Service life and scope

As it was already written earlier, the service life of cellular polycarbonate, declared by the manufacturer, is 10 years. If the installation was carried out in accordance with the technology, then during this time the sheet should not collapse, deform or significantly change its characteristics in the direction of deterioration. With proper care, the "life" of the SEC can be extended up to 20 years, but this requires the following conditions.

- During installation at the junction of sheets, it is necessary to leave a gap for thermal expansion.

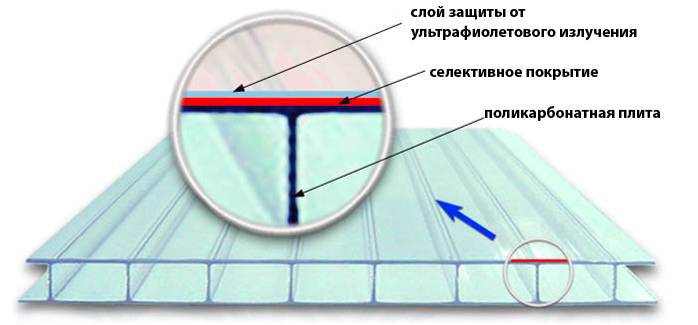

- The stabilizing layer of the SPK sheet should “look” outward.

- If there is a risk of damage to the material, then it is better to use sheets of large thickness - from 16 millimeters or more.

- To clean cellular polycarbonate from dust and dirt, you should use gentle detergents that do not contain ammonia, alkalis, aldehydes or ethers.

Sponge for washing

Sponge for washing

When caring for the sheets, do not use abrasive cleaners and accessories - with them during cleaning there is always a risk of scratches and damage to the stabilizing coating.

You can only remove paint stains from polycarbonate with gasoline or ethyl alcohol.

Due to its outstanding characteristics, superior to other transparent polymers and glass, cellular polycarbonate is widely used to create a variety of structures, including:

- canopies to protect transport or other objects and materials from the effects of precipitation;

- canopies over the entrance to the house;

- greenhouses;

- gazebos, attics and summer kitchens;

- bus stops and other facilities;

- soundproof fences along railway tracks or highways with heavy traffic;

- partitions and fences;

- railway stations, airport terminals, sports facilities and shopping centers.

Application of cellular polycarbonate

Application of cellular polycarbonate

The problem of heat loss in a polycarbonate greenhouse - what could happen

And it doesn’t matter if it’s a country greenhouse or there will be only one task - to minimize heat losses as much as possible, because it’s warm - your money

The first and most common cause of such a problem is damage to the polycarbonate. Sometimes a few cracks are enough for such an effect, albeit hardly noticeable to you. Over time, they will only grow due to temperature changes, respectively, the quality of service under the dome will fall. Your task in this case is to inspect the greenhouse and eliminate the slightest damage to the skin. This phenomenon can be avoided by carrying out greenhouse prophylaxis every six months. Similar problems can be with glass greenhouses: insufficient insulation of corners, cracks, damage to beams - all this leads to heat loss and is quite noticeable for the temperature regime maintained by an infrared heating system.

Troubleshooting options

Another common option is foundation problems. It is possible that under your greenhouse there was previously an ordinary wooden base, and now its service life has expired. The owner of the greenhouse himself, after 5 years (this is how long such a structure serves), he could well forget about this nuance, but meanwhile it was important. What should be done in this case? If you have no complaints about the state of the dome, open the foundation. You cannot replace it during this period. But the design can be slightly insulated. This will help to survive until the end of the season. After this period, the structure will have to be dismantled, and the foundation itself will have to be replaced. Preferably on a concrete or wooden counterpart.

The third possible option may be to lower the temperature due to worsening weather conditions. Snowless winters with severe frosts, which are not typical for your climate zone, can lead to similar consequences.What should be done in such a case? If you find that the problem lies in the weather, it is recommended to take measures to warm the greenhouse. To do this, it is enough to cover the existing dome with an additional layer of polycarbonate. The material does not need to be taken thicker than 8 mm. This is a standard version of greenhouse polycarbonate. If you want to take a denser analogue, you will probably have to strengthen the structure, and this is not always convenient.

Whatever the reason why your greenhouse is rapidly losing heat, in any case, the work should be concentrated on inspecting the greenhouse and replacing its defective parts. It is strongly not recommended in this case to change the temperature regime of heating. Because this can lead to drying out of the soil or overheating of the roots. Such measures will not be able to eliminate the problem. But the damage from them will make itself felt very soon.

About what are, see the video below:

Features of the structural structure of polycarbonate panels

By itself, the substance cannot guarantee the properties due to which polycarbonate finds its place in various types of transparent roofing, exterior wall decoration and in general glazing. That is why more than 70 years have passed since the discovery of the compound of polymer ether and carbonic acid in 1898 and the possibility of its use in production. Only in 1976, Israeli developers created the world's first sheet of cellular polycarbonate. Only then did large-scale consumption of structured polycarbonate material begin.

There are cellular and monolithic polycarbonate. Both of them have good heat and sound insulation, due to the natural properties of the substance. However, only the cellular version boasts a unique ability to retain heat several times better, maintaining the necessary microclimate in the room and at the same time reducing the noise level by 36 dB.

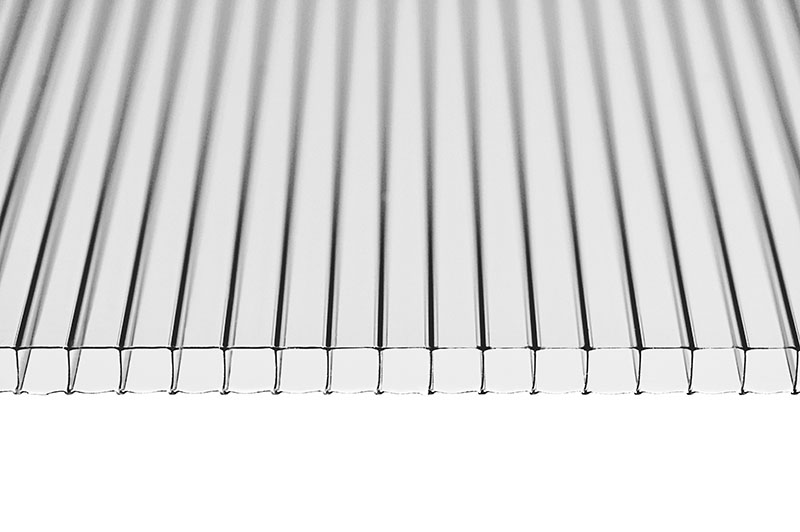

The most important difference between cellular polycarbonate is its granular base, which is two or more hollow sheets with an air gap and jumpers called stiffeners

Pay attention to the photo, the structure resembles a honeycomb. The monolithic panel is just a solid layer of polycarbonate like glass, but with improved heat retention properties and increased strength.

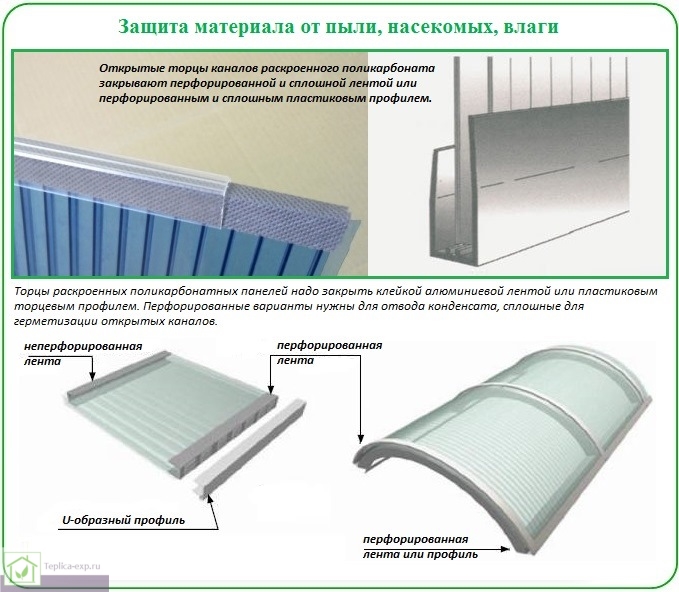

Where is perforated tape used?

The main area of application for perforated tape is the sealing of ends in honeycomb polycarbonate structures, such as greenhouses or sheds. Moreover, it is used in places where there is a high probability of the appearance and accumulation of condensate - in the lower part of the arch or wall, for example. In other cases, it is preferable to use a sealing tape.

In addition, the tape is used when sealing seams and joints in ventilation systems, in fastening cables for underfloor heating and in thermal insulation systems. In the latter case, with the help of perforated tape, it is possible to connect individual sheets and elements of the vapor barrier layer without any problems.

Where is perforated tape used?

Perforated tape for polycarbonate is used when assembling any suspended structures, for example, an air duct. Similar perforated strips are used when installing underfloor heating. They are attached to the cable, which heats the floor.

When constructing structures from polycarbonate sheets, perforated strips are an auxiliary element, with the help of which they increase the strength of the fixing unit. Perforated tape is successfully used in the installation of truss systems. It is effectively used for vertical glazing. The tape is attached to the surface of the sheet and is closed from above with a profile.

When building any semblance of an arch, it is necessary to close the polycarbonate sheets from both ends with perforated tape.

Advantages

Perforated tape has the following advantages:

- It can be used in conditions of high humidity.

- She has high strength.

- It differs in resistance to manifestations of corrosion.

- It is characterized by accuracy and ease in the implementation of the assembly.

- This tape has a high degree of tensile strength.

- Its service life is quite long.

- Tape is widely used.

Perforated tape for cellular polycarbonate has a microfilter and is called anti-dust. It is designed to protect longitudinal honeycombs from moisture and dust. This affordable and practical tape, which is easy to stick, withstands a very wide temperature range. With its help, the necessary microclimate is created inside the cells. It also prevents friction when mounting the profile along the edge.

The perforated tape protecting the bottom edge of the polycarbonate sheet has forty micron air filter pores. They do not let dust and various insects into the honeycombs. At the same time, the condensate formed inside comes out through them.

Externally, the tape looks like a self-adhesive base with silver perforation. The adhesive layer has a high adhesion force. At the same time, it is balanced so that, if necessary, the tape can be re-glued. The adhesive force of the adhesive is able to counteract the shear generated due to the different coefficients of thermal expansion of the profile and sheet.

To protect the tape from harmful factors, it is closed on top with an end profile, polycarbonate or aluminum. It is selected so that the color of it and the tape matches. Small holes are made in it through which condensate is removed from the honeycombs. To do this, leave a gap of two millimeters between the polycarbonate sheet and the end profile.

It is impossible to close up any end of the sheet with ordinary tape. Because of this, moisture can accumulate in the honeycombs, which can lead to damage to the polymer panels.

Additional mounting materials

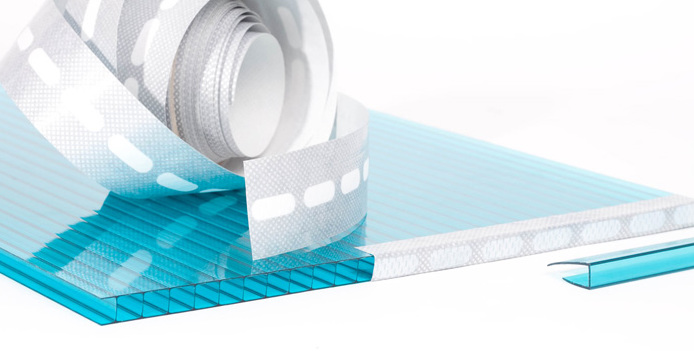

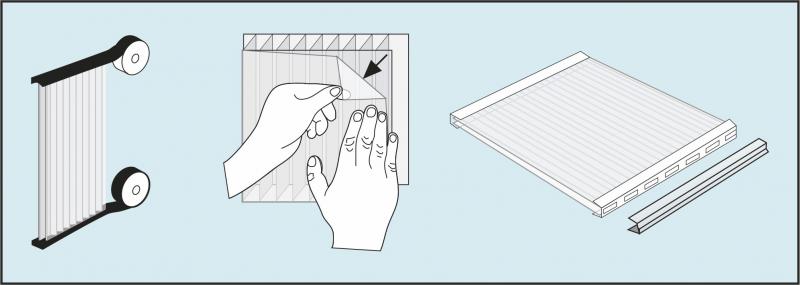

High-quality installation of structures made of honeycomb plates is impossible without sealing the ends of the sheets.

To perform work use:

- sealing tape, the width of which must correspond to the thickness of the sheet;

- perforated tape of appropriate width.

If the sheet is mounted on a sloping roof, the upper edge must be protected with aluminum sealing tape. The aluminum tape consists of a flexible plastic base, several layers of hermetic material and an adhesive layer covered with a protective film. The tape is sold in rolls, each roll is 50 meters.

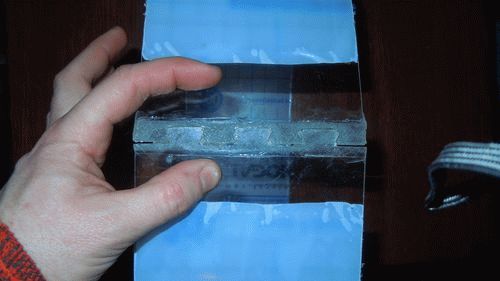

Gluing the ends before installing the profile

Gluing the ends before installing the profile

To protect the bottom of the sheet, the industry produces a special perforated tape, which also consists of a polymer base and several layers of waterproof materials. Holes (perforation) are made in the tape to allow water to pass from the honeycombs. The perforation goes along the entire length of the tape, the pore diameter is 40 microns. One roll contains 33 meters of tape.

Sealing and perforated tapes do not lose their properties for up to 10 years or more. The water-repellent coating allows moisture to move under its own weight and drain through the perforations. The tape does not become brittle and brittle at sub-zero temperatures, does not soften in extreme heat. Fungus does not multiply on the surface of the material, mold does not start. The tape is not destroyed under the influence of ultraviolet radiation.

Sealing tape for polycarbonate ends

Sealing tape for polycarbonate ends

If the sheet of cellular polycarbonate is curved and fixed on the roof of the arched frame, then both edges of the sheet are sealed only with perforated tape (the sheet can only be bent across the strips so that moisture inside the cells can move freely and flow out).

Holes-membranes of the tape eventually become clogged with fine dust, which penetrates into the protective profile.Because of this, the removal of moisture from the cells will deteriorate over time. Installers advise sometimes to remove the end profile, tear off the old membrane tape and change it to a new one.

When applying the protective tape, follow these guidelines:

- the ends of the canvas should be even and smooth, if necessary, remove burrs, align the sections of the canvas and clean them with sandpaper;

- after removing the protective film from the canvas, glue stains may remain on it - they must be removed with a soapy solution and clean water;

- the tape is glued strictly symmetrically with respect to the middle of the end part of the web;

- when sticking the tape can not be pulled;

- the tape should not warp and gather into folds.

- the surface of the sheet must be dry before the tape is fixed.

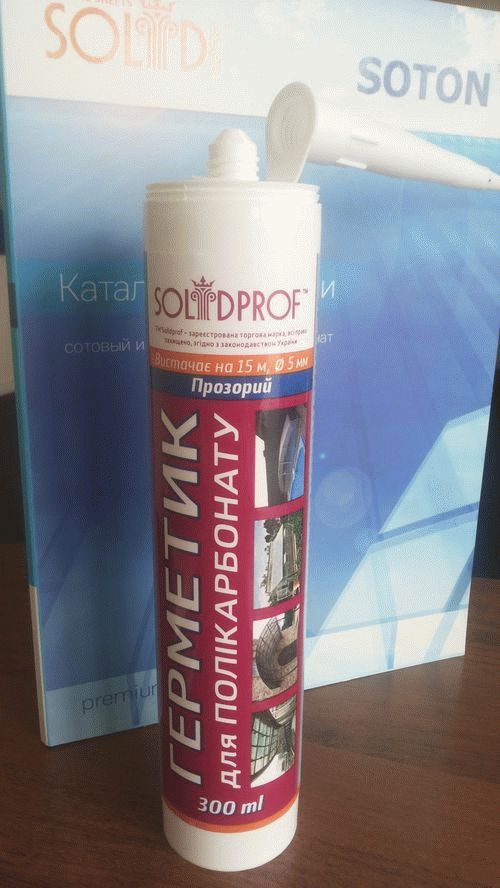

Sealant for polycarbonate how to seal joints

Polycarbonate sheets can be easily cut, bent and drilled during assembly. However, be sure to remember to seal the ends. This operation is one of the most important in the installation of structures. Fulfilling all the installation rules, the structure will serve for more than a dozen years. What to choose a sealant for polycarbonate: how to seal the joints?

Application

Polycarbonate has found wide application in construction, folk and agriculture. This material is reliable in many properties: stable, durable, environmentally friendly, etc.

Especially carbonate panels are often used to create greenhouses and hotbeds, as shown in the photo. They transmit and diffuse daylight very well, which has a positive effect on green spaces. In addition, in such greenhouses heat is retained up to 35%.

When erecting polycarbonate structures, it is imperative to think about sealing the ends. To do this, you can use a special tape for this material. Currently, 2 types of such tapes are used:

These accessories are specifically designed to protect honeycomb carbonate from debris and water intrusion. The service life of self-adhesive tape is unlimited. It withstands temperature changes and also follows the fluctuations of carbonate sheets. In addition, adhesive tape maintains a relative microclimate in the cavity of cellular polycarbonate. Also, the tape is able to withstand the friction of the edging when assembling the structure.

The product is resistant to temperature fluctuations and a high degree of humidity. The surface of the adhesive tape for polycarbonate is coated with a special substance that prevents the appearance of various fungi. Its service life can last more than 10 years. The adhesive layer of the tape is quite reliable, but it has such a property that it can be re-glued if necessary.

Hermetic tape (solid)

The sealing tape is used to protect the upper part of the joint of carbonate sheets from precipitation. If the panel is mounted vertically, and the honeycombs are also in a vertical position, then with polycarbonate tape it is necessary to seal the upper end of the panels completely, as shown in the photo. The solid tape is designed to prevent various types of wet precipitation (snow, rain, hail) from getting into the hollow part of the honeycomb carbonate.

Perforated tape

This accessory is used to protect the lycarbonate connection from below, as shown in the photo. The perforated tape is equipped with an air filter, the pores of which have a size of 40 microns. It is they who do not allow the entry of various litter into the hollow part of the material. In addition, the filter is able to let moisture through, which accumulates in the carbonate combs. If the panel is installed vertically, and the cells have the same direction, then this tape will protect its lower joint.

Depending on the type of construction, the tapes have different purposes.Two inclined panels at the junction are covered with a sealed tape from above, and covered with a perforated tape at the bottom. When building arched structures from cellular carbonate, only perforated tape is applied at both ends. At the same time, at the end, it is necessary to drill small holes in steps of 25-35 centimeters so that condensate does not linger, as shown in the photo.

If moisture cannot leave the honeycombs where it always collects, the material will soon begin to deteriorate. In this case, you will have to spend a lot of money to repair the structure. And never use ordinary tape, as it is not able to protect the material from any damage.

There are many different ways to embed different materials at their junctions. These include silicone sealant, which is used to seal polycarbonate products, as shown in the photo.

To seal the carbonate panels at the joints, and also so that they do not move from their place, silicone sealants are used. For example, they are used when assembling greenhouses from polycarbonate sheets, as shown in the photo.

Sealants have the following advantages:

- Elasticity. The material with temperature changes is able to compensate for any shifts in the joints on which it is applied;

- Tolerate any temperature during long-term operation;

- Excellent adhesion to polycarbonate;

- It is not exposed to various atmospheric influences, as well as mechanical damage.

Summing up

In conclusion, it should be noted that for polycarbonate it is necessary to choose special sealants. In this case, the design will serve you for a long time without requiring repairs and additional costs.

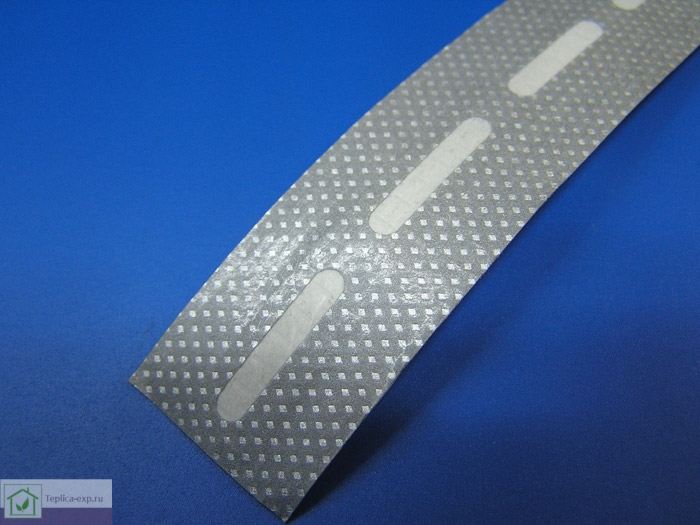

What is perforated tape

Now it's time to find out what perforated tape is made of and how it is used. In general terms, it is a flexible and adhesive tape with many small holes. They allow condensate vapors to escape from the SEC cells to the outside, but at the same time they do not allow moisture and dust to pass inside.

Perforated tape for honeycomb polycarbonate is also known as anti-dust or anti-condensation tape.

Tape perforated for polycarbonate for 4-8 mm

Obsolete samples of tapes had aluminum foil as a base, and the perforated layer was made of non-woven polypropylene or its equivalent. The result of the operation of such samples often did not meet expectations - the tape either let through not only condensate, but also external moisture, or, conversely, did not allow excess vapor to escape from the SEC cells. In addition, outdated samples had many problems with strength and reliability - the aluminum foil base was easily torn both during installation and during subsequent operation. Due to the lack of elasticity and the difference in linear expansion coefficients, as the temperature increased, the polycarbonate sheet "stretched" the perforated tape at the end. When the strength threshold was exceeded, a rupture occurred.

Perforated tape with aluminum backing

But time passed, technologies did not stand still, and engineers of companies specializing in the production of components for SEC took into account the experience of operating perforated belts. In the latest models, the above disadvantages have been largely eliminated.

The basis of a modern anti-condensation tape is made of a rather elastic polymer with a linear expansion coefficient close to that of cellular polycarbonate. Therefore, when expanding or narrowing the end of the SPK sheet, its integrity is not violated. Modern samples of anti-dust tapes can be extended in width without breaks by 10-15%.

Tape perforated, 38 mm

A water-repellent non-woven fabric is used as a perforated layer in quality samples.The pore size is 40-45 microns, so most dust particles or water drops cannot penetrate through them. But at the same time, the SPK cells can “breathe”, because condensate vapors freely pass through such holes. The result is a kind of one-way filter.

To combat bacteria, pollen and fungal spores, the non-woven fabric of modern perforated tapes is treated with a biocide - a substance that suppresses activity and kills all microorganisms (regardless of their species).

Installation of a perforated tape on the end of cellular polycarbonate is carried out using a self-adhesive layer applied to the surface. Acrylic adhesive is used as a fastening material, which adheres well to the surface, is resistant to temperature extremes from -30 to +80 ° C and has high shear strength. To protect against premature drying during storage and transportation, the adhesive layer is covered with a paper strip.

Aluminum tape sealing/perforated

The width of the perforated tape must be selected based on the thickness of the cellular polycarbonate sheets that you have or plan to purchase.

Table. Width and thickness of cellular polycarbonate sheets.

| 25 | 4, 6, 8, 10 |

| 38 | 16, 20 |

| 50 | 25 |

| 60 | 32 or more |

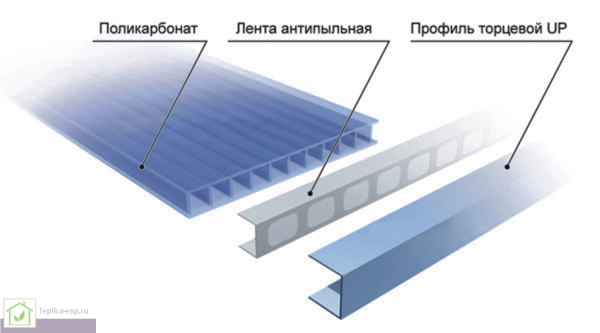

In addition to the anti-condensation tape, to seal the ends of cellular polycarbonate during the construction of a greenhouse or other structure, you will need end profiles and a sealing tape. Profiles are necessary for additional protection of the cells from dust and moisture, as well as for a more attractive appearance of the ends. End profiles are divided into aluminum and polycarbonate.

The former have the following advantages:

- high strength;

- durability;

- the presence of drainage grooves for the removal of condensate.

End profile and perforated tape

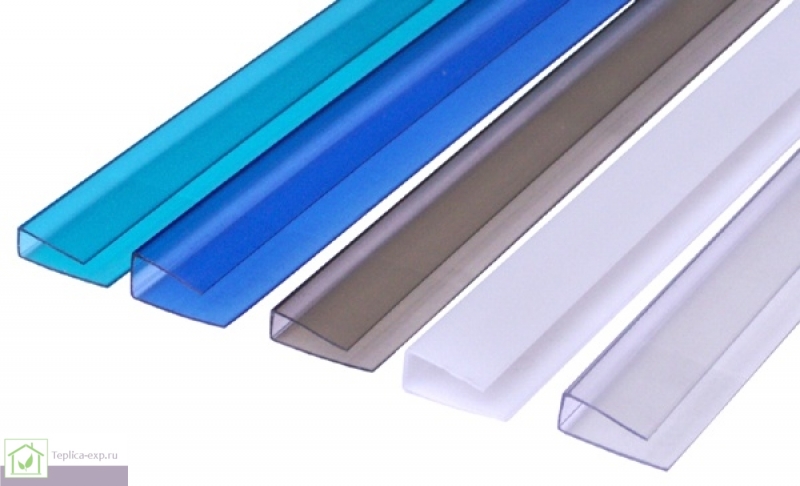

Polycarbonate end profiles also have their own advantages, including:

- low price;

- ease;

- the presence of models of different colors;

- ease of fastening;

- flexibility.

Aluminum end profile

Polycarbonate end profile

Domovest

In recent years, greenhouses made of cellular polycarbonate have become popular. This material is new, unfamiliar to many gardeners. And of course, any owner wants his greenhouse with a new covering material, not very cheap, by the way, to stand for as long as possible without losing its appearance. And although manufacturers give a guarantee for polycarbonate of 3 years or more, it, like any other thing, must be properly maintained.

1) How to keep the appearance of cellular polycarbonate.

2) How to install polycarbonate sheets.

3) How to mark cellular polycarbonate.

For marking cellular polycarbonate, a marker (felt-tip pen) is best suited, pencils and pens, including gel ones, practically do not leave marks on plastic. So don't forget to stock up on this drawing accessory.

4) How to seal the ends of polycarbonate sheets.

5) How to cut cellular polycarbonate.

Cellular polycarbonate is cut with an ordinary construction knife. You can use any other knife, for example, a shoemaker. The main condition is that the knife must be sharp and thin. Cutting along the length does not cause any difficulties at all. The sheet is easily cut into a honeycomb tube, the walls of which serve as a good limiter for the blade. It is more difficult to cut cellular polycarbonate across and diagonally. To cut the walls of the honeycomb, you need a fairly large effort. And it is better to cut across in two steps - first cut the top layer, and then finally separate the parts of the sheet.

6) Under what weather conditions can the greenhouse be covered with cellular polycarbonate.

Install polycarbonate in dry, calm weather. Rain and wind, even small ones, will not only interfere with work, but can also spoil the appearance of the covering material. Dust and water that get inside the honeycomb tubes will drastically worsen the appearance of polycarbonate.And although a small amount of litter and moisture will not affect the strength of the covering material in any way, foreign inclusions inside will annoy your eyes for a long time and spoil your mood. In addition, even on plastic slightly dampened by splashing rain, the marker ceases to leave traces and marking for cutting the sheet becomes difficult.

7) How to reduce the sticking of dust and litter on the covering material of the greenhouse.

Therefore, it is desirable to ground the metal frame of the greenhouse. Moreover, it is done simply and quickly. A metal pin is driven into the ground. It is most convenient to place the pin in the corner of the greenhouse. A thick wire, preferably stranded, is screwed to the pin with a self-tapping screw, the second end of which, also through a self-tapping screw, is connected to the frame of the greenhouse. Of course, this will not ensure complete elimination of static electricity, yet the frame is painted, and the polycarbonate is screwed to it through plastic or rubber gaskets. But the conditions for the discharge of charges will be much better. By the way, it is desirable to make the grounding of the iron frame for the film greenhouse. This will slightly extend the life of the film.

What is the sealing of cellular polycarbonate for?

SPK, i.e. cellular polycarbonate, is a very popular building material from which greenhouses, visors, awnings and much more are built. Its structure is as follows: there are several (from two or more) polycarbonate layers parallel to each other, and between them there are several rows of rectangular or triangular cells.

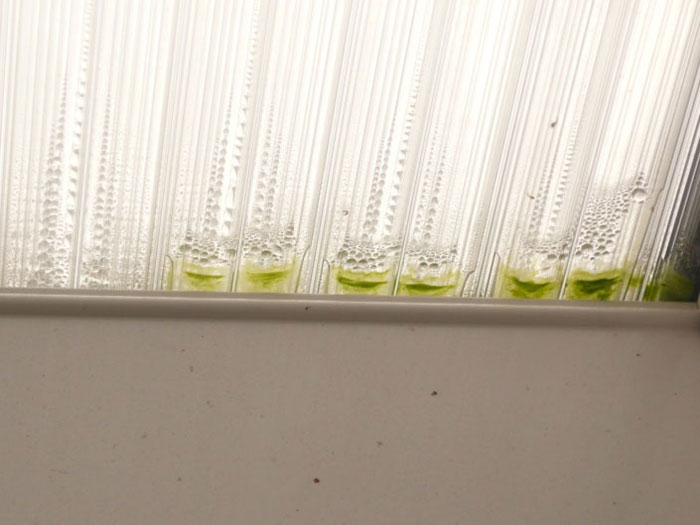

SPK itself is a waterproof material, but during operation, the ends of the sheets often remain open and are in no way protected from the external environment. In such cases, water, debris and dust almost instantly enter the cells of cellular polycarbonate. At the same time, it is almost impossible to blow or rinse them without dismantling the sheet from the frame of the greenhouse or canopy.

Benefits of Perforated Tape

Benefits of Perforated Tape

At first glance, there is no problem in this - the SPK does not let water through, does not corrode (if there is a stabilized coating and the sheet is correctly positioned during installation) and is not afraid of dust or debris. However, in reality the situation is quite different.

Getting inside the cells of cellular polycarbonate, moisture settles on their walls in the form of condensate. In this case, the light transmission of the material drops by a third, and in some cases even half of its nominal value. For greenhouses, this is critical, because the less sunlight passes through the skin, the worse crops will grow.

The situation can be aggravated by the ingress of dust and small debris through unprotected ends into the cells of the SPK. Together with condensate, they form dark dirt, which creates many internal stains and leads to clouding of the cellular polycarbonate sheet. From an aesthetic point of view, a canopy or greenhouse with such defects looks terrible - you can verify this by looking at the image below.

An example of what dirt can get into unprotected cells of cellular polycarbonate

An example of what dirt can get into unprotected cells of cellular polycarbonate

Along with dust and moisture, many microorganisms and fungal spores also get inside the SEC. As a result, polycarbonate will not only become dirty and cloudy, it will “bloom”, which will further affect its light transmission, thermal conductivity and appearance. It will be almost impossible to clean such a sheet, even removing the greenhouse from the frame, it remains only to replace the sheathing element with a new one. And this is a waste of time and money.

Diagnosis - replacement of polycarbonate sheets

Diagnosis - replacement of polycarbonate sheets

Using perforated tape, you can avoid the deplorable consequences of the external environment on polycarbonate structures.

Using perforated tape, you can avoid the deplorable consequences of the external environment on polycarbonate structures.

A fungus that has appeared in the cells of cellular polycarbonate will make it not only cloudy and ugly, but also less durable - over time, microorganisms will destroy the structure of the SPK sheet.

The best way to deal with these problems is to avoid them. And sealing and perforated tapes for cellular polycarbonate will help you with this.

general information

Polycarbonate is a polymeric material, which is a compound of carbonic acid and dihydric alcohols. It is produced in the form of small granules. These granules are subsequently melted and turned into a homogeneous plastic mass, to which dyes and components are added to improve the technical characteristics of the final product. Then the plastic mass is subjected to extrusion - extrusion through a special form. After cooling and cutting, a finished cellular polycarbonate is obtained - a building material in the form of sheets.

In cross section, it consists of several layers - monolithic surfaces parallel to each other. Between them are rows of cells having a rectangular or triangular shape. Cellular polycarbonate acquired its name precisely because of this feature of its structure.

Until recently, the requirements for this material and the characteristics were regulated by the document TU-2256-001-54141872-2006. Subsequently, on the basis of these specifications and other standards, the state standard GOST R 56712-2015 was drawn up, therefore, at the moment, the quality of cellular polycarbonate sheets (or SPK for short) is determined by it.

According to this document, the material must meet the following requirements.

- Smooth outer surface, without transverse and longitudinal stripes.

- Uniform coloration (if any) throughout the volume of the material.

- Mandatory presence on the outer side of the sheet of a stabilizing layer that protects cellular polycarbonate from exposure to ultraviolet rays. The minimum thickness is 30 micrometers.

- Absence of serious defects such as chips, creases, swelling, dents, delamination and cracks. Minor scratches are allowed.

- Compliance with the length and width of the sheet declared by the manufacturer. Tolerances for these parameters are 2 and 3 millimeters per meter of length and width, respectively. For thickness, the allowable deviation from the nominal figures cannot exceed 0.5 mm.

- The minimum number of extraneous inclusions. The last requirement was included due to the fact that unscrupulous manufacturers used recycled polycarbonate of different grades and characteristics in the manufacture of SPC sheets. As a result, the quality of the material dropped sharply.

How to glue polycarbonate in a greenhouse

One of the most popular materials in construction is polycarbonate, as it perfectly combines excellent performance and functionality. At the same time, such plastic has an affordable cost and a wide range of applications. It has a high level of strength, is quite light, has a neat appearance.

Polycarbonate bonding process

Due to the transparency of this material, it will be an excellent solution for the construction of a greenhouse. Depending on the selected type of polycarbonate, some characteristics and installation methods may differ, which must be taken into account in order to obtain the desired result for a long time.

Adhesive for polycarbonate

To date, there are two main types of material: monolithic and cellular. Moreover, each of them has its own advantages and features.How to glue it, you can watch the video, as well as take into account the various features and nuances of the installation process.

Features of gluing monolithic polycarbonate

When choosing polycarbonate, it is necessary to take into account the features and nature of its application. For small structures, a monolithic material would be an excellent solution. It differs from other products in a high level of strength and reliability. Depending on the design, it can be glued using:

- hot curing glue;

- silicone glue;

- polyurethane adhesive.

Small products or individual elements of the greenhouse can be glued using special guns that use hot-curing glue. Experts recommend giving preference to polyamide bases in the selection process, as they provide an excellent result.

If you plan to create a loaded structure that must have a high level of resistance to mechanical and atmospheric influences, it is better to choose a silicone adhesive that can be applied without prior surface preparation and priming. In this case, it is enough to degrease it by treating it with alcohol. For greater convenience, it is better to use a special filling container.

During the installation of the greenhouse, polycarbonate can be combined with other building materials, such as glass, metal, plastic. If it is necessary to achieve the maximum level of strength of the connected monolithic elements from the effects of chemicals, it is better to choose a two-component polyurethane adhesive. In this case, the design of the greenhouse will be not only functional, but also reliable.

Methods for gluing honeycomb material

The use of this type of polycarbonate during the installation of a greenhouse has such advantages as:

To achieve a neat appearance of the greenhouse, it is necessary to use the technology of gluing individual elements of honeycomb material into one structure. For this, experts recommend using special glue and panels. The gluing process does not require additional tools or special skills, it is enough to apply the selected mass to the polycarbonate surface and press the sheets together until they harden. For greater convenience, you can use a gun that will make the process of applying the adhesive easier.

It should be borne in mind that freezing occurs very quickly. Sheets of honeycomb material can be combined into one structure using a solvent based on ethyl chloride or methylene chloride. A greenhouse created in this way will have an aesthetic appearance and at the same time a high level of strength.

Preparation for the gluing process

To obtain a good result that will remain in its original form over a long operational period, it is important to responsibly approach the preparation. Experts recommend pre-treatment of polycarbonate, so as not to be distracted during the gluing process

It is also advisable to take care of the availability of all necessary tools. For glue, it is better to use a special gun, with which the installation process will be much easier, and the result is as accurate as possible. It will also allow to achieve a higher quality of the created structure, which is important in the process of operation.

Criteria for choosing polycarbonate for a greenhouse

The appearance of polycarbonate sheets is almost the same, however, in the process of choosing a material, you need to make sure of its quality. It should be as strong as possible, while being transparent enough so that sunlight and heat penetrate the greenhouse. It is also worth checking the quality of the protective layer, since the service life of polycarbonate depends on it.With proper and responsible selection, you can ensure the excellent quality and reliability of the greenhouse, regardless of weather conditions for many years.