Advantages of a do-it-yourself heating boiler

A do-it-yourself water boiler is simply indispensable for a country dwelling, where heating services are often too high. A do-it-yourself wood-fired water boiler for a stove is a great alternative to gas. and also it will significantly save hot water.

When it comes to a country house, not all houses are connected to gas heating, and connecting is also not a cheap pleasure. Of course, the problem can be solved in another way by purchasing an electric model for heating in the store, but it is also very expensive, and the cost of electricity, if installed, will also increase.

When starting work, do not forget about the correct temperature calculation, and also choose not too thin sheets of metal so that it does not burn out. In addition, as a material for work, you can take old used boilers or on the basis of a finished wood-burning stove.

Key advantages of a hand-made water boiler for heating with a stove:

- environmental friendliness;

- good indicator of efficiency;

- low cost of materials and fuel;

- safety;

- acceptable working conditions;

- offline installation.

Assembly process

The process of creating a boiler includes several stages. In the manufacture of each element, it is worth considering the special operating conditions of the manufactured product.

Air supply device

We cut off a segment from a thick-walled pipe with a diameter of 100 mm, the length of which will be equal to the height of the furnace. Weld a bolt to the bottom. From the steel sheet we cut out a circle of the same diameter as the pipe or larger. We drill a hole in the circle, sufficient for the passage of a bolt welded to the pipe. We connect the circle and the air pipe by screwing the nut onto the bolt.

As a result, we will get an air supply pipe, the lower part of which can be closed with a freely moving metal circle. During operation, this will allow you to regulate the intensity of burning firewood and, consequently, the temperature in the room.

Using a grinder and a metal disk, we make vertical cuts in the pipe with a thickness of approximately 10 mm. Through them, air will flow into the combustion chamber.

Housing (furnace)

The case requires a cylinder with a sealed bottom with a diameter of 400 mm and a length of 1000 mm. The dimensions may be different, depending on the available free space, but sufficient for laying firewood. You can use a ready-made barrel or weld the bottom to a steel thick-walled cylinder.

Sometimes heating boilers are made from gas cylinders for a longer service life.

In the upper part of the body we form a hole for the removal of gases. Its diameter must be at least 100 mm. We weld a pipe to the hole through which exhaust gases will be removed.

The length of the pipe is selected depending on the design considerations.

We connect the case and the air supply device

In the bottom of the case, we cut a hole with a diameter equal to the diameter of the air supply pipe. We insert the pipe into the body so that the blower goes beyond the bottom.

The air supply pipe should end a few centimeters before the start of the chimney.

Heat dissipating disc

From a metal sheet with a thickness of 10 mm, we cut out a circle, the size of which is slightly smaller than the diameter of the body. We weld to it a handle made of reinforcement or steel wire.

This will greatly simplify the subsequent operation of the boiler.

convection hood

We make a cylinder from sheet steel or cut off a piece of pipe, the diameter of which is several centimeters larger than the outer diameter of the furnace (body). You can use a pipe with a diameter of 500 mm. We connect together the convection casing and the firebox.

This can be done using metal jumpers welded to the inner surface of the casing and the outer surface of the furnace, if the gap is large enough. With a smaller gap, you can weld the casing to the furnace around the entire perimeter.

From a steel sheet we cut out a circle of the same diameter as the firebox or a little more. We weld handles to it using electrodes, wire or other improvised means.

Considering that during the operation of the boiler, the handles can become very hot, it is worth providing special protection from a material with low thermal conductivity.

To ensure long burning, we weld the legs to the bottom. Their height must be sufficient to raise the wood-burning boiler at least 25 cm above the floor. To do this, you can use a different rental (channel, corner).

Congratulations, you have made a wood-burning boiler with your own hands. You can start heating your home. To do this, it is enough to load firewood and set it on fire by opening the lid and the heat-dissipating disk.

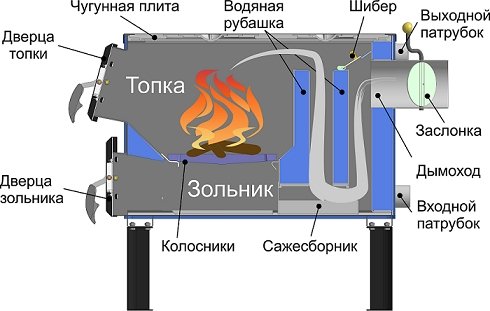

What is a boiler made of and how does it work

Fuel in such boilers burns much longer than in conventional units. This is due to their principle of operation, which provides for the burning of firewood in the firebox from top to bottom. The combustion chamber has a cylindrical shape and is completely loaded with wood through a door in the upper part of the body. Ignition is carried out through the same door, the design of long-burning solid fuel boilers is such that air is also supplied to the combustion zone from above along a vertical pipe. A flat round load made of thick metal (10-15 mm) is attached to the end of this pipe, arc-shaped air distributors made of strip metal are welded to it from below. A similar design can also be applied to the manufacture of a sawdust boiler.

Cargo for a homemade boiler

The size of the load is 5 mm smaller than the inner diameter of the furnace cylinder, which allows the structure to move up and down. The other end of the pipe passes through the upper wall of the boiler, a damper is installed on it, with the help of which the amount of air can be adjusted manually. The length of the pipe is 15-20 cm more than the height of the combustion chamber. The latter can be arbitrary, home-made long-burning units work the longer, the larger the diameter and height of the furnace. This increases the volume of the water jacket of the unit and its thermal power.

Long burning boiler design

After ignition, the pipe with the load descends, pressing down the array of firewood. Air enters directly into the combustion zone, the design of the long-burning boiler provides for operation on natural draft, created by a chimney of the required diameter and height. The released heat heats the water in the installation jacket, it begins to flow into the heating system through the upper pipe. The principle of convection works here, the use of a circulation pump is optional. The water jacket in a home-made apparatus is located not only around the side walls of the firebox, but also in its top cover.

The grate of a home-made long-burning wood-fired boiler does not perform its usual function; air does not pass through it into the working area. The grate only serves as a support for the fuel array, and through its cells, ash and ashes fall into the lower section, from which they are freely removed with an iron scoop. As the fuel burns out in the chamber, the load lowers and it is possible to determine how much firewood is left by the upper end of the pipe. After the end of the process, the ash compartment door opens, combustion products are cleaned out of it, the load, together with the pipe, rises and is fixed in this position. You can do the next download.

Homemade long burning wood boiler

Advantages of using a water boiler in a brick oven

One of the key benefits is efficient heat dissipation. also an important fact that pipes can be brought to all rooms from the pipe.

The water-based boiler is perfectly capable of being combined with various heat generators. When using antifreeze, the system will not defrost when the oven is turned off. Among other things, a water boiler in a brick stove is able to work both in the presence of central heating and offline.

For a typical Russian winter, only two fireboxes a day will be enough to create a comfortable indoor temperature. In addition, the temperature can be controlled using modern automated systems.

Water heating on wood

This more complex organized system is a pyrolysis boiler. consisting of two departments. In the lower one, firewood is burned, and in the upper one, the gas formed due to combustion circulates. Thanks to the scheme, according to which the gas does not enter the chimney immediately. its efficiency increases, and it requires less wood for long-term burning.

Around the boiler are thick pipes through which water heated from it flows. Keep in mind that only dry firewood is suitable for this type of boiler, so you should always have a good supply of them at home.

There are also systems that use hot air for heating instead of water. It, passing through the circuit, is transmitted into the airspace of the house. Cold air, falling down, again enters the boiler for further heating.

Peculiarities

Today, heating boilers have sufficient power to heat rooms for various purposes. They are economical. The time of their continuous operation is almost the entire heating season.

These devices can work on wood, coal, pellets (wood waste compressed and processed into granules), briquettes, peat, wood gas.

Boiler types

Depending on the type of solid fuel, they are divided into the following types:

- wood-burning (heated not only with wood, but also with pellets);

- universal (for work they use different types of fuel and their combinations);

- gas-generating boilers (they have an increased efficiency, they work on wood and wood gas).

Models of the latter type are more convenient to use, since soot does not accumulate inside them, and a minimum of ash remains.

There are models of long-burning boilers, dependent on the carrier of electricity and independent.

Such heating equipment works on the principle of top combustion (the hearth burns from top to bottom). The combustion chamber located at the top of the structure is filled with fuel. The fan blows air through the duct, and the heat released during combustion is sent to the heat exchanger. The volume of the combustion chamber is about 500 dm3, so such a heating device can work for several days without interruption.

Advantages

Long-burning designs are heating devices that are very popular among the population. This is explained by their many advantages: it is not only the use of various types of fuel, but also their long burning time, as well as the simplicity and environmental safety of their use.

A boiler of this type in its modern variation is a design equipped with automation, a fan to increase the pressure in the system.With a small amount of fuel consumed, such devices can maintain the temperature in large rooms.

A big disadvantage of the design is the high cost, more than 1000 USD. e.

What is pyrolysis combustion

As you know, it is not very convenient to heat a particular room with firewood, since this fuel burns quickly without releasing the required amount of energy. However, if the oxygen content in the furnace is reduced, the material will be consumed much more slowly. It is on this that the principle of pyrolysis combustion is based, due to which much less fuel is required, and efficiency increases. The main products obtained in this case are coke, ash, and combustible gas, which also releases a large amount of heat.

This means that when designing a home-made long-burning boiler, the following points must be taken into account:

- initially, wood that burns with a limited supply of oxygen emits combustible gas;

- then the resulting mixture is burned, giving off heat in turn.

Many home-made boilers work according to this principle, but it is important to remember that the equipment must be adjusted so that during its operation the general system for providing heat to the home is not damaged.

Useful extras

A home-made long-burning boiler assembled at home must be equipped with control devices - a pressure gauge and a thermometer. If you decide to install an automation kit and a fan-supercharger on your unit, then you will need to make a seat for it. The fan is placed in the top cover of the housing, it is better to make the electronic control unit remote, fixing it on the nearest wall inside the furnace room. Temperature and pressure sensors cut into the water jacket housing. Ordinary indicating devices in this case should not be ignored, because they can work when the power is turned off. Therefore, it is also better to put them, since not every electronic display displays the pressure of the coolant.

After assembly, wood-fired heating boilers must be checked for the permeability of the welds. With the help of a compressor, this is easy to do: fill the apparatus jacket with water and create an excess pressure of 3 bar in it. Before testing, the seams must be cleaned of slags. Sinks and uncooked places will make themselves felt with a leak. When there is no compressor on the farm, the heating installation will need to be ignited and heated on the street until a critical pressure of 3 bar is created in the jacket. Control over the pressure and temperature of the water can be carried out by thermometer and pressure gauge.

It is recommended to cover the lining of the water jacket and the inside of all doors of the home-made unit with heat-insulating material. As the latter, asbestos sheets and basalt wool are used, which are not afraid of high temperatures. For the outer lining of the insulation, you can use thin metal 0.3-0.5 mm with a polymer coating of the desired color.

Advantages of double-circuit heating

Double-circuit heating is the type of heating in which water is heated with the help of a boiler specifically for its use in everyday life and for heating the entire room. Thus, the entire need for hot water is provided by one double-circuit boiler. There are other reasons why it is gaining more and more popularity:

- It makes it possible not to depend on utilities and allows you to regulate the heating yourself, thereby creating comfort at home

- Possibility of installation in any part of the house. since no additional exhaust system is required, ventilation is also not required

- In addition to the boiler itself, you will not need anything, because everything necessary for heating and supplying the house with hot water will already be built in for a long time

- Favorable and affordable price

How a wood-burning stove with a water circuit works Choosing fireplace stoves for a summer residence with a water circuit and a heat exchanger Brick stove with a water circuit A stove with a water circuit for working out - how to do it yourself.

Production of a water circuit

You yourself can easily install and make a water boiler on a ready-made long-burning water furnace, and if you don’t have it, then it won’t be difficult to lay it out of brick yourself. For heating water. You can make a water circuit from old cast-iron radiators for heating, which you can easily find.

Their capacity is on average one and a half liters. You can connect several of these with each other and get a heater with a volume of 15 liters at the output, but due to its large dimensions it may not be suitable for use in all rooms. The most acceptable option is a Russian bath.

First, take it apart with your own hands. clean and rinse them with hydrochloric acid, or rather its solution. Before installing the entire structure, the gaskets separating the sections should be changed, since initially they are not adapted to high temperature drops. which can reach more than five hundred degrees. Since the old separator will not withstand and the radiator may leak, use an impregnated asbestos cord for laying. After that, you can start assembling. It must be assembled in such a way that the exit pipe is located above the entire structure, and for the entrance - under it.

Place the circuit ready for use in the chimney as close as possible to the firebox. The hot air coming from there will heat the circuit and, accordingly, the water, making it suitable for heating the house. Subsequently, you will connect the entire water circuit system to radiators that heat your home

Be sure to pre-check the entire system for any leaks, paying special attention to the circuit. which you have hand-picked

If you did not find old cast-iron batteries for its manufacture, then you can use ordinary pipes for the circuit, but with sufficiently thick walls.

The water circuit can be applied to absolutely any long-burning stove: from a fireplace to a potbelly stove. You can also make a boiler out of fairly thick metal and place it directly under the firebox, which will make it heat up much faster.

Self-manufacturing

It is quite difficult to design a heating boiler with your own hands. The slightest inaccuracy, and it will not work correctly, which can lead to tragedy. Therefore, it is necessary to carefully study the technology of their manufacture and carry out all activities very efficiently.

Mine type heating appliances

You can independently create a mine or pyrolysis boiler. The first one functions not only on wood, but also on coal, peat or sawdust. Up to 50 kg of firewood can be loaded into its chamber at once.

When the chamber is fully loaded with fuel and high power, such a device will continuously work up to 5 hours, at the lowest power (15-20 kW) - up to a day. Its efficiency is 75%. The power of such models can be adjusted using automation.

pyrolysis model

The yellow or colorless wood gas, which is released under the influence of high temperature, is the heat source in the pyrolysis boiler. For such a heater, only completely dried firewood can be used, otherwise it will not start. The pyrolysis structure can also work on pellets. Their automatic feeding into the furnace (using special screws) will be an additional advantage of the boiler. The duration of the model of this type when fully loaded is 12 hours.

Cons - high cost (you can reduce it if you make it yourself), volatility (the fan works with electricity), large sizes.

To make such a device you need:

- pipe and sheet of steel 4 mm thick;

- professional pipes, metal bars with a section of 2 cm;

- electrodes;

- fan;

- refractory bricks;

- automatic temperature controller;

- fasteners.

Preliminarily draw up a diagram of the future boiler with all the calculations. The most successful design of a home-made boiler, developed by engineer Belyaev, is taken as the basis. Adjustments are made to it according to the wishes of the owner of the house. For example, heating can be made more efficient by increasing the volume of the heat exchanger jacket.

Home-made pyrolysis devices must be installed on fireclay brick sites specially equipped for them. After that, they are connected to the water circuit.

At the first, test inclusion, they find out if there were any mistakes made in the design of the boiler. If everything was done correctly, the device will be able to quickly switch to the gas generator mode. The room will become much warmer within half an hour.

Tools and materials

A wood-burning heater is the safest design. The autonomy of its work, ease of operation, the minimum likelihood of an explosion, the possibility of self-production - these are its main advantages. Its disadvantage is the regularity of fuel injection.

Homemade wood-burning boiler models can be made from the following materials and parts:

- metal barrel (volume - 200 l);

- steel sheet 3-5 mm thick (to create a firebox);

- metal pipe with a diameter of 20 mm and a wall thickness of 3 mm;

- L-shaped pipe (diameter - 20 mm);

- grate;

- doors for the blower and firebox.

Home-made models of wood-burning boilers are made using gas welding equipment and a grinder.

Sequence of work

Before starting work, it is necessary to carefully consider the scheme of the device, purchase all the necessary materials and tools.

Cut out 3 circles (each 57 cm in diameter): this is the bottom, the top cover and the partition between the blower and the firebox. In two of them, make a hole with a diameter of 20 mm.

A strip 400 mm wide and 3600 mm long was cut out of the steel sheet, holes were cut in it for the firebox door, below it - for the blower. Connect the sheet by welding in a circle.

Weld a circle with a hole on top, without it on the bottom. Between them, install a partition with a grate.

Weld the pipe and the barrel together according to the “one inside the other” principle. From below, install a firebox with a blower. Connect all elements by welding.

In the upper part of the barrel, fix the L-shaped pipe section: it will connect the heating container and the chimney. Water, heated in a barrel, forms steam, which will freely exit into the chimney, thereby preventing the pressure in the boiler from rising.

At the top and bottom, install nozzles for cold water inlet and hot outlet.

Hang the doors on the firebox and blower.

Install the structure on a refractory brick foundation.

Such a device heats with the help of firewood, pellets or peat, tightly packed inside the firebox.

Even the simplest model of a wood-fired boiler requires care and attention when making it yourself.

Device

Before making a solid fuel boiler, it is advisable to design or find an accurate drawing. This will help to avoid a lengthy fitting process in the manufacture of individual parts. The principle of operation of all such devices is approximately the same, which means that the drawings will be similar to each other.

It is worth paying attention to the dimensions of the installation, the diameters of the pipes, the depth of the boot space. A homemade boiler is good because the parameters can be changed to fit your needs

The heater should not take up too much space, be close to the wall, and have pipe sizes incomparable with the room in which it will be located.

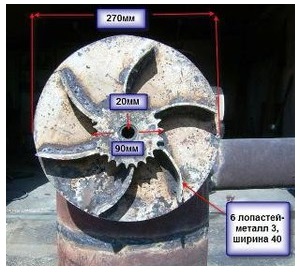

A long-burning boiler with a vertical firebox (also called "bubafonya"). Collected, mainly from steel with high heat resistance. The thickness of the metal walls should be 4-6 mm so that the steel does not burn out in the shortest possible time. Very often, an empty gas cylinder or a small barrel is taken as a basis. Kindling will go on wood or pellets. A piston is placed on top of them, which exerts pressure, preventing the formation of an air gap that accelerates combustion. Otherwise, this device is called an “air distributor”, in the middle of the distributor there is a hole for air to pass into the furnace. The part is a piece of sheet steel in the form of a disk, not more than 5 mm thick, and with a diameter slightly less than the diameter of the furnace, so that it can be freely moved in the furnace, with a steel rod welded to it. On the distributor from the side of the firewood there are 50 cm partitions for air passage. This is the optimal size, because with an increase, the fuel will burn out very quickly, and with a decrease, they will fade

Partitions are installed (it is important that they are in the form of an arc) so that it looks like an impeller

Solid fuel boiler device

Solid fuel boiler device

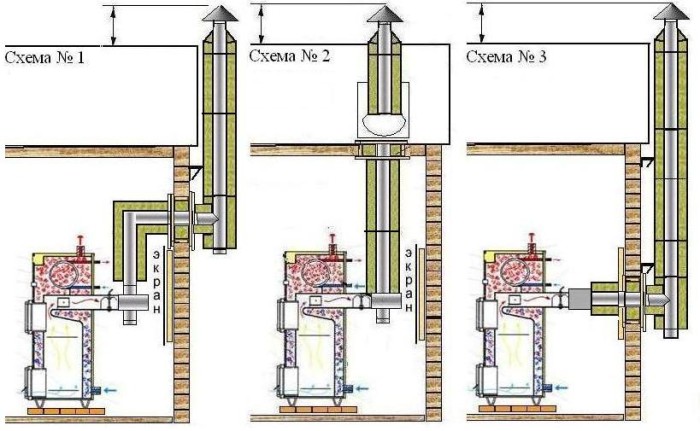

The solid fuel boiler can be connected to the heating system in the house. To do this, you must implement one of the following schemes:

- Run a coil through the furnace, through which the liquid will flow and heat up;

- Install the chimney so that it passes through a vessel with liquid, the smoke has a sufficiently high outlet temperature, which means it will effectively heat the liquid.