Basic principles of work

The heating of the room with the help of a warm water floor occurs due to the transfer of thermal energy from the water passing through the pipes to the surrounding space. It follows from this that it is necessary to use heat-insulating materials under the carrier and materials with high thermal conductivity above the carrier in order to maximize the heat transfer to the room. Water heating is carried out by means of electric or gas water heaters, in the apartment hot water is taken from the central heating system.

Underfloor heating can act as an additional heating system, as well as the only source of heat in the house. In the latter case, it is necessary to contact specialists who, using special programs, will calculate the feasibility of this method of heating and select the appropriate materials, as well as give recommendations on the use of certain methods of arranging the system.

It is important to understand that any underfloor heating can serve as the only and complete heating system if there is a guarantee of an uninterrupted supply of energy and the installation of finished floors from materials that conduct heat well (stone, tile, thin laminate)

- waterproofing and heat-insulating materials;

- pipes that circulate water;

- manifolds with fittings;

- fastener elements;

- the upper heat-conducting layer (in the classic version it is a concrete screed);

- pump for forced supply of heat carrier.

The main disadvantages and advantages of this type of systems

Due to the economic situation in the world, each person seeks to minimize the costs of maintaining their own housing. If it was decided to carry out the installation of a water-heated floor on your own, then this will help save not only on utility bills, but also on further maintenance of the system.

Advantages:

- it is necessary to invest funds only once and only for the installation of the system itself, after which it is necessary to realize the degree of its efficiency, after receiving the first payments for utility bills;

- the possibility of heating a large quadrature of residential premises, taking into account minimal costs;

- the complete absence of visible elements of the system and their connections, which can worsen the attractiveness of any room;

- heating occurs evenly over the entire surface of the floor.

Advantages

Main disadvantages:

- you need a quality water pump;

- decrease in temperature in neighboring apartments;

- installation of a thermal water floor has specific design features and ensuing difficulties;

- there will be a decrease in pressure in the riser;

- there will always be a chance of a leak and difficulty in finding it;

- setting the temperature regime will be accompanied by difficulties.

Example of a leak

It is worth noting that the likelihood of a leak is very high if metal pipes were used during the installation of the underfloor heating system, which eventually corrode. Products made of polyethylene, metal-plastic and polybutylene do not lend themselves to such exposure. Their service life can reach 50 years, while the installation of such a system of warm water floors can be done independently. It is possible to use special ribbed substrates, on which there is a special marking for laying pipes.

The process of installing a pipeline on a concrete base

To begin with, you should have a diagram drawn up according to which you will lay the pipes of the warm floor. The following work is carried out:

- Dismantling of the old flooring and thorough cleaning of the base.If necessary, seal all cracks and eliminate all flaws in the base. If there are significant differences in height, they also need to be eliminated. To do this, most likely, you will have to make a screed.

- Waterproofing flooring. In this case, it is better to use plastic wrap. Please note that its thickness should be 250 microns. Separate sheets of material must be connected with construction tape. Pieces of film must be overlapped. In addition, one should not forget about the overlap on the walls (10 cm).

- Installation of damper tape. It is attached around the perimeter of the room. This material will protect the screed from temperature deformation.

- Arrangement of thermal insulation. If you plan to equip a warm floor on the ground floor of the house, then this layer can be quite thick, at least 5 cm. For the rest of the premises, a 2-centimeter layer is enough. For the arrangement of thermal insulation, you can use penofol.

Laying reinforcing mesh and fixing pipes. Here you will need the previously drawn outline layout. Please note that the size of the grid cells should not exceed 15 * 15 cm. Now you can mount the warm floor itself. The pitch between the pipes can vary from 7 to 30 cm. They should be attached to the grid with plastic clamps. Please note that the fastener should not be tightened too tight, because the pipes tend to expand when heated. In places where there are expansion joints, corrugated elements should be put on the structure

During installation, pay attention to the step between the pipes at the outer walls: it must be reduced, because there is more heat loss in this area.

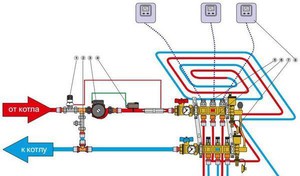

Connecting the system to the manifold. In order for the underfloor heating to work as efficiently as possible, it must be properly connected to the supply and return manifolds.

Structural pressure testing

At this stage, you are required to test the entire system that needs to be enabled. Thanks to this action, you can check the design for operability. Exposure should be at least a day. The working pressure in the pipes of the underfloor heating system should be 3-4 bar.

Screed filling. Its thickness should be 5-7 cm. You can prepare the solution yourself or you can use special building mixtures that need to be diluted with plain water. Filling is made on pipes under pressure.

Laying the final floor covering. You can do this no earlier than a month later. In this case, before installing the cladding, the system must be checked again.

Pros and cons of underfloor heating

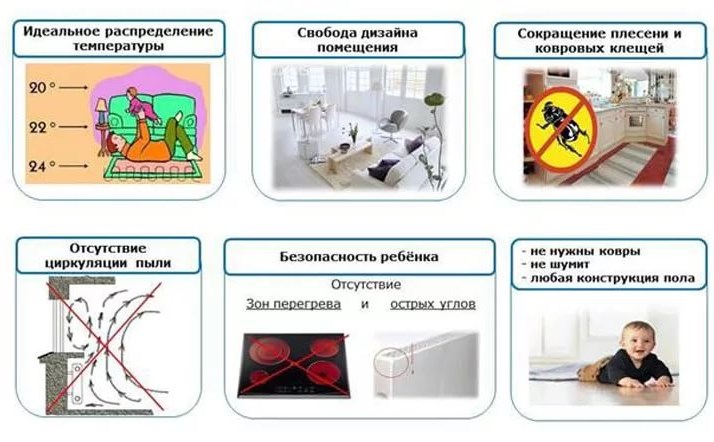

Advantages of underfloor heating in general:

- uniform heating of the entire room;

- natural circulation of heated air from the bottom up, to the ceiling;

- air humidity is within the normal range, there is no drying out, also due to uniform heating, wet corners are excluded, mold fungi do not develop;

- the economy of heating the room, with the usual method of heating, the floor temperature is lower, this leads to the fact that by touching the feet with a cold surface, a person loses a lot of heat, when the field is heated, such a loss does not occur and, in general, the comfortable temperature of the room can be several degrees lower;

- additional space is freed up due to the absence of radiator batteries, the design of the room is improved.

Compared to electric underfloor heating:

- compatibility with any types of floor coverings;

- independence from interruptions in power supply;

- significant energy savings;

- self-regulation of the temperature in the room due to heat transfer, if the temperature rises, the heat transfer from the floor becomes lower, and vice versa;

- the complete absence of electromagnetic fields, the dangers of which are still being discussed.

- difficulty in installation;

- when pouring concrete, you will have to wait about 28 days until it dries completely, during this period you can not use the room;

- difficulty in calculations if this is the only source of heating;

- when connecting in apartments, you will have to issue a special permit for connecting to central heating, and you will not be able to connect the floor at will when the heating season is over;

- the cost of installation is higher than that of other heating systems, but here it should be borne in mind that done once, it will last a long time and no longer have to bear any material costs;

- risk of flooding due to violation of the integrity of the pipeline.

System device

To function, the underfloor heating system uses water and electricity. Using such a system will make the room as comfortable and cozy as possible. A warm water floor uses a built-in coolant, which is a heating cable or pipes with water, as in this case. This arrangement is more than optimal, as it contributes to the uniform distribution of heat inside the room. Thus, the room temperature will be around 22°C, while the floor temperature will be around 30°C.

Scheme of uniform distribution of heat from a warm water floor (click to enlarge)

For the correct and economical functioning of such systems, it is recommended to install a thermostat, which will allow you to independently regulate the temperature in the room and maintain it at an optimal level for a person. A warm water floor uses a system of batteries that are filled with hot water. The heat from them rises, thereby evenly warming the air in the room. After all, it is much more pleasant to walk barefoot on a warm floor surface than on a cold one. Water heated floor will appeal to young parents, whose child spends a lot of time sitting on the floor and playing a variety of games.

Warm water floors have high aesthetic performance, because the main part of the system will be hidden from view under a layer of screed and flooring. When using the usual cast iron or more modern bimetallic batteries, there is a chance of drafts. Such devices are heated to a high temperature, due to which convection occurs. Due to the significant temperature difference, the movement of air masses is greatly accelerated, which leads to drafts. Water heated floor will help solve this problem. Drafts also contribute to the rise of dust and other allergens that can exacerbate the disease of allergy sufferers. But the warm floor from a gas boiler does not have such characteristics. Niches are used to mask heating radiators, which impair heat transfer.

Uniform temperature distribution

Filling the final screed

This process is very important. Filling the screed consists of several stages:

- On top of the first layer of reinforcing mesh and, accordingly, pipes, it is necessary to lay another layer of mesh, the mesh size of which is 10 * 10 cm. This material should not cross those areas where decompression seams are planned.

- Solution pouring. It is best in this case to use ready-made mixtures purchased at the store. To improve the quality of the prepared solution, you can add a plasticizer to it. In this case, the thickness of the screed may not exceed 3 cm. Please note that the air temperature in the room during pouring the mixture should be 5-30 °C.

In order for the screed to dry completely, it takes a lot of time (at least 28 days). Remember that pouring concrete should only be done when the system is turned on. The pipes must have the required working pressure.

How to connect a water heated floor

For these purposes, three-way or two-way valves are mounted. Next, the supply pipe is led into a distribution manifold, which should include outputs according to the number of circuits, thermostatic valves and flow controllers. Cranes are installed on the supply and return pipes so that, if necessary, the heating of this circuit can be turned off. You can also consider the option of connecting to the return of a common heating system.

When connecting in an apartment, difficulties may arise, since a number of conditions must be met. In old houses, this can often be impossible, while in new buildings, floor-by-floor heating is provided. To obtain permission, you should write applications to the housing office and the heating network company. For heating a small area, you can use the exit to the heated towel rail coil, in this case, permission is not needed.

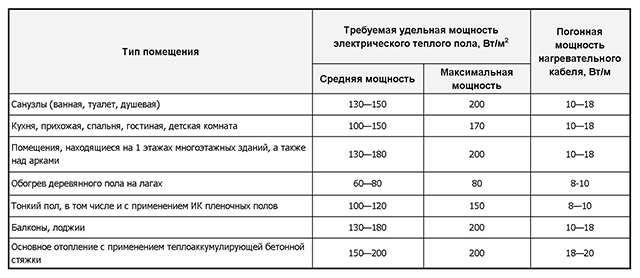

System power selection

Before buying, you should carefully examine the packaging, because warm water floors come with a cable of a certain length and power, which implies the possibility of heating a certain square. When choosing, you should be guided by the following rule:

- for full heating of the room, a power of 170 W is used;

- if such a system is optional, then a power of 110 watts will be sufficient.

Power table

The use of water heated floors can lead to a number of problems. To begin with, not every floor covering will be able to endure such a temperature regime without damage. Installed linoleum or tile will feel great at this temperature, which cannot be said about parquet. It is also worth calculating the possible power that the underfloor heating system will consume, because there are some restrictions regarding the power consumption for certain categories of citizens. In this case, it is worth considering other electrical appliances that are in the house or apartment.

Installation of a warm floor

To begin with, I would like to note that only those people who have some experience in such work can independently install a boiler for a heated floor and the system itself. Such systems can be installed both for heating large areas and for small ones. Hot water here will play the role of a coolant. In order to make the correct installation of water heated floors, it is necessary to create an additional screed, where polymer pipes will subsequently be placed.

Laying

It is possible to use other materials, but they are all expensive, or do not belong to the category of durable. The laying of such systems also speaks of the cost-effectiveness of their use. This system allows the installation of different types of flooring and the possibility of rearranging furniture (no visible pipes and radiators). High efficiency and durability of such systems allowed them to become an excellent replacement for central heating systems.

Using the novelty

Water heated floors could be an excellent solution for heating large areas. In small rooms, such as a toilet or bathroom, it will not be possible to place such a system due to the abundance of pipes. In this case, it is recommended to mount such a system

It is worth paying attention to the fact that the connection of such devices to centralized heating is prohibited and punishable by law. Such actions require coordination with the relevant state or local authorities and inspections.

What is the basis of technology:

- Soil or slab is required. If we are talking about the ground, then first you need to apply a sand bed, but not more than 10 cm.You will also need crushed stone of a fine fraction, a layer of vapor barrier and a rough screed, about 10 cm.

- A layer of waterproofing material. A water heated floor requires a coating or gluing waterproofing. It is recommended to use mastics based on polymers, cement, rubber and bitumen.

- High quality thermal insulation. It is possible to use both simple and extruded polystyrene foam.

- A thermal insulation layer is recommended, but not required.

- The pipes that make up the water floor system.

- A screed made from a concrete mixture using a reinforcing mesh. Taking into account the pipes, its height should not exceed 10 cm. The reinforcement is carried out directly above the level of the pipes, which allows you to evenly distribute the existing load. Water floors have a significant weight.

- The material used must be appropriately labeled regarding the use of a warm water floor.

Design

Main types of systems

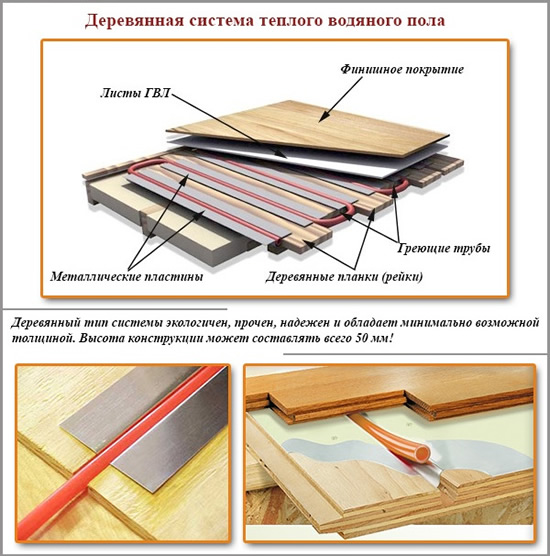

There are only a few types of systems. When using concrete technology, all heating elements are under the cement screed. A similar approach, for the installation of warm water floors, is used because of the many necessary works, which will require significant investment and time costs. It is possible to install such a coating only after the concrete screed has dried. This time period can be equal to a month (to give the screed branded strength), and depending on its thickness. This method is not simple, but this did not prevent him from becoming so popular.

When using wall technology, the installation of underfloor heating pipes is carried out from pre-prepared materials. This made it possible to minimize the duration of the necessary work aimed at installing the system. After all, we are talking about the complete absence of work with the solution

It is worth noting that we are talking about buying ready-made materials that are expensive.

Depending on the materials, there are:

- Modular type of wooden system.

- polystyrene system.

- Rack type of wooden system.

Under wood flooring

Servo motor installation

Before installing the servomotor, you need to decide what type of thermostat the device will need to work with. If the thermostat controls one water circuit, then both equipments are connected by wires directly to each other. If a multi-zone thermostat is considered, that is, a device that serves several circuits at the same time, then the servo drive is connected according to a special scheme.

To connect the wires, a switch is used. The main task of this equipment is to connect and connect devices for various purposes into a common circuit. In addition to the linking function, the switch is also a fuse. When all shut-off valves in the circuits are closed, the device turns off the pump.

Attention: during the operation of the heating system from a solid fuel boiler, such a property of the switch as turning off the pump is fraught with stopping the operation of the heating equipment itself. The bypass valve and bypass will make it possible to prevent the pump from stopping and the equipment from idling

It must be said that due to the emergence of modern devices, controlling the operation of a warm floor today is a fairly simple process. The design of most devices that are used to operate heating circuits is not complicated. The same applies to servos. The equipment is easy to use, practical and reliable. With the help of servomotors, you can automate the heating system, make the operating conditions simple and affordable.

Testing of thermoelements of various types: