Text GOST 14202-69 Pipelines of industrial enterprises. Identification painting, warning signs and labels

IDENTIFICATION COLORATION, WARNING SIGNS

AND MARKING PLATES

PUBLISHING HOUSE OF STANDARDS Moscow

UDC 621.643.4-777.6:006.354 Group G19

PIPELINES OF INDUSTRIAL ENTERPRISES

Identification painting, warning signs and labels

Pipe lines of industrial plants. Identification colouring, safety signs and marking screens

By the Decree of the Committee of Standards, Measures and Measuring Instruments under the Council of Ministers of the USSR dated February 7, 1969 No. 168, the deadline for introduction was established

1. This standard applies to identification coloring, warning signs and marking plates of pipelines (including fittings, fittings, fittings and insulation) in designed, newly built, reconstructed and existing industrial enterprises inside buildings, on outdoor installations and communications located on overpasses and in underground channels in order to quickly determine the contents of pipelines and facilitate the management of production processes, as well as ensuring labor safety.

The standard does not apply to the identification coloring of pipelines and ducts with electrical wiring.

2. The following ten enlarged groups of substances transported through pipelines are established:

4) combustible gases (including liquefied gases);

5) non-flammable gases (including liquefied gases);

combustible liquids;

9) non-flammable liquids;

0) other substances.

3. Identification coloring and digital designation of enlarged groups of pipelines must correspond to those indicated in Table. one.

4. Characteristics of colors of identification coloring should correspond to those specified in Appendix 1.

5. Fire-fighting pipelines, regardless of their contents (water, foam, steam for extinguishing a fire, etc.), sprinkler and deluge systems in the areas of shut-off and control valves and at the points of connection of hoses and other fire extinguishing devices must be painted red ( signal).

If it is necessary to indicate the contents of fire-fighting pipelines, it is allowed to additionally designate them by means of marking plates painted in the appropriate distinctive colors.

6. Identification painting of pipelines should be carried out continuously over the entire surface of communications or in separate sections.

The method for performing identification painting should be selected depending on the location of the pipelines, their length, diameter, the number of lines located together, safety and industrial sanitation requirements, lighting conditions and visibility of pipelines for maintenance personnel and the general architectural solution.

Official publication Reprint prohibited

IPK Standards Publishing House, 2001 Reissue. September 2001

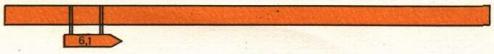

1. When applying yellow rings for the identification color of gas and acid pipelines, the rings must have black borders with a width of at least 10 mm.

2. When applying green rings for the identification color of water pipelines, the rings must have white borders with a width of at least 10 mm.

13. In cases where a substance simultaneously has several dangerous properties, indicated by different colors, rings of several colors should be applied to pipelines at the same time.

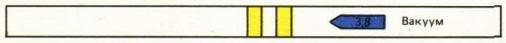

On vacuum pipelines, in addition to the distinctive color, it is necessary to give the inscription "vacuum".

14. According to the degree of danger to human life and health or the operation of the enterprise, substances transported through pipelines should be divided into three groups, indicated by the corresponding number of warning rings in accordance with Table. 3.

Types of coatings

To cover linear systems, a paintwork material is used that corresponds to GOST and depends on the internal component, the physico-chemical composition of the pipes, their insulating characteristics, and also on the cost of the paint.

In rooms where there is no aggressive environment, good ventilation is established, it is possible to use enamels in accordance with technical documentation.

Marking must be carried out strictly in accordance with safety regulations in order to avoid accidents and injury hazards.

Periodically, all marking products are subject to renewal to restore the original color.

It is no coincidence that polypropylene pipelines are becoming increasingly popular with home craftsmen and professional installers. Polypropylene pipes have a number of advantages due to which they are gradually replacing products from traditional materials. The choice of plastic pipes today is simply huge and all products are different. according to their characteristics and appointment. To find out which of them are suitable for a heating system, cold or hot water supply, ventilation, decoding the marking of polypropylene pipes will help.

APPENDIX 3

| Numerical designations | Substance being transported

Name |

| 1 | Water |

| 1.1 | drinking |

| 1.2 | technical |

| 1.3 | hot (water supply) |

| 1.4 | hot (heating) |

| 1.5 | nutritious |

| 1.6 | reserve |

| 1.7 | reserve |

| 1.8 | condensate |

| 1.9 | other types of water |

| 1.0 | waste, waste |

| 2 | Steam |

| 2.1 | low pressure (up to 2 kgf/cm2) |

| 2.2 | saturated |

| 2.3 | overheated |

| 2.4 | heating |

| 2.5 | wet (juice) |

| 2.6 | selective |

| 2.7 | reserve |

| 2.8 | vacuum |

| 2.9 | other types of steam |

| 2.0 | spent |

| 3 | Air |

| 3.1 | atmospheric |

| 3.2 | conditioned |

| 3.3 | circulation |

| 3.4 | hot |

| 3.5 | compressed |

| 3.6 | pneumatic transport |

| 3.7 | oxygen |

| 3.8 | vacuum |

| 3.9 | other types of air |

| 3.0 | spent |

| 4 | combustible gases |

| 4.1 | luminous |

| 4.2 | generator |

| 4.3 | acetylene |

| 4.4 | ammonia |

| 4.5 | hydrogen and gases containing it |

| 4.6 | hydrocarbons and their derivatives |

| 4.7 | carbon monoxide and gases containing it |

| 4.8 | reserve |

| 4.9 | other types of combustible gases |

| 4.0 | waste combustible gases |

| 5 | Non-flammable gases |

| 5.1 | nitrogen and gases containing it |

| 5.2 | reserve |

| 5.3 | chlorine and gases containing it |

| 5.4 | carbon dioxide and gases containing it |

| 5.5 | inert gases |

| 5.6 | sulfur dioxide and gases containing it |

| 5.7 | reserve |

| 5.8 | reserve |

| 5.9 | other types of non-flammable gases |

| 5.0 | waste non-combustible gases |

| 6 | acids |

| 6.1 | sulfuric |

| 6.2 | hydrochloric |

| 6.3 | nitric |

| 6.4 | reserve |

| 6.5 | inorganic acids and their solutions |

| 6.6 | organic acids and their solutions |

| 6.7 | acid salt solutions |

| 6.8 | reserve |

| 6.9 | other acid reaction liquids |

| 6.0 | waste acids and acidic effluents (at pH |

| 7 | alkalis |

| 7.1 | sodium |

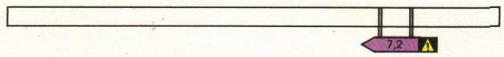

| 7.2 | potash |

| 7.3 | calcareous |

| 7.4 | lime water |

| 7.5 | inorganic alkalis and their solutions |

| 7.6 | organic alkalis and their solutions |

| 7.7 | reserve |

| 7.8 | reserve |

| 7.9 | other alkaline liquids |

| 7.Yu | spent alkalis and alkaline effluents (рН>8.5) |

| 8 | Flammable liquids |

| 8.1 | category A liquids (tc.p. |

| 8.2 | category B fluids (tc.p.>28 °С |

| 8.3 | category B fluids (tc.p.>120 °С) |

| 8.4 | lubricating oils |

| 8.5 | other organic flammable liquids |

| 8.6 | explosive liquids |

| 8.7 | reserve |

| 8.8 | reserve |

| 8.9 | other flammable liquids |

| 8.0 | combustible drains |

| 9 | Non-flammable liquids |

| 9.1 | liquid food products |

| 9.2 | aqueous solutions (neutral) |

| 9.3 | other solutions (neutral) |

| 9.4 | aqueous suspensions |

| 9.5 | other suspensions |

| 9.6 | emulsions |

| 9.7 | reserve |

| 9.8 | reserve |

| 9.9 | other non-flammable liquids |

| 9.0 | non-combustible drains (neutral) |

| Other substances | |

| 0.1 | powder materials |

| 0.2 | bulk materials granular |

| 0.3 | mixtures of solid materials with air |

| 0.4 | gels |

| 0.5 | water pulps |

| 0.6 | pulps of other liquids |

| 0.7 | reserve |

| 0.8 | reserve |

| 0.9 | reserve |

| 0.0 | waste hard materials |

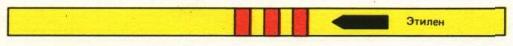

Note. If necessary, each of the subgroups can be divided into ten smaller subdivisions, indicated by the third character of the digital designation (for example, in the enlarged group 4 "Combustible gases" as part of subgroup 6 "Hydrocarbons and their derivatives", ethylene can be distinguished by the third character - 4.61 ).

REFERENCE APPENDIX TO GOST 14202-69

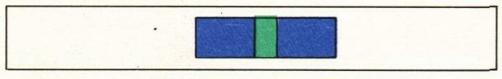

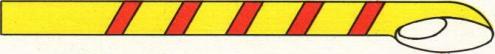

Examples of performing identification painting of pipelines

Sulphuric acid

Potash alkalis

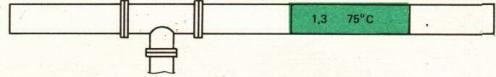

Hot water for water supply

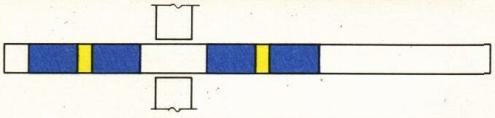

Steam superheated 450°C

Compressed air

Leaded gasoline

Ethylene

air vacuum

atmospheric air

Gas outlet line

Water for fire fighting

Note: Hot water and leaded petrol pipes must have white inscriptions on the decals.

Rated pressure

The letters PN are the designation of the permitted working pressure. The next figure indicates the level of internal pressure in bar that the product can withstand during a service life of 50 years at a water temperature of 20 degrees. This indicator directly depends on the wall thickness of the product.

PN10. This designation has an inexpensive thin-walled pipe, the nominal pressure in which is 10 bar. The maximum temperature that it can withstand is 45 degrees. Such a product is used for pumping cold water and underfloor heating.

PN16. Higher nominal pressure, higher limiting liquid temperature - 60 degrees Celsius. Such a pipe is significantly deformed under the influence of strong heat, therefore it is not suitable for use in heating systems and for supplying hot liquids. Its purpose is cold water supply.

PN20. The polypropylene pipe of this brand can withstand a pressure of 20 bar and temperatures up to 75 degrees Celsius. It is quite versatile and is used to supply hot and cold water, but should not be used in a heating system, since it has a high coefficient of deformation under the influence of heat. At a temperature of 60 degrees, a segment of such a pipeline of 5 m is extended by almost 5 cm.

Reading information

- The name of the manufacturer usually comes first.

- Next comes the designation of the type of material from which the product is made: PPH, PPR, PPB.

- On pipe products, the working pressure must be indicated, which is indicated by two letters - PN, - and numbers - 10, 16, 20, 25.

- Several numbers indicate the diameter of the product and the wall thickness in millimeters.

- On domestic modifications, the class of operation in accordance with GOST may be indicated.

- The maximum allowed.

Additionally indicated:

- Regulatory documents in accordance with which pipe products are manufactured, international regulations.

- Quality mark.

- Information about the technology by which the product is made, and the classification according to MRS (Minimum Long-Term Strength).

- 15 digits containing information about the date of production, batch number, etc. (the last 2 are the year of issue).

And now let us dwell in more detail on the most important characteristics of polypropylene pipes indicated in the marking.

Requirements for dyes

The coloring with which decals are applied must be resistant to chemicals and weather conditions, since marking of communications is necessary both in the industrial sector and in residential complexes. GOST 14202-69 does not apply to electrically conductive networks.

There are several ways to apply paint to systems.

The continuous painting method is applied if the pipeline is short and consists of a small number of connections.

With a large number of components of wired networks, long kilometers, and also if the architecture of the building does not imply large areas of coloring, coloring is used in separate fragments. The rest of the pipeline is tinted to match the color of the walls, ceiling, floor, etc. In the case when communications are located outside buildings and structures, the color should reduce the thermal effect on the pipes.

The size of the coating also depends on the outer diameter of the pipes. In the event that the diameter is large, the color designation is applied in the form of stripes with a height of at least 1/4 of the pipe circumference.

According to GOST, the paint is applied to the most important and critical areas, for example, at the joints and passage of pipes through walls, ceilings, floors, etc., at flanges, at points of selection and control, in the area of \u200b\u200bentrance and exit to the room and from it after 10 -meter sections inside the building and after 30-60 m outside.

Important!

On pipelines with increased pressure, connecting flanges are subject to painting, since the linear systems themselves are in protective casings.

Marking communications with various devices

In the event that the contents of communications are particularly aggressive, warning rings are applied to them in one of three colors: red corresponds to flammability, flammability and explosiveness; yellow color - dangers and harmfulness (toxicity, radioactivity, the ability to cause various types of burns, etc.); the green color with a white border corresponds to the safety of the internal content. The width of the rings, the distance between them, the application methods are standardized by GOST 14202-69.

Network marking is possible with the help of stickers. In the event that the sticker contains text, it is made in a clearly distinguishable font, without unnecessary symbols, words, abbreviations, in the maximum accessible syllable. Fonts comply with GOST 10807-78.

Stickers are also made in the form of arrows showing the direction of the flow of the substance inside the pipe. Arrows are also standardized in terms of size

The designation on the arrows is differentiated: “flammable substances”, “explosive and fire hazardous”, “poisonous substances”, “corrosive substances”, “radioactive substances”, “attention - danger!”, “flammable - oxidizer”, “allergic substances ". The color of the arrows, as well as the inscriptions, is applied in black or white, in order to achieve the greatest contrast with respect to the main coating of the pipe.

With a particularly dangerous communication component, stickers are made in the form of warning signs (in addition to color rings). The signs are triangular in shape with a black image on a yellow background.

Important!

In plumbing systems with hot water and in the case of transporting leaded gasoline, the inscriptions must be white.

If the contents of the pipeline can damage the color designation, change its shade, special shields are used as additional markings, which are informative in nature, numerical and alphabetic. The requirements for the graphics of the shields are identical to those of the stickers. Dimensional characteristics of the shields correspond to the characteristics of the arrows. Marking boards should be located in clearly visible places, if necessary, illuminated by artificial lighting without interference for viewing by maintenance personnel.