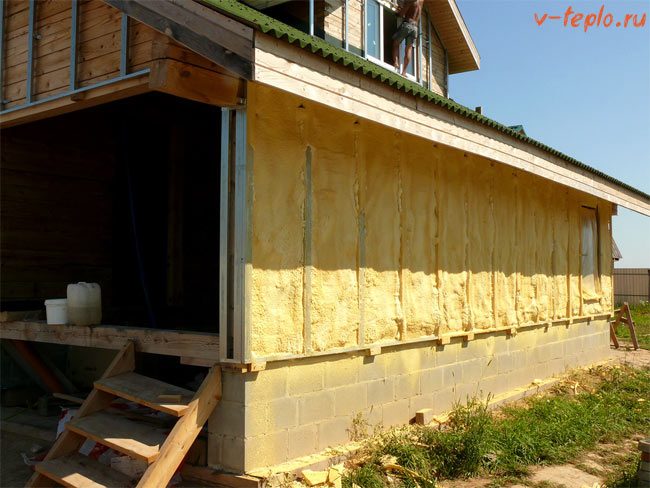

The only difficulty you may encounter is the application of the material. Polyurethane foam consists of two components that form foam when mixed. It is applied using a special device.

The foam is sprayed directly onto the wall on which the frame is installed.

There is no need to use fasteners. Polyurethane foam quickly hardens and dries.

A nylon mesh can be installed on top, and any finishing work can be done on it.

Insulation of metal doors

Metal doors can create so-called cold bridges. Through them, frost sneaks into the room, even if the door leaf is completely sealed and closes tightly. Therefore, the purpose of insulating a metal door is the following:

- increasing the sealing of the door;

- insulation of all metal parts of the product, except for the door handle;

- the placement of insulating material inside the door leaf.

The design of almost all metal doors is hollow. Thanks to this, it is very easy to place mineral wool or foam board inside as an insulating material.

So, the process of warming metal doors will look like this:

- Carefully remove the locks and door handles;

- Disassemble the box (in case the fastening is carried out by welding seams, they must be removed with an angle grinder);

- Lay the insulation inside the empty box;

- Assemble the door structure to its original position.

If you chose polystyrene to insulate the door, then there will be gaps between the sheet and the fixing and fixing metal profiles. In order to ensure complete thermal insulation, fill these spaces with mounting foam.

If you have a non-separable door, it can be insulated with an internal additional lining. To do this, remove the door from the hinges, remove the handles, locks and other adjusting fittings. Screw a beam with a diameter of 10 X 10 mm along the perimeter of the door leaf from the inside, stretch the upholstery for the entrance doors and fix it on the beam with special nails.

How to insulate an old garden house for the winter

The most practical today are such heat-insulating materials as Rocklite mineral wool, foam plastic and foam slabs. Many are still trying to use inexpensive old-fashioned ways of warming, one can say from what lies under their feet. So, when insulating attic floors, you can use sawdust, moss, expanded clay, etc. But we will consider exclusively modern materials.

Materials for thermal insulation of a summer house

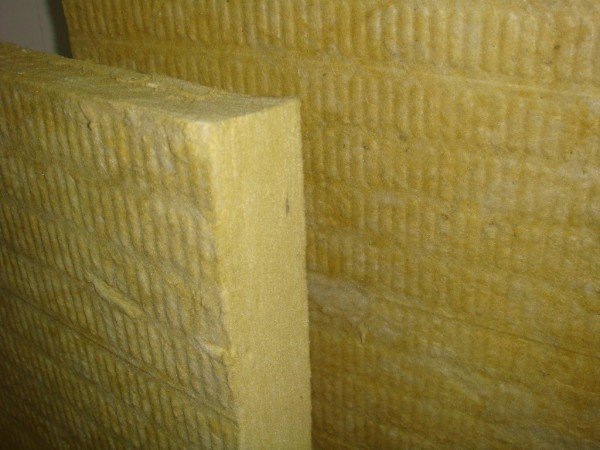

When using mineral wool and cellulose insulation, high-quality hydro-vapor barrier of the material from moisture is required. Basalt heaters are mainly used to protect facades, warm wooden floors from the cold. Mineral wool has been used for decades in construction, and has proven itself in the best way. It is believed that this insulation does not gnaw mice.

Styrofoam and extruded polystyrene foam are used in the insulation of strip foundations and blind areas. Penoplex is a dense and durable material that is not afraid of high humidity. Styrofoam, on the contrary, is a fragile material that rodents have chosen.Along with this, polystyrene is the most popular insulation in Russia due to its low cost and ease of installation.

In order not to overpay and make the thermal insulation layer optimal, you should calculate the thickness of the insulation on a heat engineering calculator. As a first approximation, it should be noted that for basalt materials, the thickness of the thermal insulation of structures should be taken at least 10 centimeters. For expanded polystyrenes, the thickness of the thermal insulation layer should already be at least 15 centimeters.

Requirements for materials for thermal insulation

When laying, mineral insulation should be tightly packed into the frame, the material returns to its original state after pressing. Mineral wool absorbs moisture, so they must be covered with a vapor barrier. The insulation layer is always laid only on the cold side. Before use, the material must be dry, otherwise it will rot with all the ensuing troubles.

Since rodents start up in garden houses, it is worth choosing a material resistant to moisture and rodents for thermal insulation. To save money and improve the thermal insulation characteristics of building structures, mineral and organic heaters can be used, laying them like a layer cake. In this case, the moisture-proof material is laid on the side of the warm room.

How to insulate the walls of the house from the inside: various options

By and large, there are no options for internal wall insulation - all this is one technology that involves the creation of a so-called false wall, the space behind which is filled with insulation of all stripes and types. Just kidding, not all - it is better not to use polystyrene. The most suitable insulation for internal thermal insulation is mineral wool - it is a vapor-permeable material that does not create a greenhouse effect and prerequisites for the reproduction of fungal and mold microorganisms

Styrofoam should be used outside the room - you can also pay attention to the methods of external insulation in the case of saving square meters in the house. Well, in general, the whole technology for solving the issue of how to properly insulate a house from the inside, or rather its walls, can be represented as a sequence of work consisting of three stages

- Support frame device. The scheme is standard, and adhering to it (with the exception of some details that depend on the panels), frames are mounted for almost all types of finishes - drywall, MDF panels, lining and so on are no exception. The frame can be made of two types of material - a wooden beam or a special metal profile. The profile is better, because, unlike wood, it is practically not subject to deformation under the influence of temperature and humidity changes.

How to insulate a house from the inside photo

To learn how to insulate the walls of a country house, see this video.

Wall insulation will give a good effect, but it should be understood that it can be strengthened, and this can be done to a large extent - practice shows that the main heat losses do not occur through walls and not through the floor, and not even through windows and doors. Heat escapes through the ceiling and roof - this is elementary physics, so to speak, the laws of nature, from which you cannot escape. That is why the question of how to insulate a wooden house from the inside with your own hands cannot be considered resolved until the ceiling and roof are thermally insulated.

Thermal insulation of the walls of the house from the foam block

Buildings made of different materials require the use of a certain type of thermal insulation. If mineral wool is better than others for housing made of wood, then other coatings are preferable for a house made of foam blocks. In addition, it is desirable to produce insulation on both sides of the walls: both outside and inside. Or choose the option of exclusively external thermal insulation.

If the installation method is chosen only on internal surfaces, in this case you need to be prepared for the fact that the walls in a private house made of foam blocks will remain cold and damp, and this will eventually lead to dampness and mold.

Material selection

Cork coating has a number of advantages, due to which this material is often used to insulate walls from the inside:

- low thermal conductivity

- easy installation (attached with glue)

- does not require special preparation of the walls

- multitasking, as it can also be used for thermal insulation of the ceiling

- characterized by soundproofing properties

- does not need decorative finishing

Before pasting the walls with cork, it is important to thoroughly clean them from litter and dust. If there are visible irregularities, it is better to correct them so that the material does not sag.

Also, before starting the installation, leave the coating for about a day and let it rest in the room where the work will be performed.

Penofol is perfect for buildings made of foam blocks. This is a material made of foamed polyethylene, on one side covered with aluminum foil. The result is effective protection against heat loss. It is necessary to have such a heater with the foil side inside the room.

Thermal insulation of housing from foam blocks can also be made using polyurethane foam. This is a universal material that provides a seamless coating on any surface outside and inside: floors, walls, ceilings. With the help of polyurethane foam, you can create an impervious coating on the wall of the box of a house from foam blocks of any configuration, while eliminating the risk of the formation of "cold bridges".

Materials for thermal insulation

The building materials market offers a huge range of types and manufacturers of thermal insulation materials. It is easy to get lost in this variety. The choice depends on the location of the thermal insulation and the wishes of the owner of the house. The main heat insulators include:

The main heat insulators of the house

Mineral wool. It is produced in the form of mats (rolls) and rigid plates. The first option is suitable for walls and floors along the logs, the second for walls, floors, roofs. The advantages include incombustibility, high efficiency, durability, resistance to decay and mold. Disadvantage - the ability to absorb moisture

It is important to remember that when working with this material, you need to use masks, gloves and overalls. Neglect of safety measures will lead to the ingress of cotton particles on the skin and lungs, and eventually to irritation and allergic reactions.

Styrofoam

The material is made from polystyrene. It is a plate of small balls filled with air. The indisputable advantage was the low cost of the material and availability. There are quite a few shortcomings. These include combustibility, inability to pass air (the house will need additional ventilation), low strength and instability to the simultaneous effects of moisture and low temperatures. Suitable for do-it-yourself insulation of walls (it is recommended not to use it from the outside), floors (better for insulation from below), attic roofs.

Extruded polystyrene foam (penoplex). The material is similar to foam, but is an improved version of it. It belongs to low-combustibility, has increased strength and moisture resistance. The disadvantages include air tightness. Suitable for insulating walls and floors (both interfloor ceilings and on the ground).

Expanded clay. Inexpensive material. Compared to the previous three, it does not have high efficiency. Represents small granules of the baked clay, free-flowing. The disadvantages include high thermal conductivity and a large mass. Suitable for floor insulation (simultaneously levels the surface).

There are also a number of less common materials, these include:

- polyurethane foam;

- ecowool (insulation mats made of flax);

- penoizol (foamed polymer resin);

- isocom (foil material);

- sawdust.

What to do with the roof

The question of the need to insulate the roof would be irrelevant. This isolation must be carried out without failure. Only in this case, the material characteristics and climatic conditions in the region should be taken into account.

When the leakage of thermal insulation of the roof of the house is reduced by 15%.

And if the attic space is used as an attic, it is simply impossible to do without reliable roof insulation. In the absence of a planned residential building in the attic, it is sufficient to insulate the ceiling of the house or attic.

Conclusion. From the foregoing, we can conclude that those people for whom convenience and comfort will not neglect the heating of the house.

The money saved on electricity, water and gas can be considered well-deserved, and the material will be paid in the first cold season.

Warming the cottage is an event that should not be postponed, but completed before the cold snap sets in. You should know that the insulation procedure itself concerns many elements of the building, moreover, it can last several weeks.

But something else is more important - to correctly choose materials and execution technology, since it depends on this how effective the result will be. It is worth adding that with the help of the simple tricks described in the article, you can save a little on thermal insulation.

So, how to insulate a country house? Immediately make a reservation that insulation can be of two types:

Consider the features of each of them.

Canvas insulation

It is worth starting work with the insulation of the door leaf, regardless of whether it is wooden or metal.

Warming of a cloth from a tree

It is advisable to choose a model from the array for the entrance group, since hollow models are less durable. To qualitatively insulate the canvas of a wooden door, you will need:

- Insulation. This can be foam rubber, synthetic winterizer, polystyrene, etc.

- Glue.

- Carnations are furniture.

- Finishing material. As a finish, you can choose leatherette, leather, laminated MDF lining, etc.

- Rails are wooden.

- the canvas is removed from the hinges, all fittings (handles, lining, etc.) are dismantled;

- clean the canvas from dirt, allow it to dry;

- lay the door on a flat horizontal surface - a workbench, a table, two stools installed at a distance from each other;

- a blank is cut out of the insulating material according to the size of the canvas;

- apply universal glue to the canvas and lay a layer of insulation on it.

After installing the insulation on a wooden door, you need to complete its decorative finish. When using soft insulation, various upholstery fabrics, artificial or natural leather are used. If foam plastic is used, you can upholster the door with clapboard or install a ready-made decorative MDF overlay, the material is attached to a wooden frame around the perimeter of the door.

Insulation of a metal sheet

When buying a metal front door, you should choose a model with ready-made thermal insulation. But even in this case, additional insulation will not be superfluous, especially if an inexpensive Chinese-made model is purchased.

- the sheet is removed from the inside of the door;

- the selected insulation is placed in the cavity;

- all gaps are filled with foam;

the removable sheet is put in place.

In the event that the canvas is non-separable, then before laying the insulation, it will be necessary to assemble the frame. To do this, you can use a metal profile or wooden slats. The frame is fixed at the locations of the stiffeners with self-tapping screws.

Insulation of the front door with foam rubber

If you want the insulation of the front door to not take you a lot of time and money, use the most familiar, common material - foam rubber. It is not suitable for sealing on the sides of the door frame, but it can be sewn onto a wooden door on both sides.

To work, you will need the following:

- Foam rubber;

- Upholstery fabric;

- Glue;

- Threshold board;

- Rails made of wood and plastic.

- First of all, cut off the outdated coating from the door and get rid of the remnants of insulating materials. Wash the surface thoroughly.

- After the door dries, stick on its inside and outside with layers of foam rubber, cut strictly to size. If necessary, pieces of foam rubber can be glued together in 2-3 layers (for example, if the material is thin, or you think that additional insulation will not damage).

- Now stretch the upholstery over the foam rubber, fixing it to the door with nails or a construction stapler. You can decorate the surface with a pattern of wallpaper nails. Do not overdo it: the nails are pressed and pressed into the insulation, because of this, its heat-saving properties are lost.

- It's time for the door frame. Fill the rails around the perimeter of the door, which were previously covered with foam rubber and fabric. At the same time, control the position of the closed door: it should fit snugly, without gaps.

- The last stage of warming is the installation of the threshold. The board for the threshold should completely close the gap under the door, but not prevent the door leaf from opening and closing.

Instead of foam rubber, you can use materials such as foam (2 to 5 cm thick) or polyethylene foam. In terms of their heat capacity, they are superior to any traditionally used materials.

Such a simple and economical way will help you quickly insulate the door, additionally protecting you from extraneous noise.

We insulate the door leaf around the perimeter

No matter how well the door leaf is insulated, no matter what materials you use for this, the work will not be enough if the door does not fit snugly against the frame.

Gaps between the jamb and the door occur in the event of installation errors, or after some time due to the shrinkage of the building or the distortion of the structure. The sealant will help to solve this problem quickly and easily. It is enough to fit it tightly to the door frame, and the structure will become completely airtight, all the cracks will be filled, and, accordingly, the heat loss of your house or apartment will be significantly reduced.

- The modern building materials market offers a large selection of sealants. The best option is rubber tubular seals with a self-adhesive base.

- In order to select the desired width of the seal, be guided by the width of the canvas. Its thickness during compression should be equal to the width of the gap between the frame and the door.

- The thickness of the seal also requires special attention. Too thin material is not effective enough, and too thick material will cause inconvenience when closing doors.

Work on insulation using a sealant is quite simple: remove the protective film and glue the sealant around the entire perimeter of the canvas. If your caulk does not have an adhesive backing, use liquid nails or silicone.

Do not forget to check the integrity and condition of the door frame. If it is rotten, replace it before you start insulating the door. If you mounted the box on mounting foam, check if it crumbled.

As you can see, self-insulation of almost any door can be done even by a beginner. Share with us and other readers your practical experience in such work, ask any questions, and we will be happy to discuss all comments and suggestions. Warmth and comfort to your home!

Owners of private houses, as a rule, are well aware of the need for thorough insulation of all structures, since heating costs directly depend on this.The front door deserves special attention, since in a private house it does not go out into a relatively warm entrance, but directly onto the street. Consider how to insulate a door in a private house, video instructions will help us in performing these works.

One of the conditions for the comfort of a residential building is the quality of the insulation. In order not to spend extra money on heating, it is worth insulating all structures through which heat can escape. These are the windows, the roof, the outer walls and, of course, the front door.

In a private house, the front door can be made of different materials, but in the vast majority of cases, the owners install metal or wooden models.

Like a glove

The heat-insulating-bonded system includes adhesives, plasters and reinforcing meshes (they provide fixation of the heat-insulating layer, as well as its protection from external influences).

To keep the facade insulation firmly on the walls, you should use branded complexes, that is, a set of components produced by one manufacturer (RockFacade from Rockwool, Denmark-Russia; Warm Wall from Knauf, Germany-Russia; Capatect from Caparol, BauColor from BauCoior; Ceresit from Henkel Bautechnik - both Germany, weber.therm.cottage, trade mark weber-vetonit international concern Saint-Gobain, etc.). "Foreign" products may not take root in a friendly family of "native" materials, which will lead to partial delamination or even destruction of the thermal insulation system.

Thermal insulation boards are glued to the walls with special mineral glue and additionally fixed with facade dowels.

The first row is mounted on an aluminum rail. The insulation is mounted without gaps and voids. True, there are narrow gaps between the polystyrene foam plates, which are filled with mounting foam. A polymer-modified adhesive mixture is applied to the heat-insulating lining, into which an alkali-resistant fiberglass mesh is embedded. This is followed by another layer of mineral glue and a decorative coating (structural plaster, facade paint and ceramic tiles, etc.). If all work is carried out strictly according to the instructions, then the warm wet-type facade will seem to grow together with the outer wall, becoming a stable basis for implementing architectural ideas in any style.

One-Stop Solution

If you need to quickly insulate and decorate the house, then it makes sense to use effective and aesthetically attractive thermal panels.

At the heart of these products is a plate of dense polystyrene foam 40-100 mm thick or polyurethane foam 25-40 mm thick. Some models also have a rigid OSB substrate, which provides the facade insulation with additional strength and geometric stability.

From the outside, the thermal panels are lined with thin-walled clinker bricks, porcelain stoneware, glazed or engobed ceramic tiles, and artificial stone.

Installation begins with marking the base surface (smooth and clean) and fixing the starting aluminum profile, on which corner and then ordinary thermal panels are installed first. Panel insulation is attached to the wall with self-tapping screws. The joints are filled with mounting foam, and at the final stage - with colored mineral grout.

Unity and struggle of heaters

The mineral heat insulator is durable, vapor permeable (that is, it does not prevent the walls from "breathing"), resistant to biological damage and fire resistant (prevents the spread of fire and thereby increases the fire safety of the building).

An alternative option - facade expanded polystyrene - is cheaper and at the same time noticeably surpasses stone and glass wool in terms of thermal performance.

However, the polymer heat insulator burns (although it belongs to slow-burning and self-extinguishing materials) and almost does not let steam through.

For reasons of fire safety, cuts are made from mineral wool on the polystyrene foam "field".

In addition, windows and doors are framed with “stone” insulation.

Almost half of the heat in our homes is not blown out through windows and doors. Up to 40% of the heat literally escapes through the cold walls. Realizing and feeling this fact, have you decided to insulate the walls outside your house? Well, the costs of these works will more than pay off in the near future - your loved ones will be warm and comfortable, and gas or electricity bills due to the insulation of the walls outside the house will become much smaller.

It is the insulation of the walls of a private house from the outside, and not from the inside, that is the most effective way to make your house really warm and at the same time prevent excessive moisture condensation on the walls: an incorrectly calculated “dew point” often increases the accumulation of moisture on the walls of a house insulated from the inside.

In addition, the loss of 5 centimeters of area from each wall, as well as the complete release and thorough preliminary preparation of internal vertical surfaces, are pushing to make a choice in favor of insulating the walls of a private house from the outside.

The insulation layer becomes a barrier between the cold outside air and the internal microclimate of the house. Another plus is that the insulated walls of the house from the outside will be additionally protected from moisture and sunlight, which means they will last longer and will not require updating.

So, the insulation of the walls of the house from the outside has the following advantages compared to the internal insulation:

- the entire interior space of the house is preserved to the millimeter;

- the walls are not subject to a sharp temperature drop, the humidity level remains approximately the same.

When insulating the walls of the house from the outside, some features should be taken into account:

- it is necessary to install scaffolding and dismantle it after work - this is additional time and money;

- in rain and strong wind, as well as in the cold season, work cannot be carried out;

- the appearance of the building will change.

Benefits of an insulated home

By looking at modern isolation methods, you can find many advantages:

- Mushrooms or mold will never appear on the walls of a heated house.

This quality is achieved by the fact that the insulation protects the walls from condensation and moisture;

Throughout the year, the space will retain a warm microclimate;

The level of soundproofing of the building is increased.

Absorbs up to 90% of sound vibrations;

Improves the hygienic condition of premises and auxiliary premises;

Electricity or natural gas is stored (if the heating in the house is gas);

The emission of harmful substances into the atmosphere is significantly reduced;

The service life of the house is increased;

Construction costs are falling.

It should be noted that it is impossible to completely eliminate heat losses, but it is very possible to reduce them.

Do-it-yourself high-quality home insulation will help the owner maintain an acceptable temperature and save the family budget.

In the summer, the insulated walls of the house perform the opposite function. High temperature is not allowed in the room, passengers will always be cool and comfortable.

And if the rooms use air conditioning, then an insulated house allows you to cut down on your work several times over.

You can feel the effect immediately after covering the house with a heater. If the temperature reaches + 30 ° in summer, it is difficult for the room temperature to rise above + 20 °. In winter, everything else will be.

Floor

simple and cheap options

The first is to insulate the living quarters around the perimeter: no matter how well the floor is fitted and the baseboard is selected, there is a gap between the floor and the wall. If the basement is not insulated, cold air will penetrate through these gaps from below. And this is where penofol helps us: we fix the strips of this material (with a foil layer inside the room) with a furniture stapler (or small nails, if there is no stapler) so that one edge goes to the wall and the other lies on the floor. Quickly, simply - and the room becomes noticeably warmer. Check it out!

Penofol is also used for continuous thermal insulation of the floor (here someone already does it: someone fixes it from the basement side, someone uses it instead of a substrate for flooring, but I heard only positive reviews from both).

The second is the floor surface. Homespun rugs in village houses, in addition to a decorative function, also have a purely practical function: this is additional insulation. So if there is carpets, rugs, runners and rugs

- lay them on the floor, and you will be warm))