Floor insulation

Expanded clay - a natural natural material, can be used in bulk or poured with concrete

Expanded clay - a natural natural material, can be used in bulk or poured with concrete

Since the dressing room is used for changing clothes, people often stand barefoot on the floor. Warming is done to protect health and ensure comfort. For concrete surfaces, you can make a wooden coating, but it is better to perform full thermal insulation.

It is necessary to choose a material that is well breathable. Otherwise, condensation will accumulate, which can lead to the formation of harmful microorganisms. Expanded polystyrene, foam plastic, foam plastic, expanded perlite can act as a heater. Styrofoam and polystyrene are laid on the subfloor. Perlite must be mixed with cement mortar. Glass wool, expanded clay, gravel, boiler slag can also be used for insulation.

If the floor is insulated in the dressing room of a wooden bath, it is necessary to make a layer of waterproofing. The most popular type is ruberoid. On top of it, insulation is laid, and then again a layer of roofing material. The finish is made of wood

It is preliminary important to work out the wood with special compounds against the formation of fungus and mold. Glass wool and stone wool, polystyrene foam, polystyrene foam act as a heater for a wooden floor

A warm floor can be made throughout the bath. There are different options:

Warm water floor. Laid on a concrete foundation. This is a safe and effective method of heating, but you need to consider that you will have to install a boiler.

electric floor

With this method, it is important to carefully make waterproofing to ensure safe operation. Can be installed cable and film construction

In the first case, energy consumption increases, but the reliability of the system is higher. Films are harmless and have high strength. The cost of a film construction is higher than a cable one.

Ceiling insulation in the steam room of the bath

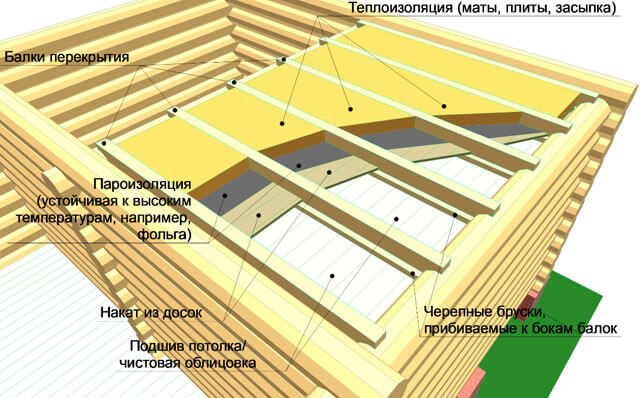

In the event that the bath has an attic or attic, then the insulation process should proceed as follows: the board is coated with clay with a layer of 20 cm. This material does a good job of retaining moisture. Wood chips must be filled in the cracks between the boards. If they are not available, then you can use any other material that provides good thermal insulation. For example, you can backfill with expanded clay. But the thickness of the layer of this material must be at least 200 mm.

Warming a bath without an attic

first, the material for the vapor barrier is laid, then the insulation is attached, on which the beam beam is sewn. Then shelf boards are nailed.

When insulating the ceiling of the bath, special attention must be paid to the junction of the pipe and insulation. To ensure that fire safety standards are not violated, it is necessary to make an indent of 200 mm between the pipe and the heat-insulating material

This problem is easily solved by creating a box of rafter legs. It will be a barrier separating the pipe and insulation. Inside the box, the space can be filled with fire-resistant insulation, for example, stone wool.

It is optimal if the roof of the bath is designed in such a way that there are no places through which warm air can escape from the room and cold air can enter from outside. Ceiling insulation has another goal - to avoid condensation.Condensation is converted into moisture, which, in turn, is the main enemy for most building materials.

Note that not all materials are suitable for ceiling insulation work. It is worth refusing to use materials such as chipboard, plywood, fiberboard for thermal insulation. They can not only deform during operation, but also release substances harmful to human health under the influence of high temperatures.

Insulation of the bath that you need for work

Warming the bath from the inside with your own hands will save money on work and heating. It is not a shame to invite friends to a comfortable bathhouse exuding warmth and comfort. High-quality thermal insulation, competently made of good materials, can maintain a unique microclimate. The work is laborious, but anyone with the necessary knowledge and skillful hands can cope with it.

Insulation of the bath from the inside differs from thermal insulation work in ordinary rooms by the conditions in which the materials are found. First of all, it is humidity, especially in the steam room and washing room, and in other rooms the air is not dry. Therefore, the insulation either should not absorb moisture, or it must be reliably protected from steam and moisture. In the steam room, the temperature can rise even above 100 °. Materials such as polystyrene foam, polystyrene foam are deformed at high temperatures, emit substances harmful to health. For the same reason, plastic or linoleum is never used in the bath. Part of the heat is lost as infrared radiation, so a foil layer is needed to reflect the rays.

To insulate the bath, you will definitely need a foil heat-resistant hydro-vapor barrier

In addition to the heat insulator, other materials will be required, in particular, the crate. For stone, brick baths, it is better to use a drywall profile. The CD ceiling profile is usually used, the UD guide is used for edging around the perimeter. Hangers are fixed on average after 0.7 m, the distance between the profiles is slightly less than the width of the insulation. In a wooden bath, instead of a drywall profile, it is advisable to use bars, they are cheaper and will last as long as the walls.

You will need foil heat-resistant waterproofing. for example, foam. It is able to protect walls from dampness, reflect infrared rays, and additionally insulate the room due to the presence of foam material. For wooden baths, it can be used as the main material for insulation. On top of the insulation layer, they arrange a fine finish from the lining. Linden or aspen is considered the best material, they are durable even in such difficult conditions, and besides, they do not burn.

Warming algorithm

Before starting work, prepare all materials and tools. The master will need:

- rail beam;

- foil;

- self-tapping screws;

- electrical tape and aluminum tape;

- roll paper;

- insulation;

- knife;

- screwdriver;

- building level.

It is important to follow the sequence - first they insulate the ceiling, and finish with the floor. All work begins with the initial preparation of the surface

It must be cleaned of dust, mold and dirt, all holes are sealed with mounting foam. Broken parts should be replaced with new ones.

Installation of insulation on the ceiling

Step-by-step algorithm for the correct insulation of the ceiling:

- Covering the ceiling with rolled paper overlap.

- Fastening bars on top of paper. The distance between them depends on the size of the insulation.

- Covering the frame surface with foil. It is necessary to reflect heat into the room. Joints are sealed with aluminum tape.

- Leak test. You need to make sure that all joints are securely sealed and there are no gaps.

- Laying the insulator in the formed cells between the bars.

- Finishing the front part with clapboard.

Installation of insulation on the wall

When insulating the walls of the dressing room, it is important not to close the ventilation holes

Wall insulation works are similar to ceiling insulation

But in the process it is important not to forget about the ventilation inlets.

Installation sequence:

- Fixing rails on the surface. They should be in the form of narrow strips so that the temperature difference does not change their shape. The panels must be treated with a special tool for baths.

- Foil stacking. You can fix it with a construction stapler.

- Thermal insulation laying.

- Clapboard trim.

Installation of insulation on the floor

The last step in warming the dressing room is laying insulation on the floor

A large amount of heat escapes through it, especially in a structure on piles, so it is important to make high-quality thermal insulation. Most often, expanded clay is used as a material, which prevents the formation of fungus and condensation.

It is also environmentally friendly and weighs little.

In the case of laying wooden floors, the material is placed between the joists. When pouring concrete floors, expanded clay is placed between each layer.

The floor insulation in the dressing room is carried out according to the following algorithm:

- Filling the initial layer. Waiting for it to dry.

- After complete solidification, a layer of expanded clay with a thickness of 10 cm is laid.

- Expanded clay crumb is sprinkled between the layers of concrete.

- Pouring a layer of concrete on a reinforced grid.

- Implementation of a cement-sand screed.

How to insulate a dressing room from the inside Good Steam

Probably every owner of his own house or summer cottage dreams of building a bathhouse.

You can entrust this work to specialists, but with all the variety of materials and a sufficient amount of information, there is an opportunity to realize your plans on your own.

How to insulate the walls in the waiting room with your own hands, as well as the floors - these are the questions that you need to think about already in the process of erecting a strip foundation.

Scheme of wall insulation in the dressing room

Why you need to insulate the room

The room in the bathhouse preceding the steam room is of great importance for the functioning of the entire structure:

- excludes the possibility of penetration of cold air into the steam room;

- contributes to the long-term preservation of heat in the bath itself.

How and with what can you insulate the dressing room?

- How to make the dressing room warm

- How to make the floors of the dressing room warm

- Warm walls of the dressing room

- Warm ceiling

Even the smallest bath has two rooms: the first is the room in which they undress, the second is the steam room.

So that in the first room the temperature allows people to change clothes comfortably, and in the second room the high temperature remains as long as possible, you need to think about how to insulate the dressing room and the steam room before starting the construction of the bath. During the period of design work, future heat losses through windows and doors should be immediately taken into account.

The insulated dressing room does not allow cold air to enter the steam room and ensures the preservation of high temperature in the steam room. You can also insulate an already built bath.

The scheme of insulation of a brick bath using the technology of a ventilated facade.

How to make the dressing room warm

The largest flow of cold air enters the dressing room through doors and windows. In small baths, the area of \u200b\u200bthe dressing room is small - on average it is 1.5x2.3 m. One small window is enough to illuminate such a room.

A window with a double frame is installed, and the width of the window opening is made greater than its height, the lower edge of the window is placed at a distance of 1.5 m from the floor.

All gaps between the frame and the wall opening are carefully sealed, which also ensures the insulation of the dressing room.

The entrance door of the dressing room is made no larger than 1.8-1.85x0.8-0.85 m in size. The door frame can be insulated with wooden bars with foam rubber padding. The door to the steam room is usually lower than the front door in height. It should open inside the dressing room.In addition to windows and doors, almost 20% of the heat in the bath escapes through the walls, ceiling and floor. Therefore, it will be necessary to carry out their warming too.

Dressing room: insulation from the inside and finishing

The dressing room serves as a connecting room between the street and the premises for taking bath procedures, whether it is a steam room, a washing room, a pool. How to properly insulate it from the inside, as well as finish it, will be discussed in this article.

The functions that the dressing room performs are as follows:

- maintaining optimal temperature and humidity, protecting both from adverse outdoor influences and from the influence of hot or humid indoor air (a kind of gateway);

- providing rest after bathing procedures and before them, creating a favorable microclimate (recreation area);

- creation of conditions for changing clothes, its storage in normal conditions;

- providing opportunities for collective leisure (the leisure zone may include a media zone - a music center, TV, etc.);

- providing conditions for the use of drinks and products, storage of dishes (kitchen block);

- creation of a positive psychological atmosphere and comfort (comfortable design and decoration);

- providing a firebox for a bath, possibly keeping a small supply of firewood or other fuel (a furnace firebox zone);

- storage of accessories (racks, cabinets).

Insulating a dressing room with your own hands is not at all difficult.

The dressing room does not impose such increased requirements on finishing materials as a steam room or a washing room. The main requirement is the environmental friendliness and comfort of the materials used.

If the bath is built of timber or logs, then usually its interior does not need significant improvement. Wood is a classic, beauty, naturalness, environmental friendliness.

For wall decoration are used:

- PVC panels;

- rubber-based paint;

- sheathing board (lining) and its varieties.

Insulation of the dressing room methods of insulation and the choice of heat-insulating material

The Russian bath consists of 2 rooms - a dressing room and a steam room. The thermal insulation of the steam room is carried out in order to reduce the heat loss of the room, and the warming of the dressing room will create a comfortable temperature and will prevent the penetration of cold air into the building. It is worth wondering how to insulate the dressing room during the construction of the bath, since the insulation of the room begins at the stage of laying the foundation.

Material selection

the quality of the warming of the dressing room depends on the safety of the temperature in the steam room itself

The question of how to properly insulate the dressing room is quite important, since the quality of the warming of the dressing room depends on the safety of the temperature in the steam room itself.

As a heat-insulating material for the dressing room, it is necessary to choose an inorganic moisture-resistant material, since organic materials, with constant contact with water, quickly rot and mold.

Used as a heater:

- perlite;

- Styrofoam;

- extruded polystyrene foam;

- polyurethane foam;

- mineral wool;

- glass wool.

The ideal heat-insulating material for the dressing room is polyurethane foam, because due to its qualities, such as durability, moisture resistance, sound insulation, inertness to chemical and biological effects, fire resistance, it provides reliable insulation of the room, levels out the sharp temperature difference between the dressing room and the steam room, provides air circulation .

When spraying polyurethane foam, a monolithic coating without joints is obtained, the material has high adhesion, which allows it to be sprayed directly onto the walls and ceiling of the room.

What is better to insulate: with mineral wool or with polyurethane foam from ecotermix? We recommend watching the video below so as not to torture yourself with reasoning:

How to insulate the dressing room from the inside

Interior decoration also refers to the process of insulation

In order to qualitatively insulate the dressing room, it is necessary to pay attention to the insulation of the walls, floor, ceiling, windows and doors of the room. Interior decoration also refers to the process of insulation and affects not only the appearance, but also the technical characteristics of the room.

Wall and ceiling insulation

For the construction of baths, as a rule, wood is used. Before insulating the walls of the room, you should not additionally treat them with chemical impregnation, since when exposed to high temperatures, the harmful substances that make up them evaporate and can cause damage to human health.

Wall insulation technology consists of the following steps:

- preparation of the frame on which the insulation will be attached;

- installation of vapor barrier;

- installation of a heat-insulating layer;

- outer cladding.

Ceiling insulation is as follows:

- laying waterproofing;

- installation of a heater;

- installation of vapor barrier;

- exterior finish.

If the thermal insulation of the ceiling in the dressing room is carried out by applying polyurethane foam, there is no need to lay a vapor barrier. When insulating walls with polyurethane foam, it is not necessary to prepare a frame to fix the insulation, and use a vapor barrier material.

The use of polyurethane foam will allow you to get high-quality thermal insulation of walls and ceilings. The material is absolutely safe for human life, it will reduce the cost of air conditioning and heating of both the dressing room and the bath.

Insulation of the dressing room with polyurethane foam is best left to professionals, such as Ecotermix. The company provides polyurethane foam insulation services for private buildings, both at the construction stage and during operation.

Insulation of windows and doors

The heat loss of the dressing room is significantly affected by the overall dimensions of its windows and doors. For the dressing room there is no need to install large windows and a door structure, since the larger the size of the windows and doors, the more warm air will “disappear” from the room.

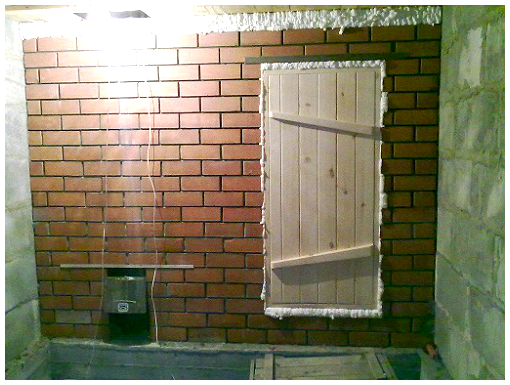

Regardless of the overall dimensions of the dressing room door, it is necessary to take care of its thermal insulation.

You can insulate the door if you create a frame of timber on its canvas, the thickness of which should be 20-25 mm, lay heat-insulating material inside the frame and sheathe the outside with a sheet of plywood.

Interior decoration

The interior decoration of the dressing room depends on the purpose for which it is supposed to be used. When choosing a finishing material, one should also take into account the material from which the bath itself is built. So, for example, wooden lining is most often used to finish a log bath, and plaster is usually used as an interior decoration of a brick room. Read about how and what is the best way to insulate a bath from the inside.

How to insulate a bath with your own hands from the inside

First, you need to create a frame on the surface of the insulated wall. For this, a crate of bars is fastened on it. which are placed horizontally and vertically. Note that the timber should exceed the insulation by 20-30 mm in thickness.

Next, the wall is sheathed with mineral wool. When the material is installed, a layer of vapor barrier is applied. Most often, foil material is used to create it. Note that its overlay must be overlapped. The joints of the material must be sealed with thin slats. A distance of about 3 cm must remain between the layers of vapor barrier and mineral wool.

Further, this material is fixed to a vertical crate 350 mm wide.

The effectiveness of this method is quite high, since it has been used to insulate the walls of the bath from the inside for quite a long time.However, you should be aware that, having made a choice in favor of this option of thermal insulation, you will have to spend a lot of effort on creating a high-quality insulation design. Modern materials offered on the market will reduce the complexity of such insulation. Often materials for insulation combine several properties at once: they provide effective insulation and waterproofing. Foil foam is just such a material. It is characterized by high resistance to fire. In addition, it provides convenience during operation and during installation.

The scheme that was described above is ideal for baths built from timber. Insulation of frame walls and panel-type buildings has its own characteristics. If the walls in the bath are panel, then the choice is made in favor of light materials. The most commonly used polystyrene foam, reed plates, mineral wool. The processing of the heat insulator in this case is a mandatory requirement. As a composition to protect it from harmful negative factors, milk of lime is used, followed by drying. The use of such protection will exclude the occurrence of decay processes. In addition, the resistance of the material to fire will increase.

If the bath has frame walls, then in cold climates, when it is insulated, slabs of fiberboard or reeds are used. In areas with a mild climate, the choice is made in favor of gypsum, sawdust. For wall insulation, for example, a mixture of sawdust and gypsum can be used. The material is taken in a ratio of 1:10. The finished mixture is poured between the walls and the sheathing with a layer of 200 mm.

Thermal insulation of floors, windows and doors

When a decision is made on how to insulate the bath inside with your own hands, take into account the possibility of increasing the degree of thermal resistance at the ceiling and walls. True, the cool floor and the presence of drafts also take away a lot of heat.

To insulate the door leading to the steam room, a thick felt frame is attached to it, which will reliably cover the cracks. Wooden frames at the windows located in the steam room, dressing room and washing room are insulated with cotton wool.

As for plastic, it is not installed in places with high temperatures, but in other rooms you should not be afraid that polymers will undergo thermal decomposition. Self-adhesive foam strips are used to protect plastic windows.

The choice of products, the better to insulate the bath inside, depends on the type of flooring. Expanded clay is poured onto the surface of the leaking wooden floor, and boards are already mounted on top of the leveled backfill.

They begin to equip a concrete leaking floor with digging a foundation pit 50 centimeters deep.

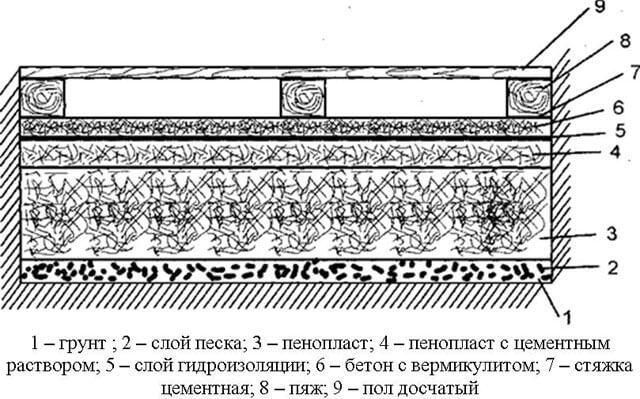

The layers of the thermal insulation structure are arranged in the direction from bottom to top in the following sequence:

- sand -5 centimeters;

- polystyrene -20 centimeters;

- concrete mixed in a ratio of 1: 1 with foam chips - 5 centimeters;

- waterproofing;

- concrete combined with vermiculite in a ratio of 1: 1 (this is the name of a natural material with low thermal conductivity) - 5 centimeters;

- reinforced screed -5 centimeters.

In the process of pouring the foundation, it is necessary to equip the slope. A boardwalk is mounted on top of the concrete screed on the logs.

In the case when a continuous floor covering is needed, a heat-insulating material is laid on top of the rough base with a layer of 10-20 centimeters, it can be mineral wool or polystyrene. Then it is covered with waterproofing, not forgetting to overlap the walls. A reinforced screed 5-10 centimeters high is mounted on top of this layer.

Then, as a rule, lay a tile. Despite the fact that the tiles in the steam room do not heat up to a high temperature, it is advisable to provide for the presence of wooden footrests to make visiting the bath more enjoyable.

Which walls are the most durable for a dressing room

Considering that there is increased condensate in the dressing room, due attention should be paid to the moment of resistance of the material to moisture. Best of all survive the effects of moisture natural materials

If it is not possible to purchase just such raw materials, because they are usually expensive, then you can give preference to any material and choose a good surface protection agent.

There are a lot of such tools in construction stores, you just need to consult with an experienced specialist. Let the bath please with its aroma and warmth. Only proper preparation for the process of building a bath can make the space complete.

Choosing the right heater

The issue of thermal insulation of the dressing room should be approached in good faith. Click on the photo to enlarge.

At the same time, the material must be resistant to moisture and biological influences, fireproof and, if possible, environmentally friendly.

Most often, foil-foamed polyethylene is used to insulate the dressing room.

It allows you to level the sharp temperature difference between the dressing room and the steam room, provides the necessary air circulation. The role of additional thermal insulation can be played by the outer finish of the dressing room.

Do you need windows in the dressing room?

When deciding how to insulate a dressing room, many refuse to install windows in it. Meanwhile, the presence or absence of a window will not particularly affect the thermal characteristics of the room.

Do not give up natural light in the dressing room.

The main thing is that the windows are of high quality - without gaps, if possible without jumpers, with reliable double-glazed windows. Windows should be located no lower than one and a half meters from the floor.

Plastic windows in the bath are not recommended. The best option would be a regular wooden window. Modern manufacturers have learned how to make windows with wooden frames and reliable double-glazed windows.

Choose at least double glazing. And, in order to avoid additional gaps, it is best to make a window in the dressing room without the possibility of opening.

wall insulation

Usually baths are made of wood. It is environmentally friendly, it is easy to breathe in such a room. Less commonly, buildings are made of brick, foam blocks or cinder blocks. The latter material already has good thermal insulation properties due to the porosity of the block structure, but in winter the walls freeze through. Brick buildings are practically not made.

As heaters for the wall are:

- mineral wool;

- fiberglass;

- Styrofoam.

From above it is recommended to make a layer of polystyrene foam. It is highly durable, does not compress, lasts a long time and does not rot.

A frame made of timber is attached to the walls. Each part is placed at a certain distance, which depends on the material of the insulation. A heat insulator and a layer of foil polystyrene foam are placed between the obtained strips. From above, the finishing finishing layer is performed.

Insulation of the concrete base

If the bath is not placed on piles, but on an ordinary concrete foundation, then the subfloor is usually done with a cement screed. Such a base can also be quite easily insulated with your own hands. Two methods can be applied for this.

First way

This method involves the implementation of a finishing cement screed. The procedure for performing such floor insulation in the steam room and other rooms of the bath is as follows:

- First, the base must be waterproofed. For these purposes, bituminous coating materials or rolled thick polyethylene are used.

- The prepared concrete base is covered with fine-grained expanded clay, a layer of 15-20 cm and carefully compacted.

- A galvanized mesh is laid on top of the insulation, which performs the function of reinforcement.

- Then the whole structure is poured with a cement screed, which is carefully leveled and rubbed when dry.

- The finished, finished concrete floor (after drying for 14 days) can be covered with floor coverings such as ceramic tiles.

Second method

This option for insulating a concrete base with your own hands is similar to the way in which a wooden floor is insulated.

With this method, it is important to adhere to the following technology:

- The pre-prepared and reinforced concrete floor is subject to waterproofing. To do this, it is better to use bitumen-based mastic.

- Then wooden logs with a section of at least 10x10 cm are laid on the base.

- These logs are leveled and fixed with anchors.

- A heater is placed in the resulting space. In this case, you can use any material: expanded clay, foam plastic, foam plastic or other moisture-resistant insulation.

- After filling the space between the lags with insulation, the latter is covered with dense polyethylene for waterproofing.

- Boards are laid on top of the lags. It should be remembered that the flooring must be covered with a water-repellent coating.

As you can see, do-it-yourself floor insulation in the bath is not such a difficult thing.

In this matter, it is important to responsibly approach waterproofing work and fine-tune the fine wood flooring. In this case, the floor in the bath will serve as long as possible.

How to insulate the door to the bath

Without a securely insulated door, all work on warming the dressing room will not give the desired effect. A huge amount of heat will escape through the cracks in the door and the unprotected doorway. Meanwhile, it is not difficult to insulate the door to the bath. For this you will need:

- Bar, 20-25 mm thick.

- Sheet of plywood or fiberboard.

- Insulation.

The technology is simple - a timber is stuffed onto the door around the perimeter, so that a kind of frame is obtained. The beam is not stuffed close to the edge, but at a distance of about 1.5 cm from it. Insulation is put inside the frame, from above all this is covered with a sheet of plywood. The sheet is fixed with a construction stapler or wallpaper carnations.

The principle of operation of such insulation is simple. When the door is closed, the insulation will rest against the door block, bending outward. This bend will completely block the access of cold air to the dressing room. In this case, the insulation will not be clamped, leaving a layer of air near the door leaf.

This will protect the door from frost, allowing it to remain dry on both sides. No sealing gaskets should be installed on the door block itself. The edges of the door must be even and clean.

thermal curtain

Another common way to insulate the door in the bath is to install a thermal curtain. To do this, a sealing frame is installed on the door block inside the dressing room.

The frame is made of a bar wrapped with insulation. After installation, a soft cloth is attached to the frame, which acts as a screen. This method is simple, but well proven and quite effective.

Before carrying out work on the insulation of the dressing room door, check the condition of the door frame. She may have begun to rot. In this case, door insulation will not help, the box will have to be replaced.

box replacement process

If the door frame is rotten, then it must be replaced. Click on the photo to enlarge.

If the log cabin of the bath was installed according to the rules, then the work of replacing the box will not cause difficulties.

The dismantling of the old box occurs, starting from the lintel.

When sawing the ceiling beam and side rails, be careful not to damage the walls of the dressing room.

Mounting spikes should not be sawn off.

In a situation where it is impossible to insulate the old dressing room door, it is necessary to replace it with a new one. The door can be made with your own hands according to the size of the old door.

It is better to use timber and boards for this.

For the dressing room, it is recommended to make a two-chamber door, in which, between the sheets of the door leaf, lay a layer of heat-insulating material. You can order a finished door from any carpentry company.

How should the walls in the dressing room look like?

The question of what walls should be is quite complicated. After all, each owner of a land plot on which to build a bathhouse has his own preferences and ideas regarding the interior of the dressing room. However, there are some standards that most people prefer:

- Wooden walls with grooved patterns. Such coatings in the bath look more than harmonious. Carved images on wood create a romantic and magical atmosphere in the bathhouse.

-

Also, such types of wood as lining are often chosen. Thanks to this material, a wide variety of design ideas can be realized. For example, draw patterns on the surface of the material or simply paint the finish in rainbow colors. This will help create the lovely, vibrant atmosphere that a bath space should have.