Other causes of increased pressure

- Partially or completely blocked shut-off valves. As a result, the pressure on the water supply rises sharply and the boiler is blocked. It is necessary to open the stopcocks and valves, check the heating fittings for leaks;

- If a mechanical sump filter is installed, its mesh may become clogged with rust, slag or sand particles. As a result, pressure rises in the “boiler-filter” section. Flushing the filters will help relieve the pressure of the coolant. The simplest corner filter should be washed at least 3-4 times a year. Flushing and magnetic filters are more expensive, but such devices purify water better and require cleaning only once a year;

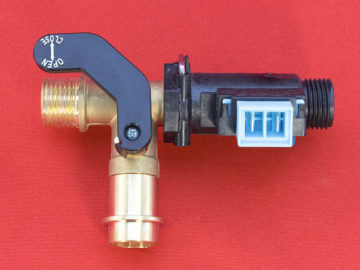

- Passes or does not “hold” the make-up water tap. The pressure in the water supply network is in the range of 2.5 - 3.5 bar, that is, the water will flow into the heating system, where the pressure is lower. This will inevitably lead to an increase in the volume of the coolant. To solve problems, you need to shut off or replace the make-up water tap. Most often they become unusable and require replacement rubber gaskets. As a temporary solution to the problem before replacing damaged parts, you can reset the indicators by completely shutting off the water supply to the double-circuit boiler;

- Failure of the boiler automation, failure of the thermostat or controllers. It is not always possible to determine why this occurs. The reason may be a manufacturing defect, the use of low-quality materials in the manufacture of the control board, improper installation, etc. You can fix the problem yourself, knowing the error code and having the technical passport of the device. If the technical passport does not contain an error code and a way to eliminate it, you cannot do without a service department.

Why did the water pressure drop

What affects the performance in the circuit:

- The installation height of the housing, as a result - the height and length of the pipes.

- The impact of liquid on pipes and other elements.

- Construction of highways.

If autonomous heating is installed in your house, then the norms depend on:

- Boiler models, piping paths.

- Mounting locations.

- The number of floors in the building.

- Characteristics of the outer pipe.

Next, we will look at reasons not related to installation. If the device releases and does not build up pressure, this may be an internal failure or external factors.

Leak in the system

You add coolant to the circuit, but the pressure is still low. If the batteries are well heated, the moisture evaporates quickly, so the leak is difficult to detect. Take a dry napkin and go through all the pipe joints, connections. Look, perhaps puddles accumulate under the radiators.

If the leak could not be found, use a compressor.

- Disconnect the radiators from the heating device.

- Drain all liquid.

- Connect the compressor to the taps.

- Purge the circuit with air.

- You will hear an extraneous sound in those places where there is damage.

- For sealing, use sanitary tow or sealant.

Incorrectly selected boiler - the power does not match the established parameters of the pipeline. Therefore, the pressure constantly drops and does not hold.

If the values drop rapidly, the reason may be in the expansion tank. At the same time, you fill in the coolant every week, but it becomes less and less, although no leaks were found. There is also a pressure drop in the mixers.

How to gain and improve indicators:

- Shut off the water supply valves.

- Drain the circuit completely.

- Open the fitting on the expansion tank (RB) and record the numbers.

- Pump in air until all the water comes out.

- Bleed the air and repeat the steps. Make sure that the pointer on the pressure gauge does not exceed 1.3 bar.

- Open the faucets and fill with liquid.

If after the procedure the pressure drops and does not rise, inspect the membrane for damage. Replace if necessary.

Heat exchanger failure. After checking the pipes and connections, no violations were found? Inspect the radiator for damage. A large accumulation of scale on the tubes leads to frequent flushing with reagents. From this, the material wears out quickly, cracks appear.

The bithermic assembly cannot be repaired due to its design. Replacement required. If a tubular radiator is installed, remove it. Fistulas can be detected by green spots on the surface. Dry the device, clean the damaged area with sandpaper. After soldering with a soldering iron or torch.

Problems with the feed tap. When leaking, the faucet leads to a constant drop in pressure. How to add coolant to the system? Only a replacement part will help.

Three-way valve problems. In double-circuit devices, the valve is used to switch flows from heating to hot water supply. Clean the valve, scale and debris may interfere with its operation.

Airiness. It is not difficult to determine that an air pocket has appeared in the batteries. This is clear from the gurgling sounds where water collides with air. Do this:

- Record the pressure gauge.

- Turn off technology.

- Place a container under Mayevsky's faucet and open its valve.

- You will hear air flowing, liquid may drip. Wait for the hiss to stop.

- Turn on the water and supply it until the pressure gauge needle reaches the initial position. Shut off the taps.

- Start the boiler and listen to the work. If sounds are heard again, repeat the procedure.

Problems with gas in the highway

Interruptions in the fuel supply lead to violations of heating and blocking of the boiler. What are the reasons for interruptions:

- Clogged gas fittings: filters, nozzles, hose.

- Faulty or blocked gas supply valve.

- Fuel leak. Close the valves and call the gas service.

As you can see, problems with the operation of the boiler arise both for internal and external reasons. If you are unable to locate the problem, call the wizard. He will diagnose the system and fix the problem.

A frequent cause of failures in the operation of a gas boiler is a rapid decrease in pressure in the heating system. This often results in the device shutting down. Then the owners have a question, how to add pressure to the gas boiler. The answer to it depends on the reason for the decrease in the indicator on the pressure gauge.

Pressure control in a gas boiler

All modern heating equipment is equipped with control sensors. The pressure sensor monitors normal operation. In case of deviation from the norm, it sends a signal to the control module, which causes the boiler to block. Additionally, an error code may appear on the display.

What pressure should be? A pressure gauge helps keep track of the values. Mounted unit "Bosch", "Ariston", "Navien", Baxi, installed in the house, supports values from 1.5 to 2 atm. A drop in performance is observed only in systems with forced fluid movement (pump).

How the equipment works

Under normal conditions, the work goes like this:

- Sensors record the temperature of the coolant. If an outdoor thermostat is installed, the burner automatically ignites and heats up.

- As the temperature rises, the pressure rises. When heated, water expands, so an expansion tank is provided to discharge excess coolant. The safety valve also discharges excess into the sewer.

- If the operation fails, too much water is drained. As a result, the pressure drops.

- As soon as the temperature reaches the set temperature, the boiler switches off.

More about the operation of the expansion tank:

- The tank consists of two parts, which are divided by a diaphragm. Nitrogen is in one cavity, excess fluid accumulates in the other.

- The coolant fills it as much as the difference in the values of the system and nitrogen is.

- As soon as heating stops, nitrogen pushes water out of the cavity by deforming the membrane.

Varieties of pressure

Why does the pressure drop in the wall-mounted appliance? First, let's figure out what types are and how they affect the operation of technology.

- Static. The higher the height, the higher the performance. With each meter there is an increase of 0.1 bar.

- Dynamic. Forced operation of the pump creates a nominal pressure in a closed system.

- Working. Includes the above two options.

- Excess. It is determined by a pressure gauge as the difference between atmospheric and fixed.

- Nominal. The one indicated by the manufacturer in the documentation for a particular model.

- Max. The maximum that is allowed to avoid breakdowns and accidents.

- Crimping. Used in production for testing equipment.

In the heating circuit, indicators are measured by atmospheres

They may vary; it is important that the value does not exceed the allowable maximum and minimum thresholds. A low value is possible only when the coolant is pumped into the circuit

In other cases, it should not deviate from the norm.

Pressure increase due to expansion vessel

Reasons for an increase in pressure in the heating circuit due to problems with the expansion tank:

- Small expansion tank. Water, when heated to 85-90 ° C, adds about 4% in volume. If a small tank is selected, then the coolant expands when heated and fills the tank. There is a complete discharge of air through the valve. With further heating, the tank can no longer compensate for the thermal increase in the volume of water, as a result, the pressure rises in the system. The volume of the expansion tank must be at least 10% of the total volume of the coolant in the circuit if a gas boiler is installed, and at least 20% if the boiler is solid fuel. The volume of the tank can be taken approximately - according to the power of the boiler: about 15 liters of water per 1 kW. But it is better to calculate the volume of a single circuit (by heating surfaces);

- Damage to the rubber membrane of the tank. In this case, the water will completely fill the tank, and the pressure gauge will show the pressure drop in the system. But, if you open the make-up valve and add water, then when the coolant is heated, the pressure in the heating circuit will become much higher than the working one. To solve the problem, it will be necessary to replace the tank if the membrane is of a diaphragm type, or to replace the membrane if it is of a balloon type;

- Expansion vessel pressure too high or too low. Expansion tank malfunctions are one of the main causes of pressure buildup in a closed system. You can check the pressure and pump it up if necessary with an ordinary automobile pump. Before checking, you need to drain the water from the heating system - the arrow on the system pressure gauge should be at zero. If there are shut-off valves and a drainage drain on the water pipeline to the expansion tank, then it is enough to drain the water only from the tank. Then, through the nipple, which is located on the side opposite to the water supply, air descends. If the boiler is operating at a pressure of 2 bar, then the pressure gauge on the pump should show 1.6 bar. It is necessary to open the shut-off valve for water and add the volume of water drained from the expansion tank through the make-up valve. This adjustment method works for both tanks with a lower and upper water supply;

- The tank is located immediately after the circulation pump. This leads to the fact that the pressure rises sharply, and almost immediately it is released, and pressure surges are observed. This situation can provoke hydraulic shocks in the circuit. To solve this problem in a closed heating circuit, an expansion tank is installed on the return pipe - in the laminar flow zone with a minimum coolant temperature. The pump crashes into the return line after the tank, in front of the boiler.