Pipe surface preparation and painting

Before using enamel for galvanized sheet, a hardener is added to it and mixed thoroughly.

The surface must be prepared before painting. Grease must be removed from the pipes, which may form on them, especially in the kitchen.

To remove fat, organic solvents, special detergents soluble in water, or an emulsion intended for this purpose are used. In particular, for degreasing, you can use "Chistomet-C".

Before painting cold water pipes, there may be a problem with the formation of condensate on their surface.

This happens if their temperature is lower than the temperature of the surrounding air, that is, if water moves along them and they are constantly cooled. The cause must be removed. There must be a leak somewhere, perhaps in one of the faucets or in the toilet bowl.

With paint such as tsikrol, you can work at room temperature. Paint consumption is 0.3 kg/m2.

It is easy to calculate that for an inch pipe 10 m long, the surface of which will be approximately 1 m2, 300 g of paint will be required. To ensure good staining, cyclol is diluted with butyl acetate or solvent P646. If the room temperature is not less than 20 ° C, then the paint will dry after 12, maximum after 18 hours.

Surface preparation for stainless steel enamel is the same as for cyclol.

Places of welding should be pre-primed with phosphor primer. Painted in 2-3 layers. The drying time of the layer is 30 minutes.

The total drying time will be no more than 2 hours. With a thickness of one layer of 25-30 microns, the consumption of enamel per 1 layer is 180 g/m2. Dilute the enamel with organic solvents R-4, R-4A or solvent.

Surface preparation for silverl is the same as for cyclol, but it is recommended to prime the surface with a phosphor primer before painting, and apply the paint in two layers. A second layer is applied after the previous layer has completely dried, which at an ambient temperature of 20 ° C will last no more than 3 hours.

To increase the service life of VGP systems, they should be painted.

This is especially useful for those whose inner surface has the same coating. If the inner surface is not coated, then the outer coating will not increase the service life, as the VGP systems will rust from the inside. There is enough oxygen in the water.

Share this helpful article:

Some more tips

In order for heating batteries to serve you for many years, you need to take care of them. For maximum heat dissipation, radiators should be kept clean. A simple wipe of dust from the surface of pipelines and radiators will allow you to keep them for many years. Batteries located in the kitchen should be periodically wiped with special detergents that will remove grease from the surface. In a non-heated period, it is recommended to rinse the batteries with water at least once, which will remove dust and dirt from hard-to-reach places.

After the end of the heating season, radiators and heating pipes should be carefully checked. On their surface there should be no traces of rust and chips. If there are any, then you should get rid of them. Such simple procedures will save your pipes for many years, ensure their reliability and durability.

Before painting batteries, carefully study the technology by which painting should be carried out. This will not only correctly paint the radiator and pipeline, but also ensure the reliability and attractive appearance of the surface.

Subtleties of the processing process

The application of soil to metal pipes and radiators is similar to that of other surfaces, but has certain properties:

- The surface is thoroughly cleaned from a layer of outdated paint and rust to a shine. For this purpose, it is better to use metal brushes. Cleaning inaccessible places of heating radiators, you can take metal brushes.

- If the layer of outdated paint leaves badly, then it is necessary to use a specialized softening solution, which is applied to pipes and radiators and covered with a film. After waiting a little time, the extra layers can be easily removed with a spatula.

- Then, the work area must be perfectly cleaned with a “sandpaper”, gradually changing its grain size to a much smaller one, and cleaning the metal to a shine and smoothness.

- Wash and let dry.

- Treat dried products with white spirit or any other suitable degreaser and dry.

The next step is to start applying the primer mixture. Depending on the size of the surface and the composition of the primer, it is applied:

- By brush. The brush provides a more detailed finish on poor surfaces, but on large flat areas (for example, thin long pipes) it takes a long time to work with it and the material consumption is high.

- Rollers of various sizes. The use of small rollers in smaller areas significantly reduces the consumption of protection composition.

- Paint sprayer.

Priming takes place in several layers. The first is applied very thinly, filling small bumps and cracks.

After it sets, 1-3 more layers are added as needed. The consumption of the primer mixture will decrease with each new layer.

The processing process is best carried out on products at home temperature. Heating batteries should be turned off for a certain period of time. This will give the same drying, improve the quality of work and reduce the consumption of the primer mixture.

On a surface finished in this way, paintwork with a decorative effect will lie very evenly, without streaks and streaks, providing the pipe with protection from moisture and temperature changes and significantly extending its service life. If you take the time and correctly carry out all the processing steps before painting, then the water meter assembly and the heating system will not require replacement for a long time.

A pipe primer is a very important processing step, which makes it possible to perfectly fix the future coating and guarantee protection against rust. The primer mixture is selected depending on the purpose of the pipe, be it a radiator or a gas pipeline.

Tools and materials for painting radiators

To paint radiators, you will need the following inventory:

- coloring composition of a suitable color;

- suitable soil;

- solvent;

- brushes with a straight and curved handle;

- paper or polyethylene to protect the flooring;

- respirator;

- glasses;

- gloves.

This is interesting: Primer for the walls of the bathroom and bath - we describe in order

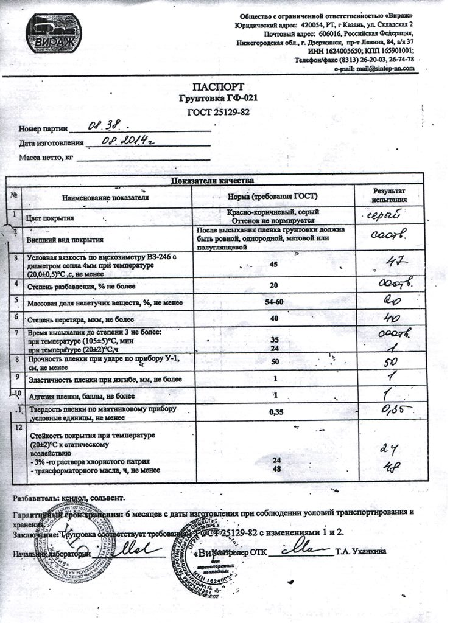

Soil gf 021 21. characteristics, application experience, review. primer

Price. At first, I considered this soil as an inexpensive substitute for imported universal soils, which had sharply risen in price in 2009. Soil GF 21 showed its high quality, and I began to use it everywhere.

Relatively harmless. You can work with soil in a well-ventilated area without special protective equipment.

The thinner is white spirit. Available, not very toxic, inexpensive chemical.

The soil is very durable. After drying, it does not wear out at all, just like enamel. I painted the handle of a sledgehammer with it for an experiment. For two years, the soil has not been erased.

Almost any alkyd, acrylic, latex, nitro paint and enamel, universal adhesives, PVA glue, wallpaper adhesives, as well as acrylic and acrylate putties, for example, universal acrylic putty, fit well on this primer. The plastered wall primed with this primer was pasted over with wallpaper using starch glue. Adhered perfectly and is still holding up (already a year).

Used primer GF-21 for priming knots. Was pleased with the result.For three years, the knots did not show through.

Although this primer is positioned as a primer for metal, it fits well on plastic, laminated surfaces, concrete, plaster, wood, chipboard, fiberboard, previously painted with almost any paint and enamel surface.

You must be aware that the primer is intended for application to metal during subsequent painting with alkyd paints and enamels. Using it for other purposes is non-standard. Therefore, no one can give guarantees that it is applicable. Try it on a small piece of material first.

Accidentally left drops and spots of soil, even after complete drying, can be washed off with R-4 solvent. We can also wash the brush with this solvent, even if it is completely dry.

The characteristics of the primer allow it to be applied at low, even negative temperatures. And although in the cold it is very poorly applied and dries, but, in extreme cases, you can paint even at minus 20. I tried it - it worked.

Disadvantages of soil GF 21 (GF-21)

Takes a long time to get up. Manufacturers' statements that the GF 021 primer dries out in two hours at a temperature of 15 degrees do not correspond to reality.

Some paints curl upon contact with this primer, if the GF-21 primer is not completely dry.

White spirit solvent is a flammable and harmful substance, although of a low degree of danger. Read about working with flammable liquids, and poisonous liquids in the home. In any case, the room should be well ventilated until the soil is completely dry.

Primer GF 21 does not penetrate deep into the material on which it is applied, and cannot be used to fix crumbling and loose materials. To do this, use penetrating acrylic primers.

It is very difficult to buy white GF-21 primer in Russia for unknown reasons. Colleagues say that in Ukraine there is a whole range of primer GF 021 - gray, red, white, colorless. The price does not depend on the color. It is very difficult to buy white from us. Sellers ask for twice as much for it than for gray or red-brown. The cost of its production does not depend on color, which means that the price should not depend. Do not buy GF 021 primer, regardless of color, for more than 1,500 rubles per 20 liters. We will not encourage greedy and hucksters. I have one reliable supplier of white soil, if anyone is interested, write, I will throw off the address. But his ground is more colorless than white.

If you apply the primer with a roller or brush, then it is not possible to completely clean them after working with the primer. So we store them wrapped in a rag moistened with white spirit, and on top we wrap it very carefully with polyethylene so as to exclude air access so that the rag and the tool do not dry out. But you can still store it like that for only a few days. As experience has shown, they still dry out in a week. The brush can be washed with R-4 solvent, and the matting on the roller will have to be replaced.

It is impossible to moisten with this primer a construction bandage made of non-woven synthetic material that has not yet been completely glued to the surface. The bandage stretches and bubbles.

Summary

I use this primer wherever it is necessary to prime without impregnating the surface. The final score is very satisfied. The soil successfully replaced imported analogues when their prices rose.

(more…) (top)

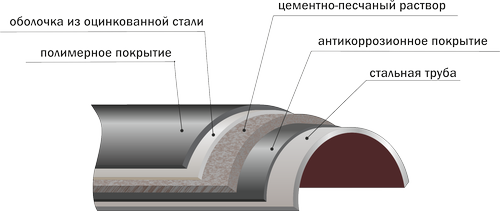

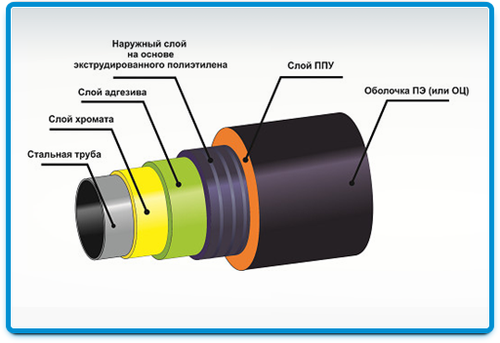

Features of using a protective coating Urizol

Steel pipe with anti-corrosion coating Urizol is most often used in pipelines intended for the transportation of oil and its derivatives, natural gas. The composition necessarily processes all elements: nodes, fittings, connection details. Urizol treatment helps protect system elements from various types of corrosion - atmospheric and underground.

The unequivocal advantage of this protective composition is the ease of application.A special spray device is used to treat tubular elements, and as soon as the substance hits the metal surface, a chemical reaction will begin, as a result of which a sufficiently thick and reliable protective coating is formed on the metal.

The mandatory anti-corrosion treatment of pipeline parts is prescribed in SNiP 2.03.11-85.

How is the anti-corrosion treatment process carried out?

To begin with, we note that the anti-corrosion treatment of pipe surfaces is not an easy task, requiring compliance with many nuances. Preparations for work begin with a visual inspection of all elements of the system that need to be coated with a protective compound.

Attention! The condition of pipes and other elements that need protection against rust should be assessed exclusively by specialists. Professionals will accurately determine the extent to which the surface is damaged, as well as make an estimate for the work and purchase of the necessary materials.

In choosing an anti-corrosion composition, specialists will start from many factors: the temperature regime at which the system is operated, the material for the manufacture of elements, the specifics of the use of the pipeline.

Before the process of directly applying the composition to the surface, it must be carefully cleaned. All types of dirt, old paint must be removed from it. Next, the surface of the treated structure is degreased with a special hydrocarbon-based solvent.

Next, proceed to the processing of the protective composition. Different compositions are applied under different conditions, and are also prepared in the right proportions immediately before the application procedure. The protective layer is applied in several layers, and at the same time, each previous layer of the coating must dry.

After the required number of layers is applied, a control inspection of the pipeline and its elements is carried out. To determine the quality of the work done, special equipment is used (photo) and upon inspection, an act is drawn up confirming the performance of the work.

Temperature ranges

At what temperature is the use of special, heat-resistant primers required? Let's analyze the coating requirements for different operating temperatures.

In this temperature range fit, in particular, elements of autonomous heating systems. Typical for them, the temperature difference between supply and return is 70/50C, which gives no more than +60C on the surface of heating devices.

At temperatures from 0 to +60, general-purpose paints and primers can be safely used. Subject to the painting technology (that is, with high-quality cleaning of the surface and the conformity of the soil to the type of paint and varnish material), you can not be afraid of delamination or fading of the paint.

General purpose paints can be used in an autonomous heating circuit.

The only significant difference from the previous scenario is the need to use paints with persistent pigments. The binder and primer remain the same as before: all popular types of paints tolerate prolonged heating without destruction.

Practical consequence: cheap and very common GF-021 is a quite suitable primer for heating radiators both in autonomous heating circuits and in central heating systems.

And here comes the finest hour of heat-resistant soils. If the instruction for the use of temperature-resistant paintwork materials contains an indication of the need for priming, you will have to select special compounds that tolerate prolonged heating and retain their properties over the entire range of operating temperatures.

Over 300C

All paints intended for temperatures above +300 degrees are applied without preliminary priming, directly on a cleaned and degreased surface. A layer of soil at such temperatures will only increase the likelihood of delamination of the coating.

Particularly heat-resistant paints are applied directly to the metal base.

Nuance: we are talking about metal surfaces. Reinforcing primers for plaster or putty for brick fireplaces and stoves are also used at higher temperatures.

The main components of the primer GF 021

The basis for the manufacture of primer material GF 021 is alkyd, more precisely, phthalic varnish, which has an unsurpassed ability to adhere to almost any dry surface. In addition to phthalic varnish, the composition of the primer material includes special additives:

- Desiccant and anti-corrosion additives. Most often it is phosphoric acid and wood processing products;

- Several metal oxides are used as a pigment, including iron oxide and zinc oxide. It is to these powders and additives that the red-brown primer gf 021 owes its color;

- Thinners and solvents. When preparing the primer GF 021 for application, it is necessary to adjust the viscosity of the material, so the manufacturer allows the addition of no more than 20% of the P649 or P650 solvent.

Under industrial conditions, a primer solvent G 021 is prepared by mixing a solvent or xylene with white spirit in a ratio of 50:50. During long-term storage, the primer, like any enamel paint, delaminates into layers, and a thin varnish film forms on the surface. It can be used for auxiliary work, for example, priming garden tools. The film is removed into a clean, dry container and a small amount of P649 is added. It is not recommended to use such material for priming the surfaces of critical metal parts.

Important! It is worth noting that the original primer G 021 is available in only one color, red-brown

Any other colors, gray or white, are used to produce an analogue of the G 021 primer. In such materials, instead of the original phthalic varnish, petroleum polymer varnishes and drying oils are used. Except by color, it is almost impossible to distinguish two different materials under the same G 021 index, therefore, originality can only be confirmed on the basis of a certificate of conformity for the GF 021 primer.

The developer and manufacturer of the primer material must appear in the appropriate columns of the document. If desired, the certificate for the primer GF 021 can be downloaded from the site and its authenticity can be checked. You can also use primer G 021 gray, but in theory, it does not have anti-corrosion properties and oxidation resistance, like a red-brown primer.

This is interesting: Features and rules for applying the primer GF-0119

Temperature norms

The next question that arises among consumers is: under what temperature conditions are heat-resistant primers used so that they do not lose their properties? In this case, it is necessary to familiarize yourself with the requirements that are encountered when painting surfaces with different temperature conditions:

Temperature indicators do not exceed 600 ° C. By all standards, this temperature is inherent in objects that are used in the arrangement of autonomous heating. Permissible deviations in the temperature regime of radiators reaches from 500 to 700°C. In this case, it is allowed to use a conventional primer that does not have the property of heat resistance. At the same time, you should not be afraid that defects such as burnout and delamination of paint will subsequently occur.

Heating devices up to 1000°C. In these cases, it is also possible to use materials that do not differ in special thermal characteristics.

But when choosing a paint, we pay attention to the degree of stability of the pigments. At this temperature, the process of burning out the color is possible.

Over 1000°С to 3000°С

At such temperatures, one should think about the characteristics of the material in terms of thermal stability.Especially if the need to perform the priming process is spelled out in the instructions for the paint composition. At the same time, it is necessary to purchase exactly the primer that will not lose its qualities when the surface is heated to 3000 ° C.

The temperature exceeds 3000°C. In such conditions, special pigments are used, adapted specifically for such conditions. In this case, the use of a primer can spoil the situation. In this mode of operation, the applied primer layer can provoke peeling of the paint.

The choice of heat-resistant primer depends on the heating temperature of the product to be painted.

Popular brands of compounds

The production of pipes with anti-corrosion coating is the main activity of many modern industrial enterprises. For the protective treatment of products, manufacturers use a variety of compositions. Let's get acquainted with the most popular brands:

- "Nerzhamet" is a special anti-corrosion enamel that is applied to clean surfaces of newly manufactured products, but it is also possible to use the substance in the repair of pipelines and treat elements already covered with rust;

- "Nerzhaluks" - this coloring composition is valued by professionals for a high degree of adhesion and the possibility of application on different surfaces. For example, it can treat aluminum, brass, titanium, copper and zinc surfaces;

- Paint "Cycrol" is used for processing pipes made of galvanized steel;

- The composition with the name "Phosphorgrunt" is used in the process of anti-corrosion treatment of products made of ferrous and non-ferrous metals.

There are also compounds with silver, plastic, modifiers that convert rust.

For the protective treatment of pipeline elements, the following compositions are more often used: Nerzhakhim, Polyurethol, Epostat, Zinconol and Urizol. Let's talk about the advantages of the latter type of anti-corrosion protection in more detail.

Analysis of market offers

What are heat resistant soils? Let's take a look at a few offers of the modern market as examples.

Alkyd heat-resistant primer is produced according to TU-2312-030-00206919-2002 and is a suspension of pigments, antioxidants and surfactants in glyptal varnish.

What can be said about its properties and features?

- The primer is designed for steel, magnesium and aluminum surfaces. In particular, GF-031 is used in civil aviation - for applying coatings to aircraft bodies.

- The maximum operating temperature is +200C.

It is curious: the reservation about the civil aircraft industry is not accidental. The outer skin of the fighter-interceptor at a speed of about 2.5M (2.5 times faster than the speed of sound) is heated up to 300-500 degrees due to friction with the air.

- Solvent - solvent; they also dilute the soil during thickening.

- The method of application is by spraying or using a hand-held painting tool.

- The thickness of a single-layer coating after drying should be 15-20 microns. The primer consumption per one layer is 60-80 g/m2.

- TU stipulates the color of the applied pigments. Produced in accordance with the specifications GF-031 - yellow.

Phosphosoil

The name is a trademark of the Moscow company KrasCo. As you might guess, we have the so-called phosphating primer.

It reacts with the base and forms a thin layer of insoluble phosphates that improve adhesion and prevent corrosion.

Chemical composition of the phosphating agent.

- A mixture of acrylic, formaldehyde and epoxy resins is used as a binder. It is logical to assume that the primer is intended exclusively for open air or industrial conditions: formaldehydes in a residential area will clearly be superfluous.

- The operating temperature range is up to +300 degrees.

- Due to its composition, the primer can be used with all types of heat-resistant and conventional paints.It can be used not only on metal: the manufacturer allows the use of the final coating on fiberglass or ceramics to improve adhesion.

- The primer can be applied not only to previously cleaned, but also to a rusty surface.

However: when applying a primer with your own hands, it is still worthwhile to first remove the sheet and loose rust. Phosphating composition may change its chemical properties, but it will not change the spatial structure of the fragile oxide.

- Phosphosoil is diluted with acetone or toluene.

- Thanks to organic solvents, the composition can be applied at low temperatures down to -10C. Drying time of a single-layer coating at +20 - no more than 30 minutes.

- The average primer consumption is 70-90 grams per square meter.

In the photo - Phosphogrund packaging.

This heat-resistant primer for stoves and fireplaces impresses with its heat resistance. The operating temperature of 1200 degrees is declared for it, which, you see, is very impressive against the background of the previously described solutions. The composition of the water-dispersion primer is not disclosed by dealers; however, the colossal heat resistance suggests that the main binder in G-77 is heat-resistant silicone.

Grounding has two purposes:

- Improving the adhesion of putties and plasters.

Useful: at high operating temperatures, you can forget about the usual gypsum and cement mixtures. A mixture of clay and sand is used to finish stoves and fireplaces; often skimmed milk is added as a binder: the casein contained in it (milk protein, also known as low-fat cottage cheese), even with temperature denaturation, retains excellent binding properties.

Plastering the oven with clay mortar.

- Strengthening the base. The resins contained in the soil penetrate into its pores and bind the surface layer of the material into a single whole.

What other information about the primer is available to a potential buyer?

- Application is quite traditional - with a roller or brush in two layers.

- Drying time of one layer - no more than an hour. At least two hours must pass before further finishing on the primed surface.

- Priming is carried out at a positive temperature. Water base, remember?

- Consumption is no more than 400 milliliters of soil per square meter of surface.

Heat-resistant penetrating G-77 is supplied in 1 kg plastic cans.

Problems in working with a primer, what is the cause and how to fix it

The primer, due to its characteristics, when applied, can cause a lot of trouble for an inexperienced builder. To avoid unpleasant situations, you should be aware of the main problems that may arise in the process of work, as well as have information on how they can be eliminated.

In various forums, most consumers complained about the lack of “seizing” of the coating even after the drying time declared by the manufacturer. The problem may lie in various factors. First of all, you need to determine whether a large layer has been applied. If its thickness exceeds the norms specified in the instructions, even 2 days may not be enough for complete drying.

Also remember that a certain interval should be maintained between milkings. This is the only way to create a good protective coating with high adhesion properties. The material may also harden poorly when creating an uneven layer. In this case, drying will be observed partially in different areas of the surface.

Let's analyze another problem - the primer has dried out, paint has been applied on top, but in some places it begins to peel off. Here, most likely, poor-quality preparation of the base was carried out - the removal of old paint, oil stains, and rust. All this will adversely affect the adhesion of the base to the primer and topcoat, respectively.

Many make the mistake of not using a degreaser in the process of preparing the base. This composition allows you to eliminate greasy stains and components that provoke the formation of rust. It also increases the level of adhesion of the primer to the surface.

VIDEO: Secrets of materials and tips from a professional

Primer gf-021 gray and red-brown for metal and primer for pipes

Soil GF-021 looks like a liquid-plastic mass, which has a specific smell of solvents used in the production process, regulating additives and a desiccant used to accelerate drying. The composition is a suspension of glyptal or alkyd varnishes and anti-corrosion pigments with additives.

The primer GF-021 has found wide application in outdoor work for the preliminary protective coating of wood, metal or other products with which it has good adhesion, allowing for durable, stable pre-painting anti-corrosion treatment. Before priming, especially if it is done using an airbrush, it is required to dilute GF-021 to reduce the viscosity level. In this case, xylene GOST 9949 or 9410, solvent GOST 10214 or 1928, or any of them together with white spirit (nefras C4 155/200) GOST 3134 are used as a diluent in the recommended ratio of 1: 1, but the proportion of solvents should not exceed a quarter of the mass of the primer itself. Turpentine can be used; when painting in an electrostatic field, RE-4V thinner or its analogue RE-3V should be used. The surfaces to be treated are preliminarily completely cleaned of dirt, dust and old paintwork, traces of possible corrosion are removed, thoroughly degreased and dried. The applied coating retains its declared characteristics in the temperature range from forty-five degrees of frost to sixty degrees Celsius, does not react with sea or fresh water, and is not affected by mineral oils and detergents.

The GF-021 primer is applied by roller, brush, spraying or vacuumization, immersion or other method at an ambient temperature of at least five degrees and not more than twenty degrees Celsius, preferably in two layers. The time required for the first layer to dry at +20°C is an astronomical day. The same conditions must be observed before working with the primer, if it was at sub-zero temperatures during storage or transportation.

It is used as a base for paints and varnishes such as PF, GF, EF, FL and the like, but can also be used as an independent coating. It is produced mainly in accordance with GOST 25129-82 in red-brownish color, or according to TU in light gray tones.

Structures treated with a primer are distinguished by a smooth matte finish or have a dull gloss, they are excellently polished without “loading” abrasive materials. Excellent strength and quality characteristics are primarily due to the use of high-quality high-molecular copolymers in the manufacturing process, and the relatively low cost of GF-021 is due to their domestic origin.

The primer should not be in the area of direct sunlight, the container must be hermetically sealed, limiting the ingress of air and precipitation. When working with it, you should use personal protective equipment that excludes the composition from getting into the eyes and open areas of the body. Painting work is recommended to be carried out either outdoors or in a well-ventilated area, away from possible sources of ignition. It must be remembered that the soil GF-021 is toxic and requires specialized disposal, it is categorically excluded to drain residues into the general sewer system.

CONSUMABLES AND RELATED PRODUCTS:

Paint brushes

flat and fluted

Overalls and

household inventory

This is interesting: Selection and application of a primer on foam and gas blocks: we study from all sides

Some application features

Painting is best done under the supervision of a specialist. In order to understand how to paint pipes correctly, you need to learn about some of the "pitfalls" and features of this process:

- If the application of the material is planned in the winter, i.e. when the heating system is operating at full capacity, it is necessary to check whether the material you have chosen meets the conditions of application in terms of temperature. There are a number of paints that should only be applied when the heating is off. If you apply this type of paint to a hot pipe, it may dry too quickly.

- It is necessary to prepare pipes for heating before painting them. Rid their surface of grease and dust. Coloring should be done after processing their surface with sandpaper.

Remember that metal does not tend to absorb enamel intended for high temperatures, so you need to take a small amount of it on the brush, carefully blending over the radiator

Painting pipes with a brush.

Preparation and application

At the preparatory stage, the agent itself and the surface are brought to the desired state.

Foundation preparation:

- The base previously covered with varnish or paint is cleaned.

- Sanded with grinding hand tools or a machine.

- Degrease. To do this, you need a solvent and a rag.

- Treated with a rust converter.

This stage is mandatory when priming structures made of ferrous metals, on which traces of corrosion are already showing. After being applied to a rusty base, the converter transforms rust into a film in 2-6 hours. The conversion time depends on the humidity level and room temperature. The product is applied with a brush, spray gun, roller and other tools.

The dissolution of the agent brings it to a working viscous state. Thoroughly mixed primer GF 021 is applied to the already cleaned and dry surface with a construction roller or sprayer. In the last option, make sure that there is no surface film on the primer, due to which the atomizer is clogged. Otherwise, it is removed.

For a primer, use no more than 25% of the solvent by weight of the agent. The primer is applied to the base in a special temperature regime - above + 5 ° С. It is also possible to apply a primer to the base using a sprayer in an electric field. In this case, RE-4V substance is used as a solvent.

Conclusion

Today on the market there is a very large number of offers of the primer GF 021 under its own trade names - Zebra, Lacra, Tex, Primer. Almost every manufacturer produces material according to its own recipes, with a large deviation from the original. Often modern toluene-containing substances are used as modifiers. Such a primer penetrates into the smallest pores of the surface, has good hiding power and even has a shine.

This is interesting: Surface treatment with a waterproofing primer: we tell in detail