Reasons for leaks

The tank water heater is a fairly simple device. Its basis is a container made of steel, covered from the inside with a protective layer, which prevents premature corrosion of the container walls and, accordingly, prolongs the service life.

The coating of the inner surface can be made of enamel, glass enamel, glass ceramic, titanium protective layer, stainless steel layer, etc.

Usually this coating is the development of the manufacturer itself, and is kept in strict confidence.

At the bottom of the boiler there is a cover in which a heating element, a thermostat and a magnesium anode are mounted. There is also a thermometer in the tank. An inlet pipe from the water supply is connected to the boiler from below and a hot water pipe leading to the shower and kitchen sink faucets is output.

Outside, the water heater tank is covered with a layer of thermal insulation made of polyurethane foam and a decorative metal casing. The main reasons that contribute to the premature failure of the boiler capacity are the following:

- if the pressure in the plumbing system is more than 2 atmospheres, it is necessary to put a reduction gear in front of the boiler, since when heated, the pressure will rise even higher, and an unacceptable deformation of the walls will occur with a violation of the integrity of the protective coating;

- a safety valve is not installed directly in front of the boiler inlet, which relieves excess pressure when water is heated in the water heater;

- if the boiler is not prevented once a year, then scale forms on the walls and the heating element, which worsens the operation of the heating element and leads to premature wear of the boiler itself. It is also necessary to change the magnesium anode once a year, which prevents corrosion of the walls.

; - heating the boiler to a high temperature above 70 degrees Celsius. The best option would be to operate the water heater at temperatures up to 50 degrees;

- do not drain the water from the boiler for a long time - this leads to premature corrosion of the metal.

By putting into practice all the above warnings, you can significantly increase the service life of the storage water heater and thereby provide yourself with comfortable conditions for many years.

Troubleshooting

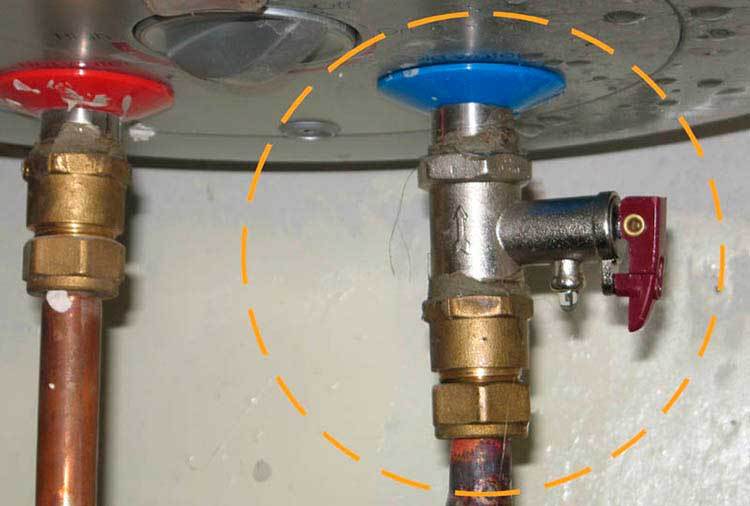

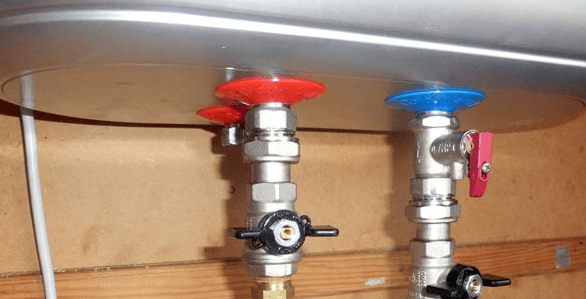

If the cause of the leak is a defective valve, then it is replaced with a serviceable part set to the same working pressure. When replacing, or better, even during the installation of a water heater, try not to use cheap Chinese products. Remember that the safety of your family directly depends on the valve. Good Italian safety valves with the same non-separable design, although they cost several times more, are bought once. As practice shows, in the future there are no problems with them. Connect a flexible transparent hose to the drain outlet of the device. This will help visually evaluate the work of the part. Lead the end of the hose into the sewer or a suitable container.

Products from well-known manufacturers are reliable and durable

To remove the valve for replacement or cleaning, you will need a plumbing and adjustable wrench. The work is done in this order:

- Disconnect the boiler from the network;

- Shut off the cold water supply to the water heater;

- Open the hot water taps and completely drain it from the tank;

- Press the lever on the safety valve and remove the remaining liquid from the tank;

- Disconnect the pipeline with cold water from the safety valve;

- Dismantle the valve.

After cleaning or replacement, the part is installed in place in the reverse order.

If the inlet pressure of your water supply system exceeds the nominal pressure for which the storage water heater is designed (it can be found in the technical data sheet for the device), a pressure reducer is installed at the water inlet to the apartment.

Before the reducer, a filter for pre-treatment of water must be mounted, and its installation is carried out in strict accordance with the direction of the liquid flow. Approximately half of the pressure reducers have a pressure gauge in their design, which greatly facilitates their adjustment and control of the parameters of the water supply system.

Storage tanks capable of heating water to a certain temperature (colloquially - water heaters or boilers) are most often installed in those rooms where there is no centralized supply of hot water, or there is a high probability of turning it off. This device does not lose its relevance from ancient times to the present day. So, the ancient Greek mechanic Heron of Alexandria (second half of the 1st century AD) is rightfully considered the inventor of the boiler. The unit he created heated cold water with steam. Then they forgot about it, in connection with which, at the end of the 17th - beginning of the 18th centuries, they were forced to invent the apparatus anew. But, like any other household electrical appliance, even an improved water heater can break down as a result of internal or external factors, as well as due to the banal wear of parts. All the reasons why hot water does not flow from the boiler, as well as ways to eliminate them, will be described in this material.

How to fix a leak with your own hands

How to identify a breakdown and deal with it yourself.

Installation problems

Shortly after connecting, you may notice water dripping from the tank. In this case, the shell of the body can be inflated or deformed.

When installing it yourself, you forgot about the safety valve, or it was connected incorrectly. As a result, the container overflows with water and swells, after which it flows. You need to install a valve. It protects the system from overpressure.

- If the valve is installed incorrectly or if it breaks, the tank is deformed while draining water from the system.

- You turned off the boiler and turned off the water. At this time, the hot water inside cools down, and the body shrinks.

- The product is filled to the brim with water. During heating, it expands, and the tank swells.

In case of deformation, repair is impossible, you will have to install a new device.

Impact of corrosion

Have you replaced the magnesium anode in a long time? Then don't be surprised if the boiler is leaking. Magnesium attracts salts that are contained in water. As a result, impurities settle on the anode and destroy it, while the tank and the heating element remain intact. If the anode has been destroyed for a long time, corrosion of the metal case begins.

Poor quality pipes or their incorrect connection

Water dripping from pipes or connections? Sealing the joints will help fix and fix the problem: you need to replace the gasket or fum-tape. It is recommended to use metal-plastic pipes, because the body suffers as a result of water hammer.

Worn flange (gasket)

The heating element and the magnesium anode are mounted on the flange, a gasket is installed for tightness. If it is worn out, it will leak from below. Replace it with a new one or tighten the fixing nuts more tightly.

Heater body rusted

Dry heating element has a shell of steel and enamel - wear entails corrosion. How to repair a leaking element? Only replacement will help.

No grounding

Why is it necessary to ground the device? In the event of a breakdown of the current on the case, the latter will be subjected to electrocorrosion. In addition, it is life-threatening: tap water or the surface of the tank can be electrocuted.

If it's not the worn parts of the water heater that can be replaced, then the tank is beyond repair. When the hull itself broke down, you have to buy new equipment.

How to avoid malfunction? Only by correct operation:

- Make sure that the pressure in the line does not exceed 3 atm. Otherwise, you need to install a reduction gear.

- Once every six months, inspect the equipment, clean the tank and heater from scale, change the anode.

- Install a water filter if the water in the area is hard.

It is always better to prevent a breakdown than to repair it. Follow instructions.

Types of leaks

If the boiler is leaking from above or below

It is necessary to disconnect it from the mains, substitute a basin and make a thorough visual inspection.Water leaks can be different: water can simply drip, or it can flow under pressure. In most cases, water flows from the bottom of the water heater. Use a flashlight to find the source of the leak.

The simplest case is when the leakage comes from the safety valve. It is adjusted at the factory so that excess pressure during water heating is released through a small fitting.

A simple solution to this issue is to divert this water to the sewer using a plastic flexible pipe with a diameter of approximately 8 mm. In this case, you need to think about where to connect the second end of the tube. If the boiler is hanging in the toilet, you can bring this tube into the flush tank;

Leakage from connections

The source of the leak may be from loose connections in the inlet and outlet pipes in the boiler itself. This is easily eliminated - all threaded connections are repacked;

Leakage from under the lid

Next, with the help of a flashlight, the place where the water flows from is determined. If leaks are found from under the cap, this is one of the best options. Since the cover is pressed against the boiler body through the gasket, you can try to eliminate the leak by tightening the nuts of the bolts on the cover.

If this does not work, it is necessary to drain the water from the boiler, remove the cover and change the gasket. And before that, you must disconnect all electrical wires.

Advice:

in order not to be confused in the future, you can first take a picture of all connections on a digital camera or smartphone and display it on the laptop screen.

These are, perhaps, all the options in which boiler leaks can be eliminated without replacing it. However, in most cases, about 80 percent, the leak comes from the top or bottom of the boiler body.

It's important to know:

often it is almost impossible to determine the location of the fistula in the body, since it is covered with heat-insulating material and an outer casing. Water can flow down under the thermal insulation or flow out in the area of the thermometer

In the lower part of the boiler there are special holes, in case of water leakage from which it is possible to accurately determine that it is the water heating tank that is flowing.

These are the most difficult and unprofitable options. All of the listed leak options refer to the most common brands on the market, such as Ariston and Termex.

Faucet contamination

Liquid will flow in a trickle if mixer spout

congestion has occurred. The pressure will be equally bad for both cold and hot water. To fix the problem, you need to carry out a number of procedures.

- Close the riser to turn off the water.

- Remove the mixer carefully.

- Unscrew the spout from the common body.

- Remove the mesh and rinse it under running water. In case of formation of salt deposits or dense dirt, let it soak in a special cleaning solution.

- Rinse the mixer spout thoroughly and clean the insides of dirt with a brush.

- Assemble the faucet in reverse order and reinstall it. Don't forget to open the riser.

This procedure may take some time, as an alternative, you can simply replace the clogged mixer with a new one. Experts recommend replacing worn parts every few years to avoid serious breakdowns in the future.

The main causes of leaks and methods for their elimination

In the course of the flow of the device, it is first necessary to establish the source of the negative factor. They can differ significantly in features, so they can be identified quickly and without professional skills. The study of the water heater is best done according to the instructions attached to the instance.Most models have a warranty card designed for such situations. In order not to aggravate the problem, the device must not be opened.

Hull deformation

The outer shell of the equipment may deform after installation. The reason for the unfavorable behavior of the device is considered to be incorrect installation of the unit. Often the consumer forgets to connect the safety valve. The product is located on the main fluid supply between the stopcock and the valve element. This part is provided for tank overflow protection, it is during this process that deformation occurs.

If the valve is installed, but water is also flowing through the supply pipe, remove this fuse and install a new one. Repair does not take much time and does not require professional knowledge of the device.

Another reason for deformations is the use of low-quality pipes during installation. Powerful water hammer with pressure change slowly destroys the structure of the product.

Healthy! If the body is deformed, the boiler cannot be repaired, it must be replaced with a new model, while observing the correct connection technology.

Manufacturing defects

Leakage can be from the top of the case, if in this situation there are no visual deformations of the unit, and the magnesium rod was mounted when connected, then a factory defect of the equipment is possible. During warranty service, it can be returned back to the supplier.

Modern models are being developed with designs in which the tank cannot be repaired. The container cannot be welded, because in the process of welding, a layer of enamel breaks off, after which corrosion forms, spreading over the entire surface of the device.

Poor device installation

Quite often there is another reason - a loose connection with the cold water inlet and hot water outlet pipes. Such symptoms may appear when you install the device yourself, when poor quality fittings or incorrect seal materials are used.

Gasket wear

Leakage of the inspection hole located in the plastic cover at the bottom of the equipment indicates the loss of elasticity of the rubber gasket on the flange. The exact determination of this cause can be carried out after the equipment is turned off: the lower cap is removed, the problem area is visually studied.

The replacement of the sealing gasket must be carried out strictly in accordance with the model number of the boiler, so that the product fits snugly against the working parts.

Valve leakage during operation of the water heater

If the water heater is plugged into the network and heats water for a long time without significant water intake, then the fault of the constant leakage is most likely a faulty safety valve. The fact is that during the initial heating of cold water, its volume in the boiler will increase by about 2-3%. It is this excess liquid that will be dumped from the tank. In the future, the boiler simply maintains the temperature of the hot water, so there should not be any leaks, so the cause should be sought either in a breakdown or in a clogged safety valve.

A completely different picture should be observed with increased water intake, for example, while taking a shower: the constantly leaving volume of hot liquid will be continuously replaced by cold water.

But when it is heated, the surplus indicated above will begin to appear. Therefore, the outflow of a certain amount of water from the drainage hole in this case is quite logical.

Safety valve device for water heater

And the third option - with a small, stretched in time water intake. For example, washing dishes or cooking.With such a flow rate of hot water, there should not be a constant leak from the drain pipe, but the periodic leakage of drops of liquid will just indicate the correct operation of the water heater.

Leaking when the boiler is off

Let's simulate the following situation: the water heater is disconnected from the network, the water supply from the water supply is turned on (the tap on the pressure line is open). Water is flowing from the boiler drain hole. The cause of this phenomenon can be both a malfunction of the safety valve, and increased pressure in the line.

To find the cause of a leaking safety valve, you need to know the water pressure in the water supply

To determine the culprit of the leak, it is necessary to measure the pressure of cold water in the water supply. The fact is that if the main pressure exceeds the accepted SNiP, then the valve will open and will perform its functions of dumping excess water into the sewer. Most water heater safety valves that manufacturers complete their products are set to a pressure of 6 to 8 atmospheres.

The maximum pressure allowed by SNiP in main water supply systems should not exceed 6 atmospheres. In fact, it often happens that the actual indicators exceed the normative ones by 1 - 2 atmospheres. Naturally, the safety mechanism will work in this case.

The second cause of leaks may be the valve itself. Wear of its plate or seat, weakening of the spring - these are the factors that can lead to leakage. Often such malfunctions are subject to cheap Chinese products.

It is impossible to drop from the scales and the possibility of particles of scale or debris getting under the plate of the locking mechanism, which can happen during an emergency release of pressure or after draining water from the boiler during maintenance or repair work.

Device and principle of operation

In general, we can talk about three types of devices capable of accumulating and heating water:

- electric water heaters;

- indirect heating boilers;

- gas water tanks.

All these devices have a similar design and function on the same principle. They differ only in the heat sources with which water is heated. In this case, the role of a heater can be performed by: a heating element, a coil with a coolant supplied to it (for example, a boiler), a gas burner. Structurally, all boilers have the form of a wall-mounted tank, the inner surfaces of which are covered with heat-insulating material.

. Cold water enters it through a pipe located in the lower part, and the selection of heated liquid is carried out from the upper part.

Heaters in all boilers are located in its lower part. The water in the tank is heated to the desired temperature, and then used by the owner for its intended purpose. To maintain and, if necessary, correct the required temperature, the water heater built-in thermostat

. In addition, the boiler is equipped with a temperature meter, with which the user can control the degree of heating of the water, and a safety valve that prevents the unreasonable leakage of liquid.

The water in the boiler is rotten There is a solution

The easiest way to appreciate and enjoy the benefits of a boiler is during the period of replacement and repair of the pipeline, when a lonely icy stream of water flows from the tap. For owners of private houses with autonomous water supply, a water heater is of particular importance, since its operation directly provides hot water.

However, you still have to pay for convenience - spending time on caring for the container, removing scale and fighting unpleasant odors. The first signs that the water in the boiler is rotten will be a characteristic change in the smell and taste of water.

The water in the boiler is rotten - causes and myths

Before judging the degree of freshness and purity of water, it is necessary to find out in which cases the water acquires such a strange smell, the main reasons are:

1. The presence of hydrogen sulfide in the water. Water treatment at a treatment plant does not always provide the proper water quality, many systems are outdated and do not function at full capacity.

Often, the smell of hydrogen sulfide is not noticed when opening a tap with water, because for a clear distinction it is necessary to conduct a simple test - fill the bottle with cold tap water halfway, close the lid, shake thoroughly. After that, unscrew the lid and smell it. If a specific smell is felt, this means that the water initially contains hydrogen sulfide.

In this case, both cold and hot water contain the source of the smell, while remaining fresh. At the same time, the idea that the water in the boiler is rotten disappears. This problem is solved by installing a water treatment system with the removal of hydrogen sulfide.

Predisposing factors for water damage are prolonged stagnation of water in the tank with infrequent use of the boiler and insufficiently high heating temperatures.

Bacteria, forming the so-called biofilm, calmly survive at a temperature of 60 °, tenaciously attached to the walls of the container.

3. The culprit of a similar situation, in which hot water changes its quality, while cold water remains quite suitable, is considered to be insufficient saturation of water with oxygen. For anaerobic bacteria, it is impossible to think of a better habitat - there is a small amount of oxygen, the water temperature is optimal for life and rapid reproduction.

4. As mentioned above, the tank and working elements of the boiler require care and periodic inspection. An important detail of the water heater is an anode made of magnesium alloy. It is designed to prevent corrosion of the tank walls and scale deposits.

The service life varies depending on the composition of the water, the intensity of work

When replacing the anode, it is very important to purchase a quality part.

If the anode contains cheap commercial magnesium, which contains a lot of sulfide, then this will affect the quality of the boiler water - its properties, and especially the smell, will deteriorate.

If the water in the boiler is rotten, no need to hesitate

It is required to drain the old water, rinse the container with sodium hypochlorite to kill bacteria.

The main task for the elimination and prevention of subsequent reproduction of microorganisms is to eliminate predisposing factors. First of all, water of the appropriate quality must enter the boiler, for this it is necessary to install water purification filters.

You should set the maximum heating temperature and actively use the boiler. It is not necessary for the water heater to stand idle and store water for a long time, which will lead to stagnation and inevitable pollution. Remember, water purification for the home and its preparation is the key to a healthy life.

The most common causes of leakage

There are several reasons why a boiler is leaking. The ability to make repairs on your own depends on how quickly and correctly they are determined.

Outer shell deformation

This problem may occur if the rules for installing the boiler are violated, and not through the fault of the manufacturer. Dripping water on the outer shell of the water heater can be noticed almost immediately after its installation. The thing is that there is no safety valve or it is broken.

When the water cools, its volume decreases, and the tank of the device shrinks. After draining all the liquid from the system, a vacuum occurs inside the tank. If at this time the safety valve is broken or missing, the container is deformed. Further, when filling the boiler and turning it on, the water expands, having heated up, the pressure increases, which leads to bursting of the tank. Such malfunctions explain why the boiler is dripping.

Storage tank leak

If liquid flows through the liner, it is the storage tank that is leaking. Such a problem may occur due to gross violations of the installation or connection rules. When connecting a water heater, it is highly undesirable to use plastic pipes. If pipes of this type are nevertheless used, because they look more attractive, water hammer will be transmitted to the tank, which will gradually destroy it.

Heating element leak

Not all models have a special hole through which a drain of water is provided when the heater starts to leak. You need to check its availability when buying a boiler.

Leaking safety valve

This boiler element is a small faucet with a hole in it. The problem is easily fixed by replacing the part with a new one.

Storage tank cap leaking

If such a problem is observed, it may be a leakage of the heating element, which can be provoked by the accumulation of a large amount of scale.

After replacing the heating element, the problem will be fixed.

Leakage from under the heating element seal or under its bolts

If water flows from under the seal, you just need to slightly tighten the nuts with which it is attached. In the second case, the heating element needs to be replaced.

The supply channels are loosely connected

This is the most common reason why a boiler is leaking. It is not difficult to eliminate it, you just need to check all the connections.

Inlet connections

Leakage in the upper part without visual damage

If there is a leak in the upper part of the water heater, and no deformations were found during visual inspection, the installation and connection were performed correctly, the magnesium rod was checked and changed, it is better to return such a device to the store until the warranty period has expired. You can only fix a leak if its tank is made of stainless steel.

Lack of preventive work

Too hard water or the presence of a large amount of impurities in it affects the quality of the boiler. During its operation, it is required to periodically carry out preventive maintenance, cleaning from contaminants and replacing worn-out elements.

Defective device or violated the rules of installation and connection

In the first case, the leaked equipment must be returned to the store until the warranty period has ended. You do not need to try to fix the leak yourself, because after that you will not be able to return the defective boiler under warranty. In the second case, you need to double-check whether all the points of the installation and connection instructions are observed.

Boiler Life Prevention

You can extend the life of the device and ensure proper maintenance of the equipment by following these recommendations:

- the internal water pressure must be below 3 atmospheres, otherwise a reduction gear should be installed, which will be placed between the supply pipe and the inlet branch of the apparatus. The optimal setting of the reducer corresponds to 2 atmospheres;

- the tank located inside and the heating element must be cleaned at frequent intervals to remove scale and salt deposits. Thus, the service life of the unit will increase;

There are many reasons that affect the flow of the device, however, if any of them occurs, you should immediately disconnect the device from the electrical network, and then carry out a visual inspection. Without an exact determination of the cause of the malfunction, it is forbidden to open the equipment so as not to aggravate the situation, which may get out of control.

Only compliance with the rules of use and proper maintenance of the water heater contribute to extending the service life. If you have problems with self-inspection of the unit, you should resort to the help of professional specialists.They will quickly establish the cause of the failure and notify you of the possibility of repairing the boiler.

A boiler is an indispensable device for apartments and country houses. But sometimes technology fails and breaks down. What to do if the water heater is leaking? After reading our article, you will learn: the causes of tank leaks, how to fix them yourself and how to avoid such problems.

Best selling storage water heaters

Accumulative water heater Thermex Champion Silverheat ERS 50 V

on Yandex Market

Storage water heater Thermex Flat Plus Pro IF 50V (pro)

on Yandex Market

Storage water heater Gorenje OTG 50 SLSIMB6/SLSIMBB6

on Yandex Market

Accumulative water heater Electrolux EWH 100 Centurio IQ 2.0

on Yandex Market

Accumulative water heater Electrolux EWH 50 Magnum Unifix

on Yandex Market

In an apartment or country house, such a boiler allows you to solve the problem of hot water if there is running water and electricity. You can list the positive points from the use of water heaters for a long time and it is very unpleasant when it fails.

It is worth noting that there are no household appliances that would work forever. In addition, it is contrary to the goals of companies that produce water heaters.

If they work forever, then the demand for them will dry up as these devices are provided to everyone. Consider the main causes of failure associated with leaks.