Why stove channels get clogged and how they can be cleaned

The need to clean chimneys and internal flues of solid fuel heating units (boilers, fireplaces, stoves and various stoves) has both objective and subjective reasons. The first ones are related to the fact that any smoke consists of a gaseous part and the smallest particles of carbon that have not had time to oxidize. in the process of combustion. Most of them leave the chimney, flying out into the atmosphere, but the part that has the largest weight and electric charge settles in the chimney channels. The situation is further aggravated due to water vapor and creosote, which moisten the walls of the flue and thereby contribute to the adherence of soot. These deposits reduce the cross section of the chimney, due to which the draft decreases, which means that the efficiency of the furnace decreases and fuel consumption increases. But the main danger lies in the fact that the further use of the heater becomes unsafe.

Subjective reasons include:

- burning low-quality coal and raw firewood;

- furnace firebox with high carbon waste (plastic, rubber, etc.);

- incorrectly selected operating mode of the heater;

- mistakes made during the construction of the furnace or chimney.

After analyzing the factors that cause soot to build up in a chimney, you will see that the situation can only be partially improved by reducing the amount of particulate matter in the smoke. Nevertheless, the chimney will have to be cleaned sooner or later.

You can do this in two ways:

- mechanical,

- chemical.

The first involves the removal of soot and soot with the help of various devices - scrapers, spatulas, brushes, etc. Using such tools in the chimney and gas ducts, one can very successfully scrape soot from the walls, rake it in heaps and dispose of it.

Chemical soot removal consists in the fact that a product with a complex chemical composition is burned in the furnace of the furnace. The substances released during its combustion interact with the most persistent deposits, due to which they soften, exfoliate from the walls of the channels and burn out. As practice shows, chemical compounds are a fairly effective tool in the fight against soot, but due to the relatively high cost, they are used much less frequently than scrapers, brooms and brooms.

How to make homemade ruff

If the price seemed too high for you, you can make such tools with your own hands. The main thing is to determine which shape you need and for which pipe. There are three main types of brushes:

- Ruff - a classic brush made of metal, in the shape of a cylinder. Additional devices included in the kit can be either a simple long rope, usually 5 meters, or a kettlebell weighing up to 2 kg. with extension.

- An ordinary brush equipped with steel or nylon "bristles". Has a special handle.

- Scraper. It saves when there are soot growths on the channels, which the two previous options cannot cope with. May be any suitable shape.

From a plastic bottle

A homemade chimney brush can be made from an ordinary water bottle. Manufacturing steps:

- In the center of the bottom, we make a small hole.

- A hole is made in the lid of the same diameter.

- Next, we cut the bottle into small ribbons, and fasten a hairpin with a hook on one side.

- On the other hand, a hairpin is also inserted, which are connected together.

- Using nuts, squeeze the bottle and attach a weight on one side.

The process of making a plastic brush

The process of making a plastic brush

This design is suitable for cleaning metal, ceramic channels.

From a broom

A chimney brush can be made from an ordinary plastic broom, which is now a network in almost every household. Manufacturing stage:

- Cut off the stem.

- We straighten the “bristle”, you can use a hair dryer. After straightening, we clamp with a hairpin with a washer.

- From the side of the handle we wind the hairpin with a hook.

- The structure is tightened on both sides, after which a cable with a sinker is attached.

Great for cleaning wide channels.

From a metal brush for a grinder

A metal ruff or brush can even be made from such a device. At the moment, the price is not so high, so we recommend buying a finished product. If you decide to make a chimney brush with your own hands, remember that you will need two sheets, a threaded stud and nuts. Also, do not forget to use a hard wire or, in some cases, nylon as a "bristle".

From a metal cable, a difficult option

A cable can also be used to clean chimneys. The manufacturing process is much more complicated and requires certain efforts and skills. You will need a cable, preferably from 1 cm in diameter. An edge of about 10 cm is unraveled into individual fibers. They unbend in different directions, and in order to hold the form to clean the pipe, two plates are taken and compressed. A counterweight must be attached to the bottom edge to break up lumps and soot growths.

Common mistakes and problems when making a brush

The main difficulty in the manufacture of a ruff is the search for a suitable material. The most difficult thing is to make the head of the fixture. At this stage, precision and considerable effort are required.

Most masters make the following mistakes:

- Short cable length. As a result, the ruff does not reach the end of the pipe. As a result, the most inaccessible area near the firebox remains clogged.

- Weak wire tightening between washers. This leads to the destruction of the homemade ruff in the process of cleaning the chimney.

- Pole or plugs of insufficient strength. When loaded, these parts bend, not providing brush advancement. In the worst case, the handle breaks, and its fragments get stuck in the pipe.

- Selecting a cleaning material that does not match the inside of the chimney. So, a metal-worker can hopelessly ruin ceramics.

- The head width does not match the channel parameters. The head either does not pass into it, or does not reach the walls.

How to make a chimney brush

How to make devices for cleaning soot in a pipe yourself?

In principle, it will be enough to take a long pole, corresponding to the length of the chimney, and fix a brush, a brush with a hard force, a brush with plastic bristles on its end. You can pick up a brush from those available on the farm, or purchase something suitable. All of course will depend on the size of the chimney. Further, with this brush or mop, it is necessary to clean deposits from the walls of the chimney.

It is also sometimes recommended to use a chain with links. Having lowered the chain into the chimney, it is necessary to rotate it around the axis so that its links touch the walls.

In any pipe brush there should be three main elements, this is the load, the brush itself, and the cable or chain. The load ensures that the brush is pressed against the wall of the chimney. The brush itself can be made from pieces of steel wire laid between layers of plywood discs, and fastened together with a bolt and nut through the central holes of these discs.

If you don’t mind burning a tire from a passenger car, then we do this - we burn the tire and we get a wire from the cord, with mittens we wind the wire into a roll a couple of centimeters in diameter less than the diameter of the chimney (usually it is 100 mm), so make a brush 80 millimeters, even if the chimney is wider than anything, clean it without problems.Then, in one place, we tightly twist the entire bundle with the wire so that it does not unravel, but on the other hand, let it open, take a strong rope of sufficient length and tie a sinker to it, you can have half a brick for a hole or a piece of iron, but so that it freely walks through the pipe, and ten centimeters above the beam (you can specially fluff it in the form of a washcloth) and you're done!

The wire released on the fire is soft and it will never get stuck, but at the same time it will clean it well enough by scraping the soot from the walls, you need to do this carefully without sudden movements, the weight of the sinker should be pulled down, while holding it down, and then gently lift it up , you can wind the rope around a thin stick and also create horizontal torsion, which will improve efficiency. After cleaning the chimney, the brush wire can be thrown away, since there is no need to store it, you can make a new one at any time

What is a ruff (brush) for cleaning the chimney: a disc-shaped metal brush, a cable (rope), a load (core or weight), it must be with an unbiased, with a stable center of gravity.

At home, you can make a ruff from a plastic bottle:

Cut a 1.5-2 liter bottle in half, only the top is needed.

Make your own or buy

This question invariably arises before the owners of real estate heated by coal or wood. If you have skills in handling household tools, making a brush will not be difficult.

But, for this you will need to spend time, which everyone is sorely lacking. It is much easier to purchase a finished product of factory production. Fortunately, today in the retail trade there is an extensive range of such products, and their price is quite loyal.

When buying chimney cleaners, you should not focus on their cost. A cheap purchase may not be effective and will lie in the pantry for years.

The following factors need to be taken into account:

- can be processed with any material;

- for cleaning ceramic pipes, only a plastic ruff is allowed;

- steel chimneys can be cleaned with copper or brass bristle heads;

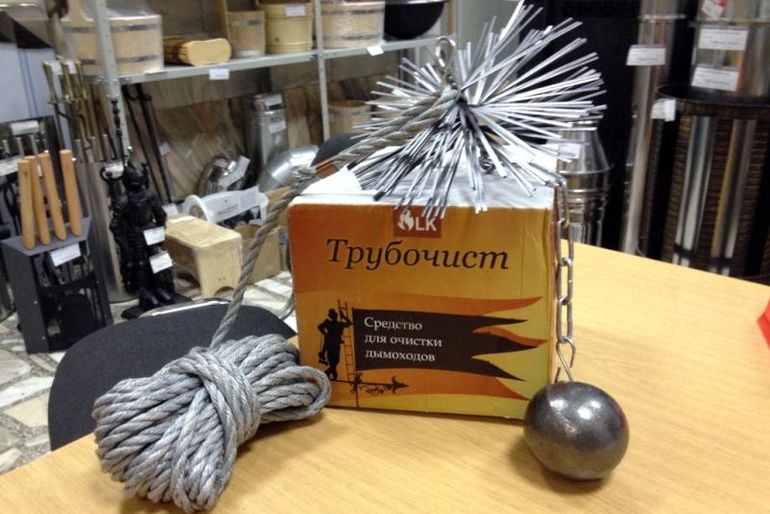

The most popular are ruffs from such manufacturers:

- PCC (Poland) - plastic and metal, with a diameter of 120-400 mm;

- Hansa (Lithuania) - universal 150-400 mm;

- Chimney sweep (Russia) - set with interchangeable nozzles.

Advantages and disadvantages of a brush

The most difficult thing is to remove soot, which filled almost the entire volume of the channel. In addition, the length of the chimney also plays a role. In some buildings, it can be ten meters or more. It is simply impossible to work with poles of this length.

The wire brush has the following advantages:

- light and compact, easy to carry and transport;

- no restrictions on the height of the pipe, the shape and size of the section;

- the ability to adjust the weight of the load and, accordingly, the applied force.

The disadvantages of this device include its inability to break through solid blockages, remove condensate and remove foreign objects.

Cargo manufacturing

A metal brush for cleaning the chimney must necessarily have not only a base and bristles, but also a load that allows you to correctly position the center of gravity and greatly facilitates the work, allowing you to effectively remove dirt, plaque and soot from the walls of the structure.

- The main material for the manufacture of a weight - a plumb line, is any metal object of a rounded shape. You can also use weights;

- It is recommended that the plumb line be represented by a single element. In the absence of a weight or a large bolt, special metal plates can also be used. Such elements must have a thickness of at least 6-10 centimeters;

- Another way to manufacture cargo is a special pipe with a diameter of 50 to 60 millimeters. In such a pipe, it is necessary to drill about 8 holes and fix the cable in this way.

Making a ruff from bottles

Instructions for making a ruff from plastic bottles:

- It is necessary to take 4-5 bottles and cut off the bottom of each of them;

- Cut the sidewalls into small segments - vertical stripes;

- The cut should end at the edge of the container bend;

- The cuts should be of varying thickness;

- The blanks must be connected in such a way that the largest strips are on the outside of the product;

- Bottles with smaller stripes must be inserted inside and cut off the neck;

- In order to fix the structure, it is necessary to screw the base with a simple lid;

- It is necessary to make a small hole in the lid and insert a flexible cable into it;

- The end of the cable must end with a loop for the subsequent installation of the weight;

- A flexible cable is inserted into the loop at the end and rotated clockwise;

- For the manufacture of pile, you can use both sheet rubber and plastic;

- Ruff is mounted on a metal hairpin, the length of which is from 20 to 25 centimeters;

- Fixing is done with a washer. The teeth can vary in length. The space between them is filled with the same rubberized or plastic material, only of a shorter length;

- The washer must be additionally secured with a nut.

You can view photos of cleaning ruffs in this article.

The second option for making a ruff for 10 minutes

- The base of a plastic bottle, the widest part, is used as the base of the ruff;

- We cut the base into horizontal segments, in total there should be from 5 to 8 pieces;

- On the sides we make large cuts and in the center of each part we make a hole that is suitable in diameter to the cable;

- We thread the connector into the hole and fix it on one side with a washer;

- We use hardware as a hook for cargo;

- We fix on the hook a metal load of a round or oblong shape.

Furnace soot is removed from chimneys as follows:

- burning carbon-rich plaque with the help of a rather complex technology and an expensive tool;

- dissolving the settled crust with the help of chemicals introduced into the furnace during the combustion of fuel;

- scraping from the inner surface and removing from the outlet channel through pre-arranged hatches for cleaning.

At the same time, the first method of struggle is extremely dangerous and is practiced only in the case of cleaning the chimneys of industrial heat-generating units. The second technique involves the destruction of the body of the outlet pipe, which survived the impact of chemically active drugs.

The third technology - mechanical cleaning - guarantees a high level of safety, while ensuring the safety of the chimney itself. Therefore, most household flue gas outlets are cleaned only with their own hands mechanically.

Robot protection

For cargo, weights or metal objects are taken. Almost always, the weight is an independent part of the structure with stiff bristles, the strips of which are up to 8 mm long, they are connected with bolts. This design is used when cleaning very dirty pipes.

The load is made in the form of a pipe, the diameter of which is from 5 cm, up to 8 holes are made around it, pieces of rope are fixed there. For this design to last as long as possible

To prepare a square-shaped pipe cleaner, use large plastic eggplants. Similar

- the basis of the design will be a blank with wide stripes, they are tucked a little, this gives shape;

- other blanks are cut off at the neck so that they can be firmly planted on the base;

- put on from the largest to the smallest blanks and secure with a lid.

A hole is made in the lid so that the loop from the cable can pass into it. For reliable fastening, the loop is connected to the base of the wire. When using a metal cable, a wire is taken as a basis, the length of which is a maximum of 20 cm. The ends of the cable are fixed in a copper tube, a loop is made at the ends to attach a weight. Such a base is fixed in a vice, a rod is inserted into the loop. Turning the rod, pieces of the cable are inserted into the cavity formed. So gain the entire surface to the end. Such an element is suitable for cleaning when all pieces of wire are straightened. Such inexpensive and easy-to-prepare equipment for cleaning pipes from soot should be in all owners who have a fireplace or stove. Such a tool allows you to get the maximum amount of heat from a fireplace or stove.

How to make a chimney brush with your own hands

You can make a chimney brush with your own hands. The design of a homemade brush should be as follows:

- base - a cable made of a rigid spring or wire;

- a brush with metal bristles sticking out in all directions;

- cargo - a removable suspension that is attached to the end of the cable behind the brush.

In this form, the device is used to clean the vertical channel. When a horizontal surface needs to be cleaned, the attached weight is removed.

When making a ruff, you should focus on the following dimensions:

- the length of the cable should be 10-15% longer than the vertical channel;

- the diameter of the brush should be 0.8-1.2 of the diameter of the pipe being cleaned;

- suspension diameter - 0.3 chimney diameter.

A device of the right size will help you quickly and efficiently clean a chimney clogged with soot.

For vertical channel

First you need to clean the vertical channel with a brush. For this you need:

- Cut out two squares from plywood or metal with sides of 5 cm. Put them together and drill a hole in the center with a diameter like that of a steel stud by 8-10 mm.

- Fix the hairpin in a vise and bend the free end into a loop.

- Turn the stud over and screw the nut onto the thread. After that, put on one of the plywood or metal squares.

- Cut the wire into lengths 2-2.5 pipe diameters. Wrap the resulting segments around the wire, bending them in half. As a result, the wire should stick out evenly around the entire circumference of the brush being made. Instead of wire, you can take an old panicle with synthetic bristles.

- To fix the brush, you need to put a second square of plywood or metal on the stud and tighten another nut.

- Make a second loop from the free end of the hairpin.

- Make a removable hanger. For this, carabiners are threaded into the loops.

- A weight should be attached to one of the carabiners. You can take a heavy nut, a small weight, a lead blank, etc.

- Fasten the steel cable with a shackle. As a cable, you can use a chain with small cells.

In addition, you can use a grinder disc as a brush. This is a round brush with hard and short bristles. To prevent it from getting stuck in the pipe, you should make sure that its diameter is no more than 0.8 of the diameter of the chimney.

Preparation method:

- attach a weight to one side of the brush;

- at the other end, fasten a steel cable with a length equal to approximately 1.1 times the length of the chimney.

The resulting brush should easily walk inside the pipe. Otherwise, due to the rigidity of the bristles, it will be problematic to get it.

For horizontal channel

To clean the horizontal channel, you will need to make another brush. The easiest way is to make it from a plastic bottle.

Action algorithm:

- take a 2-liter plastic bottle;

- cut off the bottom of the bottle, leaving only the top half;

- cut the walls of the bottle into strips about 1.5 cm wide;

- drill a hole in the cover with a diameter equal to the diameter of the cable;

- remove the old nozzle and suspension from the ruff to clean the vertical channel;

- fix a new nozzle from the bottle;

- pass the cable through the hole in the cover.

The upgraded brush cleans the soot from the horizontal channel.

Fir branches

There is another proven way to clean the chimney. You will need:

- prepare large fir branches and a stick that will be slightly longer than the chimney;

- branches should be firmly tied to a stick;

- the resulting brush is carried up and down the chimney;

- branches can be replaced as needed.

In addition, you can take a small Christmas tree with a length slightly exceeding the length of the chimney. The tree is sucked into the pipe to the very bottom and pulled back by the top.

It may seem that this method has already become obsolete. However, he still receives good reviews from the owners of stoves and fireplaces.

After such a cleaning, it remains only to clean the soot and crumbled needles through a horizontal channel. Then you need to collect garbage from the floor with an ordinary whisk and dustpan.

Cleaning the pipe yourself is not so difficult

The main thing is to take precautions when working on the roof. And making a homemade ruff is not difficult at home

How to clean a chimney

In order to clean the pipe coming from the boiler, stove and fireplace, there are many ways and means.

They fall into the following categories:

- Thermal. The essence of this method is the destruction of clogging by high temperature. An object is placed in the furnace or directly into the chimney that emits intense heat during combustion. Good results are given by termite checkers, anthracite and aspen firewood. Manually carbon deposits are burned out with a gas burner.

- Chemical. They are available in the form of tablets, granules and powders. Means are stacked on smoldering coals. Under the influence of heat, ingredients are released that turn soot into dust, which completely crumbles into the firebox within a few days.

- Mechanical. Scrapers, brooms and brushes are used to remove blockages. Foreign objects are removed with a hook or crowbar. Flexible garden hoses, choppers, logs and weights on a rope, poles and telescopic fishing rods, and other improvised means are used as an auxiliary tool.

Chimney cleaning rules

Even the highest quality or most expensive burnt brush will not be effective if it is not cleaned properly. When removing soot, it is recommended to follow the basic rules of the procedure:

- Work should be carried out only in special clothes and shoes. It is advisable to use gloves, goggles and a respirator.

- Before cleaning, it is necessary to inspect the channel for the presence of bird nests, accumulations of leaves and other foreign objects, and assess its condition.

- It is necessary to close all the openings of the furnace channels, leaving only the one through which the work will be carried out.

- The tool (ruff) is lowered by the cable or handle from top to bottom and the channel is cleaned with the same movements (from top to bottom).

- If everything is clean from above, then cleaning should be carried out through the lower hatch.

- When the work is completed, open the firebox and remove the garbage that poured into it.

You can get rid of blockages in the chimney yourself, without resorting to the services of chimney sweeps. Not only the cleanliness of the pipe, but also the safety of people living in the house depends on the quality of the work carried out.

Do-it-yourself chimney brush is simple and affordable

Cut the walls of the bottle (not to the very neck) into petals ~ 1.5 cm wide. Drill a hole in the bottle cap for the screw part of the load and the rope. A round brass door handle is suitable as a load.Tie the rope tightly to the load, then pass it through the cork hole, pull it tight so that all parts of the brush are tightly connected to each other and tie a knot, the brush is ready:

Can also be made from a synthetic broom:

- unbend the pile of the broom in different directions, in this position lower it into boiling water or heat the place of the bend of the pile with a building hair dryer,

- screw the “ear” onto the threaded stud, put on the washer and insert it into the hole from the bottom of the brush, put the washer on top. Screw the second fastener onto the base from above. From twisting the bristles of the brush will disperse to the sides,

- using the bracket on the brush, fix the cable,

- it remains to cut the brush exactly to the size of the chimney.

You can make such a brush with your own hands, but you still can’t do without going to a hardware store to purchase some accessories. We will have to buy: a round synthetic broom,

steel cable along the length of the chimney, 2 ears with a thread of 8 mm, clamps for tightening the ends of the cable,

washers of different diameters, a threaded stud 8mm long 10cm. At home, we begin to work with all this: we unbend the pile at the broom in different directions, then onto the hairpin, wind the ear from one end, put on the washer and insert the bottom of the brush into the hole, then put another washer on top. Then we press on the base from above and wind the second mount. As the pressure increases, the villi move apart more strongly in different directions. And at the very end we attach a cable to our structure with a bracket. And lastly, we cut our brush to the diameter of the pipe we are going to clean.

More questions about your topic:

leave a comment

Builder's dictionary :: Repair questions :: Calculators :: Special equipment :: Miscellaneous

2006 - 2017 user agreement :: contact with the site administration max@remotn.ru

Why clean your chimney

Photo of a dirty chimney

We have already said that cleaning contaminated chimneys is a necessary event. But why do it with your own hands with a certain frequency? There are two main reasons.

- Maintaining high chimney draft efficiency. Soot, which gradually accumulates on the surface of the channels and ventilation ducts, disrupts the process of normal exit from the smoke channels. A thick layer of contaminants leads to an increase in pipe temperature, which negatively affects traction. The most unpleasant thing is that if you do not clean the chimney, the smoke may soon begin to enter the room, and not leave the ventilation ducts.

- Improving the safety of heating equipment. If the pipes and surfaces of the ventilation ducts are not cleaned, soot can ignite at any time. Consequences - destruction of the chimney, damage to the house, fire, carbon monoxide poisoning.

Main materials of manufacture and characteristics

If you have a stove or a fireplace in your house that functions through a chimney, then this unit, of course, periodically needs high-quality cleaning. A do-it-yourself chimney brush will allow you to make this process simple, and the result is guaranteed to be positive.

The main design of this device is represented by a large flexible cable on one side of which there is a load, and on the other a special brush.

The base is made of wire or metal cable

It is important that this part is as flexible, durable and not brittle as possible;

It is possible to use special plastic plaits or fishing line with a large diameter;

For better grip, secure the frame with springs;

Plastic bottles can be used as a base;

One of the most durable and inexpensive materials, the price of which is affordable, is rubber. Brush with a large diameter and bristles of medium hardness

Brush with a large diameter and bristles of medium hardness