Why insulate walls

The enclosing structures of a building for a car are made of large-block materials, for example, cinder block or gas block, less often of brick. Depending on the method of laying products, the thickness of such walls will vary from 12 to 30 centimeters. This width is not enough to protect the room from the penetration of cold air. Even when installing a heating system, the difference between the air temperature outside and inside the building will lead to condensation.

There is no need to artificially raise the temperature in the garage to high levels. After a car enters a warm room from a cold street, condensation will certainly appear on its surface, which will lead to metal corrosion. The thermal insulation of the garage should be selected and laid in such a way that the difference in temperatures in the room and outside the window is minimal. +5 degrees is considered optimal for a car.

Note! During the insulation of enclosing structures, motorists close up all the cracks, including ventilation holes. It is forbidden to clog exhaust pipes, they are used to remove accumulated moisture, help to remove carbon monoxide from the room

What material to do it

In fact, the question here will be solely in the budget allocated for the event. If you need savings, then there is only one option - foam. If there is a little more money, then mineral wool is the best solution. Exotic sprayed polyurethane foam will surpass the main types of heat insulators in terms of properties and efficiency, but this will be the most expensive option, and besides, it will not work to create such thermal protection with your own hands, you need to have certain knowledge of technology, as well as special equipment. Therefore, there are few options:

The latter option, as already mentioned, is too expensive and it is not easy to implement such insulation, even with the necessary knowledge and tools. Therefore, we will consider the most accessible and simple types of thermal insulation.

What materials are suitable for garage insulation

Mineral wool

An important advantage of using mineral wool to insulate a garage with your own hands is the ability to create a “breathable” layer of insulation. The fibrous structure of the cotton wool does not interfere with the natural circulation of air inside the garage, exhaust gases, fumes of fuel and other technical liquids, which are always stored in abundance on the shelves, will quickly vent out without stagnation or poisoning the air. An additional argument in favor of cotton wool can be its incombustibility. In a garage where there is a lot of flammable stuff, this can be a deciding factor.

Among the variety, it is recommended to choose basalt or stone wool. It has the best thermal conductivity of 0.03-0.1 W / m ° C and at the same time serves as excellent sound insulation.

The easiest way to lay mineral wool is in the form of semi-rigid mats. The mats fit tightly into the spacer of the frame, mounted from timber or galvanized profile on the internal surfaces of the garage: walls, ceiling, gates

And do not forget that in order to preserve its heat-insulating properties with mineral wool, it is important to use a vapor barrier membrane that will remove excess condensate and prevent moisture from accumulating inside the insulation

Styrofoam

Styrofoam is perhaps the most popular material for do-it-yourself garage insulation. It is easily cut and processed with the help of simple tools, like a knife. It has extremely low thermal conductivity - only 0.03-0.04 W / m ° C. And he's cheap.

Although it was not without its downsides. Styrofoam noticeably “eats” the interior space and is also combustible, it is better to keep a fire extinguisher in a conspicuous place.

You can mount foam sheets on internal surfaces using polystyrene glue, polyurethane foam or plastic dowels (they will need a crate). The optimal thickness of the insulating layer is 50-100 mm. Joints must be sealed with mounting foam.

Heat-insulating plaster

In the composition of such plaster, in addition to the binder, gypsum or cement, there are porous materials - quartz sand, vermiculite or polystyrene foam, which provide heat-insulating properties. Thermal conductivity coefficient of “warm” plaster: 0.065 to 0.13 W / m ° C.

Heat-insulating plaster is applied to the walls and ceiling according to standard technology: installation of beacons, preparation of the mixture, application of the mixture to the surface, leveling. It is recommended to apply one or two layers up to 50 mm thick on the walls, one layer of 5-30 mm on the ceiling.

It is best to use heat-insulating plaster for brick or cinder block garages. It will insulate the room, and will allow you to align the walls and ceiling.

Thermal insulation paint

Heat-insulating paint is a new word in room insulation. It is a polymer composite filled with hollow ceramic microspheres.

Read more about the structure and features of thermal insulation paint in the article Everything about ultra-thin ceramic thermal insulation

The thermal conductivity of the paint is about 0.065 W / m ° C, which is approximately comparable to “warm” plaster. Only the insulation layer in this case will be only 2-4 mm. What an economy of interior space.

In finished form, the insulation is a liquid consistency that is applied like ordinary paint, with a brush, roller or spray gun. This application method will be especially appreciated by the owners of metal garages. After all, the internal surfaces of such garages have a complex profile due to various corners, beams and protruding fasteners, and it is rather difficult to fix a tightly fitting insulation layer on them. But to paint the surface of any, arbitrarily complex profile, is not difficult.

However, it would be a mistake to assume that a thin layer of heat-insulating paint will create the desired microclimate in the garage. Yes, it can replace a fairly thick layer of traditional insulation. But for the desired result - + 5 ° C inside the garage - you still need to supplement it with a layer of another insulation, mineral wool or polystyrene.

Why you need to insulate the garage

The temperature regime, which has a positive effect on the condition of the car, is significantly different from the one in which it is comfortable for a person. If in residential premises the standard is to maintain the air temperature at the level of + 20-22 degrees Celsius, then +5 degrees is considered the most optimal for storing the car. At this temperature, almost no condensation forms on metal parts, which causes destructive corrosion.

Therefore, to create a microclimate suitable for equipment in the garage, other approaches to insulation are used. After all, the desire to recreate indoor conditions in the garage with the help of insulation and heating devices will harm the vehicle. For example, in winter, getting into a heated room from frost, the car will instantly fog up, the air humidity will increase, and in such a warm-humid fog the car will stand all night.

How to properly insulate a garage? Let's figure it out.

Types of thermal insulation materials for garage walls

In the modern construction market there is a huge selection of heaters. Consider the characteristics of the most popular thermal insulation materials:

- Mineral wool is supplied to stores in the form of rigid mats with a density of up to 240 kg/m3. Such products are characterized by high resistance to fire, well pass water vapor through their structure (breathe).The only disadvantage of using basalt wool is the need for a vapor barrier film that will protect the product from getting wet. Under the influence of moisture, the insulation loses its properties.

- Glass wool is considered a cheaper analogue of mineral wool. Such products consist of hard and prickly fibers, so you need to work with a heater with glasses and mittens. After getting wet, the mats get knocked down and become heavy, so glass wool must be protected from moisture penetration by laying special films or foils.

- Polyfoam is considered the most convenient heat-insulating material in use. Products are not afraid of dampness, are easily cut into pieces with an ordinary hacksaw, and have an affordable cost. Garage insulation can be done using an analogue of polystyrene foam, polystyrene foam, which will last up to 40 years. The main disadvantages of the products under consideration are combustibility, low resistance to sunlight. Styrofoam unprotected with plaster turns yellow and crumbles.

- Another heater for the garage, warm plaster consists of vermiculite or Styrofoam balls. Such materials have good thermal insulation qualities, but to obtain the maximum effect, a thick layer of mortar must be applied to the walls.

Polyurethane foam for garage insulation

And a few words about polyurethane foam, the thermal conductivity of which is 0.019 W / m K. That is, it is better than polystyrene. But it is more expensive and requires special equipment to apply it. More recently, such equipment was a huge tank and a compressor. Today, manufacturers offer compact devices, the weight of which does not exceed 30 kg.

These are two cylinders and a mini-compressor with hoses and nozzles. Cylinders have two components that are connected and fed through hoses under pressure

The applied layer is of small thickness (15-20 mm), please note that it is continuous, without seams and joints, more effective than many modern heat-insulating materials used to insulate garages. But if compared by cost, then he loses to the same foam

Although good insulation can not be cheap.

There are several effective and inexpensive technologies for insulating iron garages. But, as practice shows, foam is most often used if the conversation turns to do-it-yourself processes. There are no restrictions or contraindications in the use of this material. At the same time, the insulation has a number of good technical characteristics, plus the low price of the product itself.

How to insulate garage doors

Not everyone knows how to properly insulate a garage from the inside. Effective and reliable thermal insulation of the walls will not be enough, because a significant amount of heat escapes through the gate. The lack of insulation in this design will not allow the garage to warm up to the required temperature. At the initial stage of work, a hole is made in one of the wings and doors are inserted. To reduce heat loss, a thick fabric curtain is fixed in this place.

A transparent polyethylene film with a minimum thickness of 0.8 mm will help isolate the entire plane of the gate. This material is cut into strips 20-30 centimeters wide and fixed above the opening, so that the lower edge does not reach the floor surface by 1-2 centimeters. The strips are fixed on a wooden beam using stapler staples. Such a heater is very effective - at the entrance to the garage, the driver will see the surrounding space. In addition, narrow strips of polyethylene will smoothly flow around the car and return to their original position.

Some motorists insulate the garage door from the inside with foam. To do this, a crate of wooden bars is mounted on the inner side of the structure and the voids are filled with expanded polystyrene plates.To prevent the penetration of cold air through the gaps, the joints of the thermal insulation are glued with adhesive tape.

To eliminate drafts penetrating through the gate, it is necessary to replace the rubber seals. Condensation forms at the points of contact between the thermal insulation and the metal surface. To prevent destruction, steel is treated with paint or other anti-corrosion compound. Waterproofing substances are applied to other surfaces.

The wooden guide elements of the frame are coated with a primer or heated drying oil, which will protect the material from rotting and the effects of fungus. After laying the foam, the surface is cleaned. Finishing the garage door is done with OSB boards or thin boards. It is not advisable to use moisture-resistant products for this, for example, GKL.

Wall insulation from the inside

The choice of insulation, as well as the technology of insulation of enclosing structures, will depend on the material from which the enclosing structures are made. Many motorists are interested in the question of how to insulate a brick garage. First you need to clean the surface of dust and dirt, mount the frame into which the thermal insulation will be laid.

The crate is made from a drywall profile. The guides are fixed on the wall with dowels, which are driven in every 30 centimeters. The distance between the guides must correspond to the width of the insulation boards. For finishing the walls, you can use sheets of drywall or asbestos fiber. It is better to use the latest products, because they have a high degree of fire resistance compared to similar material.

Advice! Asbestos fiber is quite fragile, to prevent its destruction as a result of various mechanical influences, reduce the step between the frame guides.

Insulation of the walls of the garage from the inside is carried out using mineral wool or other products made in the form of plates. In this case, the mats are inserted between the guides, their position is fixed with the help of special hooks. After that, they proceed to the installation of a vapor barrier membrane, which must be joined to the cotton wool insulation.

We also insulate the garage from the outside, using warm plaster or special paint for this. Carrying out such work shifts the dew point, which will protect the walls from moisture penetration and further freezing. The owner of the building must carry out the installation of forced ventilation. Such a system is designed for intensive air exchange.

For insulation of metal walls, insulation of the garage with polystyrene foam is suitable. Expanded polystyrene plates are fixed to the base surface with an adhesive mixture. For reliable fixation of thermal insulation, it is necessary to pre-clean and degrease the metal. The sheets are fixed on the walls with the seams aligned, mounting foam is poured into the gaps. Styrofoam undergoes combustion, so a thin layer of plaster must be applied to its surface.

Metal garage walls are often insulated with polyurethane foam or special paint. In the presence of voids between the frame, insulation is carried out using penoizol. The liquid mass penetrates into the wall through special holes. The foam clings well to the surrounding surfaces, hardens, turning into high-quality and reliable thermal insulation.

Design features of the garage that affect the process of insulation

The main feature of the garage, which directly affects the insulation technology, is thin walls and a roof. Even garages built of brick or cinder blocks rarely have a wall thickness of more than 25 cm. And the thickness of metal garages is measured in millimeters. Such walls are not able to provide the necessary thermal insulation and require proper insulation.

For comparison, in residential premises, the thickness of external brick walls ranges from 51 cm (two bricks) to 64 cm (two and a half bricks).

When choosing a future insulation and calculating the thickness of its layer, one should strive to ensure that the temperature inside the garage is maintained slightly above zero.

Moreover, with proper installation, the insulating layer will work for the desired result at any time of the year: in winter, it will keep heat inside the garage, and in summer it will prevent heat from outside. This is achieved due to the so-called thermal inertia, which occurs due to a decrease in the thermal conductivity of the surfaces in the direction from the outside to the inside.

You can create the desired direction of thermal inertia by insulating the garage from the inside. Then outside in relation to the external atmosphere there will be a material with a higher thermal conductivity - cinder blocks, brickwork or metal, and inside - thermal insulation with low thermal conductivity.

How to insulate a cellar in a garage

Insulation of a cellar in a garage is technologically not much different from the insulation of premises for other purposes, but it has several important nuances. The main one is increased humidity due to direct contact of the walls and floor of the cellar with the soil. Therefore, waterproofing becomes a key step.

Ideally, a layer of waterproofing is best applied to the outer surfaces of the walls, creating an airtight capsule around the cellar. However, in an already built garage or a garage located in a cooperative, it is sometimes impossible to get to the outer surface. In this case, waterproofing is performed from the inside.

As a waterproofing material, you can use polymer films, roll insulation or bituminous mastics. The result should be a complete waterproofing layer. To isolate the ceiling, a special vapor-waterproofing membrane is suitable.

Then, insulation is laid on the walls, floor and ceiling: mineral wool, polystyrene foam or extruded polystyrene foam. For mineral wool, you will need to build a frame, and sheets of polystyrene foam are glued to surfaces or fixed with plastic dowels with a mushroom cap.

The wooden frame for the installation of mineral wool must be treated with protective compounds.

From above, the insulation layer is closed with a vapor barrier. After that, you can proceed to sheathing with decorative materials, for example, plastic panels.

Do I need to insulate the floor in the garage

To insulate the floor of the garage or not, everyone decides for himself. From the point of view of full-fledged thermal insulation of the internal space, of course, it is better to insulate. Indeed, through the floor, laid directly on the ground, in late autumn and winter, cold will always flow, upsetting the balance of the microclimate.

On the other hand, insulating the floor in an already built garage can be quite a challenge. After all, after installing the insulation, the floor level will rise to a height of 10 to 20 cm. At a minimum, this will create problems when the car arrives. And as a maximum, it will make it impossible to park your car in the garage due to the fact that it will no longer pass through the gate in height.

Therefore, before you start warming the floor, you need to carefully measure everything and find out if there is enough margin in height.

Among the options for insulating the floor in the garage with your own hands, there are two main approaches:

- Rapid completion of the floor to reduce heat loss.

- Installation of a full layer of insulation.

For the first option, when time, and most importantly finances, are limited, you can cover the floor of the garage with boards or osb-plates. Of course, this cannot be called a serious warming, but a noticeable effect will still appear. The floor will no longer be cold, and an additional air layer will appear under the flooring, holding back the cold from the base of the floor.

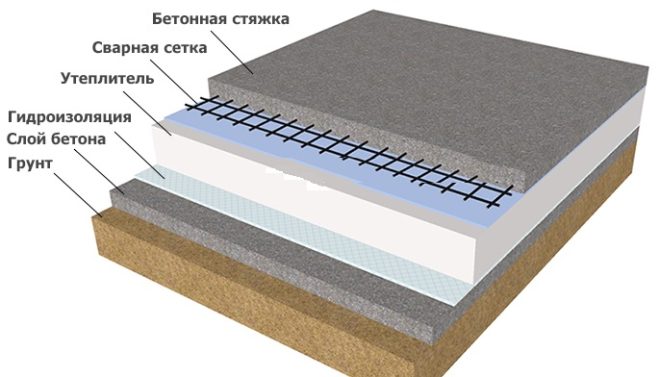

The second option is already a full-fledged floor insulation with the creation of a multilayer heat-insulating cake.

Taking into account the fact that the car exerts a significant load on the floor of the garage, extruded polystyrene foam will be the best option for insulation.

Floor insulation

If the garage has a cellar for storing preserves, vegetables and fruits, there is no need to insulate the floor. In the absence of such an underground room, insulation is carried out without fail. The easiest way to insulate the floor is with foam boards. The whole workflow is as follows:

- vacuum the base, clean it from dirt;

- we lay roofing material or plastic film on the base;

- we fix sheets of foam of maximum density (the thickness of the cake is not less than 10 centimeters);

- we lay waterproofing material and reinforcing mesh;

- we install beacons and fill in the leveling screed.

Following the above recommendations, you can quickly insulate all the structural elements of the garage. At the final stage of work, surfaces are painted or finished with the selected material.

Polyfoam and all its analogues

The technology of insulation in this case is simple to disgrace. It is required first to carry out several activities to prepare the scope of work - treat the walls with antiseptics and primer. If necessary, degreasing is carried out - for metal surfaces. Further, the foam plates are simply glued to the plane without gaps and cracks. If they nevertheless formed, then after the completion of the work, all existing flaws are filled with mounting foam. There is a more complex method with the assembly of wood sheathing, the same as for mineral wool. The principle of its assembly will be the same in both cases, so you can just consider it further.

Mineral wool

The preparation of the base for insulation is carried out similarly to the previous option, but the insulation of the walls of the garage from the inside in this case will differ in technology. First, it is worth assembling a crate made of wood or metal parts. Usually, these are all familiar profiles intended for the installation of structures from gypsum boards. The installation step of the elements almost corresponds to the width of a mineral wool roll or a rigid mat of the same material, but slightly less. So the insulation will be securely fixed in the cells of the frame.

Next, you should take care of protecting the insulator from moisture and lay a layer of waterproofing. Rigid mats of a cotton heat insulator are laid inside the cells or parts of rolled wool cut to size are inserted. On top of the resulting design is closed with a layer of vapor barrier and decorated to your liking. It should be noted that mineral wool will completely lose its properties when it gets wet and protect it as well as possible from water ingress.