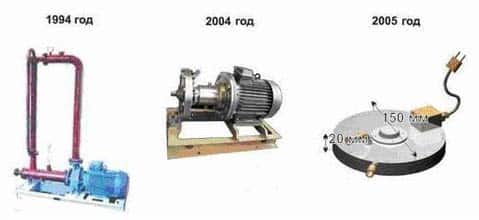

A bit of history

The vortex heat generator is considered a promising and innovative development. Meanwhile, the technology is not new, since almost 100 years ago, scientists were thinking about how to apply the phenomenon of cavitation.

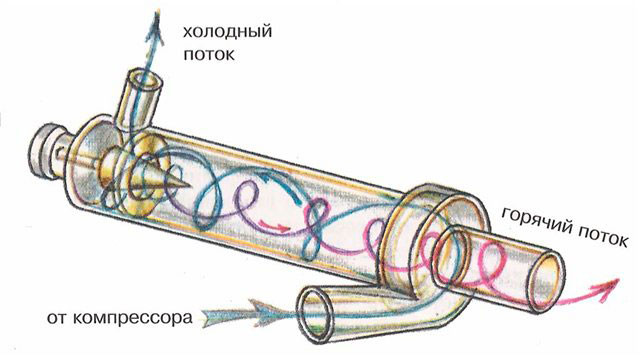

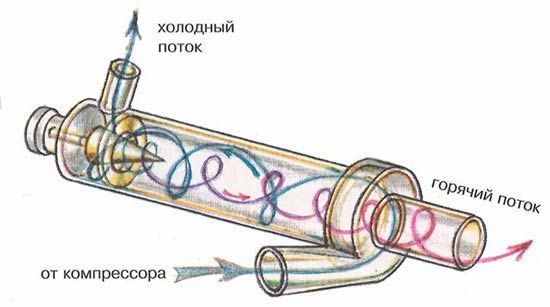

The first operating pilot plant, the so-called "vortex tube", was manufactured and patented by the French engineer Joseph Rank in 1934.

Rank was the first to notice that the air temperature at the entrance to the cyclone (air cleaner) differs from the temperature of the same air jet at the exit. However, at the initial stages of bench tests, the vortex tube was tested not for heating efficiency, but, on the contrary, for air jet cooling efficiency.

The technology received a new development in the 60s of the twentieth century, when Soviet scientists guessed to improve the Rank tube by launching liquid into it instead of an air jet.

Due to the greater, in comparison with air, density of the liquid medium, the temperature of the liquid, when passing through the vortex tube, changed more intensively. As a result, it was experimentally established that the liquid medium, passing through the improved Rank pipe, warmed up anomalously quickly with an energy conversion coefficient of 100%!

Unfortunately, there was no need for cheap sources of thermal energy at that time, and the technology did not find practical application. The first operating cavitation installations designed to heat a liquid medium appeared only in the mid-90s of the twentieth century.

A series of energy crises and, as a result, an increasing interest in alternative energy sources caused the resumption of work on efficient converters of the energy of the movement of a water jet into heat. As a result, today you can buy an installation of the required power and use it in most heating systems.

Operating principle

Cavitation allows not to give heat to water, but to extract heat from moving water, while heating it to significant temperatures.

The device of operating samples of vortex heat generators is outwardly simple. We can see a massive engine to which a cylindrical "snail" device is connected.

"Snail" is a modified version of Rank's pipe. Due to the characteristic shape, the intensity of cavitation processes in the cavity of the "snail" is much higher in comparison with the vortex tube.

In the cavity of the "cochlea" there is a disk activator - a disk with a special perforation. When the disc rotates, the liquid medium in the “snail” is activated, due to which cavitation processes occur:

-

The electric motor turns the disk activator

. The disk activator is the most important element in the design of the heat generator and is connected to the electric motor via a direct shaft or via a belt drive. When the device is turned on in operating mode, the engine transmits torque to the activator; -

The activator spins the liquid medium

. The activator is designed in such a way that the liquid medium, getting into the disk cavity, twists and acquires kinetic energy; -

Converting mechanical energy into heat

. Leaving the activator, the liquid medium loses its acceleration and, as a result of sharp braking, the cavitation effect occurs. As a result, the kinetic energy heats the liquid medium up to + 95 °C, and the mechanical energy becomes thermal.

Pump installation

Now it will be necessary to pick up a water pump. Now in specialized stores you can buy a unit of any modification and power

What should you pay attention to?

- The pump must be centrifugal.

- Your engine will be able to spin it.

Install the pump on the frame, if you need to make more crossbars, then make them either from a corner or from strip iron of the same thickness as the corner. The coupling is hardly possible to make without a lathe. So you have to order it somewhere.

Scheme of a hydrovortex heat generator.

Potapov's vortex heat generator consists of a body made in the form of a closed cylinder. At its ends there must be through holes and branch pipes for connection to the heating system. The secret of the design is inside the cylinder. A jet should be located behind the inlet. Its hole is selected individually for this device, but it is desirable that it be half the size of a quarter of the diameter of the pipe body. If you do less, then the pump will not be able to pass water through this hole and will start to heat up itself. In addition, internal parts will begin to break down intensively due to the phenomenon of cavitation.

Tools: angle grinder or hacksaw, welding machine, electric drill, adjustable wrench.

Materials: thick metal pipe, electrodes, drills, 2 threaded pipes, couplings.

- Cut a piece of thick pipe with a diameter of 100 mm and a length of 500-600 mm. Make an external groove on it about 20-25 mm and half the thickness of the pipe. Cut the thread.

- Make two rings 50 mm long from the same pipe diameter. Cut an internal thread on one side of each half ring.

- From the same thickness of flat metal as the pipe, make covers and weld them on the side of the rings where there is no thread.

- Make a central hole in the covers: one for the diameter of the jet, and the other for the diameter of the pipe. On the inside of the cover, where the jet is located, make a chamfer with a larger diameter drill. The result should be a nozzle.

- Connect the heat generator to the system. Attach the pipe where the nozzle is located to the pump in the hole from which water is supplied under pressure. Connect the inlet of the heating system to the second branch pipe. Connect the system outlet to the pump inlet.

The water under pressure that the pump will create will pass through the nozzle of the vortex heat generator, which you make yourself. In the chamber, it will begin to heat up due to intensive mixing. Then feed it into the heating system. To regulate the temperature, place a ball lock behind the nozzle. Cover it, and the vortex heat generator will drive water inside the housing longer, which means that the temperature in it will begin to rise. This is how the heater works.

Working principle of induction heating

In the work of the induction heater, the energy of the electromagnetic field is used, which the heated object absorbs and converts into heat. To generate a magnetic field, an inductor is used, that is, a multi-turn cylindrical coil. Passing through this inductor, an alternating electric current creates an alternating magnetic field around the coil.

A homemade inventory heater allows you to heat up quickly and to very high temperatures. With the help of such devices, you can not only heat water, but even melt various metals.

If a heated object is placed inside or near the inductor, it will be pierced by the flux of the magnetic induction vector, which is constantly changing in time. In this case, an electric field arises, the lines of which are located perpendicular to the direction of the magnetic flux and move in a vicious circle. Thanks to these vortex flows, electrical energy is transformed into thermal energy and the object heats up.

Thus, the electrical energy of the inductor is transferred to the object without the use of contacts, as happens in resistance furnaces. As a result, thermal energy is spent more efficiently, and the heating rate increases markedly.This principle is widely used in the field of metal processing: its melting, forging, brazing, etc. With no less success, a vortex induction heater can be used to heat water.

Operating principle

There are various explanations for the causes of the vortex effect of rotation in the absence of motion and magnetic fields.

In this case, the gas acts as a body of revolution, due to its rapid movement inside the device. This principle of operation differs from the generally accepted standard, where cold and hot air flow separately, because. when the flows are combined, according to the laws of physics, different pressures are formed, which in our case causes the vortex motion of gases.

Due to the presence of centrifugal force, the outlet air temperature is much higher than its inlet temperature, which allows the use of devices both for heat generation and for efficient cooling.

There is another theory of the principle of operation of the heat generator, due to the fact that both vortices rotate with the same angular velocity and direction, the internal vortex angle loses its angular momentum. The decrease in torque is transferred to the kinetic energy to the external vortex, resulting in the formation of separated flows of hot and cold gas. This principle of operation is a complete analog of the Peltier effect, in which the device uses electrical pressure (voltage) energy to move heat to one side of the dissimilar metal junction, as a result of which the other side is cooled and the consumed energy is returned to the source.

Advantages of a vortex heat generator

:

- Provides significant (up to 200 ºС) temperature difference between "cold" and "hot" gas, works even at low inlet pressure;

- Works with efficiency up to 92%, does not need forced cooling;

- Converts the entire inlet flow into one cooling flow. Due to this, the possibility of overheating of heating systems is practically excluded.

- The energy generated in the vortex tube is used as a single flow, which contributes to the efficient heating of natural gas with minimal heat loss;

- Provides efficient separation of swirl temperature of inlet gas at atmospheric pressure and outlet gas at negative pressure.

Such alternative heating, at almost zero volt cost, perfectly heats a room from 100 square meters (depending on modification). Main cons

: this is a high cost and rare application in practice.

Scope of application

| Illustration | Description of the scope |

|

Heating . Equipment that converts the mechanical energy of water movement into heat is successfully used for heating various buildings, from small private buildings to large industrial facilities.

By the way, on the territory of Russia today one can count at least ten settlements where centralized heating is provided not by traditional boiler houses, but by gravitational generators. |

|

Domestic hot water heating . The heat generator, when connected to the network, heats the water very quickly. Therefore, such equipment can be used to heat water in an autonomous water supply system, in swimming pools, baths, laundries, etc. |

|

Mixing immiscible liquids . In laboratory conditions, cavitation units can be used for high-quality mixing of liquid media with different densities until a homogeneous consistency is obtained. |

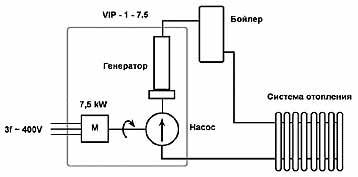

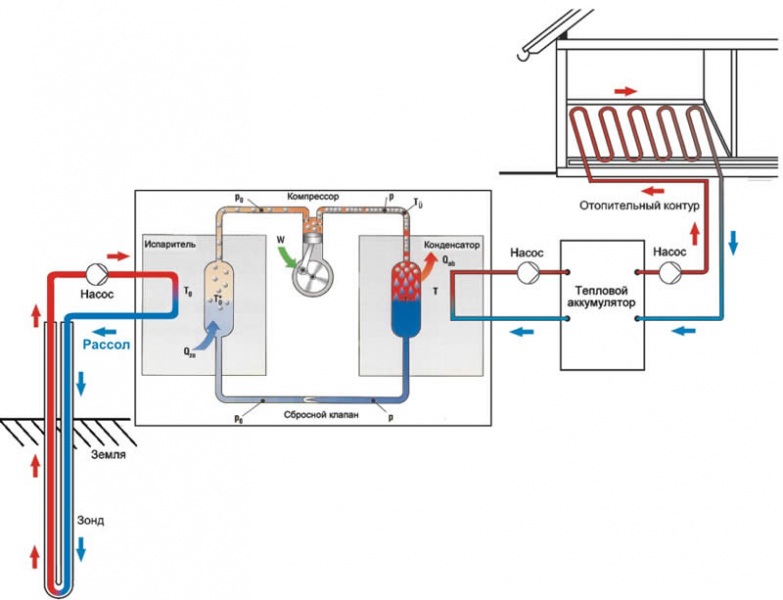

Integration into the heating system of a private house

In order to use a heat generator in a heating system, it must be introduced into it. How to do it right? In fact, there is nothing difficult in this.

In front of the generator (marked with the number 2 in the figure), a centrifugal pump is installed (in the figure - 1), which will supply water with a pressure of up to 6 atmospheres.After the generator, an expansion tank is installed (in the figure - 6) and shutoff valves.

Advantages of using cavitation heat generators

| Advantages of a vortex source of alternative energy | |

|

economy . Due to the efficient consumption of electricity and high efficiency, the heat generator is more economical in comparison with other types of heating equipment. |

|

Small dimensions compared to conventional heating equipment of similar power . A stationary generator, suitable for heating a small house, is twice as compact as a modern gas boiler.

If you install a heat generator in a conventional boiler room instead of a solid fuel boiler, there will be a lot of free space. |

|

Light installation weight |

|

Simple design . The cavitation-type heat generator is so simple that there is nothing to break in it.

The device has a small number of mechanically moving elements, and there is no complex electronics in principle. Therefore, the likelihood of a breakdown of the device, in comparison with gas or even solid fuel boilers, is minimal. |

|

No need for additional modifications . The heat generator can be integrated into an existing heating system. That is, it will not be necessary to change the diameter of the pipes or their location. |

|

No need for water treatment . If a running water filter is needed for the normal operation of a gas boiler, then by installing a cavitation heater, you can not be afraid of blockages.

Due to specific processes in the working chamber of the generator, blockages and scale do not appear on the walls. |

|

The operation of the equipment does not require constant monitoring . If you need to look after solid fuel boilers, then the cavitation heater works offline.

The operating instructions for the device are simple - just turn on the engine in the network and, if necessary, turn it off. |

|

Environmental friendliness . Cavitation installations do not affect the ecosystem in any way, because the only energy-consuming component is the electric motor. |

How to make a heat generator with your own hands

Vortex heat generators are very complex devices; in practice, Potapov's automatic WTG can be made, the scheme of which is suitable for both home and industrial work.

This is how the Potapov mechanical heat generator (93% efficiency) appeared, the diagram of which is shown in the figure. Despite the fact that Nikolai Petrakov was the first to receive a patent, it is Potapov's device that is particularly popular with home craftsmen.

This diagram shows the design of the vortex generator. The mixing pipe 1 is connected to the pressure pump by a flange, which in turn supplies liquid with a pressure of 4 to 6 atmospheres. When water enters the collector, in drawing 2, a vortex is formed and it is fed into a special vortex tube (3), which is designed so that the length is 10 times greater than the diameter. The vortex of water moves along the spiral pipe near the walls to the hot pipe. This end ends with bottom 4, in the center of which there is a special hole for hot water to exit.

To control the flow, a special braking device, or a water flow straightener 5, is located in front of the bottom, it consists of several rows of plates that are welded to the sleeve in the center. The sleeve is aligned with the tube 3. At the moment when the water moves through the pipe to the rectifier along the walls, a countercurrent flow is formed in the axial section. Here, the water moves towards the fitting 6, which is cut into the wall of the volute and the fluid supply pipe. Here the manufacturer installed another 7 disc flow straightener to control the flow of cold water.If heat comes out of the liquid, then it is directed through a special bypass 8 to the hot end 9, where water is mixed with water heated by a mixer 5.

Directly from the hot water pipe, the liquid enters the radiators, after which, making a “circle”, it returns to the coolant for reheating. Further, the source heats the liquid, the pump repeats the circle.

According to this theory, there are even modifications of the heat generator for mass production of low pressure. Unfortunately, projects are good only on paper, few people really use them, especially considering that the calculation is carried out using the Virial theorem, which must take into account the energy of the Sun (a non-constant value) and the centrifugal force in the pipe.

The formula is as follows:

Epot \u003d - 2 Ekin

Where Ekin =mV2/2 is the kinetic motion of the Sun;

Mass of the planet - m, kg.

A household vortex-type heat generator for Potapov water can have the following technical characteristics:

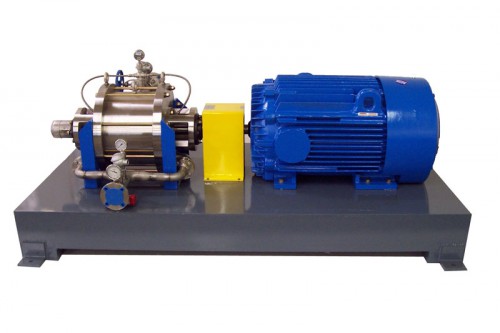

Rotary heat generator

This unit is a modernized centrifugal pump, or rather its casing, which will serve as a stator. You can not do without a working chamber and nozzles.

Inside the body of our hydrodynamic design is a flywheel as an impeller. There is a huge variety of rotary designs of heat generators. The simplest among them is the disk design.

The required number of holes are applied to the cylindrical surface of the rotor disk, which must have a certain diameter and depth. They are called "Griggs cells". It is worth noting that the size and number of drilled holes will vary depending on the caliber of the rotor disk and the speed of the electric motor shaft.

The body of such a heat source is most often made in the form of a hollow cylinder. In fact, this is an ordinary pipe with welded flanges at the ends. The gap between the inside of the housing and the flywheel will be very small (approximately 1.5-2 mm).

Direct heating of water will occur in this gap. The heating of the liquid is obtained due to its friction on the surface of the rotor and housing at the same time, while the flywheel disk moves almost at maximum speeds.

Cavitation (formation of bubbles) processes that occur in rotary cells have a great influence on the heating of the liquid.

A rotary heat generator is a modernized centrifugal pump, or rather its casing, which will serve as a stator

As a rule, the disk diameter in this type of heat generators is 300 mm, and the rotation speed of the hydraulic device is 3200 rpm. Depending on the size of the rotor, the speed will vary.

Analyzing the design of this installation, we can conclude that its service life is quite small. Due to the constant heating and abrasive action of the water, the gap gradually expands.

Description of the generator

There are different types of vortex heat generators, they are mainly distinguished by their shape. Previously, only tubular models were used, now round, asymmetric or oval ones are actively used. It should be noted that this small device can provide completely autonomous heating, and with the right approach, it can also provide hot water.

A vortex and hydrovortex heat generator is a mechanical device that separates the compressed gas from hot and cold streams. The air leaving the “hot” end can reach temperatures of 200 ° C, and from the cold end it can reach -50. It should be noted that the main advantage of such a generator is that this electrical device does not have moving parts, everything is permanently fixed.Pipes are most often made of stainless alloy steel, which perfectly resists high temperatures and external destructive factors (pressure, corrosion, shock loads).

The compressed gas is blown tangentially into the vortex chamber, after which it is accelerated to a high rotational speed. Due to the conical nozzle at the end of the outlet pipe, only the "incoming" part of the compressed gas is allowed to move in a given direction. The rest is forced to return to the inner vortex, which is smaller in diameter than the outer one.

Where are vortex heat generators used:

- in refrigeration units;

- To provide heating for residential buildings;

- For heating industrial premises;

It must be taken into account that the vortex gas and hydraulic generator has a lower efficiency than traditional air conditioning equipment. They are widely used for low cost spot cooling when compressed air is available from the local heating network.

Video: study of vortex heat generators

Price overview

Despite the relative simplicity, it is often easier to buy vortex cavitation heat generators than to assemble a home-made device on your own. Sale of new generation generators is carried out in many large cities of Russia, Ukraine, Belarus and Kazakhstan.

Consider the price list from open sources (mini-devices will be cheaper), how much the Mustafaev, Bolotov and Potapov generator costs:

The lowest price for a vortex energy heat generator of the brand Akoil, Vita, Graviton, Must, Euroalliance, Yusmar, NTK, in Izhevsk, for example, is about 700,000 rubles. When buying, be sure to check the device passport and quality certificates.

The purpose of the Potapov vortex heat generator (VTG), made by hand, is to get heat only with the help of an electric motor and a pump. Basically, this device is used as an economical heater.

Scheme of the device of the vortex heat system.

The easiest way is to make a vortex heat generator from standard parts. Any electric motor will work for this. The more powerful it is, the greater the volume of water will heat up to a given temperature.

Vortex motor insulation

Before putting the device into operation, it should be insulated. This is done after the construction of the casing. It is recommended to wrap the structure with thermal insulation. As a rule, material resistant to high temperatures is used for this purpose. The insulation layer is attached to the casing of the device with a wire. As thermal insulation, one of the following materials should be used:

Ready heat generator.

- glass wool;

- mineral wool;

- basalt wool.

As you can see from the list, almost any fibrous thermal insulation will do. A vortex induction heater, reviews of which can be found throughout the Runet, should be insulated with high quality. Otherwise, there is a risk that the device will give off more heat to the room where it is installed. Good to know: "Insulation of pipelines with mineral wool."

What features are endowed with long-burning wood stoves, read in this article.

At the end, some advice should be given. First - the surface of the product is recommended to be painted. This will protect it from corrosion. Secondly, it is desirable to make all the internal elements of the device thicker. This approach will increase their wear resistance and resistance to aggressive environments. Thirdly, it is worth making several spare covers. They must also have holes of the required diameter in the required places on the plane. This is necessary in order to achieve a higher efficiency of the unit by selection.

Ways to improve performance

Heat pump diagram.

There is heat loss in the pump. So Potapov's vortex heat generator in this version has a significant drawback.Therefore, it is logical to surround the submerged pump with a water jacket so that its heat also goes to useful heating.

Make the outer case of the entire device slightly larger than the diameter of the available pump. This can be either a finished pipe, which is desirable, or a parallelepiped made of sheet material. Its dimensions must be such that the pump, the coupling and the generator itself enter inside. The wall thickness must withstand the pressure in the system.

In order to reduce heat loss, make thermal insulation around the body of the device. You can protect it with a casing made of tin. As an insulator, use any heat-insulating material that can withstand the boiling point of the liquid.

- Assemble a compact device consisting of a submersible pump, a connecting pipe and a heat generator that you have assembled yourself.

- Decide on its dimensions and select a pipe of such a diameter, inside which all these mechanisms would easily fit.

- Make covers on one side and the other.

- Ensure the rigidity of the fastening of the internal mechanisms and the ability of the pump to pump water through itself from the resulting reservoir.

- Make an inlet and attach a pipe to it. The pump should, with its water intake, be located inside as close as possible to this hole.

Weld a flange on the opposite end of the pipe. With it, the cover will be attached through the rubber gasket. To make it easier to mount the insides, make a simple lightweight frame or skeleton. Inside it, assemble the device. Check the fit and tightness of all components. Insert into the case and close the lid.

Connect to consumers and check everything for tightness. If there are no leaks, turn on the pump. By opening and closing the valve, which is located at the outlet of the generator, adjust the temperature.

Vortex induction heaters - principle of operation

Eddy induction heaters work on the basis of the physical law that eddy currents arising (induced) by an alternating magnetic field heat the environment.

In theory. The hollow electromagnetic core with an induction coil is protected by a shielding shell from the environment. When voltage is applied through the terminal box, an alternating magnetic field is created that induces eddy currents in the core coil, which leads to heating of the metal systems of the heat exchange system. Heat enters the coolant circulation system, heating it. The temperature is set using a thermostat, and the thermostat automatically maintains the set temperature.

On practice. Vortex induction heaters are a tube wound with a wire to which alternating current is supplied. A cold coolant enters the pipe, more often from below, but it is also possible from the side. The eddy currents that the alternating current creates in the wires wrapped around the pipe heat the pipe and, consequently, heat the water.

Summing up

Now you know what a popular and sought-after source of alternative energy is. So, it will be easy for you to decide whether such equipment is suitable or not. I also recommend watching the video in this article.

Ready heat generator.

Depending on the type of device, the method of its manufacture also varies. It is worth familiarizing yourself with each type of device, studying the features of production, before starting work. An easy way to make a Ranke vortex tube with your own hands is to use ready-made elements. This will require any engine. At the same time, a device of greater power is able to heat more coolant, which will increase the productivity of the system.

For a successful construction, ready-made solutions must be found. You can create a vortex heat generator with your own hands, the drawings and diagrams of which will be available, without much difficulty.To carry out construction work, you will need the following tools:

- Bulgarian;

- iron corners;

- welding;

- drill and a set of several drills;

- fittings and a set of keys;

- primer, colorant and brushes.

It should be understood that rotary devices emit quite a lot of noise during operation. But compared to other devices, they are characterized by greater performance. Drawings and diagrams for the manufacture of a do-it-yourself vortex heat generator can be found everywhere. It should be understood that the work will be completed successfully only with full compliance with the production technology.