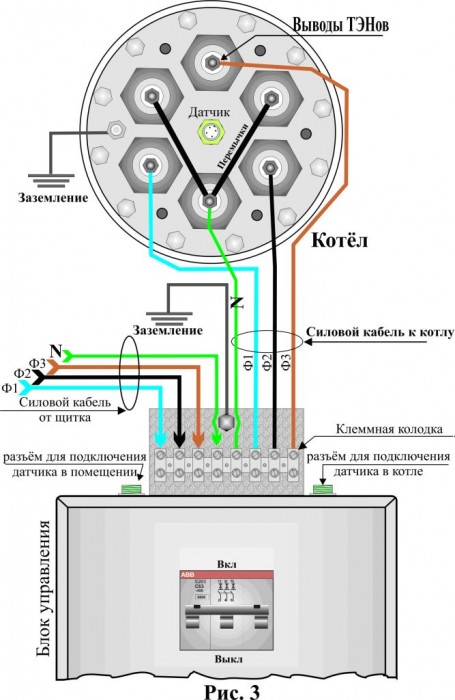

Scheme of connecting an electric boiler to the network

Before connecting an electric heating boiler, it should be noted that the electric boiler must be connected to the network through copper wiring. The cross section of the wire must not be smaller than the one indicated in the document that came with the device. The electrical connections of the external type device must be made through special cable outlets. These conclusions should be located in the lower left corner. There should also be a brass ground terminal with an M6 size bolt.

Power cable connection diagram

During the insertion of the electric boiler into the heating system and the installation of grounding, it is necessary to ensure that good and reliable contact is provided between the metal case of the device and the brass bolt. Before connecting the bolt to the frame of the device, you need to thoroughly clean the junction.

If electric heating is planned to be organized for a building with a large area, then when purchasing equipment, you need to choose one that provides for the possibility of installing a cascade. In order for the devices to work properly in a cascade, the terminals of the control device must be connected to the unit that is controlled. If the system setting is controlled by a room type controller, then the control contacts must be connected to the terminals of the control device.

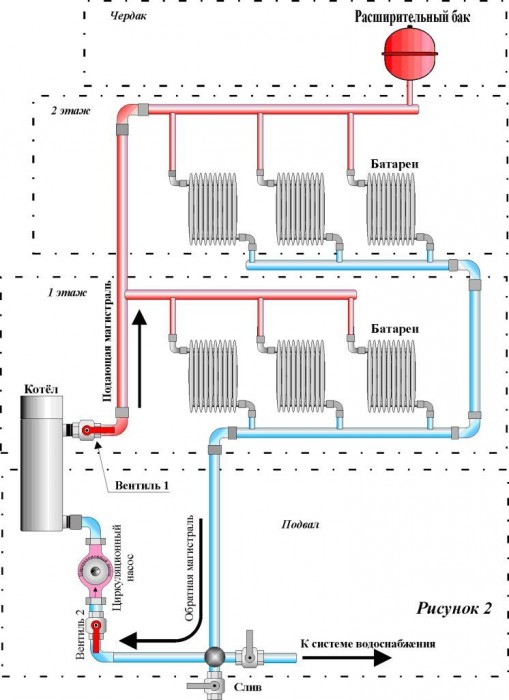

Scheme of the electrical heating system of a two-story house

The device must be visually inspected to make sure that it is in the correct position, the water pressure in the system is normal, and all communications are connected. All this is defined in the documentation of the unit.

After that, the installation scheme for an electric heating boiler involves the following steps:

- It is necessary to check the serviceability of the pipeline fittings located in front of the unit. To do this, you need to switch it from the "closed" to "open" position, and vice versa.

- All pipeline fittings of the electric heat generator are transferred to the "closed" position. It is also necessary to transfer the pipeline fittings of the water supply system and the heating system to this position.

- On those pipelines that bring cold water to the unit, you need to open the shut-off valves. If an electric heating system is used, it is not recommended to use antifreeze liquids for it. This is because they have properties that can affect the operation of the equipment in a negative way. Anti-freeze fluids have a composition that can cause aging or rapid wear of rubber components.

- It is necessary to install a sump or filter before entering the unit on the return pipeline. You can install both of these elements.

- After the heating system is completely filled with water, it is necessary to check how tight it is.

When the installation of an electric boiler with heating radiators is completed, it is necessary to check how efficient the sensors of the system are. These include such sensors as: temperature controller, water pressure sensor, signal and control components of the unit, emergency type temperature sensor.

During repair of the heating unit or during unfavorable installation conditions, it is possible to connect an electric heater using rubber hoses.

For the heating system, it is necessary to use water with a minimum hardness index. Then the service life of the heating elements can be significantly extended.

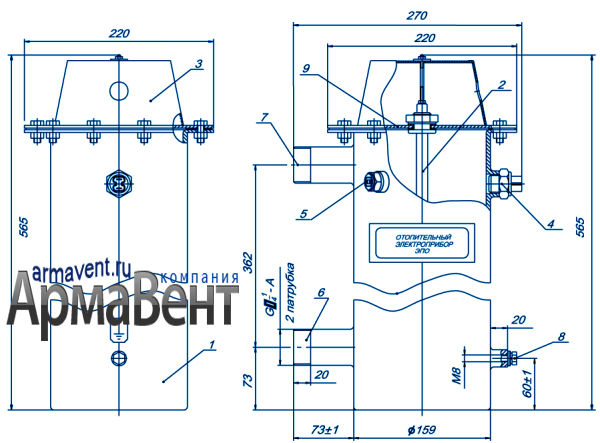

Electric boiler EVAN EPO-24

The EPO-24 boiler is a stationary electrical appliance with a power of 24 kW, designed for heating various residential and industrial premises up to 240 m2 in area. The EPO-24 boilers are powered by three-phase (380V, 50Hz) AC sources with a solidly grounded neutral. Are completed with one-stage or three-stage control panels.

Specifications

| Characteristic | EPO-24 |

| power, kWt | 24 |

| Operating voltage, V, ±10% | 380 |

| Heated area (m2), with a ceiling height of 2.7 m | 240 |

| Step power, kW | 24/8 |

| Boiler overall dimensions (mm) / thread G | 565x270x220 / G 1¼ |

| Overall dimensions of a single-stage console (WxHxD), mm | 205x250x175 |

| Overall dimensions of the three-stage console (WxHxD), mm | 380x265x180 |

| Weight, kg: boiler / remote control 1-st. / remote control 3-st. | 15 / 4 / 6 |

| Cross section of the power cable core, mm2 | 10 |

| Operating pressure in the boiler, no more | 0.3 MPa |

| Boiler test pressure | 0.5 MPa |

| Crimping pressure of the heating system with the boiler after installation, no more | 0.4 MPa |

| Heat carrier temperature adjustment range | 30-85 °С |

| Response temperature of the emergency sensor with self-reset | 92±3 °C |

| Boiler efficiency EVAN EPO-24 | 93% |

| Warranty period of operation | 18 months |

Advantages of EVAN EPO-24 boilers

- Profitability due to low investment cost and rational use of electricity, which is achieved through the use of an automatic room temperature control system in the electric boiler.

- Ease of installation and maintenance.

- No additional costs - no investment required during operation.

- Compact - no separate room required.

- Versatility - can be used as a primary or backup heat source.

- Environmental friendliness - does not reduce the level of oxygen in the room, there are no harmful emissions of combustion products.

- Reliability in the supply of energy carriers - electricity is the least dependent on the availability of traditional raw energy sources (oil, fuel oil, gas, coal, etc.).

- Independence from external factors - the temperature in the house does not depend on the operation of the CHP and utilities, there is no seasonal drop in gas pressure in the gas pipeline, it maintains the set temperature in the room regardless of weather conditions.

Structure and outline drawing

1 - housing, 2 - heating element, 3 - protective cover, 4 - emergency thermal switch with self-reset, 5 - thermostat sensor, 6 - inlet pipe, 7 - outlet pipe, 8 - M8 clamp for zero protective conductor PE9 - cover

Before installing the boiler, check the correctness and quality of the installation of the heating system with natural circulation. The pipes of the heating system must be located so as to promote the natural circulation of the coolant. In this case, the maximum level of the coolant should not exceed 30 meters to the level of the boiler (the operating pressure in the boiler is not higher than 0.3 MPa). If it is impossible or undesirable to achieve natural circulation of the coolant in the heating system, it is necessary to use a circulation pump. The heating system must have an expansion tank communicating with the atmosphere. When using an expansion tank of a membrane type, a safety valve designed for a pressure of not more than 0.4 MPa must be installed before the ball valve at the outlet of the boiler. Since when the safety valve is actuated, it is possible to release the coolant or steam through its drainage hole, it is necessary to drain this hole into the sewer system. Ball valves are installed at the inlet and outlet of the boiler, which are used during dismantling, repair and maintenance of the device. The installation of shut-off valves on the pipeline connecting the expansion tank to the heating system is prohibited!

Pressurization pressure of the heating system with the boiler after installation - no more than 0.4 MPa.

The boiler must be mounted in a vertical position (protective cover at the top). The control panel is mounted vertically at a height of 1.4-1.7 m from the floor on walls and structures in well-lit rooms.

Scheme of connecting the boiler to the heating system Order electric boilers EPO-24